Absolute Rotary Encoders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434580 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Absolute Rotary Encoders Market Size

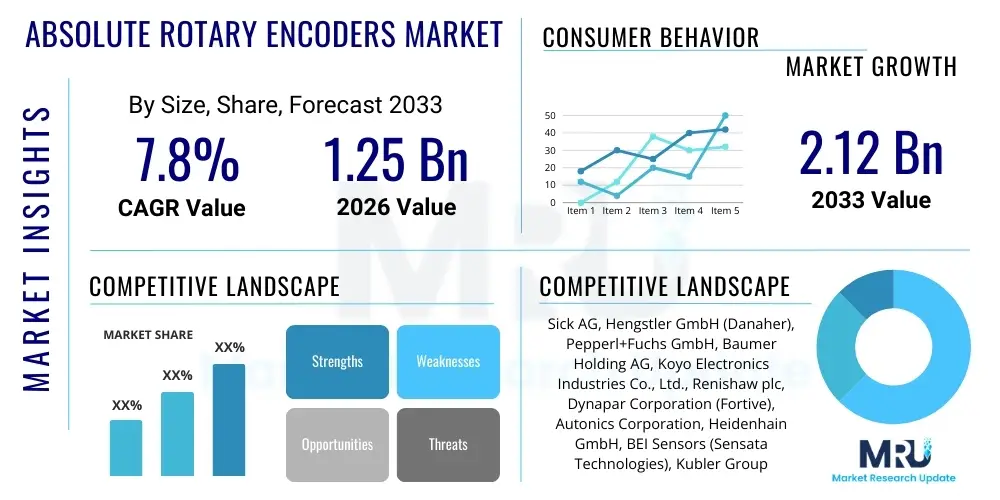

The Absolute Rotary Encoders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $2.12 Billion by the end of the forecast period in 2033.

The robust growth trajectory of the Absolute Rotary Encoders market is intrinsically linked to the global acceleration of industrial automation, particularly within the manufacturing and robotics sectors. Absolute encoders are increasingly essential because they provide unique, non-volatile position feedback, retaining position information even after power cycling. This capability is critical in high-stakes applications such as surgical robotics, advanced CNC machinery, and complex automated guided vehicles (AGVs), where restarting processes efficiently and safely is paramount. The precision requirements across diverse industries—from semiconductor fabrication equipment demanding sub-micron accuracy to large-scale wind turbine pitch control systems—are driving innovation in sensor technology, favoring highly reliable absolute measurement solutions over incremental alternatives.

Market expansion is further fueled by the adoption of Industry 4.0 principles, which necessitate intelligent, interconnected components capable of real-time data transmission and integration into sophisticated monitoring systems. Absolute rotary encoders, especially those equipped with modern fieldbus interfaces (like EtherCAT or PROFINET), are pivotal for providing the digital feedback required for predictive maintenance and optimized operational efficiency. Furthermore, the burgeoning demand for electric vehicles (EVs) and the associated expansion of automated battery manufacturing lines require stringent motion control capabilities, reinforcing the necessity for durable, compact, and high-resolution absolute encoders. Developing economies, particularly in Asia Pacific, are rapidly investing in factory modernization, creating massive untapped potential for these advanced positioning devices.

Technological advancements focused on enhancing reliability in harsh environments, such as magnetic absolute encoders offering resilience against dust, moisture, and vibration, are widening the application scope beyond traditional cleanroom settings. The competitive landscape is characterized by continuous research into miniaturization and improved communication protocols, ensuring seamless integration into space-constrained and complex multi-axis motion systems. The convergence of high-speed data processing capabilities within the encoder unit itself allows for decentralized control and faster reaction times, further solidifying the absolute rotary encoder's role as a foundational component in modern, high-performance mechanical systems across aerospace, medical diagnostics, and heavy machinery industries.

Absolute Rotary Encoders Market introduction

Absolute Rotary Encoders are electromechanical devices utilized for converting angular shaft position into a digital code, providing a unique output signal for every possible position of the shaft, typically measured over a 360-degree rotation. Unlike incremental encoders, which generate pulses proportional to movement and require a reference home position upon startup, absolute encoders maintain their positional information even if power is lost, utilizing internal memory or specialized magnetic/optical reading technology. This absolute positioning capability makes them indispensable in applications requiring instant and reliable feedback regarding machine location, offering significant advantages in terms of setup time, safety protocols, and system redundancy in dynamic operational environments.

The primary applications of absolute rotary encoders span numerous high-tech and heavy-duty industries, including industrial automation (robotics, packaging machinery, assembly lines), machine tools (CNC machines, lathes), medical equipment (MRI scanners, robotic surgery systems), aerospace (actuators, radar positioning), and renewable energy (wind turbine yaw and pitch control). The major benefits derived from utilizing absolute encoders include superior accuracy, non-volatile position storage, enhanced system safety by eliminating the need for homing cycles, and improved resilience against electrical noise interference, particularly with magnetic variants. Their ability to deliver high-resolution digital data directly contributes to tighter manufacturing tolerances and improved overall product quality in sophisticated production processes.

Several critical factors are driving the market forward, most notably the relentless push toward high-precision automation driven by global competition and labor cost optimization. The ongoing transition to the Industrial Internet of Things (IIoT) requires sensor technology that provides robust, network-ready data, a requirement perfectly met by absolute encoders integrated with advanced fieldbus connectivity. Furthermore, the rapid growth in collaborative robotics (cobots) and the increasing complexity of multi-axis systems, which rely heavily on precise, reliable initial position feedback, necessitate the deployment of absolute sensing technology. Regulatory demands for safety compliance in hazardous environments also favor these devices due to their intrinsic fault tolerance and robust design characteristics.

Absolute Rotary Encoders Market Executive Summary

The Absolute Rotary Encoders Market is experiencing significant upward momentum driven by key business trends emphasizing integration, digitalization, and enhanced ruggedness. A major trend involves the shift towards intelligent encoders that incorporate advanced diagnostic functions and sophisticated communication interfaces, allowing them to function as smart components within a connected factory ecosystem. The push for miniaturization without sacrificing resolution or durability is another dominant theme, particularly catering to smaller, faster, and more complex robotic systems and high-density electronic assemblies. Strategic mergers, acquisitions, and technological collaborations among key players are accelerating the development cycle for next-generation sensing elements, focusing heavily on solid-state and magnetic sensing technologies to overcome the limitations of traditional optical solutions in challenging industrial settings.

Geographically, the market dominance remains segmented, with the Asia Pacific (APAC) region leading in terms of production volume and demand, primarily fueled by massive government investments in smart manufacturing infrastructure in countries like China, South Korea, and Japan. North America and Europe, while slower in sheer volume growth, represent the highest value markets, driving demand for premium, high-resolution encoders suitable for demanding aerospace, defense, and high-end medical device manufacturing. These developed regions are the early adopters of cutting-edge networking standards (like Time-Sensitive Networking - TSN) integrated into encoders, positioning them as pioneers in advanced motion control system architecture, while Latin America and MEA show promising growth potential linked to infrastructure projects and mining automation.

Analysis of market segmentation reveals distinct segment trends favoring specific encoder types and output options. The Multiturn Absolute Encoders segment is projected to exhibit a faster CAGR, reflecting the growing need for tracking position over extended ranges in applications such as cranes, lifting equipment, and large-scale industrial machinery. By technology, magnetic absolute encoders are rapidly gaining market share over traditional optical encoders, particularly in environments susceptible to contamination or vibration, due to their superior robustness and reduced sensitivity to alignment issues. Furthermore, the increasing preference for Ethernet-based communication outputs (EtherCAT, Ethernet/IP) over traditional parallel or SSI interfaces highlights the industry's commitment to high-speed data throughput and system integration ease, aligning with the core tenets of digitized manufacturing processes.

AI Impact Analysis on Absolute Rotary Encoders Market

User queries regarding the impact of Artificial Intelligence (AI) on the Absolute Rotary Encoders Market commonly revolve around themes such as "How does AI enhance encoder data utility?", "Will AI replace traditional position sensors?", and "What role do smart encoders play in predictive maintenance algorithms?". Users are highly concerned about the integration layer: specifically, how raw positional data generated by encoders can be effectively utilized by AI and machine learning models to optimize complex processes and improve system reliability. Expectations center on AI's capability to transform simple positional data into actionable insights, moving beyond basic monitoring to proactive anomaly detection and self-correction in motion systems, thereby extending equipment lifespan and reducing unexpected downtime.

The impact of AI is primarily transformative rather than disruptive to the core function of the encoder; AI enhances the intelligence derived from the encoder's output. Modern absolute encoders, often incorporating edge computing capabilities, can preprocess vast amounts of positional and diagnostic data before transmission. AI models, whether residing on the edge or in the cloud, utilize this precise data stream to execute sophisticated tasks such as real-time drift compensation, vibration analysis for early fault detection in bearings or gearboxes, and optimization of multi-axis synchronization in complex robotic trajectories. This symbiotic relationship elevates the encoder from a mere sensor to a critical data node within the smart factory, making high-quality, high-resolution absolute encoders indispensable for feeding reliable inputs to demanding AI algorithms.

The future direction indicates that AI will mandate higher data rates and greater reliability from encoders. Encoders will be required not only to report position but also environmental parameters like temperature and humidity, which AI algorithms can correlate with positional variance to identify potential measurement errors or impending mechanical failure. This fusion of precise motion data with contextual environmental information, processed and analyzed by AI, is driving the demand for advanced absolute encoders capable of supporting higher bandwidth fieldbus technologies and meeting stringent data integrity standards necessary for automated quality control and closed-loop performance enhancement in critical manufacturing operations.

- AI algorithms utilize high-resolution encoder data for enhanced predictive maintenance modeling.

- Edge AI integration in smart encoders allows for localized data processing and faster anomaly detection.

- Machine learning optimizes motor control loops and robotic path planning based on continuous encoder feedback.

- AI analyzes positional drift over time, enabling automatic calibration and compensation mechanisms.

- Increased demand for encoders featuring high-speed digital outputs compatible with deep learning training datasets.

DRO & Impact Forces Of Absolute Rotary Encoders Market

The Absolute Rotary Encoders Market is significantly propelled by the increasing global emphasis on precision manufacturing and industrial robotics, categorized under Drivers (D). The mandatory requirements for non-volatile position feedback across safety-critical and high-throughput automation systems, coupled with the rapid adoption of Industry 4.0 standards, create sustained demand. However, the market faces significant challenges related to Restraints (R), including the relatively high initial cost of complex absolute encoders compared to simpler incremental counterparts, along with technical constraints like size limitations for certain integrated applications and performance degradation in extreme radiation or temperature environments. Opportunities (O) abound through the integration of these devices into the burgeoning Industrial Internet of Things (IIoT) ecosystem, offering pathways for advanced diagnostics, remote monitoring, and creating demand for specialized, custom-designed encoders for emerging applications such as augmented reality surgical systems and space exploration robotics, fostering innovation and market diversification. These dynamics are shaped by powerful Impact Forces driven by technological progress in sensing methods and global economic shifts favoring automation investment.

Segmentation Analysis

The Absolute Rotary Encoders Market segmentation provides a clear view of market dynamics based on technology, type, output format, and critical end-user applications. The technology segment distinguishes between optical (high precision, high resolution) and magnetic (high robustness, better for harsh environments) sensing methods, reflecting end-user compromises between accuracy and resilience. Segmentation by type differentiates between single-turn encoders, which measure position within one full revolution, and multi-turn encoders, which track both position within a rotation and the total number of revolutions, making them essential for long-travel systems. Furthermore, output format segmentation is crucial, differentiating between traditional parallel, proprietary serial (SSI), and modern fieldbus/Ethernet protocols (like EtherCAT, CANopen, PROFINET), reflecting the industry's evolving connectivity standards and data demands. Analyzing these segments helps stakeholders tailor product development and marketing strategies to meet specific application needs across diverse industrial landscapes.

- By Type:

- Single-Turn Absolute Rotary Encoders

- Multi-Turn Absolute Rotary Encoders

- By Technology:

- Optical Absolute Rotary Encoders

- Magnetic Absolute Rotary Encoders

- By Output Format:

- Parallel

- Serial Synchronous Interface (SSI)

- Fieldbus (PROFINET, EtherCAT, PROFIBUS, DeviceNet, CANopen)

- Ethernet/IP

- By End-User Industry:

- Industrial Automation and Robotics

- Machine Tools

- Assembly and Packaging

- Aerospace and Defense

- Medical Devices

- Renewable Energy (Wind Turbines, Solar Trackers)

- Mining and Heavy Equipment

- By Bore Size:

- Hollow Shaft

- Solid Shaft

Value Chain Analysis For Absolute Rotary Encoders Market

The value chain for the Absolute Rotary Encoders market begins with upstream activities involving the sourcing and manufacturing of highly specialized components, which include sensing elements (photodiodes, magnetoresistive sensors), specialized integrated circuits (ASICs) for signal conditioning and processing, precision optics (for optical variants), and high-grade mechanical parts (shafts, bearings, housings). Key technological barriers reside in the precision required for the raw components, such as the accuracy of code wheels or magnetic discs, which directly dictates the ultimate resolution and reliability of the final encoder product. Strong relationships with high-tech component suppliers capable of meeting rigorous quality standards are crucial at this stage, focusing on cost-effective acquisition of microelectronics and rare earth magnets, where applicable.

The midstream segment focuses on the core manufacturing and assembly processes, which involve highly specialized activities such as sensor mounting, sophisticated calibration routines, and environmental sealing. Calibration is particularly critical for absolute encoders to ensure that the output signal accurately maps to the physical position across the full range of motion. Modern manufacturing emphasizes automated assembly and testing to maintain consistency and high throughput. Significant value addition occurs here through proprietary firmware development and the integration of communication interfaces (e.g., Ethernet switches and Fieldbus stacks), which transform the physical sensing device into an intelligent network component capable of sophisticated data transmission and diagnostics required for Industry 4.0 compliance.

Downstream analysis highlights the crucial role of efficient distribution and post-sale services. Distribution channels are highly fragmented, involving a mix of direct sales to large Original Equipment Manufacturers (OEMs) in robotics and machine tool sectors, and indirect sales through specialized industrial distributors and system integrators serving smaller end-users and MRO (Maintenance, Repair, and Operations) markets. The selection of the channel is often dependent on the technical complexity and customization level required; highly customized or technically demanding solutions often necessitate direct engagement. Post-sales support, including technical consultation, application engineering, and rapid replacement services, is essential for maintaining customer loyalty, particularly in mission-critical applications where minimizing downtime is paramount, thereby ensuring the encoder system's reliable long-term performance.

Absolute Rotary Encoders Market Potential Customers

Potential customers, or end-users, for Absolute Rotary Encoders represent a broad spectrum of high-technology and heavy industrial sectors where precise, reliable, and non-volatile position sensing is non-negotiable. The largest and fastest-growing segment consists of sophisticated automation solutions, including multi-axis industrial robots, collaborative robots (cobots), and Automated Guided Vehicles (AGVs) utilized in manufacturing, warehousing, and logistics. These systems demand multi-turn absolute feedback for safe and accurate navigation and manipulation, ensuring that robots can always determine their exact joint position relative to a global frame of reference, crucial for collision avoidance and repeatable task execution, making robotics manufacturers a premier target market.

Another major customer base includes manufacturers of advanced machine tools, such as high-speed CNC milling machines, grinders, and laser cutting systems. In this sector, absolute encoders are essential for highly accurate axis positioning and ensuring micron-level precision during complex machining operations. The reliability of absolute position feedback significantly impacts the quality and consistency of manufactured components, driving demand for high-resolution optical encoders integrated into motor feedback loops and direct drives. Furthermore, the aerospace and defense sectors, requiring robust position sensing for flight control surfaces, actuator feedback, and military radar systems under extreme environmental conditions, represent high-value customers focused on certifications and long-term reliability.

The medical technology sector, particularly firms producing advanced diagnostic equipment (e.g., CT and MRI scanners), patient positioning systems, and minimally invasive surgical robots, constitutes a specialized and rapidly expanding customer segment. These applications require ultra-high reliability and often demand non-magnetic absolute encoders (in MRI environments) or sterile-compatible designs. Finally, the renewable energy sector, specifically wind turbine manufacturers, relies heavily on multi-turn absolute encoders for precise yaw control (orientation relative to the wind) and pitch control (blade angle adjustment) to maximize energy capture and prevent structural damage, solidifying this industry as a consistent long-term buyer of durable, large-format absolute encoders.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $2.12 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sick AG, Hengstler GmbH (Danaher), Pepperl+Fuchs GmbH, Baumer Holding AG, Koyo Electronics Industries Co., Ltd., Renishaw plc, Dynapar Corporation (Fortive), Autonics Corporation, Heidenhain GmbH, BEI Sensors (Sensata Technologies), Kubler Group, Tamagawa Seiki Co., Ltd., FRABA GmbH, Eltra S.p.A., Nemicon Corporation, Sensata Technologies, Shanghai Precise Instrument Co., Ltd., ifm electronic gmbh, TR-Electronic GmbH, and POSITAL Fraba. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Absolute Rotary Encoders Market Key Technology Landscape

The technological landscape of the Absolute Rotary Encoders market is dominated by two primary sensing methods: optical and magnetic, with a rapidly growing emphasis on advanced digital communication protocols. Optical technology relies on reading precise patterns on a code disk using light sources and photodetectors, offering exceptionally high resolution and accuracy, making it the preferred choice for applications like metrology and high-end CNC machining where micron-level precision is essential. Recent innovations in optical sensing focus on miniaturization, utilizing ASIC technology to integrate signal processing circuitry directly onto the sensor chip, enhancing speed and reducing vulnerability to external noise while maintaining the core advantage of high angular resolution.

Magnetic sensing technology, in contrast, utilizes magneto-resistive sensors to read changes in the magnetic field generated by a rotating magnetized disc. This technology excels in robustness, providing superior resistance to vibration, shock, contamination (dust, oil, water), and extreme temperatures, making it ideal for harsh industrial environments, mobile machinery, and heavy equipment. The technological evolution in magnetic encoders is focused on improving accuracy and resolution to rival optical counterparts, achieved through advanced signal processing algorithms and sophisticated linearization techniques. Furthermore, the development of non-contact magnetic encoders enhances lifespan by eliminating wear and tear associated with traditional bearing-supported designs, broadening their applicability in high-speed, demanding operations.

A parallel yet critical technological trend is the transition from proprietary analog or simple serial interfaces (like SSI) to high-speed industrial Ethernet protocols (Fieldbus). Key technologies such as EtherCAT, PROFINET, and Ethernet/IP are now standard offerings, enabling encoders to provide real-time, bidirectional communication, supporting advanced features like configuration, diagnostics, and integrated safety functions (functional safety). This network integration is crucial for IIoT readiness, allowing absolute encoders to be fully integrated data nodes that report not only position but also critical health metrics, contributing significantly to distributed control architecture and centralized maintenance scheduling. The ongoing development of Time-Sensitive Networking (TSN) capabilities within new encoder designs promises to further revolutionize synchronization and determinism in high-performance motion control systems.

Regional Highlights

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing region and the largest market in terms of volume, primarily driven by massive government and private sector investments in manufacturing modernization, particularly in China, Japan, and South Korea. The rapid expansion of automotive (especially EV manufacturing), consumer electronics production, and high-volume industrial automation adoption necessitate widespread deployment of reliable absolute encoders. Japan, in particular, maintains dominance in high-precision and technologically advanced encoder manufacturing.

- North America: North America holds a significant market share characterized by early adoption of advanced technology and high-value applications in aerospace, defense, and medical devices. Demand here is driven by the stringent quality requirements and complex certifications needed for these critical sectors, favoring high-performance, customized absolute encoders with robust data communication capabilities and integrated safety protocols.

- Europe: Europe is a mature and highly innovative market, led by Germany's strong machine tool industry and robotics expertise (driven by the Industrie 4.0 initiative). The European market exhibits strong demand for integrated Fieldbus encoders (PROFINET, EtherCAT, PROFIBUS) and places a premium on long-term reliability and compliance with rigorous CE and safety standards, particularly within the automotive, food and beverage, and renewable energy sectors.

- Latin America (LATAM): The LATAM market is poised for steady growth, driven by investments in infrastructure projects, mining automation (especially in Brazil and Chile), and localized manufacturing expansion. While current demand favors cost-effective, rugged magnetic encoders, increased foreign direct investment is expected to introduce more advanced, network-compatible absolute encoder solutions.

- Middle East and Africa (MEA): MEA presents niche opportunities, particularly in oil and gas extraction, energy production, and infrastructure development. The extreme environmental conditions in the Middle East necessitate highly durable and temperature-resistant magnetic absolute encoders, while automation initiatives in key sectors like logistics and materials handling contribute to gradual market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Absolute Rotary Encoders Market.- Heidenhain GmbH

- Sick AG

- Hengstler GmbH (Danaher Corporation)

- Pepperl+Fuchs GmbH

- Baumer Holding AG

- Koyo Electronics Industries Co., Ltd.

- Renishaw plc

- Dynapar Corporation (Fortive)

- Autonics Corporation

- BEI Sensors (Sensata Technologies)

- Kubler Group

- Tamagawa Seiki Co., Ltd.

- FRABA GmbH (POSITAL)

- Eltra S.p.A.

- Nemicon Corporation

- Sensata Technologies

- Shanghai Precise Instrument Co., Ltd.

- ifm electronic gmbh

- TR-Electronic GmbH

- Omron Corporation

Frequently Asked Questions

Analyze common user questions about the Absolute Rotary Encoders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of absolute rotary encoders over incremental encoders?

The primary advantage of an absolute rotary encoder is its ability to provide a unique, non-volatile position code immediately upon power-up, eliminating the need for a homing cycle or reference movement. This ensures instant, reliable position reporting, crucial for safety-critical applications and reducing machine downtime.

How is the market segmented by technology, and which type is growing faster?

The market is segmented primarily into Optical and Magnetic technologies. While optical encoders offer the highest precision for high-end applications, Magnetic absolute encoders are experiencing faster growth due to their superior durability, resilience against industrial contaminants, and robustness in harsh environments, making them highly suitable for widespread automation adoption.

Which industry accounts for the largest demand for Absolute Rotary Encoders?

The Industrial Automation and Robotics sector represents the largest consumer segment. The escalating deployment of multi-axis robots, CNC machinery, and automated assembly lines, driven by the shift towards Industry 4.0, requires the precise and reliable positional feedback that only absolute encoders can consistently provide.

What role do Fieldbus and Ethernet protocols play in the encoder market?

Fieldbus (e.g., EtherCAT, PROFINET) and industrial Ethernet protocols are critical, transforming encoders into smart, networked components. They enable high-speed, bidirectional communication, facilitate real-time diagnostics, configuration, and integration into modern decentralized control architectures, supporting IIoT functionality and enhanced system synchronization.

How does the development of AI influence future encoder specifications?

AI's development mandates higher data resolution, faster transmission speeds, and integrated diagnostics from encoders. Future specifications will prioritize encoders with edge processing capabilities and high bandwidth outputs to feed robust, real-time positional data directly into machine learning models for predictive maintenance and automated performance optimization.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager