Acrylic Yarn Line Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435704 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Acrylic Yarn Line Market Size

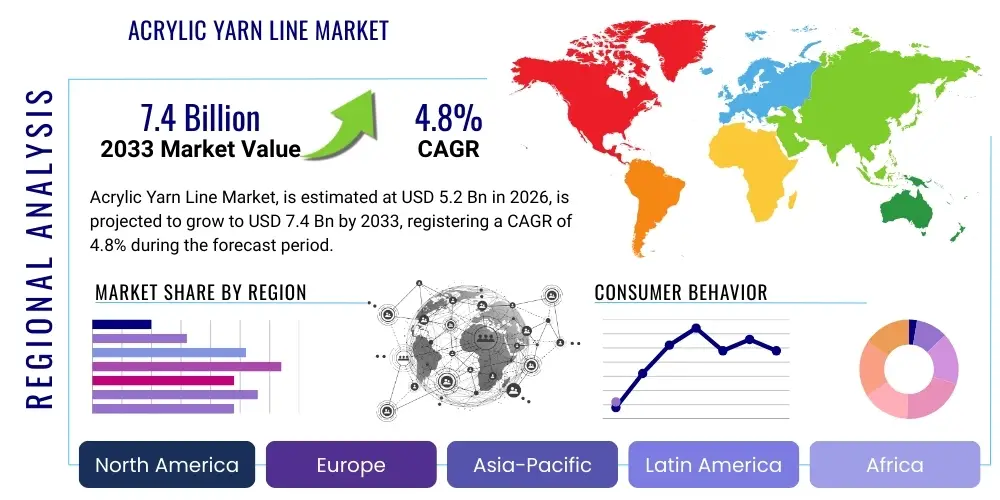

The Acrylic Yarn Line Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $5.2 Billion in 2026 and is projected to reach $7.4 Billion by the end of the forecast period in 2033.

Acrylic Yarn Line Market introduction

The Acrylic Yarn Line Market encompasses the manufacturing, processing, and distribution of yarn derived from synthetic acrylic polymers, primarily polyacrylonitrile. This versatile fiber line is characterized by its wool-like handle, excellent resilience, vibrant color retention, and relatively low cost compared to natural fibers. Acrylic yarn is produced through polymerization of acrylonitrile monomers, followed by spinning processes such as wet spinning or dry spinning, which determine the final fiber characteristics, including bulkiness and softness. The resulting yarns are widely adopted across various industries due to their durability and resistance to shrinking and fading.

Major applications of acrylic yarn span the apparel, home furnishings, and industrial sectors. In apparel, it is fundamental for knitwear, sweaters, and fleece fabrics, offering lightweight warmth and easy care properties. The home furnishings segment utilizes acrylic yarn extensively in upholstery, carpets, blankets, and specialized outdoor fabrics requiring UV resistance. Its versatility allows for blending with natural fibers like wool or cotton, enhancing the performance characteristics of the final textile product while optimizing production costs, making it a staple in cost-effective textile manufacturing strategies globally.

The primary driving factors propelling this market include the growing demand for affordable and easy-to-maintain textile products, particularly in fast-fashion and mass-market segments of developing economies. Furthermore, technological advancements in fiber modification and texturizing techniques have mitigated some traditional drawbacks of acrylic, such as pilling and moisture absorption, thereby expanding its utility into higher-performance applications. The yarn’s superior dye affinity, resulting in deeply saturated and long-lasting colors, also contributes significantly to its market attractiveness across diverse consumer product categories.

Acrylic Yarn Line Market Executive Summary

The Acrylic Yarn Line Market is poised for stable expansion, driven fundamentally by robust demand from emerging economies and continuous innovation in fiber modification aimed at enhanced sustainability and performance. Business trends are heavily focused on establishing vertically integrated supply chains, particularly within the Asia Pacific region, which serves as the global manufacturing hub for both acrylic fiber production and downstream textile conversion. Companies are investing in advanced anti-pilling and recycled acrylic variants to address mounting consumer and regulatory pressure regarding synthetic fiber environmental impact.

Regionally, Asia Pacific maintains undisputed dominance, not only in production capacity but also in consumption, fueled by large domestic textile industries in countries like China, India, and Vietnam. North America and Europe, while having limited manufacturing bases, remain crucial high-value markets demanding specialized, high-bulk, and functional acrylic blends for niche applications such as outdoor textiles and performance apparel. These mature markets are driving the adoption of circular economy models for acrylic recycling and reuse.

Segment trends indicate a strong shift towards high-bulk and specialty acrylic yarns, offering enhanced thermal retention and superior hand feel, thus narrowing the gap with high-cost natural fibers. The application segment sees accelerated growth in the home furnishings category, particularly in residential and commercial carpeting, where acrylic’s durability and cost profile provide a competitive edge. Furthermore, the craft and hobby segment, amplified by increased digital engagement and DIY culture, represents a significant and steadily expanding consumer base for direct-to-consumer acrylic yarn lines.

AI Impact Analysis on Acrylic Yarn Line Market

User queries regarding AI's influence in the Acrylic Yarn Line Market often center on how these technologies can stabilize raw material prices, optimize complex textile production schedules, and mitigate the environmental footprint associated with synthetic fibers. Key themes emerging from these questions include the role of predictive analytics in managing volatile petrochemical feedstock costs (acrylonitrile), the application of machine learning for defect detection during spinning and dyeing processes, and expectations regarding AI's ability to drive faster, more accurate trend forecasting to minimize inventory waste. Consumers are also inquiring about AI-driven personalization in the retail craft segment, expecting tools that suggest patterns and blends based on their purchase history and project goals. Manufacturers are primarily concerned with operational efficiency gains and supply chain resilience.

Artificial intelligence is profoundly affecting the acrylic yarn value chain, starting from upstream monomer sourcing to downstream market distribution. In polymerization, AI algorithms analyze reaction parameters in real-time, leading to optimized reaction conditions that improve yield, consistency, and specific fiber properties such as intrinsic viscosity and molecular weight distribution. This level of precision is critical for maintaining high quality standards required for technical applications. Furthermore, machine vision systems powered by AI are deployed on spinning lines to detect minute variations in filament thickness, fiber breaks, and yarn regularity at speeds unattainable by human inspectors, thereby reducing waste and improving overall equipment effectiveness (OEE).

The most significant long-term impact of AI lies in its ability to enable sustainable production and foster circularity. By employing sophisticated predictive models, manufacturers can more accurately forecast short-term market demand, reducing overproduction—a common challenge in the textile industry. Moreover, AI is crucial in material science for developing enhanced fiber blends and recycling processes. For example, machine learning models can accelerate the research and development of chemical recycling methodologies suitable for acrylic polymers, identifying optimal solvent compositions and thermal conditions required for efficient depolymerization, paving the way for high-quality recycled acrylic yarn lines.

- AI-powered Demand Forecasting: Optimizes inventory levels and minimizes textile waste by predicting market shifts with higher accuracy.

- Quality Control Automation: Machine vision systems utilizing deep learning identify spinning defects and dyeing inconsistencies in real-time, significantly improving yarn quality.

- Supply Chain Optimization: Predictive analytics model feedstock price volatility (acrylonitrile) and logistics routes, enhancing cost efficiency and resilience.

- R&D Acceleration: AI simulates molecular structures and processing parameters to fast-track the development of specialized acrylic variants (e.g., bio-based acrylics or superior anti-pilling fibers).

- Personalized Consumer Experience: Machine learning suggests customized yarn types, colors, and project kits for the burgeoning DIY and craft segment.

DRO & Impact Forces Of Acrylic Yarn Line Market

The market dynamics of acrylic yarn are characterized by a strong interplay between economic drivers centered on cost and versatility, strict environmental restraints related to microplastic shedding and end-of-life disposal, and significant opportunities arising from technical textile applications and advancements in recycling technology. The primary impact force influencing the market structure is the intense competition from alternative synthetic fibers (polyester, nylon) and the increasing consumer preference for natural or sustainable materials, requiring continuous product innovation to maintain market share.

Key drivers include the pervasive cost-effectiveness of acrylic yarn compared to wool and other natural fibers, making it indispensable for mass-market and high-volume textile production globally. Its superior performance attributes, such as excellent resistance to moths, chemicals, and UV degradation, further solidify its utility in outdoor and industrial textiles. Furthermore, the rising disposable income and rapid urbanization across Asian and Latin American countries are fueling demand for affordable home textiles and fast-fashion apparel, ensuring sustained baseline growth for the conventional acrylic yarn market. This economic accessibility ensures its central role in the global textile supply chain.

However, the market faces significant restraints, chiefly concerning its non-biodegradable nature and the increasing global regulatory focus on plastic pollution. The perception of acrylic as a less sustainable choice compared to natural or recycled alternatives pressures manufacturers to invest heavily in certifications and advanced recycling infrastructure, which requires substantial capital expenditure. Additionally, the fluctuating price of petrochemical precursors, particularly acrylonitrile, introduces volatility in production costs, complicating long-term profitability forecasts for manufacturers lacking long-term supply agreements or hedging strategies. These restraints necessitate strategic pivots towards circular manufacturing models.

Opportunities for market growth are abundant within specialized and technical applications, where acrylic’s unique properties offer advantages. The development of high-performance flame-retardant (FR) acrylics, inherently antimicrobial yarns, and specialized low-pill fibers opens doors to lucrative markets such as protective clothing, medical textiles, and aviation interiors. Moreover, the increasing viability of closed-loop recycling processes for textile waste provides a critical pathway for generating ‘green’ acrylics, directly addressing environmental restraints and tapping into the rapidly expanding segment of environmentally conscious consumers and corporate buyers committed to sustainable sourcing policies. The market's stability is largely dependent on the success of these technological shifts.

- Drivers:

- Cost advantage and processing efficiency compared to natural fibers.

- Excellent color fastness, bulkiness, and resilience for apparel and home furnishings.

- High resistance to UV light, moisture, and biological degradation.

- Rising demand for affordable textile products in developing economies.

- Restraints:

- Environmental concerns regarding non-biodegradability and microplastic release during washing.

- Volatile raw material prices (acrylonitrile) tied to the petrochemical industry.

- Increasing regulatory scrutiny and consumer preference for natural or sustainable fibers.

- Opportunities:

- Technological breakthroughs in chemical recycling and sustainable fiber modification.

- Expansion into high-value technical textiles (e.g., filtration media, protective gear).

- Growth of the DIY and craft market driving demand for branded, specialty yarn lines.

- Development of bio-based or partially bio-based acrylic variants.

- Impact Forces:

- Intensity of rivalry among existing synthetic fiber producers.

- Threat of substitution from high-quality recycled polyester and natural fiber blends.

- Bargaining power of large-scale textile converters demanding lower prices and customized specifications.

Segmentation Analysis

The Acrylic Yarn Line Market is comprehensively segmented based on yarn type, application, and distribution channel, reflecting the varied industrial and consumer requirements that this versatile fiber addresses. Understanding these segments is crucial for market participants to tailor their production capabilities and marketing strategies effectively. Segmentation by type differentiates between standard acrylics, high-bulk acrylics, and specialty blends, each serving distinct price points and performance expectations, influencing the value chain structure from monomer procurement to final spinning processes.

The segmentation by application highlights the primary end-use sectors driving demand. Apparel remains a foundational segment, particularly for winter wear and knitted garments, leveraging acrylic’s warmth and light weight. However, the Home Furnishings segment is demonstrating accelerated growth due to its application in high-traffic commercial textiles and outdoor resilience products. The performance characteristics required for industrial applications, such as filtration or insulation, necessitate specific polymer formulations and spinning techniques, driving innovation within the Specialty Fibers segment.

Detailed analysis reveals that the High-Bulk segment is gaining prominence as manufacturers strive to offer products that closely mimic the luxurious feel of wool while maintaining cost efficiencies. Geographically, manufacturing segmentation is heavily concentrated in APAC due to labor and infrastructure advantages, whereas consumption patterns in North America and Europe emphasize premium, branded, and sustainable acrylic yarns, necessitating complex logistics and certification compliance. Strategic market positioning requires firms to leverage regional competitive advantages, focusing on either high-volume efficiency or niche, high-margin specialization.

- By Type:

- Regular/Low Bulk Acrylic Yarn

- High Bulk Acrylic Yarn

- Super High Bulk Acrylic Yarn

- Modacrylic Yarn (Flame Retardant)

- Acrylic/Wool Blends

- Acrylic/Cotton Blends

- By Application:

- Apparel (Sweaters, Socks, Knitwear, Fleece)

- Home Furnishings (Carpets, Blankets, Upholstery, Drapes)

- Industrial & Technical Textiles (Filters, Awnings, Insulation)

- Crafts and Hobby (Knitting, Crocheting)

- By Distribution Channel:

- Direct Sales (Business-to-Business)

- Wholesale and Retail Distribution

- E-commerce Platforms (Direct-to-Consumer)

- Specialty Craft Stores

Value Chain Analysis For Acrylic Yarn Line Market

The acrylic yarn line value chain begins with the upstream procurement and processing of petrochemical feedstock, primarily propylene, which is converted into acrylonitrile (AN) monomer. This stage is capital-intensive and subject to global oil and gas price volatility, forming the foundation of the production cost structure. Major chemical companies dominate this initial phase, supplying AN to fiber manufacturers. The subsequent step involves polymerization, where AN is converted into acrylic polymers, often done by integrated companies that manage both monomer production and fiber spinning, maximizing operational efficiencies and controlling quality specifications early in the process.

Midstream activities involve the crucial processes of fiber spinning (wet or dry), washing, stretching, crimping, and cutting, transforming polymer chips into staple fibers or continuous filaments suitable for yarn production. Yarn spinning techniques—including ring, rotor, or DREF spinning—dictate the final yarn characteristics such as strength, regularity, and hairiness. Manufacturers often specialize in specific yarn types, such as high-bulk or specialty blends, requiring proprietary technology and precise process control. Effective inventory management and utilization of energy-efficient machinery are critical for profitability in this competitive segment.

The downstream segment includes dyeing, finishing, and distribution to textile mills, knitters, weavers, and consumer retailers. Distribution channels are bifurcated into direct sales (Business-to-Business, supplying large textile converters) and indirect sales (through wholesalers, agents, and increasingly, specialized e-commerce platforms targeting the craft and hobby consumer segment). Direct channels prioritize bulk efficiency and consistent supply contracts, while indirect channels require robust packaging, branding, and localized market presence. The efficiency of logistics, especially cross-border transportation from Asian manufacturing hubs to consumption centers, significantly influences final pricing and delivery lead times.

Acrylic Yarn Line Market Potential Customers

The potential customer base for the acrylic yarn market is highly diversified, encompassing three primary categories: industrial textile manufacturers, large-scale apparel brands and private labels, and the growing segment of individual consumers/hobbyists. Industrial textile manufacturers, particularly those in the home furnishings and automotive sectors, represent the largest volume buyers. They require large quantities of consistent, high-denier yarn for applications like commercial carpeting, automotive interiors, and durable upholstery, prioritizing cost stability, technical specifications (e.g., abrasion resistance), and reliability of supply chain logistics.

Apparel manufacturers, ranging from mass-market fast-fashion retailers to mid-tier specialty knitwear companies, constitute a second critical customer group. These buyers value the yarn’s softness, color retention, and ease of care, using it predominantly in seasonal garments like sweaters, hats, and scarves. Their purchasing decisions are often heavily influenced by current fashion trends and the ability of suppliers to rapidly deliver customized color palettes and specific hand-feel characteristics. They are increasingly demanding transparency regarding the sourcing and environmental credentials of the acrylic fiber.

The third customer segment, the individual consumers, typically purchases through retail and e-commerce channels for knitting, crocheting, and other DIY crafts. This segment, although lower in volume per transaction, demands a wide variety of colors, textures, and specialized yarn weights (e.g., chunky, fingering). Manufacturers targeting this market must invest heavily in branding, appealing packaging, and digital content creation (patterns, tutorials) to foster community engagement and brand loyalty. The rise of social media platforms has amplified the importance of this direct-to-consumer segment, driving demand for premium, proprietary acrylic blends.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $5.2 Billion |

| Market Forecast in 2033 | $7.4 Billion |

| Growth Rate | CAGR 4.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Reliance Industries Limited, Formosa Plastics Corporation, Dralon GmbH, Mitsubishi Chemical Corporation, Aksa Akrilik Kimya Sanayi A.S., Jilin Chemical Fiber Group Co. Ltd., Thai Acrylic Fibre Co. Ltd. (Aditya Birla Group), Sateri, Sinopec, Toray Industries Inc., Kaneka Corporation, Eastman Chemical Company, Courtaulds Textiles, China Petrochemical Corporation (Sinopec), Taekwang Industrial Co. Ltd., Pasupati Acrylon Ltd., Shanghai Petrochemical Company Limited, Zhejiang Hengyi Group Co., Exlan Japan Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acrylic Yarn Line Market Key Technology Landscape

The core technology landscape for acrylic yarn production revolves around advanced polymerization and sophisticated spinning techniques aimed at enhancing fiber properties and reducing environmental impact. Modern plants utilize continuous mass polymerization processes, which offer greater control over molecular weight distribution, resulting in yarns with improved uniformity and strength. However, the true competitive edge lies in the spinning process. Both wet spinning (used for high-quality, high-denier fibers) and dry spinning (favored for finer, low-denier fibers) are being optimized through computational fluid dynamics (CFD) modeling to improve solvent recovery efficiency and ensure consistent dope rheology, crucial for maintaining fiber integrity and reducing operational costs associated with solvent use.

A significant technological focus is placed on achieving superior bulk and anti-pilling characteristics. The high-bulk acrylic yarn production often involves differential shrinkage techniques, where fibers with varying degrees of inherent crimp are blended. Upon subsequent hot water or steam treatment, the high-shrinkage component contracts, causing the low-shrinkage component to buckle and create a voluminous, wool-like texture. Concurrent innovation in finishing chemistry involves applying advanced polymer coatings and surface modifications that physically inhibit fiber entanglement and pilling during wear and washing, directly addressing key consumer complaints about synthetic fibers and expanding market acceptance in high-end apparel.

Furthermore, sustainability-driven technologies are becoming paramount. This includes the development of modacrylics (modified acrylics) which incorporate halogen or phosphorus-containing monomers to impart inherent flame resistance, crucial for safety-critical applications in transport and interior furnishings. Crucially, research and pilot projects are accelerating the commercialization of chemical recycling technologies specific to acrylic polymers, aiming to depolymerize acrylic textile waste back into acrylonitrile monomers. This closed-loop approach, combined with the successful integration of renewable energy sources in manufacturing, defines the next generation of competitive advantage and fulfills stringent AEO criteria related to circularity and reduced carbon footprint.

Regional Highlights

The global Acrylic Yarn Line Market exhibits distinct regional dynamics driven by localized manufacturing capabilities, varying levels of industrial development, and differing consumer preferences for textiles.

- Asia Pacific (APAC): Dominates the global market, accounting for the vast majority of both production volume and consumption. China, India, and Southeast Asian nations are central due to low labor costs, strong government support for textile manufacturing, and integrated supply chains from petrochemical production to final garment assembly. This region is the primary source for bulk, low-cost acrylic yarns supplied globally.

- North America: Characterized by high-value consumption and low domestic production. Demand is concentrated in specialized sectors such as outdoor performance wear (due to acrylic’s UV resistance) and high-end craft markets. Consumers exhibit strong preferences for eco-labeled and sustainably sourced yarns, driving imports of specialized and recycled acrylic lines.

- Europe: A mature market focused on innovation, premiumization, and sustainability mandates (such as REACH regulations). While manufacturing capacity has declined, the region remains a vital hub for R&D, focusing on sophisticated fiber blends, high-quality home textiles, and the fastest adoption rate of circular economy principles for textile recycling.

- Latin America: Demonstrates stable growth, fueled by domestic textile industries in Brazil and Mexico that cater to local apparel and automotive markets. The region offers opportunities for expansion as rising middle-class disposable income drives demand for affordable, fashionable knitwear.

- Middle East and Africa (MEA): A nascent but growing market, primarily served by imports. Demand is expanding slowly in North African countries with developing textile bases, focusing on basic apparel and low-cost furnishing fabrics. Investment in local polymer production remains a key long-term potential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acrylic Yarn Line Market.- Reliance Industries Limited

- Formosa Plastics Corporation

- Dralon GmbH

- Mitsubishi Chemical Corporation

- Aksa Akrilik Kimya Sanayi A.S.

- Jilin Chemical Fiber Group Co. Ltd.

- Thai Acrylic Fibre Co. Ltd. (Aditya Birla Group)

- Sinopec

- Toray Industries Inc.

- Kaneka Corporation

- Eastman Chemical Company

- Courtaulds Textiles

- China Petrochemical Corporation (Sinopec)

- Taekwang Industrial Co. Ltd.

- Pasupati Acrylon Ltd.

- Shanghai Petrochemical Company Limited

- Zhejiang Hengyi Group Co.

- Exlan Japan Ltd.

- Fujian Jinjiang Textile Group Co. Ltd.

- Sateri

Frequently Asked Questions

Analyze common user questions about the Acrylic Yarn Line market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Acrylic Yarn Market?

The primary factor driving market growth is the superior cost-effectiveness of acrylic yarn compared to natural fibers like wool, coupled with its excellent performance characteristics such as color fastness, durability, and resistance to UV light, making it a critical material for high-volume, affordable apparel and home textiles globally.

How are environmental concerns impacting the future technological development of acrylic yarn?

Environmental concerns necessitate substantial R&D investment into sustainable alternatives, focusing on developing viable chemical recycling processes for acrylic textiles, increasing the use of recycled acrylonitrile feedstock, and commercializing anti-shedding treatments to mitigate microplastic release, shifting the industry toward circular manufacturing models.

Which region dominates the global production and supply of acrylic yarn?

Asia Pacific (APAC), particularly driven by China and India, dominates the global production and supply of acrylic yarn due to established, integrated petrochemical and textile supply chains, economies of scale, and efficient labor practices, serving as the leading global manufacturing hub for this fiber.

What is the difference between regular acrylic yarn and high-bulk acrylic yarn?

Regular acrylic yarn offers standard bulk and texture, while high-bulk acrylic yarn undergoes specialized thermal processing involving differential shrinkage techniques to maximize fiber contraction, resulting in a much loftier, softer, and wool-like hand feel, which is preferred for premium knitwear and thermal products.

What role does Artificial Intelligence play in optimizing acrylic yarn production?

AI optimizes acrylic yarn production by using predictive analytics for raw material cost management (acrylonitrile), implementing machine vision systems for real-time quality control and defect detection during spinning, and enhancing demand forecasting to minimize inventory and textile waste throughout the supply chain.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager