Acrylic Mirror Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439213 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Acrylic Mirror Market Size

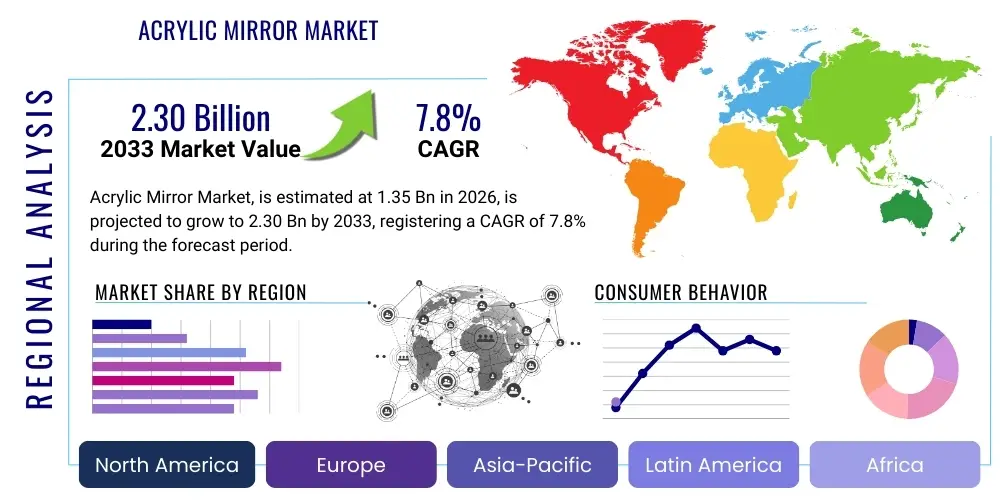

The Acrylic Mirror Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.35 Billion in 2026 and is projected to reach USD 2.30 Billion by the end of the forecast period in 2033.

Acrylic Mirror Market introduction

The Acrylic Mirror Market encompasses the production, distribution, and sale of acrylic sheets with a reflective coating, designed to mimic traditional glass mirrors while offering superior properties in specific applications. These mirrors, made primarily from polymethyl methacrylate (PMMA), are recognized for their exceptional lightweight nature, high impact resistance, and versatility, making them a preferred alternative in environments where safety, durability, and ease of fabrication are paramount. The market includes various forms, from large architectural panels to small decorative elements, catering to a broad spectrum of industrial and consumer needs. Its robust growth trajectory is driven by continuous innovation in manufacturing processes and an expanding application base across diverse sectors.

Acrylic mirrors distinguish themselves from conventional glass mirrors through their inherent characteristics. Unlike glass, which can shatter into dangerous shards upon impact, acrylic mirrors are highly shatter-resistant, significantly enhancing safety, particularly in public spaces, children's areas, and transportation. They are also considerably lighter, typically weighing half as much as glass mirrors of equivalent size and thickness, which simplifies installation, reduces structural load, and lowers transportation costs. Major applications span interior design, retail displays, automotive components, safety mirrors, and recreational vehicle interiors, benefiting from their design flexibility and ease of customization. The material can be cut, drilled, and thermoformed into complex shapes, offering designers unparalleled creative freedom.

Key benefits of acrylic mirrors include their superior clarity, excellent optical properties, and resistance to fogging and condensation in certain treated variants. Their ability to be manufactured in larger sheets than traditional glass also allows for seamless installations in expansive areas. Driving factors for market expansion are multi-faceted: increasing adoption in the construction and architecture sectors for lightweight and safe interior finishes, burgeoning demand from the automotive industry for rear-view and cosmetic mirrors due to weight reduction initiatives, and the sustained growth of the retail and advertising sectors requiring durable and visually appealing display solutions. Furthermore, advancements in coating technologies are improving scratch resistance and UV stability, further broadening their appeal and performance capabilities.

Acrylic Mirror Market Executive Summary

The Acrylic Mirror Market is experiencing robust expansion driven by evolving business trends focused on safety, sustainability, and aesthetic versatility. Businesses are increasingly investing in advanced manufacturing techniques to produce higher quality, more durable, and optically superior acrylic mirror products. There is a notable trend towards customization and specialized solutions, with manufacturers offering tailored sizes, shapes, and finishes to meet unique client specifications across architectural, automotive, and retail sectors. Additionally, the integration of smart technologies, such as embedded lighting and interactive displays within acrylic mirrors, is creating new market niches and enhancing product value. The emphasis on lightweight materials to improve energy efficiency in transportation and construction also fuels demand for acrylic mirrors, positioning them as a critical material in modern design and engineering.

Regional trends significantly influence market dynamics, with North America and Europe demonstrating mature markets characterized by stringent safety regulations and a strong emphasis on aesthetic design, driving demand for premium and specialized acrylic mirror solutions. The Asia Pacific region, conversely, is emerging as a high-growth hub, propelled by rapid urbanization, substantial investments in infrastructure development, and a booming manufacturing sector, particularly in China and India. These regions are witnessing a surge in construction activities, automotive production, and retail expansion, all of which are primary consumers of acrylic mirrors. Latin America and the Middle East & Africa also present promising growth opportunities, albeit at an earlier stage, driven by growing disposable incomes and increasing adoption of modern interior design trends, gradually replacing traditional glass alternatives.

Segmentation trends reveal strong performance across several key categories. By type, extruded acrylic mirrors hold a larger market share due to their cost-effectiveness and ease of production, while cast acrylic mirrors command a premium for their superior optical clarity and strength, catering to high-end applications. In terms of application, the architectural and interior design segment remains dominant, driven by its use in residential, commercial, and hospitality projects for decorative panels, wall cladding, and space enhancement. The automotive segment is experiencing accelerated growth as manufacturers seek lightweight solutions for interior and exterior mirror components to meet fuel efficiency standards. The retail and display segment continues to be a steady consumer, utilizing acrylic mirrors for shelving, signage, and product showcases to enhance visual appeal and product visibility, reflecting the diverse and expanding utility of these innovative materials.

AI Impact Analysis on Acrylic Mirror Market

Users frequently inquire about how Artificial Intelligence will influence the manufacturing processes, product development, and market dynamics of acrylic mirrors. Key themes revolve around the potential for AI-driven automation in production lines, improving efficiency and reducing waste. There's also significant interest in AI's role in quality control, predictive maintenance of machinery, and optimizing supply chain logistics for raw materials and finished products. Concerns often touch upon the initial investment costs for AI integration and the reskilling of the workforce. Expectations are high for AI to enable more complex design possibilities, facilitate rapid prototyping, and personalize mirror solutions based on consumer data, ultimately leading to enhanced product innovation, more efficient operations, and potentially opening new market applications for smart, interactive acrylic mirror surfaces.

- AI-powered predictive maintenance for manufacturing equipment reduces downtime and extends machinery lifespan, ensuring consistent production of acrylic mirror sheets.

- Automated quality inspection systems using AI vision identify defects in acrylic mirror surfaces with higher accuracy and speed than manual methods, improving product quality.

- AI algorithms optimize raw material sourcing and inventory management, minimizing waste and ensuring a steady supply chain for PMMA resins and reflective coatings.

- Generative design AI assists in creating complex and innovative acrylic mirror shapes and patterns, enabling faster prototyping and customization for architectural and decorative applications.

- AI-driven robotics enhance precision in cutting, shaping, and polishing acrylic mirror panels, leading to greater consistency and reduced labor costs.

- Personalized marketing and sales strategies leverage AI to analyze consumer preferences, offering tailored acrylic mirror solutions and identifying emerging market demands.

- Integration of AI into smart acrylic mirrors enables interactive features, such as gesture control, personalized displays, and real-time information, particularly in retail, automotive, and hospitality sectors.

- AI-enhanced supply chain management optimizes logistics, tracking shipments, forecasting demand, and mitigating potential disruptions in the global distribution of acrylic mirror products.

- Data analytics powered by AI provides deep insights into market trends, competitive landscapes, and consumer behavior, informing strategic business decisions for acrylic mirror manufacturers.

- AI-driven simulation tools allow for virtual testing of acrylic mirror performance under various conditions, accelerating research and development cycles for new product formulations and applications.

DRO & Impact Forces Of Acrylic Mirror Market

The Acrylic Mirror Market is significantly shaped by a combination of driving forces, inherent restraints, and burgeoning opportunities that collectively determine its growth trajectory and competitive landscape. Drivers such as the inherent lightweight nature and superior shatter resistance of acrylic mirrors make them indispensable in safety-critical applications, while their aesthetic versatility and ease of fabrication bolster demand in interior design and retail displays. Restraints, including lower scratch resistance compared to glass and a susceptibility to certain chemicals, necessitate ongoing material science advancements to mitigate these drawbacks. Opportunities lie in the development of enhanced coatings, integration into smart technologies, and expansion into emerging markets, promising sustained innovation and market penetration. These impact forces necessitate strategic responses from manufacturers, focusing on product improvement, market diversification, and cost optimization to maintain competitiveness and capitalize on growth prospects.

Specific drivers include the escalating demand for safety-oriented materials in public spaces, educational institutions, and healthcare facilities where the risk of glass breakage is a concern. The construction industry's shift towards lightweight and energy-efficient building materials further propels the adoption of acrylic mirrors, reducing structural loads and installation complexities. Additionally, the automotive sector's continuous drive for vehicle weight reduction to improve fuel efficiency and reduce emissions makes acrylic mirrors an attractive alternative to glass for interior and exterior applications. The burgeoning e-commerce and retail sectors also contribute significantly, as acrylic mirrors are widely used for attractive and durable display solutions, enhancing product visibility and store aesthetics without the safety risks associated with traditional mirrors. The material's flexibility in terms of design, allowing for intricate shapes and vibrant colors, also appeals to architects and designers seeking innovative decorative elements.

However, the market faces several restraints. Acrylic mirrors are generally more prone to scratching than glass, which can limit their use in high-contact or abrasive environments, despite advancements in hard coatings. Their chemical resistance is also lower than glass, making them vulnerable to damage from certain cleaning agents or industrial chemicals. Furthermore, while often more cost-effective than specialty glass, the initial unit cost of high-quality acrylic mirrors can be higher than standard glass mirrors, posing a challenge in budget-sensitive projects. Opportunities abound in overcoming these restraints through technological innovation. Developing advanced scratch-resistant and anti-glare coatings, exploring bio-based or recycled acrylic formulations for sustainability, and integrating acrylic mirrors with embedded electronics for smart home and automotive applications represent significant avenues for future growth. Expanding into niche markets like marine applications, aerospace interiors, and specialized medical equipment also offers untapped potential, further diversifying the market landscape.

Segmentation Analysis

The Acrylic Mirror Market is extensively segmented to reflect its diverse product offerings, varied applications, and broad end-user base, providing a granular view of market dynamics and growth opportunities. These segmentations allow for a deeper understanding of specific market niches, consumer preferences, and technological advancements driving demand in different sectors. The primary categories for segmentation typically include the type of acrylic mirror (e.g., extruded, cast), thickness variations to suit structural and aesthetic needs, a wide array of applications ranging from decorative to functional, and the distinct end-use industries that integrate these mirrors into their products or infrastructure. This detailed breakdown aids businesses in tailoring their strategies, optimizing product development, and targeting specific customer groups more effectively, ensuring comprehensive market coverage and competitive positioning.

- By Type:

- Extruded Acrylic Mirrors: Characterized by their uniform thickness and cost-effectiveness, widely used for general-purpose applications where optical clarity requirements are moderate. Produced by melting and extruding acrylic resin through a die, offering good impact resistance and ease of fabrication.

- Cast Acrylic Mirrors: Known for superior optical clarity, greater surface hardness, and enhanced chemical resistance. Manufactured by pouring liquid acrylic monomer into molds, making them suitable for high-end applications, intricate designs, and environments demanding premium aesthetics and performance.

- By Thickness:

- Less than 3mm: Primarily used for lightweight decorative purposes, crafts, small displays, and applications where minimal weight and flexibility are crucial. Easy to cut and handle.

- 3mm - 6mm: The most common range, offering a balance of strength, rigidity, and weight for a wide array of applications including wall mirrors, retail displays, signage, and furniture inserts.

- More than 6mm: Utilized in applications requiring enhanced structural integrity, greater impact resistance, or larger panel sizes, such as architectural installations, security mirrors, and specialized industrial uses.

- By Application:

- Architectural & Interior Design: Extensive use in residential and commercial spaces for wall panels, ceiling features, decorative accents, furniture components, and creating illusions of space.

- Automotive: Interior mirrors (rear-view, vanity), exterior aesthetic components, and specialized mirrors for recreational vehicles and marine applications due to lightweight and safety benefits.

- Retail & Display: Used in retail stores for product displays, signage, shelving, security mirrors, and enhancing visual merchandising due to their aesthetic appeal and durability.

- Medical & Healthcare: Non-shattering mirrors for patient rooms, dental mirrors, specialized examination mirrors, and equipment components where safety and hygiene are paramount.

- Marine: Mirrors for boats and yachts, resistant to corrosion and providing safety in humid environments.

- Others: Includes applications in arts & crafts, educational institutions, surveillance & security, gymnasium mirrors, and various industrial equipment.

- By End-Use Industry:

- Construction & Architecture: Residential and commercial building interiors, facade elements, decorative cladding, and public space installations.

- Automotive & Transportation: Car interiors, bus and train components, RVs, and specialized vehicles.

- Retail & Consumer Goods: Store fixtures, product packaging, point-of-sale displays, and consumer electronics.

- Healthcare: Hospitals, clinics, dental offices, and medical device manufacturing.

- Furniture & Decor: Cabinetry, tables, wall art, and various home and office furnishings.

- Sports & Recreation: Gyms, dance studios, recreational vehicle interiors, and amusement parks.

Value Chain Analysis For Acrylic Mirror Market

The value chain for the Acrylic Mirror Market is a comprehensive network beginning with the sourcing of raw materials and extending through various stages of manufacturing, processing, and distribution to the final end-user. It involves a sophisticated interplay of upstream suppliers, primary manufacturers, downstream processors, and diverse distribution channels, each adding value at distinct points. Understanding this chain is crucial for identifying cost efficiencies, optimizing logistics, ensuring quality control, and navigating competitive pressures across the industry. The efficiency of this value chain directly impacts product cost, availability, and the ability of manufacturers to respond to market demands and maintain a competitive edge.

Upstream analysis focuses on the procurement of fundamental raw materials, primarily polymethyl methacrylate (PMMA) resins, which are derived from petroleum. Key suppliers in this segment are major chemical companies producing MMA monomer and PMMA polymers. These suppliers provide the foundational material that dictates the optical quality, durability, and cost-effectiveness of the final acrylic mirror product. Other upstream inputs include reflective coatings (e.g., aluminum, silver), protective backings, and various additives that enhance properties like UV resistance, scratch resistance, or anti-fog capabilities. Relationships with these suppliers are critical for ensuring a stable supply, consistent quality, and competitive pricing, as fluctuations in raw material costs directly impact the profitability of acrylic mirror manufacturers.

Downstream analysis involves the various stages from manufacturing to the final end-user. This includes primary manufacturers who convert raw PMMA into acrylic sheets and then apply the reflective coating and protective backing to create the mirror product. Further down the chain, fabricators and processors cut, shape, drill, polish, and thermoform these sheets into specific designs, sizes, and applications tailored for industries such as construction, automotive, retail, and furniture. Distribution channels are varied, encompassing direct sales from manufacturers to large-scale industrial buyers, through specialized plastic distributors, building material suppliers, hardware stores, and online retailers. Both direct sales and indirect channels play crucial roles. Direct channels enable customization and large volume orders for industrial clients, while indirect channels provide wider market reach, catering to smaller businesses and individual consumers, effectively bridging the gap between producers and the diverse spectrum of end-users for acrylic mirror products.

Acrylic Mirror Market Potential Customers

The Acrylic Mirror Market caters to a remarkably diverse array of potential customers and end-users, reflecting the versatility and broad applicability of the product. These customers span various industries, from large-scale commercial enterprises to individual consumers, each seeking the unique benefits that acrylic mirrors offer over traditional glass. Identifying and understanding these distinct customer segments is paramount for manufacturers and distributors to effectively tailor their product offerings, marketing strategies, and distribution networks. The appeal of acrylic mirrors lies in their combination of safety, lightweight properties, design flexibility, and durability, which addresses specific needs across numerous applications where conventional mirrors fall short or present challenges.

In the commercial sector, key potential customers include architectural firms and interior designers who specify acrylic mirrors for commercial buildings, retail spaces, hospitality venues, and public facilities. Their preference stems from the material's aesthetic versatility, ability to create illusions of space, and crucially, its shatter-resistant properties for high-traffic environments. Similarly, the automotive industry represents a significant customer base, with car manufacturers and aftermarket suppliers integrating acrylic mirrors into vehicle interiors and specialty vehicle designs due to their lightweight contribution to fuel efficiency and enhanced safety. Retail businesses, from large department stores to small boutiques, also form a substantial customer segment, utilizing acrylic mirrors for dynamic product displays, security surveillance, and creating inviting shopping environments.

Beyond these major industrial and commercial users, the market extends to manufacturers of furniture and home decor items, who incorporate acrylic mirrors into cabinets, wall art, and decorative panels. The medical and healthcare sectors are also growing customers, requiring non-shattering mirrors for patient rooms, dental instruments, and rehabilitation facilities where safety is a critical concern. Furthermore, educational institutions, gyms, dance studios, and recreational facilities opt for large acrylic mirror panels for safety and durability. On the consumer side, DIY enthusiasts, crafters, and homeowners represent a vibrant market, purchasing acrylic mirrors for custom projects, children's rooms, bathrooms, and outdoor decor, driven by ease of handling and installation, along with the inherent safety benefits. This wide-ranging customer base underscores the significant and expanding market potential for acrylic mirror products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.35 Billion |

| Market Forecast in 2033 | USD 2.30 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Plaskolite, Evonik Industries AG, Mitsubishi Chemical Corporation, Sumitomo Chemical Co. Ltd., Arkema S.A., Lucite International (part of Mitsubishi Chemical), Roehm GmbH, Madreperla S.p.A., Acrilex Inc., Spartech LLC, Safco Products, Alro Plastics, Piedmont Plastics, Laird Plastics, Regal Plastic Supply, Fabri-Tech, Custom Plastic Fabrication Inc., Gemini Sign Products, Sheffield Plastics, Polycast Technology Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acrylic Mirror Market Key Technology Landscape

The Acrylic Mirror Market is continuously evolving through advancements in material science, manufacturing processes, and coating technologies, all contributing to enhanced product performance and expanded application possibilities. The core technology revolves around the production of high-quality polymethyl methacrylate (PMMA) sheets, followed by a precise metallization process to create the reflective surface. Innovations are focused on improving key properties such as scratch resistance, optical clarity, durability, and environmental sustainability, ensuring that acrylic mirrors remain a competitive and preferred alternative to traditional glass in various demanding environments. These technological developments are pivotal in addressing historical limitations and unlocking new market potential, driven by both consumer demand and industrial requirements for advanced materials.

A significant aspect of the technology landscape lies in the refinement of PMMA formulations. Manufacturers are investing in research and development to create advanced acrylic resins that offer superior impact strength, improved UV resistance for outdoor applications, and enhanced thermal stability. This includes developing specialized grades of PMMA that can be extruded or cast with fewer internal stresses, leading to better optical uniformity and reduced distortion. Furthermore, breakthroughs in co-extrusion technologies allow for multi-layered acrylic sheets, where different properties can be combined, such as a soft impact-absorbing layer bonded with a hard, scratch-resistant surface, optimizing the balance between durability and flexibility, thereby expanding their use in high-performance applications like automotive interiors and safety-critical enclosures.

Another critical area of technological innovation is in the reflective coating and protective backing processes. Traditional vacuum metallization (PVD) using aluminum or silver is being optimized for better adhesion and uniform reflectivity. Emerging technologies include sputtering and chemical vapor deposition (CVD) for applying more durable and environmentally friendly reflective layers. Moreover, the development of advanced hard coatings, often incorporating ceramic nanoparticles or specialized polymers, significantly improves the scratch and abrasion resistance of acrylic mirrors, making them suitable for more demanding environments without compromising optical clarity. Anti-glare and anti-fog coatings are also becoming more prevalent, enhancing functionality in applications like bathroom mirrors or outdoor signage. Finally, the integration of conductive layers and embedded sensors is paving the way for smart acrylic mirrors with interactive displays and IoT capabilities, representing a substantial leap forward in product sophistication and market value.

Regional Highlights

- North America: A mature market characterized by high adoption rates in architectural, interior design, and retail sectors. Stringent safety regulations and a strong emphasis on aesthetic appeal drive demand for premium, customized acrylic mirror solutions. The region benefits from robust construction activities and a significant automotive manufacturing base, which continually integrates lightweight materials for efficiency and safety. Key countries include the United States and Canada, known for technological innovation and high consumer spending.

- Europe: Exhibits steady growth fueled by a strong focus on sustainable and energy-efficient building materials, contributing to increased use of lightweight acrylic mirrors in construction and renovation projects. The automotive industry, particularly in Germany and France, is a significant consumer due to ongoing efforts for vehicle weight reduction. Decorative applications in retail and hospitality also drive demand, with countries like the UK and Italy leading in design-centric uses. Environmental regulations also push for sustainable production methods.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, massive infrastructure development, and a booming manufacturing sector across countries like China, India, Japan, and South Korea. Increased disposable incomes and evolving lifestyles are boosting demand in residential and commercial interior design. The expanding automotive industry and rapid growth in the retail and electronics sectors further fuel market expansion, making it a pivotal region for future growth. Lower production costs and a large consumer base contribute significantly to market volume.

- Latin America: An emerging market demonstrating promising growth, primarily driven by increasing construction activities, growing automotive production, and expanding retail infrastructure in countries like Brazil, Mexico, and Argentina. Economic development and rising middle-class populations are fostering demand for modern interior design and consumer goods, leading to greater adoption of acrylic mirrors as a cost-effective and safe alternative to traditional glass.

- Middle East and Africa (MEA): Shows gradual but consistent growth, mainly influenced by large-scale infrastructure projects, burgeoning tourism, and luxury real estate developments in the UAE, Saudi Arabia, and Qatar. The demand for aesthetically pleasing and safe interior finishes in hotels, shopping malls, and residential complexes is a key driver. Increased foreign investment and a focus on diversification away from oil economies are also stimulating growth in various end-use sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acrylic Mirror Market.- Plaskolite

- Evonik Industries AG

- Mitsubishi Chemical Corporation

- Sumitomo Chemical Co. Ltd.

- Arkema S.A.

- Lucite International (part of Mitsubishi Chemical)

- Roehm GmbH

- Madreperla S.p.A.

- Acrilex Inc.

- Spartech LLC

- Safco Products

- Alro Plastics

- Piedmont Plastics

- Laird Plastics

- Regal Plastic Supply

- Fabri-Tech

- Custom Plastic Fabrication Inc.

- Gemini Sign Products

- Sheffield Plastics Inc.

- Polycast Technology Corporation

Frequently Asked Questions

Analyze common user questions about the Acrylic Mirror market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of acrylic mirrors over traditional glass mirrors?

Acrylic mirrors offer several distinct advantages, primarily their superior shatter resistance, making them a much safer option in environments where breakage is a concern, such as schools, public spaces, or children's rooms. They are also significantly lighter than glass, typically weighing about half as much, which eases installation, reduces shipping costs, and lowers structural load. Furthermore, acrylic mirrors are highly versatile in terms of fabrication, allowing for easy cutting, drilling, and thermoforming into various shapes and designs that would be difficult or impossible with glass, offering greater design flexibility for architects and interior designers.

Where are acrylic mirrors most commonly used?

Acrylic mirrors find widespread applications across diverse sectors. They are extensively used in architectural and interior design for decorative wall panels, ceiling features, furniture components, and creating illusions of space in both residential and commercial settings. The retail and display industry utilizes them for product showcases, signage, and security mirrors due to their aesthetic appeal and durability. In the automotive sector, they are increasingly adopted for interior mirrors and custom vehicle components due to their lightweight properties and safety. Other notable applications include medical facilities, gymnasiums, marine vessels, and various arts and crafts projects where safety and ease of handling are paramount.

Are acrylic mirrors susceptible to scratching, and how can their durability be enhanced?

Yes, standard acrylic mirrors are generally more prone to scratching compared to glass mirrors. This can be a concern in high-contact environments or applications requiring frequent cleaning. However, advancements in manufacturing technology have significantly addressed this limitation. Many manufacturers now offer acrylic mirrors with specialized hard coatings or scratch-resistant surfaces. These coatings, often applied during the production process, drastically improve the mirror's resistance to abrasion and impact, making them much more durable and suitable for a wider range of demanding applications. Proper cleaning techniques using soft cloths and non-abrasive cleaners also help maintain their pristine condition.

What is the typical lifespan of an acrylic mirror, and does it yellow over time?

The typical lifespan of an acrylic mirror can vary significantly depending on its quality, exposure to environmental factors, and whether it has protective coatings. High-quality acrylic mirrors, especially those with UV-resistant coatings, can maintain their clarity and reflective properties for many years, often exceeding a decade, particularly in indoor applications. While some older or lower-grade acrylics might exhibit slight yellowing over prolonged exposure to harsh UV radiation, modern acrylic mirrors are formulated with UV stabilizers that largely prevent this issue. Manufacturers continuously innovate to enhance the material's longevity and resistance to environmental degradation, ensuring long-term aesthetic appeal and functionality.

How do acrylic mirrors contribute to sustainability efforts?

Acrylic mirrors contribute to sustainability in several ways. Their lightweight nature reduces fuel consumption during transportation, lowering the carbon footprint associated with logistics. In construction and automotive applications, their lightweight properties can lead to reduced energy consumption for heating/cooling or improved fuel efficiency, respectively. Moreover, acrylic (PMMA) is a thermoplastic, meaning it is theoretically recyclable. While recycling infrastructure for acrylic is still evolving in some regions, efforts are underway to establish more robust collection and reprocessing systems. The increasing focus on circular economy principles is driving research into bio-based acrylics and enhanced recycling technologies, positioning acrylic mirrors as a more environmentally conscious material choice in the long term.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager