Abrasion Resistant Steel Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439500 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Abrasion Resistant Steel Plate Market Size

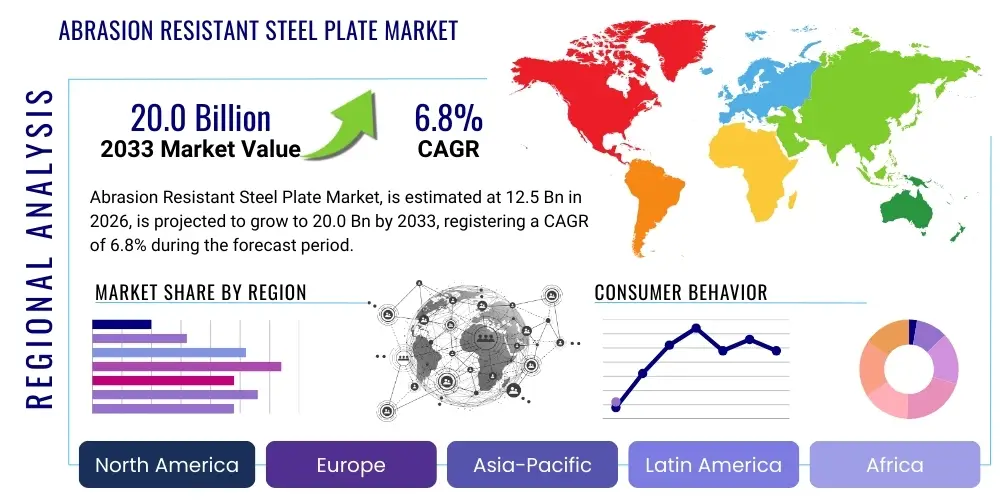

The Abrasion Resistant Steel Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 12.5 Billion in 2026 and is projected to reach USD 20.0 Billion by the end of the forecast period in 2033.

Abrasion Resistant Steel Plate Market introduction

The global Abrasion Resistant (AR) Steel Plate market plays a critical role in numerous heavy industries, providing essential materials designed to withstand severe wear and tear. These specialized steel plates are engineered with specific chemical compositions and heat treatments, primarily hardening and tempering processes, to significantly enhance their resistance to abrasive forces. This robust material is crucial in environments where friction, impact, and sliding wear would rapidly degrade conventional steel, ensuring extended operational life for machinery and infrastructure. The market is characterized by a continuous drive for innovation, focusing on developing new alloys with superior hardness, toughness, and weldability to meet evolving industrial demands and regulatory standards.

AR steel plates are foundational components in sectors such as mining, construction, material handling, and agriculture, where equipment is constantly exposed to abrasive materials like sand, gravel, ore, and rocks. Typical applications include liner plates for dump trucks, excavators, bulldozers, chutes, hoppers, and conveyor systems. Beyond these heavy-duty uses, AR steel finds utility in less obvious but equally critical areas like concrete mixers, agricultural machinery components, and even certain defense applications where material durability is paramount. The intrinsic benefits of AR steel, such as prolonged equipment lifespan, reduced maintenance costs, and minimized downtime, directly contribute to operational efficiency and cost-effectiveness for end-users, solidifying its irreplaceable position in industrial manufacturing.

Several driving factors underpin the market's sustained growth. Rapid global industrialization, particularly in developing economies, fuels demand for robust infrastructure and heavy machinery. Escalating mining and construction activities worldwide necessitate durable materials to combat severe wear conditions. Furthermore, technological advancements in steel manufacturing, including improved alloying techniques and heat treatment processes, lead to the production of higher-performance AR plates that offer superior properties at competitive costs. The increasing focus on operational efficiency, worker safety, and environmental sustainability also encourages industries to adopt materials that offer extended service life and reduce the frequency of material replacement, thereby minimizing waste and resource consumption.

Abrasion Resistant Steel Plate Market Executive Summary

The Abrasion Resistant Steel Plate market is currently experiencing robust growth, driven by an accelerating pace of global industrial and infrastructure development. Key business trends indicate a strong emphasis on product innovation, with manufacturers investing heavily in R&D to develop advanced AR plates that offer enhanced hardness, toughness, and improved processing characteristics like weldability and formability. There is a growing inclination towards custom-engineered solutions that cater to specific application requirements, moving beyond standardized products to offer tailored material properties. Furthermore, strategic collaborations and mergers and acquisitions are frequently observed as companies seek to consolidate market share, leverage technological synergies, and expand their geographical reach, particularly into rapidly industrializing regions.

From a regional perspective, Asia Pacific continues to dominate the market, primarily due to extensive construction projects, burgeoning mining operations, and significant investments in industrial infrastructure in countries like China, India, and Southeast Asian nations. North America and Europe also maintain substantial market shares, characterized by a demand for premium-grade AR plates for high-performance applications and a strong focus on automation and efficiency in heavy industries. Emerging economies in Latin America, the Middle East, and Africa are projected to exhibit considerable growth as their industrial bases expand and infrastructure development gains momentum, presenting new opportunities for market players to penetrate these underserved regions and establish strong distribution networks.

Segmentation trends highlight the increasing preference for quenched and tempered (Q&T) AR plates due to their superior hardness and impact resistance, making them ideal for the most demanding applications. By end-use industry, the mining and construction sectors remain the largest consumers, driven by the continuous need for durable equipment components. However, significant growth is also anticipated in the material handling, cement, and agriculture industries, which increasingly rely on AR steel to extend the lifespan of their machinery. The market is also seeing a shift towards higher thickness plates for extreme wear conditions, alongside ongoing development in various alloy types, including complex carbide-forming elements, to achieve optimal performance characteristics for diverse industrial challenges.

AI Impact Analysis on Abrasion Resistant Steel Plate Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is poised to revolutionize various facets of the Abrasion Resistant Steel Plate market, addressing common user questions about efficiency, quality, and cost. Users are keenly interested in how AI can optimize production processes, improve material properties, and predict equipment failure, thereby enhancing overall operational effectiveness and reducing expenditure. They often inquire about AI's potential to standardize quality, personalize material solutions, and even influence supply chain dynamics. The overarching theme is the expectation that AI will bring unprecedented levels of precision, predictive capability, and adaptive manufacturing to an industry traditionally reliant on experience and established methodologies, ultimately creating smarter, more resilient material solutions.

- AI-driven optimization of steel melting and rolling processes can lead to more consistent material properties and reduced waste, improving the quality and cost-effectiveness of AR plates.

- Predictive maintenance analytics, powered by AI, can forecast the wear rates of AR steel components in real-world applications, enabling timely replacement and minimizing unscheduled downtime.

- Machine learning algorithms can analyze vast datasets of material compositions and performance characteristics to accelerate the development of new, more durable AR steel alloys with enhanced properties.

- AI-enabled quality control systems using computer vision can detect subtle surface defects and inconsistencies in AR plates with higher accuracy and speed than traditional manual inspections.

- Robotics and automation, guided by AI, can enhance precision and safety in the handling, cutting, and shaping of heavy AR steel plates during fabrication, reducing human error and improving operational efficiency.

- Supply chain optimization through AI can predict demand fluctuations, manage inventory more effectively, and streamline logistics for AR steel plates, leading to improved lead times and reduced holding costs.

DRO & Impact Forces Of Abrasion Resistant Steel Plate Market

The Abrasion Resistant Steel Plate market is propelled by a confluence of robust drivers, notably the relentless expansion of global industrial sectors and significant infrastructure development initiatives. Emerging economies, in particular, are witnessing rapid urbanization and industrialization, leading to massive investments in construction, mining, and manufacturing facilities, all of which necessitate durable AR steel for their machinery and components. Furthermore, the increasing global demand for mineral resources and energy fuels extensive mining and quarrying activities, creating a sustained need for high-performance abrasion-resistant materials to prolong equipment lifespan and ensure operational continuity. Technological advancements in steel manufacturing, including sophisticated alloying and heat treatment processes, consistently contribute to the development of superior AR plates, offering enhanced hardness, toughness, and improved weldability, thereby meeting evolving industry standards and specialized application demands.

However, the market also faces considerable restraints that temper its growth trajectory. The volatile nature of raw material prices, particularly iron ore, nickel, chromium, and molybdenum, directly impacts the production costs of AR steel plates, leading to fluctuating market prices and posing challenges for manufacturers in maintaining consistent profitability and competitive pricing. Additionally, stringent environmental regulations governing steel production, especially concerning carbon emissions and waste management, impose significant compliance costs and necessitate substantial investments in cleaner technologies, which can constrain market expansion for some players. The high capital expenditure required for advanced manufacturing processes and the specialized expertise needed for AR steel production also act as barriers to entry, limiting the number of new market participants and contributing to market concentration among established players.

Opportunities for growth are abundant, primarily in the burgeoning markets of developing regions where industrialization is in its nascent stages but accelerating rapidly. These regions represent a vast untapped potential for AR steel applications across construction, mining, and agriculture. There is also a significant opportunity in the development of customized and application-specific AR steel solutions, catering to niche industrial requirements that demand precise material properties, such as enhanced corrosion resistance alongside abrasion resistance. Furthermore, the increasing focus on sustainability and circular economy principles is driving demand for AR plates that offer superior longevity, thereby reducing material consumption and waste over the lifecycle of industrial equipment. Innovations in advanced manufacturing techniques, including additive manufacturing for complex AR components, present long-term growth avenues.

The market is further shaped by several key impact forces. Geopolitical instability and trade disputes can disrupt global supply chains for raw materials and finished products, affecting manufacturing costs and market accessibility. Technological innovation acts as a constant force, pushing the boundaries of material science to create new, more efficient AR alloys. Environmental and social governance (ESG) factors are gaining prominence, influencing procurement decisions towards suppliers demonstrating sustainable practices and ethical sourcing. Economic downturns or slowdowns in industrial output can temporarily suppress demand for AR steel, while robust economic growth stimulates increased investment in infrastructure and heavy industries, driving market expansion. Lastly, increasing competition from alternative wear solutions and the continuous need for product differentiation also exert significant pressure on market participants.

Segmentation Analysis

The Abrasion Resistant Steel Plate market is meticulously segmented to provide a granular understanding of its diverse components, allowing for precise market analysis and strategic decision-making. These segmentations delve into various attributes of AR plates, including their material composition, manufacturing process, physical dimensions, and the specific industries or applications they serve. This detailed breakdown enables stakeholders to identify key growth areas, understand competitive dynamics within different niches, and tailor product development and marketing strategies to specific end-user needs. The multifaceted nature of AR steel applications necessitates a comprehensive segmentation approach to accurately capture market trends and predict future demand patterns across the global landscape.

- By Type:

- Quenched & Tempered (Q&T) AR Steel Plate: High hardness and toughness through heat treatment.

- As-Rolled AR Steel Plate: Cost-effective, suitable for less severe abrasion.

- Other Types (e.g., Cast AR Steel, Hardfacing AR Plates): Specialized applications.

- By Alloy Type:

- Carbon Steel: Basic AR properties, cost-effective.

- Manganese Steel: Work-hardening characteristics.

- Chromium-Molybdenum Steel: Enhanced hardness and wear resistance.

- High-Strength Low-Alloy (HSLA) Steel: Improved strength-to-weight ratio with moderate AR properties.

- Complex Carbide Steels: Superior wear resistance due to advanced alloying elements.

- By Hardness Level:

- AR 400: General purpose, good impact resistance.

- AR 450: Improved wear resistance, good formability.

- AR 500: High wear resistance, common for severe applications.

- AR 550 & Above: Extreme wear resistance, specialized applications.

- By Thickness:

- Below 10mm: Light-duty applications, liners.

- 10mm - 20mm: Medium-duty, general construction.

- Above 20mm: Heavy-duty, mining, quarrying.

- By Application:

- Mining & Quarrying Equipment (e.g., bucket liners, dump truck bodies, chutes, crushing plants).

- Construction Machinery (e.g., excavator buckets, bulldozer blades, concrete mixers, road pavers).

- Material Handling Equipment (e.g., hoppers, silos, conveyors, transfer points).

- Cement & Aggregate Plants (e.g., clinker grinders, stone crushers, separator blades).

- Agriculture Machinery (e.g., plough shares, tillage equipment, harvesters).

- Power Generation (e.g., coal handling systems, ash removal).

- Waste Management & Recycling (e.g., shredders, compactors).

- Logging & Forestry (e.g., wood chippers).

- Defence & Security (e.g., armored vehicles, ballistic protection).

- Others (e.g., metal processing, sugar industry).

- By End-Use Industry:

- Heavy Machinery & Equipment Manufacturing.

- Construction & Infrastructure Development.

- Mining & Metallurgical Industry.

- Power & Energy Sector.

- Agriculture Sector.

- Waste Management & Recycling Industry.

- Automotive & Transportation.

- By Region:

- North America (U.S., Canada, Mexico).

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe).

- Asia Pacific (China, Japan, India, South Korea, Australia, Southeast Asia, Rest of APAC).

- Latin America (Brazil, Argentina, Rest of Latin America).

- Middle East & Africa (UAE, Saudi Arabia, South Africa, Rest of MEA).

Value Chain Analysis For Abrasion Resistant Steel Plate Market

The value chain for the Abrasion Resistant Steel Plate market is a complex network that begins with the extraction of raw materials and culminates in the delivery and application of the finished product to end-users. At the upstream end, the process involves mining and sourcing essential raw materials such as iron ore, coal (for coking), and various alloying elements like manganese, chromium, nickel, and molybdenum. These materials undergo initial processing, including sintering, pelletization, and coke production, before being fed into primary steelmaking facilities. This stage is capital-intensive and requires sophisticated metallurgical processes to produce crude steel, which then forms the base for specialized AR plate manufacturing. Efficient and cost-effective sourcing of these raw materials is paramount, as their price volatility can significantly impact the final product cost and market competitiveness.

Moving downstream, the crude steel is transformed into AR plates through a series of demanding manufacturing processes. This involves hot rolling to achieve the desired thickness and dimensions, followed by critical heat treatments such as quenching and tempering, which are essential for imparting the high hardness and toughness characteristic of AR steel. Manufacturers employ advanced metallurgical techniques and quality control measures at every stage to ensure the plates meet stringent industry specifications for hardness, impact resistance, and flatness. Fabrication services often follow, where the AR plates are cut, drilled, bent, and welded into specific shapes and components required by end-users. This stage adds significant value by customizing the standard plates into ready-to-use parts, enhancing their utility and application-specific performance.

The distribution channel for AR steel plates is typically multifaceted, involving both direct and indirect sales approaches. Large-scale manufacturers often engage in direct sales to major industrial clients, original equipment manufacturers (OEMs), and large construction or mining companies, fostering long-term relationships and providing technical support. Indirect channels include a network of specialized steel distributors, service centers, and fabricators who procure AR plates in bulk and then supply them to smaller end-users, offering value-added services like cutting, bending, and just-in-time delivery. These distributors play a crucial role in market penetration, especially in regional markets, by providing accessibility and tailored solutions. The choice of distribution strategy depends on factors such as market reach, customer base, logistical capabilities, and the level of technical support required by the end-user, ensuring efficient product flow from the producer to the point of consumption.

Abrasion Resistant Steel Plate Market Potential Customers

The Abrasion Resistant Steel Plate market serves a diverse array of potential customers, primarily encompassing industries where machinery and components are subjected to extreme wear and impact conditions. The largest segment of potential customers includes heavy machinery and equipment manufacturers who integrate AR steel plates into the construction of excavators, bulldozers, dump trucks, loaders, and other robust vehicles. These OEMs prioritize materials that offer exceptional durability, extend the operational lifespan of their products, and ultimately reduce total cost of ownership for their end-buyers. The decision-making process for these customers is driven by stringent performance specifications, material certifications, and the ability to source a consistent supply of high-quality AR steel at competitive prices, influencing their choice of suppliers significantly.

Another substantial group of potential customers comprises companies operating within the mining, quarrying, and aggregate industries. These entities extensively use AR steel plates for liners in chutes, hoppers, crushing equipment, screen plates, and truck beds, where materials like ore, rocks, and gravel cause severe abrasive wear. For these customers, the primary drivers for adopting AR steel are the reduction of downtime due to equipment failure, increased operational efficiency, and enhanced safety. Their purchasing decisions are often influenced by the proven wear life of the material, ease of maintenance, and the overall economic benefits derived from prolonged service intervals, pushing demand towards higher grades of AR plates that offer superior resistance to extreme abrasive environments.

Beyond these primary sectors, potential customers also extend to the construction, cement, agriculture, and waste management industries. Construction companies utilize AR steel for components in concrete mixers, asphalt pavers, and various ground-engaging tools. Cement and aggregate plants require AR plates for crushers, grinders, and separators. In agriculture, AR steel enhances the durability of farm machinery components like plough shares and cultivators. The waste management sector employs AR plates in shredders, compactors, and transfer stations to withstand the abrasive nature of refuse. These customers typically seek reliable, cost-effective solutions that can withstand harsh operating conditions, minimize wear-related maintenance, and contribute to the longevity and performance of their industrial assets, thereby supporting a broad and sustained demand for abrasion-resistant steel plate solutions across a wide economic spectrum.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 12.5 Billion |

| Market Forecast in 2033 | USD 20.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ArcelorMittal, SSAB, ThyssenKrupp AG, JFE Steel Corporation, Nippon Steel Corporation, POSCO, Baosteel Group Corporation, Tata Steel Limited, Kobe Steel, Ltd., Hyundai Steel Company, Dillinger Hütte GTS, Voestalpine AG, Outokumpu Oyj, Bisalloy Steel Group Ltd., Leeco Steel, NLMK Group, Cleveland-Cliffs Inc., Ruukki Construction (an SSAB company), O'Neal Steel Inc., Sumitomo Metal Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Abrasion Resistant Steel Plate Market Key Technology Landscape

The Abrasion Resistant Steel Plate market is continuously shaped by a dynamic key technology landscape, primarily driven by advancements in metallurgy, heat treatment processes, and manufacturing techniques. Innovations in steel alloying are fundamental, with ongoing research focusing on developing new compositions that incorporate precise ratios of carbon, manganese, chromium, molybdenum, boron, and other elements to achieve superior combinations of hardness, toughness, and weldability. Advanced micro-alloying techniques are crucial for controlling the microstructure of steel, which directly influences its mechanical properties and abrasion resistance. These metallurgical breakthroughs allow manufacturers to produce AR plates that can withstand even more aggressive wear environments while maintaining essential characteristics for fabrication and application versatility.

Alongside alloying, sophisticated heat treatment technologies form the bedrock of AR steel production. Quenching and tempering (Q&T) processes are continuously refined to optimize the cooling rates and tempering temperatures, resulting in fine-grained martensitic microstructures that provide exceptional hardness and strength without compromising toughness. Modern Q&T facilities utilize advanced control systems to ensure uniformity across large plate dimensions, critical for consistent performance. Furthermore, specialized hot rolling processes are employed to achieve precise plate dimensions and surface finishes, reducing the need for extensive post-processing. Technologies such as controlled rolling and thermomechanical controlled processing (TMCP) are also being adopted to produce AR steels with improved properties directly from the rolling mill, enhancing efficiency and reducing manufacturing costs.

The manufacturing ecosystem for AR steel plates also benefits from cutting-edge fabrication and inspection technologies. Advanced cutting techniques, including plasma, laser, and waterjet cutting, enable precise and efficient shaping of AR plates, minimizing material waste and ensuring fit-for-purpose components. Robotic welding systems are increasingly utilized to join AR steel parts, offering superior weld quality, consistency, and speed, which is vital given the material's specific welding requirements due to its high hardness. Non-destructive testing (NDT) methods, such as ultrasonic testing and eddy current testing, are routinely employed to ensure the internal integrity and surface quality of AR plates, guaranteeing their reliability in critical applications. These integrated technologies collectively contribute to the high performance, reliability, and cost-effectiveness of abrasion-resistant steel plates available in the market today.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for abrasion resistant steel plates, fueled by robust economic growth, rapid industrialization, and extensive infrastructure development projects, particularly in China, India, and Southeast Asian nations. The burgeoning construction sector, coupled with massive investments in mining and material handling industries, drives substantial demand for durable steel solutions. Government initiatives to upgrade existing infrastructure and develop new industrial zones further cement APAC's dominance in the global AR steel market.

- North America: Characterized by a mature industrial base and a strong emphasis on technological advancement, North America represents a significant market share. Demand is primarily driven by the replacement and maintenance of aging infrastructure, consistent activity in the mining and quarrying sectors, and the adoption of high-performance AR plates in heavy machinery manufacturing. The region also sees a focus on advanced AR solutions for specialized applications requiring superior wear resistance and extended lifespan.

- Europe: A prominent market for AR steel, Europe benefits from well-established manufacturing industries, particularly in construction, automotive, and industrial machinery. Stringent quality standards and a strong focus on sustainable and high-efficiency operations drive the demand for premium AR plates. Germany, the UK, and France are key contributors, with continuous investments in modernizing industrial plants and adhering to strict environmental regulations that favor durable, long-lasting materials.

- Latin America: This region is an emerging market with significant potential, primarily driven by expanding mining operations, particularly in countries like Brazil, Chile, and Peru, which are rich in natural resources. Infrastructure projects and growth in the agriculture sector also contribute to the increasing demand for AR steel plates. Economic stability and foreign investments are crucial factors influencing market expansion in this region, as industries seek cost-effective yet resilient material solutions.

- Middle East & Africa (MEA): The MEA region is experiencing steady growth in the AR steel plate market, largely due to extensive construction projects, particularly in the GCC countries, driven by urbanization and diversification efforts away from oil economies. Investments in mining, infrastructure, and oil & gas sectors across Africa and the Middle East are also contributing factors. The demand is often for high-durability materials to withstand harsh desert environments and heavy-duty industrial applications.

- Japan & South Korea: These highly industrialized nations in Asia Pacific are key players, recognized for their advanced steel manufacturing capabilities and a strong focus on high-quality, high-performance AR steel. Their domestic markets are driven by technological innovation in construction, heavy equipment, and shipbuilding, consistently seeking materials that offer optimal performance and precision. These countries also serve as major exporters of AR steel plates globally.

- Australia: As a major global player in mining, Australia presents a robust demand for abrasion resistant steel plates. The continuous need for durable equipment in its vast resource extraction operations, coupled with ongoing infrastructure development, drives market growth. The focus is on materials that can withstand extreme abrasive conditions and offer maximum operational uptime in remote and challenging environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Abrasion Resistant Steel Plate Market.- ArcelorMittal

- SSAB

- ThyssenKrupp AG

- JFE Steel Corporation

- Nippon Steel Corporation

- POSCO

- Baosteel Group Corporation

- Tata Steel Limited

- Kobe Steel, Ltd.

- Hyundai Steel Company

- Dillinger Hütte GTS

- Voestalpine AG

- Outokumpu Oyj

- Bisalloy Steel Group Ltd.

- Leeco Steel

- NLMK Group

- Cleveland-Cliffs Inc.

- Ruukki Construction (an SSAB company)

- O'Neal Steel Inc.

- Sumitomo Metal Industries

Frequently Asked Questions

What is Abrasion Resistant (AR) steel plate and where is it primarily used?

Abrasion Resistant (AR) steel plate is a high-strength, specialized steel engineered to withstand severe wear from friction, impact, and sliding abrasive materials. Its unique properties are achieved through specific chemical compositions and advanced heat treatments, primarily hardening and tempering processes. AR steel plates are extensively used in heavy industries such as mining, construction, cement, and material handling, for components like bucket liners, dump truck bodies, chutes, hoppers, and crusher parts, where durability and extended operational life are critical to minimize maintenance and maximize efficiency.

What are the key benefits of using Abrasion Resistant steel plates compared to standard steel?

The primary benefits of utilizing Abrasion Resistant steel plates over conventional steel include significantly prolonged equipment lifespan, leading to reduced replacement frequency and lower material consumption. This translates directly into substantial cost savings due to decreased maintenance requirements, minimized downtime for repairs, and enhanced operational efficiency. AR steel's superior hardness and toughness ensure components can endure harsh abrasive environments, improving overall productivity, worker safety, and contributing to more sustainable industrial practices by extending the service life of valuable assets.

Which industries are the major consumers of Abrasion Resistant steel plates?

The major consumers of Abrasion Resistant steel plates are industries characterized by operations involving intense wear and tear. The mining and quarrying sector is a leading consumer, utilizing AR steel for heavy machinery, crushing equipment, and material transport systems. The construction industry also heavily relies on AR plates for excavators, bulldozers, concrete mixers, and road-building equipment. Other significant end-use industries include cement and aggregates, material handling (e.g., conveyors, hoppers), agriculture for farm machinery, and waste management for shredders and compactors, all seeking robust materials to withstand abrasive conditions.

What are the primary factors driving the growth of the Abrasion Resistant Steel Plate market?

The growth of the Abrasion Resistant Steel Plate market is predominantly driven by global industrial expansion, particularly in developing economies, which fuels large-scale infrastructure and construction projects. The increasing demand for mineral resources necessitates extensive mining and quarrying activities, creating a continuous need for durable equipment. Furthermore, ongoing technological advancements in steel manufacturing, which lead to the development of higher-performance AR alloys with improved hardness and toughness, also significantly contribute to market expansion. The overarching focus on operational efficiency, cost reduction, and extended equipment lifespan across industries further propels market demand.

What are the key challenges faced by manufacturers in the Abrasion Resistant Steel Plate market?

Manufacturers in the Abrasion Resistant Steel Plate market face several key challenges, including the inherent volatility of raw material prices, particularly for critical alloying elements like iron ore, chromium, and molybdenum, which directly impact production costs and profitability. Stringent environmental regulations, encompassing emissions and waste management, impose significant compliance costs and necessitate substantial investments in sustainable manufacturing technologies. Additionally, intense market competition, the need for continuous research and development to innovate new and more effective AR steel grades, and managing complex global supply chains contribute to the operational complexities and strategic pressures faced by market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager