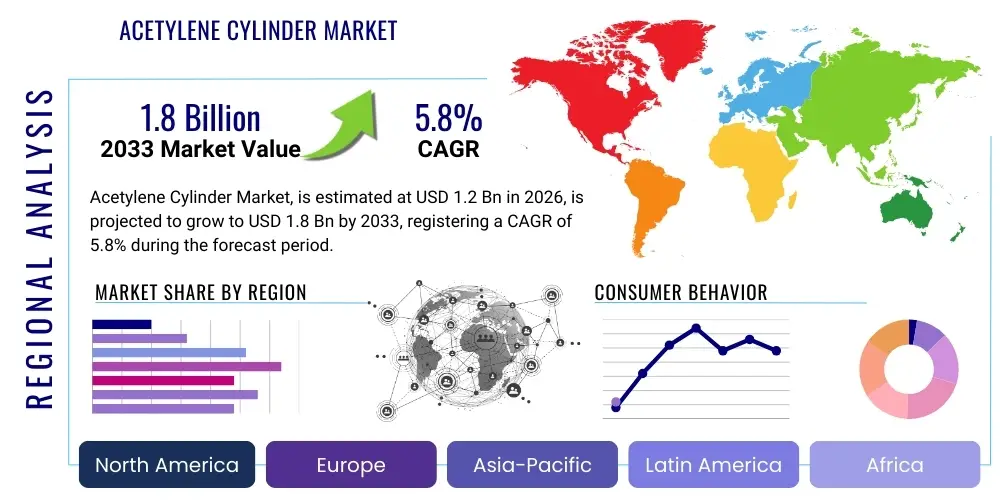

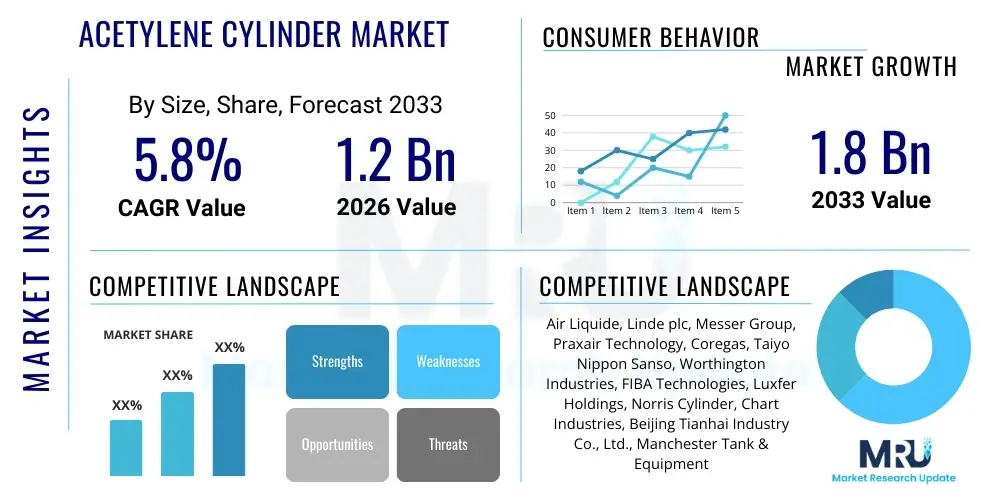

Acetylene Cylinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438179 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Acetylene Cylinder Market Size

The Acetylene Cylinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily underpinned by sustained global demand for metal fabrication services, particularly in developing economies where rapid infrastructure development and industrialization necessitate extensive welding and cutting operations. The inherent advantages of acetylene, such as its exceptionally high flame temperature and energy density, secure its position as a critical industrial fuel gas, driving the steady expansion of its specialized containment market.

The valuation reflects the increasing investment in advanced cylinder technologies designed to enhance safety and efficiency. Strict regulatory compliance regarding the transportation and storage of dissolved acetylene, which requires the use of specialized, high-integrity cylinders filled with a porous mass and a solvent like acetone or dimethylformamide (DMF), dictates premium pricing and consistent replacement cycles. Furthermore, the burgeoning automotive and aerospace maintenance, repair, and overhaul (MRO) sectors utilize portable acetylene cylinder setups extensively, contributing significantly to the overall market volume and valuation across key geographical regions such as Asia Pacific and North America.

Acetylene Cylinder Market introduction

The Acetylene Cylinder Market encompasses the manufacturing, distribution, and utilization of specialized high-pressure vessels designed specifically for the safe storage and transport of dissolved acetylene gas (C2H2). Acetylene, a highly reactive and unstable compound under pressure, necessitates unique cylinder architecture, typically featuring a steel or composite shell filled with a monolithic or granular porous material saturated with a stabilizing solvent. This complex design ensures that the gas remains dissolved and inert, preventing polymerization or explosive decomposition, making the cylinders indispensable assets for industrial safety and efficacy. These cylinders are crucial components in oxy-acetylene welding, cutting, and brazing processes due to the superior heat output achieved when acetylene is combusted with pure oxygen.

Major applications of acetylene cylinders span vital industrial sectors, including metal fabrication, shipbuilding, infrastructure construction (bridges, pipelines), and automotive manufacturing and repair. The primary benefit derived from these cylinders is the provision of a portable, high-energy fuel source required for precision cutting and robust welding of thick metals. Driving factors include escalating global investment in physical infrastructure projects, the recovery and growth of the manufacturing sector post-pandemic, and mandatory safety regulations that enforce the use of certified, regularly inspected, and high-quality cylinder units. Technological advancements in lightweight composite materials and improved porous mass integrity further enhance the market's attractiveness by offering safer and easier-to-handle products to end-users.

Acetylene Cylinder Market Executive Summary

The Acetylene Cylinder Market is characterized by stable demand driven by the robust construction and manufacturing sectors, though it faces constraints from high operational safety costs and competition from alternative fuel gases. Current business trends indicate a strong shift towards optimizing the logistics and supply chain of industrial gases, leveraging digital tracking technologies to monitor cylinder location, pressure, and testing status, thereby improving asset utilization rates among major gas suppliers. Regional trends highlight the Asia Pacific region, particularly countries like China and India, as the central growth engine, fueled by massive government investment in urban infrastructure and heavy industry expansion. North America and Europe maintain maturity, focusing primarily on cylinder replacement, refurbishment, and the adoption of high-specification composite cylinders for demanding applications.

Segment trends show that high-capacity cylinders, typically used in large fabrication workshops and industrial plants, command the largest revenue share, though small and medium-capacity cylinders are rapidly growing due to the increased adoption in portable welding systems and specialized repair services. Furthermore, the segmentation based on cylinder material is seeing steel dominating due to its cost-effectiveness and proven durability, yet composite cylinders are gaining traction in niche applications requiring maximum weight reduction, such as mobile emergency services or remote construction sites. Overall, market participants are concentrating on enhancing production safety standards and extending the service life of cylinders to maintain profitability in a highly regulated and competitive industrial landscape.

AI Impact Analysis on Acetylene Cylinder Market

Common user questions regarding AI's impact on the acetylene cylinder market predominantly center on improving operational efficiency, enhancing stringent safety protocols, and optimizing complex supply chain logistics. Users are keen to understand if AI-driven predictive maintenance can reduce catastrophic failures associated with high-pressure gas storage and if automated inspection systems can replace traditional manual testing, which is often time-consuming and prone to human error. The key themes revolve around how machine learning algorithms can analyze vast datasets from millions of cylinders globally—including temperature variances, fill rates, usage cycles, and mandatory testing dates—to forecast equipment failure, optimize inventory placement to minimize transport costs, and streamline regulatory reporting processes, ultimately improving the economic viability and safety record of dissolved gas supply.

The deployment of artificial intelligence is fundamentally transforming the lifecycle management of industrial gas cylinders, moving from reactive maintenance to proactive asset stewardship. For the acetylene market specifically, AI enhances the safety margin by analyzing vibration data and ultrasonic testing results captured during mandated periodic cylinder inspections (PCI), identifying subtle material fatigue or porous mass degradation that might be missed by conventional methods. This analytical capability ensures that only cylinders meeting the highest integrity standards remain in circulation. Furthermore, AI algorithms are critical in optimizing the filling process, precisely monitoring the solvent saturation level and gas absorption rate to maximize efficiency and maintain quality control, directly impacting product safety and operational throughput for major industrial gas manufacturers.

- AI-driven predictive maintenance reduces unscheduled cylinder downtime and failure risks by analyzing sensor data.

- Machine learning optimizes industrial gas logistics, forecasting regional demand shifts and minimizing transportation mileage.

- Automated visual inspection systems (using computer vision) improve the speed and accuracy of mandatory cylinder testing and label verification.

- AI assists in optimizing the precise charging process, ensuring optimal solvent/porous mass ratio for stability.

- Enhanced regulatory compliance tracking using AI simplifies audit trails and ensures timely retesting of assets.

DRO & Impact Forces Of Acetylene Cylinder Market

The Acetylene Cylinder Market is fundamentally shaped by powerful synergistic forces: robust global industrialization (Driver), stringent governmental safety regulations (Restraint), and the rapid expansion of emerging market infrastructure (Opportunity). Impact forces, characterized by high competition and the need for significant capital expenditure in specialized manufacturing facilities, continually influence pricing and market penetration strategies. The inherent instability of acetylene gas necessitates unparalleled levels of safety engineering, which acts as a barrier to entry for new competitors while simultaneously strengthening the market position of established global industrial gas giants who possess the requisite technology and safety compliance infrastructure.

Key market drivers include the sustained global appetite for high-quality, high-speed welding in sectors such as energy pipeline construction and structural fabrication, where the high thermal efficiency of oxy-acetylene systems remains unmatched by portable alternatives. However, restraints manifest primarily through escalating safety concerns and the high cost associated with periodic cylinder testing and refurbishment, alongside rising competition from alternative, often safer, fuel gases like propane, natural gas, and increasingly, hydrogen-based cutting technologies. Opportunities arise from geographical market expansion, the adoption of lightweight composite cylinders in specialty applications, and the strategic integration of advanced tracking and monitoring systems (IoT) to maximize asset utility and reduce operational hazards associated with cylinder handling and transportation.

Segmentation Analysis

The Acetylene Cylinder Market is segmented primarily by Capacity, Material, and Application, reflecting the diverse requirements of industrial consumers and specialized end-users. Capacity segmentation differentiates between small, medium, and large industrial cylinders, catering to everything from small automotive repair shops to vast fabrication facilities. Material segmentation highlights the distinction between traditional high-strength steel cylinders, favored for their durability and cost-effectiveness, and newer composite cylinders, chosen for their significant weight reduction and portability, despite higher unit costs. Application analysis defines usage across core industries such as metal manufacturing, construction, chemical processing, and specialized repair services, each presenting unique demand characteristics related to cylinder size and turnover rate.

Analysis of these segments reveals that the large capacity steel cylinders utilized in heavy fabrication dominate revenue streams due to the massive volume consumption in major industrial centers. However, the fastest growth is observed in the small to medium capacity composite cylinder segment, driven by the increasing need for highly mobile, field-ready welding and cutting kits for maintenance and rapid deployment scenarios. Understanding these nuanced segments is crucial for manufacturers to tailor their production lines, ensuring compliance with varied international standards and optimizing distribution channels to efficiently serve geographically dispersed and technologically divergent customer bases, ranging from automated assembly lines to remote construction sites utilizing portable welding equipment.

- By Capacity:

- Small (Below 10 Liters)

- Medium (10–40 Liters)

- Large (Above 40 Liters)

- By Material:

- Steel Cylinders

- Composite Cylinders (Fiberglass/Carbon Fiber Wrapped)

- By Application:

- Metal Fabrication & Welding

- Construction & Infrastructure Development

- Automotive MRO

- Shipbuilding & Marine Repair

- Aerospace & Defense

Value Chain Analysis For Acetylene Cylinder Market

The value chain for the Acetylene Cylinder Market begins with the upstream procurement of specialized raw materials, primarily high-grade alloy steel (or advanced composite materials like carbon fiber) required for the pressure vessel shell, and chemical inputs such as acetone or DMF for the stabilizing solvent, alongside proprietary porous mass components. Manufacturing involves complex, specialized processes including seamless tube formation, filling the cylinder shell with the precise porous material (like diatomaceous earth, calcium silicate, or monolithic carbon structures), curing, and subsequent saturation with the solvent. This upstream activity is highly regulated due to the inherent safety requirements of acetylene containment, demanding significant quality control and testing before the cylinders are released.

Midstream activities involve the highly specialized gas filling operations where purified acetylene gas is dissolved under pressure into the solvent-saturated porous mass. Distribution channels are highly centralized, often managed by major industrial gas companies (Direct distribution) who maintain large fleets specialized in transporting hazardous materials according to strict international and domestic regulations. Indirect distribution involves authorized dealers and regional distributors who serve smaller clients and geographically isolated markets. Downstream activities involve rental, leasing, and mandatory periodic testing services provided to end-users, ensuring the safety and operational integrity of the cylinders throughout their life cycle, which often exceeds fifteen years, emphasizing refurbishment and asset management.

The profitability across the value chain is significantly influenced by the efficiency of logistics and the capacity for high-volume periodic testing, which is a major recurring cost for the cylinder owner. Direct supply models dominate the large industrial consumer segment, guaranteeing strict quality control and efficient asset rotation, whereas smaller fabrication and maintenance shops rely heavily on indirect dealers who provide flexibility and localized service support. Optimization of this chain focuses heavily on reducing transport costs for heavy, bulky cylinders and leveraging digital tracking technologies to minimize loss and optimize mandatory hydrostatic testing cycles.

Acetylene Cylinder Market Potential Customers

Potential customers for acetylene cylinders are fundamentally rooted in industries requiring high-intensity heat sources for material modification, primarily heavy manufacturing, construction, and maintenance sectors globally. The largest volume buyers include large-scale metal fabrication workshops involved in structural steel assembly for commercial buildings, bridges, and industrial plants, where oxy-acetylene cutting remains the preferred method for efficiently preparing thick metal plates for welding. These customers typically require large-capacity cylinders and establish long-term rental agreements with major industrial gas suppliers to ensure continuous, high-volume supply and reliable exchange services.

A second crucial segment includes the extensive global network of automotive repair shops (MRO), specialized pipeline maintenance crews, and shipbuilding yards. In these environments, portability and reliability are paramount. Welders utilize acetylene for precision cutting, brazing, and specialized heating tasks like bending and straightening metals. For these customers, small to medium-capacity cylinders are essential, offering the necessary mobility for fieldwork and confined space operations. The selection criteria for these end-users are heavily influenced by the ease of handling, the supplier’s commitment to safety standards, and the proximity of exchange points to minimize operational downtime caused by cylinder replenishment logistics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Air Liquide, Linde plc, Messer Group, Praxair Technology, Coregas, Taiyo Nippon Sanso, Worthington Industries, FIBA Technologies, Luxfer Holdings, Norris Cylinder, Chart Industries, Beijing Tianhai Industry Co., Ltd., Manchester Tank & Equipment, Sahamitr Pressure Container, ENERPAC Tool Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acetylene Cylinder Market Key Technology Landscape

The core technology landscape for the Acetylene Cylinder Market centers on optimizing cylinder integrity, enhancing safety through porous mass innovation, and reducing weight through advanced material science. A critical area of technological focus is the development of monolithic porous materials, often based on activated carbon or improved calcium silicate structures, which offer superior mechanical strength and more uniform gas distribution compared to traditional granular fillings. These advancements maximize the safe storage capacity of the acetylene while significantly reducing the risk of internal void formation or solvent pooling, which are primary causes of cylinder failure or reduced lifespan. This technology ensures the dissolved state stability of the highly volatile gas under various operational pressures and temperatures, critical for regulatory compliance and user safety.

Another significant technological driver is the adoption of lightweight composite cylinders. While traditional steel cylinders are robust, the high weight restricts portability and increases logistics costs. Composite cylinders, utilizing high-strength materials like carbon fiber or fiberglass wrapped around a non-metallic liner, significantly cut down the cylinder weight, making them increasingly popular in specialized mobile welding applications, emergency response teams, and geographically challenging construction sites. Furthermore, embedded technologies, such as RFID tags and IoT sensors, are becoming standard features, enabling real-time tracking of cylinder location, pressure levels, and mandated retest dates. This shift towards smart assets improves overall supply chain management and enhances regulatory compliance by providing continuous data streams regarding the cylinder’s condition and usage pattern.

Safety innovation continues to drive development, focusing on improved pressure relief devices (PRDs) and fuse plug designs that offer enhanced performance under fire exposure scenarios, minimizing the risk of internal decomposition and explosion. Manufacturers are also implementing advanced non-destructive testing (NDT) techniques, such as automated ultrasonic testing (AUT) and acoustic emission testing (AET), to conduct highly accurate and efficient periodic inspections of the cylinder shell and internal porous mass integrity. These technologies not only streamline the re-qualification process but also provide a higher degree of assurance regarding the long-term structural health of the pressurized assets, which is paramount in a market defined by strict safety mandates.

Regional Highlights

Regional dynamics within the Acetylene Cylinder Market are highly stratified, reflecting varied industrial development stages, regulatory environments, and prevailing infrastructure investment levels across the globe.

- Asia Pacific (APAC): This region is the dominant and fastest-growing market globally, driven by massive investments in infrastructure development, including high-speed rail networks, extensive highway construction, and rapid urbanization in countries like China, India, and Southeast Asian nations. APAC’s large manufacturing base, particularly in steel production and automotive assembly, creates exponential demand for high-volume acetylene for cutting and welding applications. The focus here is on increasing cylinder capacity and optimizing local distribution networks to meet burgeoning industrial requirements, despite facing challenges related to inconsistent safety enforcement across smaller regional players.

- North America: Representing a mature yet highly standardized market, North America is characterized by stringent safety regulations (e.g., DOT requirements) and high asset utilization rates. Demand is steady, primarily driven by maintenance, repair, and overhaul (MRO) operations in the oil and gas sector, aerospace, and advanced manufacturing. The focus in this region is on replacing aging fleets with high-specification cylinders and exploring lightweight composite solutions for efficiency gains, ensuring compliance with rigorous periodic testing protocols managed by major industrial gas suppliers.

- Europe: The European market demonstrates stable, moderate growth, heavily influenced by strict environmental and safety directives (e.g., PED compliance). Demand is strong in advanced manufacturing (Germany) and shipbuilding (Scandinavia), prioritizing quality, durability, and technological integration. European players are pioneers in adopting digital cylinder tracking and focusing on maximizing the lifespan of existing assets through advanced refurbishment and testing techniques, ensuring sustainability and regulatory adherence.

- Latin America: This region presents significant growth potential, particularly in Brazil and Mexico, fueled by expanding domestic infrastructure projects and a growing automotive manufacturing base. Market penetration is often hampered by economic volatility and complex cross-border logistics, but the underlying industrialization trends are creating increased long-term demand for reliable industrial gas supply systems, including acetylene cylinders for heavy fabrication work.

- Middle East and Africa (MEA): Growth is sporadic but intense, primarily concentrated in the Gulf Cooperation Council (GCC) countries due to massive investments in oil and gas infrastructure, refinery maintenance, and mega-construction projects. Demand is project-driven, necessitating bulk supply of large-capacity cylinders for fabrication and construction support. Africa represents a nascent market with significant untapped potential linked to future mining and energy infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acetylene Cylinder Market.- Air Liquide

- Linde plc (formerly Praxair and Linde AG)

- Messer Group GmbH

- Taiyo Nippon Sanso Corporation

- Worthington Industries

- FIBA Technologies, Inc.

- Luxfer Holdings PLC

- Chart Industries, Inc.

- Norris Cylinder Company

- Beijing Tianhai Industry Co., Ltd. (BTIC)

- Manchester Tank & Equipment Co.

- Coregas Pty Ltd (WESFARMERS)

- Sahamitr Pressure Container Public Company Limited

- ENVIROGAS (division of General Carbon)

- Calumet Specialty Products Partners, L.P.

- A-L Compressed Gases

- GCE Group

- Cylinder Testing & Equipment (CTE)

- Weldcoa

- Cyl-Tec, Inc.

Frequently Asked Questions

Analyze common user questions about the Acetylene Cylinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Acetylene Cylinders?

The primary factor driving demand is the sustained need for high-efficiency, high-temperature welding and cutting solutions in global infrastructure development, metal fabrication, and extensive maintenance, repair, and overhaul (MRO) activities across various industrial sectors worldwide.

Why are Acetylene Cylinders designed with a porous mass and solvent, and how does this affect safety?

Acetylene gas is highly unstable and explosive when compressed above 15 psi. Cylinders use a stabilizing porous mass (like calcium silicate or activated carbon) saturated with a solvent (acetone or DMF) to dissolve the gas, keeping it in a stable, non-gaseous state under high pressure, which is critical for safe storage and transportation compliant with international regulations.

Which material segment, steel or composite, is projected to experience faster growth?

While steel cylinders currently hold the largest market share due to cost and durability, the composite cylinder segment (utilizing carbon fiber or fiberglass) is projected to experience faster growth due to the increasing demand for lightweight, highly portable cylinder solutions in specialized fieldwork and mobile maintenance applications.

What are the main regional challenges impacting the Acetylene Cylinder Market?

The main challenges involve the high cost and logistical complexity of mandatory periodic testing (hydrostatic and internal examination), varying levels of safety regulation enforcement across developing markets, and intense competition from alternative industrial fuel gases such as propane and propylene.

How is technology, such as IoT and AI, transforming the management of cylinder assets?

IoT and AI technologies are transforming asset management by enabling real-time tracking of cylinder location, pressure, and usage cycles, facilitating predictive maintenance, optimizing gas distribution logistics, ensuring timely regulatory retesting, and significantly improving overall safety compliance and asset utilization rates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager