Acoustic Fencings Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437961 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Acoustic Fencings Market Size

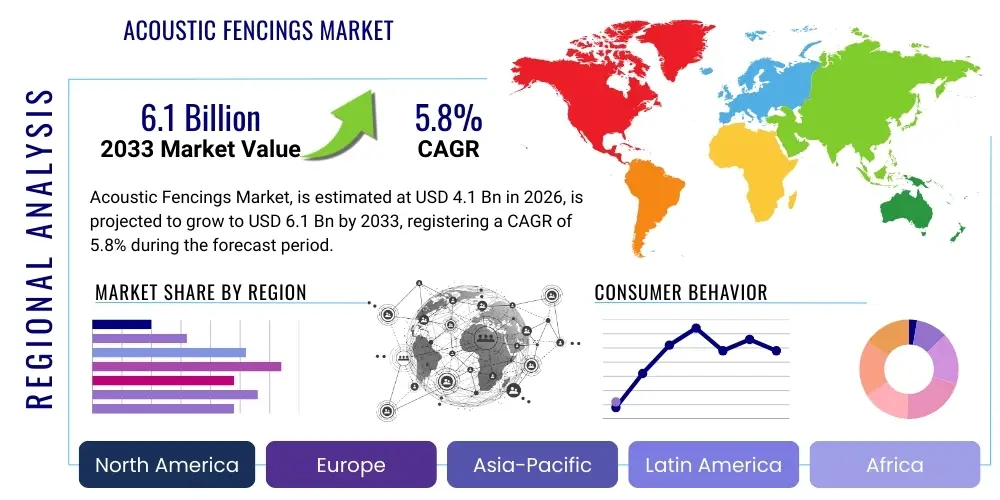

The Acoustic Fencings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Acoustic Fencings Market introduction

The Acoustic Fencings Market encompasses the design, manufacture, and installation of specialized noise reduction barriers aimed at mitigating sound propagation from sources such as roadways, railways, industrial facilities, and large commercial developments. Acoustic fencings, often referred to as sound barriers or noise walls, are crucial infrastructure components designed to improve the quality of life for residents situated near high-decibel areas, fulfilling stringent government noise pollution regulations globally. These structures utilize materials optimized for sound absorption and reflection, including composites, precast concrete, wood, metal, and engineered plastics, to achieve specific Noise Reduction Coefficient (NRC) and Sound Transmission Class (STC) ratings tailored to the application environment.

Major applications of acoustic fencings include the perimeter delineation of transportation infrastructure projects, serving as essential elements in urban planning to protect sensitive receptors like residential neighborhoods, hospitals, and educational institutions from traffic-related noise. Beyond public infrastructure, the product finds significant use in commercial and industrial settings, such as buffering data centers, oil and gas operations, construction sites, and HVAC equipment enclosures, where continuous, high-level operational noise must be contained. The effectiveness of these barriers is not solely dependent on height and length but also on material properties, density, and seamless installation techniques that prevent sound leakage, making them highly specialized engineering solutions.

The primary benefit of deploying acoustic fencings is compliance with increasingly stringent environmental noise abatement regulations mandated by regional and national environmental protection agencies, thereby reducing legal liabilities for infrastructure developers. Furthermore, they contribute directly to public health by minimizing noise exposure associated with cardiovascular problems, sleep disturbance, and cognitive impairment. Driving factors for market growth include exponential growth in global infrastructure spending, particularly in rapidly urbanizing regions; heightened public awareness and demand for noise control; and continuous technological innovation leading to lighter, more durable, and aesthetically versatile noise barrier solutions that integrate seamlessly into urban and suburban landscapes.

Acoustic Fencings Market Executive Summary

The Acoustic Fencings Market is characterized by robust business trends driven primarily by governmental investments in large-scale infrastructure and the rigorous enforcement of noise pollution standards across developed and developing economies. Key business trends involve the increasing preference for composite and recycled materials, offering better longevity and lower maintenance costs compared to traditional concrete. Strategic partnerships between material manufacturers and construction firms are optimizing supply chains, allowing for faster deployment of modular acoustic solutions. Furthermore, digitalization in planning, utilizing sophisticated noise modeling software and GIS mapping, is improving the efficiency and effectiveness of barrier placement, ensuring optimal noise mitigation performance relative to cost.

Regional trends indicate that North America and Europe remain the largest and most mature markets due to established highway networks and comprehensive regulatory frameworks such as the European Union’s Environmental Noise Directive. However, the Asia Pacific region, particularly countries like China and India, is emerging as the fastest-growing market, propelled by massive investments in new railway lines, rapid urban expansion, and the construction of new mega-cities requiring extensive noise abatement infrastructure. Latin America and the Middle East and Africa are showing steady growth, primarily linked to resource extraction projects (requiring industrial noise control) and the expansion of existing port and airport infrastructure where noise mitigation is critical.

Segment trends highlight the dominance of the transportation segment, specifically road noise barriers, although the industrial segment is exhibiting accelerated growth spurred by the need to isolate noise from 24/7 manufacturing plants and power generation facilities. Material-wise, transparent acoustic barriers (made of polycarbonate or acrylic) are gaining traction in urban areas where visual connectivity and aesthetic integration are prioritized, despite their higher initial cost. There is also a notable shift towards specialized low-height noise barriers and absorptive surface treatments designed for complex, densely populated urban environments where traditional high walls are structurally or aesthetically impractical, emphasizing innovative design over sheer size.

AI Impact Analysis on Acoustic Fencings Market

User inquiries regarding AI's influence on the Acoustic Fencings Market frequently center on predictive maintenance, optimal barrier placement, and the real-time adaptive nature of noise mitigation systems. Key themes indicate user concerns about whether AI can truly replace manual acoustic modeling and how machine learning algorithms could process vast environmental data (traffic patterns, weather, existing soundscapes) to design more efficient barriers with fewer material inputs. Users expect AI to reduce the planning phase duration and enhance the long-term performance monitoring of installed barriers, moving beyond static structures to potentially incorporating semi-active noise cancellation technologies guided by real-time data analysis. The primary expectation is cost reduction and increased precision in mitigating specific noise frequencies.

- AI-driven Predictive Modeling: Utilization of machine learning algorithms to simulate complex sound wave propagation patterns in varied terrains, optimizing barrier height, length, and material composition for maximum noise reduction effectiveness before construction begins.

- Automated Site Selection and Layout Optimization: AI processing of satellite imagery, topographical data, and real-time traffic statistics to automatically generate the most cost-effective placement strategies for noise abatement infrastructure, minimizing material waste.

- Real-time Noise Monitoring and Maintenance Scheduling: Deployment of AI-powered sensor networks integrated into fencings to continuously monitor noise levels and structure integrity, predicting potential failures or compromised performance areas requiring proactive repair.

- Generative Design for Aesthetic Integration: AI tools assisting architects and engineers in developing noise barrier designs that meet acoustic performance criteria while adhering to local aesthetic requirements and urban planning guidelines, balancing function and visual appeal.

- Supply Chain and Logistics Optimization: Machine learning applied to managing the complex logistics of delivering specialized, large-format acoustic panels, ensuring Just-In-Time (JIT) delivery to major infrastructure projects and reducing construction delays.

- Adaptive Noise Control Systems: Future application of AI in semi-active barriers that could adjust internal panel mechanisms or use smart materials to dampen specific, fluctuating noise frequencies in real-time, moving beyond traditional passive absorption.

- Regulatory Compliance Audit Automation: AI systems analyzing completed barrier installations against mandated noise reduction targets, automatically generating compliance reports and identifying non-conforming sections for immediate remediation.

DRO & Impact Forces Of Acoustic Fencings Market

The dynamics of the Acoustic Fencings Market are governed by a compelling interplay of regulatory mandates (Drivers), material limitations and initial investment costs (Restraints), and the development of sustainable, multi-functional barriers (Opportunities). Drivers include stringent national environmental regulations, rapid urbanization leading to residential encroachment near infrastructure, and significant governmental allocations for road and rail modernization projects globally. Restraints are centered around the high capital cost of specialized materials, the substantial footprint required for installation, and public resistance to the aesthetic impact of large noise walls, especially in scenic or historic areas. Opportunities arise from technological advancements in lighter, more durable materials, the integration of solar panels or green infrastructure elements into barrier design (multi-functionality), and the expansion into emerging markets requiring foundational infrastructure development.

The key Impact Forces shaping this market are rooted in macroeconomic infrastructure spending cycles and the societal prioritization of environmental quality. The political environment directly dictates the pace of new highway and rail construction, which are the primary consumers of acoustic fencings. Furthermore, shifts in material science, particularly advancements in recycled plastics and bio-based composites, exert pressure on traditional material suppliers (concrete and metal). Legislative shifts, such as stricter limits on permissible noise exposure (e.g., limits mandated by OSHA for industrial settings or by the WHO for community noise), act as powerful, non-negotiable forces compelling adoption across industrial and transportation sectors. The high cost of land acquisition for infrastructure expansion also indirectly favors acoustic fencings, as reducing the noise footprint allows developers to minimize the regulatory buffer zones around noise sources.

Market sustainability is increasingly viewed as a crucial opportunity, forcing manufacturers to innovate. Barriers incorporating living walls (green infrastructure) or integrated renewable energy generation systems are gaining market acceptance, addressing both aesthetic concerns and environmental stewardship. The increasing demand for prefabricated and modular acoustic fencing solutions minimizes installation time and disruption, which is a significant factor for urban projects. The market is thus shifting from merely providing noise mitigation to delivering integrated, sustainable infrastructure solutions, leveraging government incentives that favor eco-friendly construction materials and methods, particularly in Europe and North America.

Segmentation Analysis

The Acoustic Fencings Market is comprehensively segmented based on material type, application, end-user, and design structure, providing a detailed view of demand distribution and technological preferences across various sectors. Material segmentation distinguishes between heavy, durable options like concrete and lighter, visually appealing options such as polycarbonate and wood derivatives, reflecting trade-offs between cost, longevity, and acoustic performance (absorption vs. reflection). Application segmentation highlights the dominance of linear infrastructure projects, while end-user segmentation clearly separates large-scale governmental purchasers (transportation authorities) from private sector entities (industrial and commercial developers). This granular approach helps manufacturers align R&D efforts with specific sector needs, such as high-performance industrial sound enclosures versus aesthetically minimal residential barriers.

The segmentation by design structure is also crucial, differentiating between absorptive barriers, which are preferred in densely packed urban environments to prevent noise reflection back toward the source or adjacent barriers, and reflective barriers, which are generally used in open areas where noise can be safely diverted away from sensitive receptors. Furthermore, specialized segmentation exists for noise protection height requirements, differentiating standard roadside barriers from specialized construction hoarding and low-height residential screens. The complexity in segmentation arises from the highly customized nature of acoustic solutions; a single material (e.g., aluminum) can be deployed in both reflective and absorptive forms based on its surface treatment and internal void structure.

Understanding these segments reveals distinct market growth trajectories. While the concrete segment remains stable due to its cost-effectiveness and durability, the polymers and composites segment is experiencing accelerated growth driven by innovation in material science that offers superior sound absorption properties and reduced installation labor costs. The push for aesthetically pleasing solutions, particularly in sensitive residential areas, ensures sustained demand for timber and transparent barriers, often necessitating hybrid designs that combine the strength of concrete bases with the visual lightness of transparent tops.

- By Material Type:

- Concrete/Masonry (Precast Concrete Panels, Concrete Block Walls)

- Metal (Aluminum, Steel)

- Wood/Timber (Treated Pine, Cedar, Engineered Wood Composites)

- Plastics and Composites (Recycled Plastic, Polymer Blends, Fiber Reinforced Plastics)

- Transparent Materials (Polycarbonate, Acrylic)

- Hybrid Materials (Combining concrete bases with absorptive composite panels)

- By Application:

- Transportation Noise Abatement (Highway/Roadside Barriers, Railway Noise Walls, Airport Perimeter Fencing)

- Industrial Noise Control (Manufacturing Plants, Power Generation Facilities, HVAC and Compressor Enclosures, Oil & Gas Sites)

- Commercial Noise Mitigation (Retail Centers, Data Centers, Parking Garages)

- Residential and Municipal Noise Protection (Residential Perimeter Fences, School Yards, Public Parks)

- By End-User:

- Government and Infrastructure Authorities (DOTs, Railway Companies)

- Industrial Sector

- Construction Sector

- Residential and Commercial Developers

- By Design Structure:

- Absorptive Barriers (Panels designed to absorb sound energy)

- Reflective Barriers (Solid panels designed to reflect sound energy)

- Hybrid Barriers

Value Chain Analysis For Acoustic Fencings Market

The value chain for the Acoustic Fencings Market begins with the Upstream Analysis, dominated by raw material extraction and basic manufacturing processes. This includes suppliers of bulk commodities such as cement and aggregates for concrete, wood pulp and lumber for timber barriers, and primary metal processing companies for steel and aluminum components. A critical upstream element involves specialized chemical and plastic resin manufacturers who supply materials for high-performance composites and transparent barriers (e.g., acrylics and polycarbonates). Cost fluctuations and geopolitical stability concerning these raw materials directly impact the profitability and pricing strategies adopted further down the chain, necessitating robust supplier management and long-term contracts for large infrastructure projects.

Midstream activities involve core manufacturing, fabrication, and system integration. Manufacturers specialize in transforming raw materials into standardized or custom acoustic panels and structural supports, focusing heavily on achieving specific acoustic performance metrics (NRC/STC). This stage includes high-precision machining, panel assembly, surface treatments, and quality control testing. Distribution channels are varied: Direct distribution occurs primarily for large-scale governmental infrastructure projects where manufacturers bid directly and supply materials to major construction contractors. Indirect distribution involves working through specialized dealers, distributors, and engineering procurement and construction (EPC) firms, particularly for smaller commercial, municipal, or residential projects requiring localized installation expertise and quick turnaround.

Downstream analysis focuses on installation, maintenance, and post-sales support. The installation phase, often carried out by specialized civil engineering and construction firms, is highly critical as improper installation (leaving gaps or poor foundational work) severely compromises the acoustic performance of the barrier. End-users of the product are diverse, ranging from federal transportation agencies to private industrial operators. Maintenance includes structural integrity checks, cleaning, and replacement of panels damaged by weather or vehicular accidents. The overall value chain emphasizes collaborative planning between acoustic consultants, material suppliers, and installation contractors to ensure the final product meets the stringent regulatory performance standards mandated for noise abatement.

Acoustic Fencings Market Potential Customers

Potential customers for acoustic fencings are primarily large entities characterized by high exposure to, or responsibility for, significant noise generation, spanning governmental bodies and the private industrial sector. The largest buyers are often state and federal departments of transportation (DOTs) and specialized rail infrastructure operators who require thousands of miles of noise mitigation walls alongside new and expanded transportation corridors. These customers prioritize longevity, structural stability, and compliance with federal noise guidelines, often utilizing precast concrete or heavy metal barriers due to their proven durability and low long-term maintenance needs in harsh environments.

The second major cohort of buyers includes industrial companies that operate continuous, high-decibel equipment, such as manufacturing facilities, power generation plants, refineries, and data center operators. For these end-users, the purchase of acoustic fencings, often in the form of acoustic enclosures or high-absorption barriers, is mandatory to comply with Occupational Safety and Health Administration (OSHA) standards for worker safety and to prevent noise trespass into adjacent community areas. Their purchasing decisions are driven by acoustic performance specifications (requiring high NRC ratings) and often favor modular, easy-to-install solutions that can be rapidly deployed around existing infrastructure without extensive downtime.

A growing segment of potential customers includes large residential and commercial property developers. As urban density increases, developers constructing high-end residential complexes or mixed-use commercial properties near arterial roads or light rail lines purchase acoustic fencing not just for compliance but as a value-added amenity to market quieter living spaces. These buyers often prioritize aesthetic factors, demanding transparent, timber, or architecturally treated acoustic panels that blend seamlessly with the building design and landscaping, justifying a higher price point for visually appealing noise abatement solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Baron Barriers, Sound Absorbing Materials (SAM), Noise Barriers Inc., Durisol Inc., Kinetics Noise Control, Inc., Paracoustics, Walls & Fences (W&F), Gramm Barrier Systems Limited, Akripol Group, SVA Verticale, Evonik Industries AG, ZND Temporary Fencing, AIL Sound Walls, Armtec Inc., The Reinforced Earth Company (RECo), IKG Industries, Fanwall Systems, Premier Acoustics, Polibar Inc., Highway Noise Abatement Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acoustic Fencings Market Key Technology Landscape

The technology landscape for acoustic fencings is continuously evolving, moving beyond simple mass and density to incorporate advanced material science and structural engineering principles. One major technological shift involves the use of high-performance polymer composites and recycled plastics, offering superior sound absorption characteristics compared to traditional reflective materials like concrete. These advanced materials are lightweight, reducing structural load requirements and simplifying installation, while providing better resistance to weather, corrosion, and UV degradation. Additionally, manufacturers are heavily investing in patented internal geometric structures and resonant chambers within panels designed to specifically capture and dissipate low-frequency noise, which is notoriously difficult to mitigate using conventional solid barriers.

Another crucial technological advancement is the integration of multi-functionality into the acoustic barrier design. This includes incorporating transparent acoustic barriers made from specialized acrylics or polycarbonates that maintain acoustic integrity while providing visual sightlines, a critical feature for bridges and scenic routes. Furthermore, there is significant R&D into integrated solar noise barriers (SNBs), which combine photovoltaic technology with sound-absorbing materials, generating clean energy while simultaneously mitigating noise pollution. These green technologies are highly favored in European markets where regulatory frameworks encourage sustainable infrastructure, pushing the market toward technologically sophisticated, dual-purpose products that maximize return on investment.

Digital technology is increasingly vital in the design and deployment phase. Advanced computational fluid dynamics (CFD) and sophisticated acoustic propagation modeling software are now standard tools, allowing engineers to precisely predict noise reduction effectiveness based on localized topographical features and anticipated traffic flow. This simulation technology minimizes the risk of underperforming installations and allows for fine-tuning barrier specifications (e.g., optimizing cut-outs, staggered arrangements, and panel orientation) to address specific noise hot spots. The future technological landscape points toward smart barriers, incorporating IoT sensors for real-time monitoring of acoustic performance and structural health, facilitating data-driven maintenance and performance validation.

Regional Highlights

- North America (United States, Canada, Mexico): Dominates the market value due to extensive highway networks and robust regulatory requirements enforced by federal and state transportation agencies. The focus is on large infrastructure replacement projects and innovative solutions for urban centers, with a growing adoption of specialized timber and composite barriers to meet visual and sustainability criteria. The market is mature, driven by maintenance, replacement cycles, and high infrastructure spending allocated specifically for environmental mitigation.

- Europe (Germany, UK, France, Scandinavia): Characterized by highly stringent environmental noise directives (END) mandating comprehensive noise mapping and abatement plans. Europe leads in the adoption of sustainable and multi-functional barriers, notably those incorporating recycled materials and integrated solar panels. The high density of railway infrastructure also makes the railway segment a primary driver, focusing on highly absorptive barriers to minimize reverberation in constrained urban corridors.

- Asia Pacific (China, India, Japan, South Korea): Fastest-growing region, fueled by unprecedented rates of urbanization and massive government investments in new high-speed rail lines and expansive road networks. While cost-effectiveness often favors concrete and basic metal barriers in developing economies like India and Indonesia, technologically advanced markets like Japan and South Korea demand high-performance, aesthetically integrated transparent and composite barriers, particularly near residential areas.

- Latin America (Brazil, Argentina, Chile): Growth is primarily linked to resource development, new port expansions, and urban transit projects. The market is price-sensitive, with a strong preference for domestically sourced, durable materials like precast concrete. Demand is sporadic, depending heavily on national infrastructure funding cycles and environmental policy implementation maturity.

- Middle East and Africa (Saudi Arabia, UAE, South Africa): Driven by large-scale strategic infrastructure projects, including new city developments (e.g., NEOM in Saudi Arabia) and rapid airport expansions. The focus is on high-durability, weather-resistant barriers to withstand extreme desert conditions. The industrial segment, particularly oil, gas, and petrochemical operations, represents a significant niche for specialized acoustic enclosures and sound-blocking structures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acoustic Fencings Market.- Baron Barriers International

- Durisol Inc.

- Kinetics Noise Control, Inc.

- Gramm Barrier Systems Limited

- AIL Sound Walls

- The Reinforced Earth Company (RECo)

- Armtec Inc.

- Akripol Group

- Evonik Industries AG (Plexiglass Supplier)

- Paracoustics

- Sound Absorbing Materials (SAM)

- Noise Barriers Inc.

- Concrete Panel Systems Ltd.

- ZND Temporary Fencing

- Premier Acoustics

- Fanwall Systems

- Polibar Inc.

- SVA Verticale

- Acoustic Barrier Technology Ltd.

- Highway Noise Abatement Group

Frequently Asked Questions

Analyze common user questions about the Acoustic Fencings market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Acoustic Fencings Market?

Market growth is primarily driven by stringent global government regulations on noise pollution, increased public awareness of health impacts from environmental noise, and substantial governmental investment in modernizing and expanding transportation infrastructure (highways, railways) globally, especially in rapidly urbanizing areas requiring mandatory noise mitigation.

How do absorptive barriers differ technologically from reflective acoustic barriers?

Reflective barriers, typically solid concrete or metal, function by bouncing sound energy away from the protected area, often used in open fields. Absorptive barriers incorporate porous or fibrous internal materials (like mineral wool or specialized polymers) that capture and dissipate sound energy, preventing reflection. Absorptive barriers are preferred in complex, dense urban areas where reflections could exacerbate noise in adjacent corridors or back onto the noise source.

Which material segment holds the largest share, and which is projected to grow the fastest?

The precast concrete and masonry segment currently holds the largest market share due to its low cost, inherent durability, and proven longevity in large-scale infrastructure projects. However, the composites and recycled plastics segment is projected to exhibit the fastest growth, driven by their lightweight characteristics, superior acoustic absorption performance, and alignment with modern sustainability mandates and green building codes.

What role does Artificial Intelligence (AI) play in the future of acoustic fencing design?

AI is increasingly used in the design phase for predictive acoustic modeling and optimization. AI algorithms process complex topographical and traffic data to determine the most effective barrier height, length, and placement configuration, minimizing material use and maximizing noise reduction efficiency, leading to faster planning cycles and reduced installation costs for complex projects.

What challenges restrain the widespread adoption of acoustic fencings in developing regions?

Major restraints in developing regions include the high initial capital expenditure required for specialized noise abatement infrastructure, particularly the cost of sophisticated absorptive materials. Other challenges include a lack of stringent, consistently enforced noise pollution regulations and significant aesthetic resistance or resistance related to large-scale infrastructure footprint requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager