Acetylacetone Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439374 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Acetylacetone Market Size

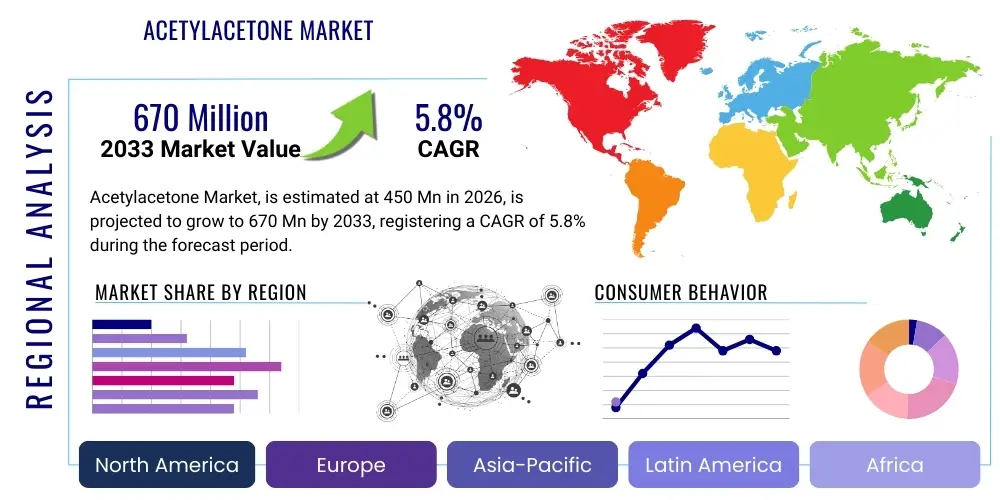

The Acetylacetone Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 670 Million by the end of the forecast period in 2033. This growth trajectory underscores the increasing demand for acetylacetone across diverse industrial applications, driven by its unique chemical properties and versatility as a precursor, solvent, and chelating agent in various sectors.

Acetylacetone Market introduction

Acetylacetone, chemically known as pentane-2,4-dione and commonly abbreviated as AcAc, is a versatile organic compound recognized for its distinctive tautomeric properties, existing as a keto-enol mixture. This unique structural characteristic, particularly the stability of its enol form, allows it to function as a powerful bidentate ligand, forming stable chelate complexes with a wide array of metal ions. These chelating capabilities are central to its extensive utility, making it an indispensable chemical intermediate in numerous industrial processes and scientific research applications. Its ability to act as both a proton donor and acceptor, alongside its capacity to form stable rings with metals, provides a broad spectrum of chemical reactivity.

Major applications of acetylacetone span a multitude of sectors, including the pharmaceutical industry where it is utilized in the synthesis of active pharmaceutical ingredients and as a precursor for various drug molecules. In the agrochemical sector, it plays a crucial role in the production of pesticides, herbicides, and fungicides, contributing to enhanced agricultural productivity and crop protection. Furthermore, acetylacetone serves as a vital solvent in specialized chemical reactions, particularly in processes requiring precise control over solubility and reactivity. Its application extends to being a crucial component in catalyst synthesis, enhancing reaction rates and selectivity in organic transformations, and as a raw material for various specialty chemicals and fine chemicals. The compound's high purity and controlled reactivity are paramount for its efficacy in these demanding applications, necessitating rigorous quality control throughout its production and distribution.

The market for acetylacetone is primarily driven by its expanding use as a chelating agent in metal extraction and purification processes, particularly in the recovery of rare earth elements and other valuable metals from ores and industrial waste streams. Its efficiency in forming stable, soluble metal chelates facilitates separation and purification, offering significant economic and environmental benefits. Additionally, the growing demand from the electronics industry for synthesizing metal oxide films and nanoparticles, which often employ metal acetylacetonates as precursors, further propels market expansion. The continuous innovation in materials science and the development of new synthetic pathways that leverage acetylacetone's unique properties are also significant growth factors. Benefits associated with acetylacetone include its high reactivity, excellent solvent properties, and ability to form stable complexes, which translate into improved product quality, process efficiency, and cost-effectiveness across its wide range of applications.

Acetylacetone Market Executive Summary

The Acetylacetone Market is experiencing dynamic shifts, characterized by evolving business trends, significant regional growth disparities, and segmented demand patterns. A key business trend shaping the market is the increasing focus on sustainable production methods and green chemistry principles, driven by tightening environmental regulations and growing consumer preference for eco-friendly products. Manufacturers are investing in R&D to develop more efficient, less hazardous synthetic routes for acetylacetone and its derivatives, aiming to reduce waste generation and energy consumption. Furthermore, strategic collaborations and partnerships between raw material suppliers, acetylacetone producers, and end-use industries are becoming more prevalent, fostering innovation and ensuring a stable supply chain amidst global economic fluctuations. Digitalization and automation in manufacturing processes are also emerging as crucial trends, optimizing production yields and reducing operational costs. Consolidation within the specialty chemical sector through mergers and acquisitions is another notable trend, as companies seek to expand their product portfolios and geographical reach, enhancing their competitive advantage.

From a regional perspective, the Asia Pacific (APAC) region continues to dominate the global acetylacetone market, primarily due to rapid industrialization, burgeoning pharmaceutical and agrochemical sectors, and significant investments in manufacturing capabilities, particularly in China and India. The robust growth in these economies, coupled with increasing disposable incomes and expanding consumer bases, fuels the demand for acetylacetone across various end-use applications. Europe and North America represent mature markets, characterized by stable demand from established industries such as pharmaceuticals, specialty chemicals, and advanced materials, alongside a strong emphasis on research and development for novel applications. These regions are witnessing a shift towards higher-purity grades and specialized derivatives of acetylacetone, catering to niche applications requiring stringent quality standards. Latin America and the Middle East & Africa regions are emerging as promising markets, driven by infrastructure development, growth in agricultural activities, and increasing foreign direct investment in chemical manufacturing, albeit from a smaller base.

Segmentation trends highlight the varied drivers within the acetylacetone market. The application segment, particularly its use as a chemical intermediate and a ligand for metal complexes, continues to be a primary growth engine. The pharmaceutical and agrochemical end-use industries are expected to exhibit robust growth, propelled by increasing global population, rising healthcare expenditure, and the need for enhanced food security. The demand for higher-purity acetylacetone, such as pharmaceutical grade and research grade, is growing faster than industrial grade, reflecting the stringent requirements of specialized applications and R&D activities. Moreover, the market is witnessing an uptick in demand for acetylacetone in emerging applications like semiconductor manufacturing, advanced ceramics, and catalysis, where its unique properties are highly valued. This diversification across applications and end-use sectors underscores the resilience and adaptability of the acetylacetone market to evolving industrial needs and technological advancements.

AI Impact Analysis on Acetylacetone Market

Common user questions regarding AI's impact on the Acetylacetone market frequently revolve around its potential to revolutionize manufacturing processes, optimize research and development, enhance supply chain efficiencies, and predict market trends. Users are keen to understand how AI-driven automation might improve production yields, reduce energy consumption, and ensure higher product purity, addressing concerns about cost-effectiveness and environmental sustainability. There is also significant interest in AI's role in accelerating the discovery of new acetylacetone derivatives or applications, particularly in complex chemical synthesis and materials science. Furthermore, questions often arise about AI's capacity to forecast demand fluctuations, manage inventory more effectively, and mitigate supply chain disruptions, thereby offering greater market stability and operational resilience. Users are generally optimistic about AI's transformative potential, viewing it as a tool to enhance competitive advantage and drive innovation within the specialty chemicals sector, while also acknowledging potential challenges related to data integration, algorithm development, and skill requirements.

- AI-driven process optimization in acetylacetone manufacturing can lead to enhanced reaction yields, reduced processing times, and significant energy savings, thereby lowering operational costs.

- Predictive maintenance powered by AI algorithms can identify potential equipment failures in production facilities, minimizing downtime and increasing overall plant efficiency and safety.

- AI accelerates research and development efforts by screening vast chemical databases to identify novel derivatives of acetylacetone with enhanced properties or entirely new applications.

- Machine learning models can analyze complex market data to provide highly accurate forecasts of acetylacetone demand, enabling better production planning and inventory management.

- AI-enabled supply chain management systems optimize logistics, track raw material availability, and anticipate potential disruptions, ensuring a more resilient and efficient delivery network for acetylacetone products.

- Quality control processes can be significantly improved through AI-powered visual inspection systems and analytical tools, detecting impurities or deviations from specifications with higher precision and speed.

- Robotics and automation, often integrated with AI, can handle hazardous chemical processes in acetylacetone production, enhancing worker safety and reducing human error.

- AI facilitates the development of sustainable synthesis routes by simulating various reaction pathways and identifying those with minimal environmental impact and resource consumption.

- Data analytics and AI can provide deeper insights into customer behavior and application-specific requirements, allowing manufacturers to tailor acetylacetone products more precisely to market needs.

- Intelligent systems can manage complex combinatorial chemistry experiments, exploring new catalytic systems or ligand structures involving acetylacetone much faster than traditional methods.

DRO & Impact Forces Of Acetylacetone Market

The Acetylacetone Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand from the pharmaceutical sector, where acetylacetone serves as a crucial building block for synthesizing a wide range of therapeutic compounds and drug intermediates. The burgeoning agrochemical industry also significantly propels demand, with acetylacetone derivatives being integral components in the formulation of effective pesticides, herbicides, and fungicides essential for modern agriculture and food security. Furthermore, its versatile role as a chelating agent in metal extraction and purification, especially for precious and rare earth metals, continues to expand, driven by technological advancements and the increasing need for high-purity metals in various advanced applications like electronics and catalysis. The growth of the specialty chemicals sector, which constantly seeks highly reactive and selective chemical intermediates, further contributes to the robust demand for acetylacetone, leveraging its unique tautomeric and complexing properties to create innovative products and processes.

However, the market faces significant restraints that can impede its growth. One of the primary challenges is the volatility of raw material prices, particularly acetone and acetic anhydride or diketene derivatives, which are crucial precursors for acetylacetone synthesis. Fluctuations in the cost of these petrochemical-derived feedstocks can directly impact production costs and profit margins for manufacturers, leading to price instability in the end product. Stringent environmental regulations and health concerns associated with the handling and disposal of certain chemical intermediates also pose considerable restraints. Governments worldwide are imposing stricter rules on chemical manufacturing and waste management, necessitating significant investments in compliance, pollution control technologies, and cleaner production processes, which can increase operational expenses and limit production capacities. Additionally, the availability of substitute products or alternative chemical pathways in some applications, though limited due to acetylacetone's unique properties, can introduce competitive pressure and potentially constrain market expansion in specific niches.

Despite these restraints, the Acetylacetone Market is characterized by substantial opportunities for growth and innovation. The increasing focus on green chemistry and sustainable practices presents a significant avenue for development, encouraging research into bio-based or more environmentally friendly production methods for acetylacetone and its derivatives. Emerging markets in Asia Pacific, Latin America, and Africa offer immense untapped potential, driven by rapid industrialization, urbanization, and expanding manufacturing bases, creating new demand centers for specialty chemicals. Technological advancements in catalysis and materials science are continuously opening new applications for acetylacetone, such as in the synthesis of advanced ceramics, metal-organic frameworks (MOFs), and new generation catalysts, which require precise control over metal coordination. Furthermore, ongoing research and development aimed at creating novel acetylacetone derivatives with enhanced functionality or tailor-made properties for specific high-value applications, such as in advanced electronics or specialized coatings, will further stimulate market expansion. These opportunities, coupled with the inherent versatility of acetylacetone, are expected to sustain its market relevance and drive future growth.

Segmentation Analysis

The Acetylacetone market is strategically segmented to provide a granular understanding of its diverse landscape, enabling stakeholders to identify key growth pockets, competitive advantages, and potential areas for investment. This segmentation is crucial for dissecting the market's complexities, revealing how various factors such as product purity, application end-use, and geographical distribution influence demand and supply dynamics. By classifying the market based on distinct characteristics, companies can tailor their product offerings, marketing strategies, and R&D efforts to address specific market needs more effectively. The comprehensive segmentation analysis facilitates a deeper insight into consumer preferences, technological adoption rates, and regulatory impacts across different sub-segments, thereby informing strategic decision-making for market players aiming to capitalize on emerging trends and consolidate their market position within the global chemical industry. Understanding these segmented demands is paramount for forecasting future market trajectories and allocating resources efficiently to maximize returns.

- By Grade: This segment categorizes acetylacetone based on its purity level and intended use, influencing pricing and specific application suitability.

- Industrial Grade: Used in large-scale chemical processes, such as general synthesis, solvent applications, and as an intermediate in less sensitive manufacturing. It represents the bulk of the market by volume.

- Pharmaceutical Grade: Characterized by extremely high purity, minimal impurities, and strict compliance with pharmacopoeial standards. Essential for pharmaceutical synthesis and drug manufacturing where product integrity is paramount.

- Research Grade: Typically used in laboratories for analytical purposes, academic research, and the development of new chemical compounds. Often sold in smaller quantities but at a higher price due to its specialized purity requirements.

- By Application: This segmentation highlights the diverse end-uses where acetylacetone's unique properties are leveraged, showcasing its versatility across industries.

- Chemical Intermediate: A primary application, where acetylacetone serves as a building block for synthesizing various organic compounds, heterocycles, and specialized chemicals.

- Solvent: Utilized in specific organic reactions, metal extraction processes, and as a component in paint strippers and cleaning formulations due to its excellent solvency properties.

- Catalyst: Employed as a ligand in transition metal catalysts (e.g., in polymerization reactions, organic synthesis) or as a precursor for generating active catalytic species.

- Ligand for Metal Complexes: Extensively used to form stable chelate complexes with a wide range of metal ions, critical in analytical chemistry, metal separation, and material science.

- Agrochemicals: Incorporated into the synthesis of various pesticides, herbicides, fungicides, and other crop protection agents to enhance agricultural yield and protect crops.

- Pharmaceuticals: A key ingredient or precursor in the synthesis of active pharmaceutical ingredients (APIs), diagnostic agents, and other medical compounds.

- Flavors & Fragrances: Used in the creation of certain synthetic flavorants and perfumery components due to its specific chemical structure.

- Paints & Coatings: Functions as a cross-linking agent, solvent, or additive to improve the properties, adhesion, and durability of paints, lacquers, and resins.

- Plastic & Rubber Additives: Employed as a stabilizer, cross-linking agent, or curing agent to enhance the performance, durability, and processing of polymers.

- Metal Extraction & Separation: Crucial in hydrometallurgical processes for the selective extraction and purification of valuable metals, including rare earth elements, from aqueous solutions.

- Dyes & Pigments: Used in the synthesis of certain colorants and pigments, contributing to their chemical structure and performance characteristics.

- Others: Includes niche applications in photography, fuel additives, and specialized research areas.

- By End-Use Industry: This segment focuses on the major industries that consume acetylacetone, reflecting industrial demand patterns.

- Chemical Industry: The largest consumer, encompassing various chemical manufacturing processes, including specialty chemicals, fine chemicals, and bulk intermediates.

- Pharmaceutical Industry: Driven by drug discovery, API synthesis, and the growing demand for healthcare products globally.

- Agrochemical Industry: Fueled by the need for crop protection solutions and agricultural productivity enhancements worldwide.

- Electronics Industry: Uses acetylacetone and its metal complexes in the synthesis of semiconductors, thin films, and advanced electronic materials.

- Automotive Industry: Consumes acetylacetone indirectly through coatings, plastics, and catalysts used in vehicle manufacturing.

- Construction Industry: Utilizes acetylacetone-derived products in specific coatings, adhesives, and sealants.

- Food & Beverage Industry: Limited but present in certain flavor and fragrance applications.

- Research & Academia: Continuous demand from universities and research institutions for experimental purposes and scientific studies.

- Others: Includes metal processing, photography, and cosmetic industries.

Value Chain Analysis For Acetylacetone Market

The value chain for the Acetylacetone Market is a complex network that begins with the sourcing of fundamental raw materials and extends through various manufacturing stages, distribution channels, and ultimately to a diverse range of end-use industries. At the upstream end, the market relies heavily on petrochemical derivatives, primarily acetone and acetic anhydride or diketene. Suppliers of these base chemicals constitute the initial link, providing the essential building blocks for acetylacetone synthesis. The stability and cost-effectiveness of these raw material supplies are critical determinants of the overall market dynamics, influencing production costs and the competitive positioning of acetylacetone manufacturers. The quality and purity of these upstream components directly impact the final product's specifications, especially for pharmaceutical and research-grade acetylacetone, necessitating stringent quality control measures from the outset of the value chain.

Moving downstream, the value chain encompasses the actual production of acetylacetone by chemical manufacturers, which involves complex condensation reactions followed by purification processes to achieve desired grades. These manufacturers often invest significantly in advanced chemical engineering, quality assurance, and sustainable production technologies. After production, the product moves through various distribution channels to reach its diverse clientele. Direct distribution channels are typically employed for large-volume sales to major industrial consumers, such as large pharmaceutical companies, agrochemical giants, or specialty chemical manufacturers, where established relationships and technical support are crucial. This direct approach allows for better control over product delivery, technical service, and customer feedback mechanisms, fostering stronger client relationships and facilitating customization of supply terms.

Indirect distribution channels involve a network of distributors, agents, and chemical traders who bridge the gap between acetylacetone producers and smaller-to-medium-sized enterprises or geographically dispersed customers. These intermediaries play a vital role in market penetration, inventory management, and providing localized support, particularly in emerging markets where direct sales might not be economically viable. They often handle warehousing, logistics, and smaller batch deliveries, making acetylacetone accessible to a broader customer base, including research laboratories and niche industrial applications. The effectiveness of these distribution channels, whether direct or indirect, is paramount for efficient market reach and customer satisfaction. The entire value chain culminates with the end-users across pharmaceutical, agrochemical, electronics, paints and coatings, and metal extraction industries, whose evolving demands and technological advancements continuously influence the product specifications and innovation within the acetylacetone market.

Acetylacetone Market Potential Customers

The Acetylacetone Market serves a broad spectrum of potential customers across various industries, each leveraging the compound's unique chemical properties for specialized applications. The pharmaceutical industry stands as a major end-user, with pharmaceutical companies and contract manufacturing organizations (CMOs) consistently requiring high-purity acetylacetone as a critical intermediate in the synthesis of active pharmaceutical ingredients (APIs). Its role in forming stable metal complexes is particularly valuable in creating new drug candidates, chelating agents for therapeutic purposes, and as a reagent in the production of various heterocyclic compounds foundational to drug structures. The stringent quality and regulatory requirements of this sector drive demand for pharmaceutical-grade acetylacetone, making these buyers a premium segment for manufacturers.

Another significant customer segment is the agrochemical industry, comprising manufacturers of pesticides, herbicides, and fungicides. These companies utilize acetylacetone and its derivatives as key building blocks to develop novel crop protection agents that enhance agricultural productivity and ensure food security. The demand from this sector is influenced by global population growth, changing agricultural practices, and the continuous need for more effective and environmentally friendly agrochemical solutions. Furthermore, the electronics industry represents a growing customer base, with companies involved in semiconductor manufacturing, advanced materials production, and thin-film deposition using metal acetylacetonates as precursors for creating high-performance electronic components and sensors. The precision and purity required in these applications make acetylacetone an indispensable material for this technologically advanced sector.

Beyond these primary sectors, the specialty chemical manufacturers and chemical research institutions form a substantial and diverse customer group. Specialty chemical producers incorporate acetylacetone into a wide range of products, including catalysts for various industrial processes, paint and coating additives for enhanced durability, and plastic and rubber additives for improved material properties. Metal extraction and refining companies are also key buyers, utilizing acetylacetone as a selective chelating agent for the separation and purification of valuable metals, including rare earth elements and transition metals. Research laboratories, both industrial and academic, continuously purchase acetylacetone for fundamental research, analytical chemistry, and the development of new chemical syntheses and materials, thereby contributing to the innovation pipeline for future applications. The versatility of acetylacetone ensures its relevance to a continually expanding base of industrial and scientific users.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 670 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Daicel Corporation, Wacker Chemie AG, Mitsubishi Chemical Corporation, Lonza Group AG, Merck KGaA, Dow Inc., Eastman Chemical Company, Sigma-Aldrich, TCI Chemicals, Ashok Alco-Chem Limited, Nantong Acetyl Chemical Co., Ltd., Shanghai Mintchem Development Co., Ltd., Lianyungang Jindun Chemical Co., Ltd., Huzhou Sunny Chemical Co., Ltd., Henan Tianfu Chemical Co., Ltd., Jinan Haohua Industry Co., Ltd., Jiangsu Jinsheng Chemical Co., Ltd., Changzhou Wujin Hengtong Chemical Co., Ltd., Tokyo Chemical Industry Co., Ltd. (TCI) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acetylacetone Market Key Technology Landscape

The Acetylacetone market is characterized by a dynamic technological landscape, predominantly driven by advancements in synthesis methods, purification techniques, and the development of sustainable chemical processes. The most common and industrially significant production method for acetylacetone involves the condensation of acetone with acetic anhydride or ethyl acetate. Continuous innovation in this area focuses on optimizing reaction conditions, such as temperature, pressure, and catalyst selection, to enhance reaction yields, reduce by-product formation, and improve energy efficiency. The adoption of advanced catalytic systems, including solid acid catalysts or specific metal-organic frameworks, is gaining traction, as these can offer higher selectivity, milder operating conditions, and improved catalyst recyclability, thereby lowering operational costs and environmental impact. Manufacturers are also exploring microreactor technology for acetylacetone synthesis, which offers advantages in terms of enhanced heat and mass transfer, improved safety for exothermic reactions, and greater process control, potentially leading to more compact and efficient production facilities.

Beyond synthesis, purification technologies play a critical role, especially for producing high-purity grades required by the pharmaceutical and electronics industries. Traditional distillation methods are continually being refined through the implementation of advanced column designs and vacuum distillation techniques to achieve higher separation efficiency and lower energy consumption. Emerging purification technologies, such as membrane separation, supercritical fluid extraction, and chromatographic purification, are being explored for their ability to selectively remove trace impurities, thereby achieving ultra-high purity levels that are difficult to attain through conventional methods. These advanced purification techniques are essential for meeting the stringent quality specifications for specialized applications where even minute levels of contaminants can compromise product performance. The integration of inline analytical techniques, such as gas chromatography-mass spectrometry (GC-MS) and Fourier-transform infrared spectroscopy (FTIR), for real-time process monitoring and quality assurance is also becoming standard practice, ensuring consistent product quality throughout the manufacturing process.

Furthermore, the technology landscape is being shaped by a growing emphasis on green chemistry principles and process intensification. This involves developing more environmentally benign synthesis routes for acetylacetone, utilizing renewable raw materials where possible, and minimizing the generation of hazardous waste. Researchers are investigating enzymatic synthesis methods or biocatalytic routes as sustainable alternatives, aiming to replace traditional petrochemical-based precursors and reduce the carbon footprint of production. Solvent-free reactions or the use of environmentally friendly solvents, such as ionic liquids or supercritical carbon dioxide, are also areas of active research and development. The integration of process analytical technology (PAT) and automation across the production line is another key technological trend, enabling manufacturers to monitor and control processes with greater precision, optimize resource utilization, and ensure compliance with evolving environmental and safety regulations. These technological advancements collectively drive efficiency, sustainability, and product quality in the Acetylacetone market, positioning it for continued growth and innovation.

Regional Highlights

- North America: The market in North America, particularly the United States, is characterized by a mature industrial base with a strong emphasis on research and development, especially in the pharmaceutical, specialty chemicals, and advanced materials sectors. High-purity acetylacetone demand is driven by innovation in drug synthesis, electronic materials, and catalysis. Strict environmental regulations encourage investment in sustainable production methods and advanced waste treatment, influencing market dynamics. Mexico and Canada also contribute to the regional demand, primarily in chemical manufacturing and localized agricultural applications.

- Europe: Europe represents a significant market for acetylacetone, with countries like Germany, the UK, France, and Italy leading the demand. The region benefits from a robust chemical industry, a strong pharmaceutical sector, and an active research community. European markets are pioneers in adopting green chemistry principles, fostering demand for sustainably produced acetylacetone and its derivatives. The automotive industry and stringent REACH regulations further influence product specifications and market trends, pushing for higher quality and environmental compliance.

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for acetylacetone, fueled by rapid industrialization, urbanization, and a burgeoning manufacturing sector across China, India, Japan, and South Korea. The immense growth in pharmaceutical, agrochemical, and electronics industries in these countries is a primary driver. Favorable government policies, lower manufacturing costs, and increasing foreign direct investment contribute to expanding production capacities and consumption rates, establishing APAC as the global hub for acetylacetone production and consumption.

- Latin America: The Latin American market for acetylacetone is emerging, with Brazil and Argentina being key contributors. Growth is primarily driven by expanding agricultural activities, necessitating increased use of agrochemicals, and the developing pharmaceutical and chemical industries. Investments in infrastructure and manufacturing capabilities are gradually increasing, leading to a steady rise in demand. Economic stability and regional trade agreements play a crucial role in shaping market opportunities and import-export dynamics.

- Middle East & Africa (MEA): The MEA region presents nascent but promising growth opportunities for acetylacetone. Demand is largely driven by diversification efforts in industrial sectors beyond oil and gas, including petrochemicals, specialty chemicals, and some pharmaceutical manufacturing in GCC countries. Agricultural expansion in parts of Africa also contributes to the demand for agrochemicals. However, market development is contingent on industrialization rates, investment in manufacturing infrastructure, and the establishment of robust supply chains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acetylacetone Market.- BASF SE

- Daicel Corporation

- Wacker Chemie AG

- Mitsubishi Chemical Corporation

- Lonza Group AG

- Merck KGaA

- Dow Inc.

- Eastman Chemical Company

- Sigma-Aldrich

- TCI Chemicals

- Ashok Alco-Chem Limited

- Nantong Acetyl Chemical Co., Ltd.

- Shanghai Mintchem Development Co., Ltd.

- Lianyungang Jindun Chemical Co., Ltd.

- Huzhou Sunny Chemical Co., Ltd.

- Henan Tianfu Chemical Co., Ltd.

- Jinan Haohua Industry Co., Ltd.

- Jiangsu Jinsheng Chemical Co., Ltd.

- Changzhou Wujin Hengtong Chemical Co., Ltd.

- Tokyo Chemical Industry Co., Ltd. (TCI)

Frequently Asked Questions

Analyze common user questions about the Acetylacetone market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary industrial applications of Acetylacetone?

Acetylacetone is primarily used as a versatile chemical intermediate in the synthesis of pharmaceuticals, agrochemicals, and specialty chemicals. It also serves as an effective solvent in various reactions, a critical ligand for forming stable metal complexes used in catalysis and metal extraction, and as a component in paints, coatings, and plastic additives. Its unique tautomeric properties and chelating capabilities make it indispensable across a wide range of industrial and scientific applications.

Which geographical region dominates the global Acetylacetone market, and why?

The Asia Pacific (APAC) region currently dominates the global Acetylacetone market. This dominance is attributed to rapid industrialization, significant expansion of the pharmaceutical and agrochemical industries, and substantial investments in manufacturing infrastructure in countries like China and India. The robust economic growth, increasing demand for specialty chemicals, and relatively lower production costs in APAC further solidify its leading position in both production and consumption of acetylacetone.

What are the key drivers propelling the growth of the Acetylacetone market?

Key drivers include the escalating global demand from the pharmaceutical sector for drug synthesis and API production, the burgeoning agrochemical industry's need for effective crop protection agents, and its expanding use in metal extraction and purification processes, especially for rare earth elements. Additionally, continuous technological advancements in catalyst synthesis, new applications in the electronics industry, and overall growth in the specialty chemicals sector significantly contribute to market expansion.

What are the main challenges or restraints impacting the Acetylacetone market?

The Acetylacetone market faces several significant restraints, including the volatility of raw material prices, particularly for acetone and acetic anhydride, which directly affects production costs and market stability. Stringent environmental regulations and increasing concerns over the health impacts of chemical manufacturing also pose challenges, necessitating substantial investments in compliance and sustainable production methods. Additionally, potential competition from alternative products or synthesis routes in specific applications can restrain market growth.

How is technological advancement influencing the Acetylacetone market?

Technological advancements are profoundly influencing the Acetylacetone market by optimizing synthesis processes for higher yields and purity, enhancing energy efficiency, and reducing waste generation through improved catalysis and microreactor technology. Innovations in purification techniques are crucial for meeting stringent quality standards, particularly for pharmaceutical and electronic grades. Furthermore, the adoption of green chemistry principles and AI-driven process optimization is leading to more sustainable and cost-effective production methods, opening new avenues for product development and application.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager