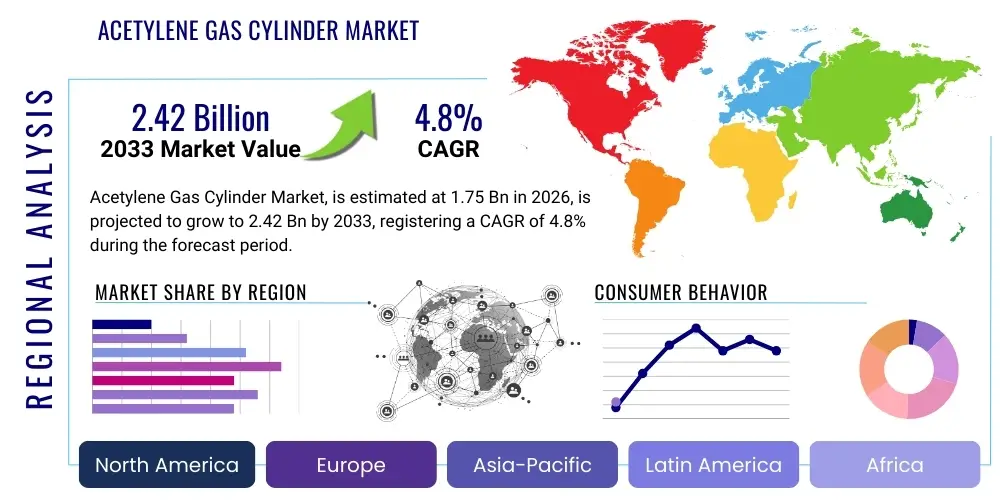

Acetylene Gas Cylinder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440433 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Acetylene Gas Cylinder Market Size

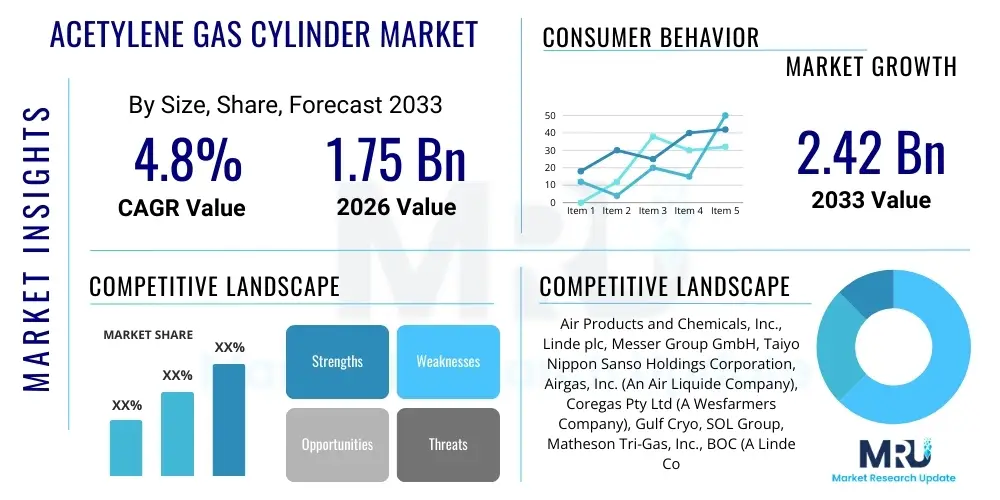

The Acetylene Gas Cylinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.75 Billion in 2026 and is projected to reach USD 2.42 Billion by the end of the forecast period in 2033.

Acetylene Gas Cylinder Market introduction

The Acetylene Gas Cylinder Market encompasses the global trade and utilization of acetylene gas stored under pressure in specialized cylinders for various industrial applications. Acetylene, a highly flammable and efficient fuel gas, is primarily produced through the reaction of calcium carbide with water, or as a byproduct of petroleum cracking. Its unique properties, including a high flame temperature when combined with oxygen, make it indispensable across numerous sectors.

Major applications for acetylene gas stored in cylinders include metal fabrication processes such as oxy-fuel welding, cutting, brazing, and soldering, where its precise heat output and localized heating capabilities are highly valued. Beyond metallurgy, acetylene finds significant use in chemical synthesis for producing various organic compounds, including vinyl chloride and acrylonitrile, which are precursors for plastics and synthetic rubbers. It is also critical in atomic absorption spectrophotometry as a fuel source for analytical testing and in the glass forming industry for specialized heating tasks. The primary benefits of using acetylene in cylinders include its high energy density, portability, and the ability to achieve extremely high temperatures, leading to efficient and precise operations. Key driving factors for this market include robust growth in the manufacturing and construction sectors, increasing demand for metalworking services, and advancements in industrial infrastructure globally.

Acetylene Gas Cylinder Market Executive Summary

The Acetylene Gas Cylinder Market is experiencing steady expansion driven by sustained industrial growth and technological advancements in manufacturing processes. Business trends indicate a focus on enhanced safety features in cylinder design and transportation, alongside an increasing demand for higher purity acetylene for specialized applications. Companies are investing in optimizing their supply chain networks to ensure timely and efficient delivery, especially to remote industrial sites. Strategic collaborations and mergers are also prevalent as key players aim to consolidate market share and leverage economies of scale.

Regionally, Asia Pacific continues to dominate the market due to rapid industrialization, extensive infrastructure development projects, and a thriving manufacturing base in countries like China and India. North America and Europe demonstrate mature markets with a strong emphasis on advanced technological adoption and adherence to stringent safety regulations. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, fueled by increasing investment in metal fabrication, construction, and chemical industries. Segment trends highlight a consistent demand for industrial-grade acetylene in metalworking, while high-purity acetylene gains traction in analytical and specialized chemical applications. The market is also witnessing a shift towards lightweight and safer composite cylinders, driven by regulatory pressures and efficiency demands.

AI Impact Analysis on Acetylene Gas Cylinder Market

User inquiries regarding AI's impact on the Acetylene Gas Cylinder Market frequently revolve around optimizing operational efficiencies, enhancing safety protocols, and improving supply chain management. Key themes include the potential for AI-driven predictive maintenance to reduce downtime in production facilities, the use of computer vision for automated cylinder inspection and quality control, and the application of machine learning algorithms for demand forecasting and inventory optimization. Users are particularly interested in how AI can mitigate inherent risks associated with handling and transporting flammable gases, as well as its role in developing more sustainable and resource-efficient production methods for acetylene. Expectations are high for AI to bring about significant improvements in safety, cost-effectiveness, and operational agility within the sector.

- AI-driven predictive maintenance for acetylene production equipment and cylinder integrity, reducing unexpected failures and improving operational safety.

- Automated visual inspection systems utilizing AI to detect defects in cylinders, valves, and welds with higher accuracy and speed, enhancing quality control and preventing hazards.

- Optimization of supply chain logistics and inventory management through machine learning algorithms for demand forecasting, route optimization, and real-time tracking of cylinder assets.

- Enhanced safety protocols and risk management through AI-powered sensors and analytics that monitor gas leaks, pressure variations, and environmental conditions during storage and transport.

- Development of smart manufacturing processes for acetylene, including AI-controlled reaction parameters to optimize yield, purity, and energy consumption, leading to more sustainable production.

- Personalized training and simulation environments for workers handling acetylene, leveraging AI to create realistic scenarios for safety procedure practice and emergency response.

DRO & Impact Forces Of Acetylene Gas Cylinder Market

The Acetylene Gas Cylinder Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, alongside various impact forces. Key drivers include the robust expansion of the global manufacturing sector, particularly in metal fabrication, automotive, and construction industries, which consistently demand acetylene for welding, cutting, and other thermal applications. The increasing need for reliable and high-temperature fuel gas in emerging economies, coupled with infrastructure development projects, further propels market growth. Additionally, the growing utilization of acetylene in chemical synthesis for plastics and synthetic fibers contributes to its sustained demand.

However, the market faces several restraints. Stringent safety regulations governing the production, storage, and transportation of highly flammable acetylene gas pose significant operational and compliance challenges, leading to higher costs. Competition from alternative fuel gases such as propane, propylene, and natural gas, especially in less demanding applications, can limit market expansion. The high initial investment required for establishing acetylene production facilities and maintaining specialized cylinder fleets also acts as a barrier to new entrants. Opportunities for market growth lie in technological advancements for safer and more efficient cylinder designs, the development of sustainable and "green" acetylene production methods, and the expanding applications in niche sectors like analytical instrumentation and specialized material processing. The impact forces, including evolving regulatory landscapes, global economic fluctuations, and the pace of industrial automation, significantly shape the market's trajectory.

Segmentation Analysis

The Acetylene Gas Cylinder Market is comprehensively segmented to provide granular insights into its various facets, enabling a deeper understanding of market dynamics and consumer preferences. These segmentations are critical for identifying specific growth pockets, tailoring market strategies, and assessing the competitive landscape. The market is typically categorized by parameters such as cylinder type, gas purity, application, and end-user industry, reflecting the diverse requirements across different industrial sectors and geographical regions. Each segment represents a distinct demand profile and set of market drivers, contributing uniquely to the overall market structure.

- By Type:

- Industrial Grade Acetylene Gas

- High Purity Acetylene Gas

- By Application:

- Metal Fabrication (Welding, Cutting, Brazing, Soldering)

- Chemical Synthesis

- Atomic Absorption Spectrophotometry

- Glass Forming

- Plastics Manufacturing

- Others (e.g., carbon black production, research & development)

- By End-User Industry:

- Manufacturing (Automotive, Aerospace, Heavy Machinery, Shipbuilding)

- Construction

- Chemical & Petrochemical

- Pharmaceutical & Biotechnology

- Research & Development

- Food & Beverage

- Healthcare

- Others (e.g., Mining, Electronics)

Value Chain Analysis For Acetylene Gas Cylinder Market

The value chain for the Acetylene Gas Cylinder Market involves several critical stages, from raw material sourcing to end-user delivery, each adding value and incurring costs. Upstream analysis focuses on the procurement of raw materials, primarily calcium carbide or hydrocarbons, which are then processed to produce acetylene gas. This stage includes sourcing suppliers, managing logistics for bulk materials, and ensuring consistent quality. The subsequent production phase involves specialized chemical processes to synthesize acetylene, followed by purification, compression, and filling into high-pressure cylinders. Manufacturing of the cylinders themselves, including specialized alloys and valve systems, also forms a crucial upstream component, requiring precision engineering and adherence to stringent safety standards.

Downstream analysis encompasses the distribution, sales, and post-sales services of filled acetylene gas cylinders. Distribution channels are varied, including direct sales from manufacturers to large industrial clients, and indirect sales through a network of distributors, wholesalers, and specialized gas suppliers who cater to smaller businesses and individual contractors. These channels often involve complex logistics for cylinder transportation, exchanges, and refills, given the hazardous nature of the product. Direct distribution allows for greater control over customer relationships and service, while indirect channels provide wider market reach and localized support. Effective management of cylinder fleets, including maintenance, inspection, and return logistics, is paramount for operational efficiency and safety across the entire value chain.

Acetylene Gas Cylinder Market Potential Customers

The potential customers for the Acetylene Gas Cylinder Market span a diverse range of industries, all requiring a reliable and efficient source of high-temperature fuel gas or a key chemical precursor. These end-users or buyers are primarily industrial entities that leverage acetylene for its unique properties in various manufacturing and operational processes. The largest segment of customers includes metal fabrication shops, welding and cutting contractors, and large-scale manufacturing facilities in the automotive, aerospace, and heavy machinery sectors. These entities depend on acetylene for precision metalworking tasks such as welding, brazing, soldering, and oxy-fuel cutting due to its superior flame characteristics.

Beyond metalworking, chemical and petrochemical companies represent a significant customer base, utilizing acetylene as a crucial building block in organic synthesis for the production of vinyl chloride monomer, acetaldehyde, and other essential industrial chemicals. The construction industry also forms a substantial customer segment, employing acetylene for on-site metalwork and structural fabrication. Furthermore, research and development laboratories, academic institutions, and pharmaceutical companies use high-purity acetylene for analytical instrumentation like atomic absorption spectrophotometry. Even niche sectors such as glass manufacturing, where precise heat application is required, and certain food processing applications contribute to the diverse customer landscape, all valuing the portability, energy density, and high performance offered by acetylene in cylinders.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.75 Billion |

| Market Forecast in 2033 | USD 2.42 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Air Products and Chemicals, Inc., Linde plc, Messer Group GmbH, Taiyo Nippon Sanso Holdings Corporation, Airgas, Inc. (An Air Liquide Company), Coregas Pty Ltd (A Wesfarmers Company), Gulf Cryo, SOL Group, Matheson Tri-Gas, Inc., BOC (A Linde Company), Yingde Gases Group Company Limited, Sichuan Mingrui Gas Equipment Co., Ltd., Nanjing Yuefeng Gas Co., Ltd., Hangzhou Oxygen Plant Group Co., Ltd., Chengdu Jiesheng Gas Equipment Co., Ltd., Zhejiang Kaishan Compressor Co., Ltd., Beijing Huayu Gas Co., Ltd., Suzhou Jinhong Gas Co., Ltd., Shanghai Qidong Gas Co., Ltd., Praxair (Part of Linde plc) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acetylene Gas Cylinder Market Key Technology Landscape

The Acetylene Gas Cylinder Market is continually evolving, driven by advancements in material science, engineering, and digital technologies aimed at enhancing safety, efficiency, and performance. Key technological innovations focus on improving the integrity and functionality of the cylinders themselves, as well as optimizing the processes involved in gas production, filling, and distribution. Advanced cylinder materials, such as high-strength steel alloys and composite materials, are being developed to reduce cylinder weight while increasing durability and safety. These materials offer better resistance to internal pressures and external impacts, mitigating risks associated with transport and handling. Furthermore, improvements in valve technology, including integrated pressure regulators and safety relief devices, are crucial for precise gas flow control and preventing over-pressurization.

In terms of operational technology, automated cylinder filling and inspection systems are becoming standard, utilizing sensors and robotics to ensure accurate filling volumes and detect any defects or damage in the cylinders more efficiently than manual processes. Gas purification technologies are also advancing to produce higher grades of acetylene required for sensitive applications like atomic absorption spectroscopy and specialized chemical synthesis. Additionally, the integration of IoT (Internet of Things) and telemetry systems allows for real-time monitoring of cylinder locations, inventory levels, and usage patterns, enabling optimized logistics and preventive maintenance. This digital transformation not only improves operational efficiency but also significantly enhances safety by providing immediate alerts for potential issues, contributing to a more secure and streamlined acetylene gas supply chain.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to robust industrialization, massive infrastructure development, and thriving manufacturing sectors in countries like China, India, and Southeast Asia. High demand from metal fabrication, automotive, and construction industries fuels growth.

- North America: Characterized by a mature industrial base and advanced technological adoption. Strong focus on safety regulations and innovation in cylinder technology and efficient supply chain management. Demand driven by automotive, aerospace, and chemical industries.

- Europe: A well-established market with stringent environmental and safety standards. Significant demand from the automotive, chemical, and precision engineering sectors. Emphasis on sustainable production methods and advanced gas handling solutions.

- Latin America: Emerging market with growing industrial activities, particularly in Brazil and Mexico. Increasing investments in construction, mining, and manufacturing sectors are driving the demand for acetylene gas.

- Middle East & Africa (MEA): Exhibiting steady growth attributed to expanding oil & gas industries, infrastructure development projects, and diversification efforts into manufacturing. Increasing industrialization and urbanization are key growth factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acetylene Gas Cylinder Market.- Air Products and Chemicals, Inc.

- Linde plc

- Messer Group GmbH

- Taiyo Nippon Sanso Holdings Corporation

- Airgas, Inc. (An Air Liquide Company)

- Coregas Pty Ltd (A Wesfarmers Company)

- Gulf Cryo

- SOL Group

- Matheson Tri-Gas, Inc.

- BOC (A Linde Company)

- Yingde Gases Group Company Limited

- Sichuan Mingrui Gas Equipment Co., Ltd.

- Nanjing Yuefeng Gas Co., Ltd.

- Hangzhou Oxygen Plant Group Co., Ltd.

- Chengdu Jiesheng Gas Equipment Co., Ltd.

- Zhejiang Kaishan Compressor Co., Ltd.

- Beijing Huayu Gas Co., Ltd.

- Suzhou Jinhong Gas Co., Ltd.

- Shanghai Qidong Gas Co., Ltd.

- Praxair (Part of Linde plc)

Frequently Asked Questions

What is acetylene gas primarily used for in cylinders?

Acetylene gas in cylinders is primarily used for industrial applications, most notably in metal fabrication for oxy-fuel welding, cutting, brazing, and soldering due to its high flame temperature and precise heat control. It also serves as a crucial raw material in chemical synthesis and as a fuel in atomic absorption spectrophotometry.

What are the key safety considerations for acetylene gas cylinders?

Key safety considerations include proper storage in well-ventilated areas away from ignition sources, secure handling to prevent falls, regular inspection for damage, and adherence to pressure limits. Acetylene cylinders contain a porous material saturated with acetone to safely store the gas, reducing explosion risk. Training on safe operation and emergency procedures is essential.

Which industries are the largest consumers of acetylene gas cylinders?

The largest consumers are industries involved in metal fabrication, including automotive, aerospace, shipbuilding, and general manufacturing. Other significant consumers include construction, chemical and petrochemical industries for synthesis, and research and development for analytical applications.

How is the Acetylene Gas Cylinder Market affected by environmental regulations?

Environmental regulations primarily impact the production processes of acetylene, encouraging more sustainable and energy-efficient methods. For cylinders, regulations focus on safe disposal, recycling, and ensuring the integrity and lifespan of containers to minimize environmental hazards and promote circular economy principles.

What are the emerging trends in acetylene gas cylinder technology?

Emerging trends include the development of lightweight composite cylinders for easier transport, advanced valve technologies for enhanced safety and precision, and the integration of IoT for real-time tracking and inventory management. Automation in cylinder filling and inspection, along with cleaner production methods, are also key trends.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager