Agricultural Pneumatic Integrated Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439544 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Agricultural Pneumatic Integrated Equipment Market Size

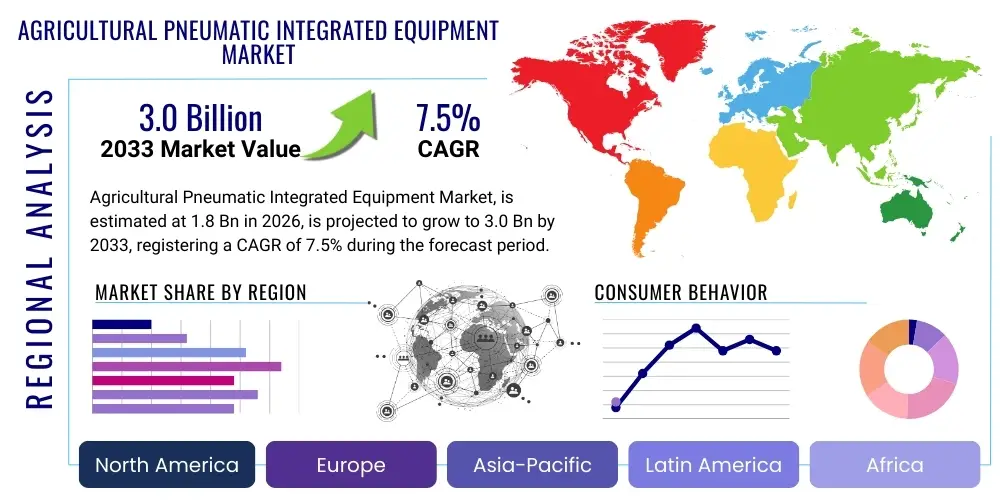

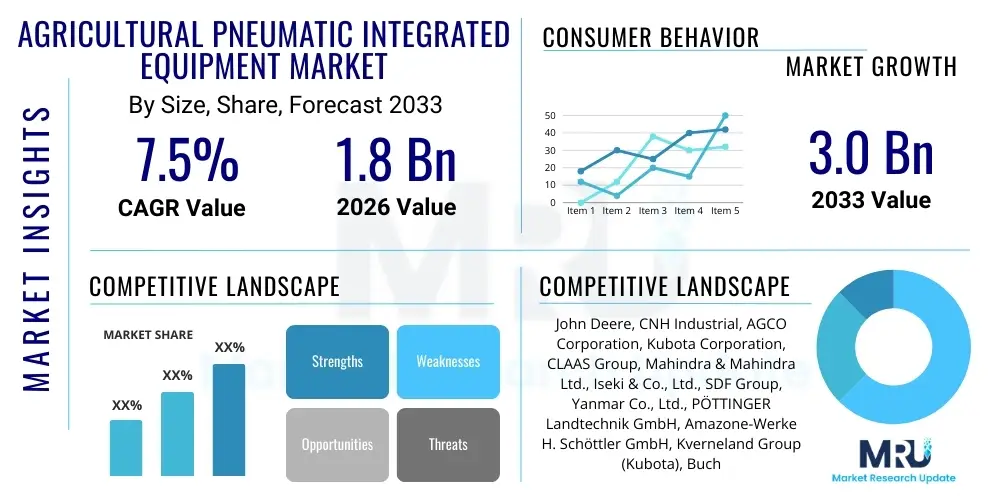

The Agricultural Pneumatic Integrated Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 1.8 Billion in 2026 and is projected to reach USD 3.0 Billion by the end of the forecast period in 2033.

Agricultural Pneumatic Integrated Equipment Market introduction

The Agricultural Pneumatic Integrated Equipment Market encompasses a sophisticated array of machinery and systems that leverage compressed air technology to enhance efficiency, precision, and automation in various farming operations. This market primarily revolves around equipment designed to optimize tasks such as planting, sowing, fertilizing, spraying, harvesting, and material handling, by employing pneumatic principles for actuation, control, and power transmission. The integration aspect signifies the synergistic combination of pneumatic components with advanced electronics, sensors, and control systems, leading to smarter, more responsive agricultural machinery capable of executing complex functions with high accuracy.

Key products within this sector include pneumatic planters, seed drills, sprayers, harvesters with pneumatic separation systems, and various attachments that utilize air pressure for precise material delivery or component manipulation. Major applications span across row crop farming, horticulture, viticulture, and even specialized livestock operations where automated feeding or sorting systems might be employed. The core benefits derived from these integrated solutions include significant reductions in labor costs, optimized input utilization (seeds, fertilizers, pesticides), enhanced operational speed, and ultimately, improved crop yields and quality. The driving factors for this market's growth are multifaceted, primarily fueled by the global demand for increased food production, the pervasive issue of labor scarcity in agricultural sectors worldwide, the escalating adoption of precision agriculture practices, and continuous technological advancements aimed at making farming more sustainable and productive.

Agricultural Pneumatic Integrated Equipment Market Executive Summary

The Agricultural Pneumatic Integrated Equipment Market is undergoing transformative growth, characterized by significant business trends that prioritize automation, data integration, and sustainability. Key business trends include the increasing investment in research and development to create more intelligent and autonomous farming solutions, a shift towards equipment-as-a-service models, and strategic collaborations between traditional machinery manufacturers and technology firms specializing in IoT and AI. Companies are focusing on developing modular and customizable pneumatic systems that can adapt to diverse farm sizes and crop types, enhancing their market reach and utility. Furthermore, there is a strong emphasis on improving energy efficiency and reducing the environmental footprint of agricultural operations, aligning with global sustainability goals.

Regionally, the market exhibits varied dynamics. North America and Europe continue to lead in adoption due to robust precision agriculture frameworks, substantial farm subsidies, and high labor costs driving automation. However, the Asia Pacific region, particularly countries like China and India, is emerging as a significant growth engine, propelled by government initiatives promoting farm mechanization, increasing agricultural output demands, and a growing awareness among farmers about the benefits of modern equipment. Latin America also presents considerable opportunities, driven by the expansion of large-scale commercial farming operations. Segment-wise, the market is seeing increased penetration of pneumatic systems in planting and spraying applications, where precision is paramount. The demand for automatic and robotic pneumatic solutions is rapidly accelerating, reflecting the broader trend towards fully autonomous farm management. The component segment, particularly advanced sensors and control systems integrated with pneumatic actuators, is experiencing robust growth as farmers seek more sophisticated and data-driven operational capabilities.

AI Impact Analysis on Agricultural Pneumatic Integrated Equipment Market

The integration of Artificial Intelligence (AI) is profoundly reshaping the Agricultural Pneumatic Integrated Equipment Market, addressing common user questions about enhancing operational intelligence, predictive capabilities, and overall farm efficiency. Users frequently inquire about how AI can improve the precision of pneumatic systems, reduce input waste, automate complex decision-making, and offer proactive maintenance insights. There is a strong interest in AI's role in optimizing seeding patterns, precise fertilizer and pesticide application, and smart irrigation, directly leveraging pneumatic components for accurate delivery. Farmers are seeking solutions that use AI to analyze real-time data from fields to adjust pneumatic equipment parameters autonomously, ensuring optimal performance under varying environmental conditions and crop needs. The expectation is that AI will make pneumatic equipment not just automated, but truly intelligent, capable of learning and adapting to maximize yield and minimize resource consumption.

- AI enhances precision agriculture by enabling real-time adjustments to pneumatic equipment, optimizing seed placement, fertilizer dosage, and pesticide application based on sensor data and predictive analytics.

- Predictive maintenance powered by AI algorithms monitors the operational health of pneumatic components, forecasting potential failures and scheduling proactive servicing, thereby reducing downtime and extending equipment lifespan.

- AI-driven automation facilitates complex tasks such as selective harvesting or intelligent sorting through pneumatic manipulators, reducing manual labor dependency and improving efficiency.

- Data analytics capabilities of AI process vast amounts of agricultural data (soil conditions, weather patterns, crop health) to inform pneumatic equipment settings for optimized resource utilization and yield maximization.

- Autonomous navigation and control systems, guided by AI, allow pneumatic machinery to operate independently in the field, improving operational efficiency and reducing human error.

- AI assists in dynamic task planning and route optimization for pneumatic equipment, minimizing fuel consumption and operational time across large agricultural lands.

- Intelligent fault detection and diagnostics within pneumatic systems are improved by AI, enabling quicker troubleshooting and resolution of operational issues, enhancing reliability.

- AI integration supports hyper-localization of agricultural practices, allowing pneumatic equipment to tailor operations down to individual plant needs, leading to more sustainable farming.

DRO & Impact Forces Of Agricultural Pneumatic Integrated Equipment Market

The Agricultural Pneumatic Integrated Equipment Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by various impact forces. The primary drivers fueling market expansion include the escalating global demand for food, which necessitates increased agricultural productivity and efficiency. Concurrently, the pervasive issue of labor scarcity in farming regions worldwide pushes for greater automation and mechanization, making pneumatic integrated solutions highly attractive. The growing adoption of precision agriculture practices, aimed at optimizing resource use and maximizing yields, directly benefits from the accuracy and control offered by pneumatic systems. Furthermore, supportive government policies and subsidies in many countries encourage the modernization of agricultural infrastructure, promoting the uptake of advanced machinery. Technological advancements, particularly in sensor technology, IoT, and AI integration, continually enhance the capabilities and appeal of pneumatic equipment, transforming traditional farming methods.

However, several restraints impede the market's full potential. The high initial investment cost associated with advanced pneumatic integrated equipment can be a significant barrier for small and medium-sized farms, especially in developing economies. The complexity of these systems often requires specialized technical knowledge for operation and maintenance, and a shortage of skilled labor to manage and repair such sophisticated machinery can deter adoption. Additionally, the fragmentation of landholdings in many parts of the world makes it challenging to implement large-scale, automated pneumatic solutions efficiently. Resistance to adopting new technologies among traditional farming communities and concerns regarding data privacy and cybersecurity in integrated smart farming systems also pose hurdles. These factors collectively require manufacturers and policymakers to develop accessible, user-friendly, and cost-effective solutions to overcome these adoption barriers.

Opportunities for growth are abundant within this evolving landscape. Emerging economies in Asia Pacific, Latin America, and Africa present vast untapped markets where agricultural mechanization is still in nascent stages, offering significant potential for market penetration. The continuous integration of pneumatic systems with cutting-edge technologies like the Internet of Things (IoT), Artificial intelligence (AI), and robotics opens new avenues for innovation, leading to more intelligent and autonomous farming solutions. Expansion into niche applications, such as specialized horticulture, vertical farming, and controlled environment agriculture, offers diversification opportunities. Moreover, the development of rental and leasing models for expensive equipment can lower the entry barrier for smaller farmers, expanding the customer base. The increasing focus on sustainable agriculture, coupled with the precision capabilities of pneumatic equipment, creates opportunities for solutions that reduce environmental impact and improve resource efficiency. Key impact forces shaping this market include rapid technological advancements, evolving environmental regulations pushing for sustainable practices, global food security concerns, fluctuating economic conditions influencing farmer purchasing power, and dynamic labor market dynamics.

Segmentation Analysis

The Agricultural Pneumatic Integrated Equipment Market is segmented across various critical dimensions to provide a comprehensive understanding of its structure, growth drivers, and evolving dynamics. These segments allow for a granular analysis of market demand, technological preferences, and regional adoption patterns, enabling stakeholders to identify specific opportunities and tailor strategies effectively. The primary segmentation criteria typically include components, applications, farm size, end-use, and the level of automation. Each segment reflects distinct operational needs, investment capacities, and technological integration levels within the diverse agricultural landscape, showcasing the market's intricate structure. Understanding these segmentations is crucial for manufacturers to innovate, for distributors to target, and for farmers to adopt solutions that best fit their operational scale and crop types, ultimately driving efficiency and productivity across the agricultural value chain.

- By Component

- Compressors

- Actuators (Cylinders, Rotary Actuators)

- Valves (Directional Control Valves, Pressure Control Valves, Flow Control Valves)

- Air Motors

- Filters, Regulators, and Lubricators (FRLs)

- Hoses and Fittings

- Sensors and Transducers

- Control Systems (PLCs, Microcontrollers)

- By Application

- Tillage and Soil Preparation

- Planting and Sowing (Pneumatic Planters, Seed Drills)

- Fertilizing and Nutrient Management

- Crop Protection (Pneumatic Sprayers)

- Harvesting (Pneumatic Separators, Conveyors)

- Material Handling and Logistics

- Irrigation Systems

- Post-Harvest Processing

- By Farm Size

- Small Farms (Less than 10 Hectares)

- Medium Farms (10-100 Hectares)

- Large Farms (More than 100 Hectares)

- By End-Use

- Crop Farming

- Livestock Farming (Automated Feeding, Sorting)

- Horticulture and Viticulture

- Specialty Crops

- By Operation

- Semi-Automatic Equipment

- Automatic Equipment

- Robotic and Autonomous Equipment

Value Chain Analysis For Agricultural Pneumatic Integrated Equipment Market

The value chain for the Agricultural Pneumatic Integrated Equipment Market is a complex network involving multiple stages, from raw material sourcing to end-user deployment and post-sale services. It begins with upstream activities, where critical components and materials are manufactured. This includes suppliers of various metals (steel, aluminum), plastics, rubber, and electronic components essential for pneumatic systems, such as sensors, microcontrollers, and wiring. Specialized manufacturers produce core pneumatic components like compressors, actuators (cylinders, rotary actuators), various types of valves (directional, pressure, flow control), air motors, and air preparation units (filters, regulators, lubricators). These upstream players form the foundational layer, providing the specialized parts that make integrated equipment functional and reliable. The quality and availability of these components directly impact the overall cost, performance, and innovation capacity of the finished agricultural machinery.

Moving downstream, the value chain encompasses the assembly, integration, distribution, and utilization of the complete agricultural pneumatic equipment. Midstream activities involve the design, engineering, and manufacturing of the integrated equipment, where agricultural machinery OEMs (Original Equipment Manufacturers) procure pneumatic components and combine them with mechanical structures, electronic control units, and software to create functional machines like pneumatic planters, sprayers, and harvesters. This stage often includes significant R&D efforts to innovate and integrate new technologies like IoT and AI. The distribution channel plays a crucial role in delivering these complex machines to the end-users. This involves a network of direct sales forces, authorized dealers, and independent distributors who handle sales, after-sales support, spare parts supply, and maintenance services. The effectiveness of this distribution network, including its reach and technical expertise, directly influences market penetration and customer satisfaction. The end-users, primarily farmers and agricultural enterprises, then utilize this equipment, and their feedback loops back through the chain to inform future product development and improvements, creating a continuous cycle of innovation and adaptation within the market.

Agricultural Pneumatic Integrated Equipment Market Potential Customers

The Agricultural Pneumatic Integrated Equipment Market serves a diverse range of end-users and buyers, each with unique needs and operational scales. Large commercial farms constitute a significant customer base, characterized by extensive landholdings and a strong emphasis on maximizing efficiency, yield, and profitability through advanced mechanization. These farms often invest in high-capacity, fully automated, and robotic pneumatic systems to manage vast areas and reduce dependency on manual labor. Their demand is driven by the need for precision, speed, and data integration across various farming operations, from planting to harvesting. Medium-sized farms, while perhaps not requiring the largest machinery, increasingly seek pneumatic solutions to optimize their operations, improve resource utilization, and enhance competitiveness. They are often early adopters of semi-automatic or automatic pneumatic equipment that offers a balance between cost-effectiveness and improved performance, particularly in precision tasks like seeding and spraying.

Small farms, particularly those aggregating through cooperatives or operating in specialized segments like horticulture or protected cultivation, represent a growing segment of potential customers. Although their individual investment capacity might be limited, the availability of smaller-scale, modular, or rental pneumatic equipment makes these technologies accessible. Agricultural cooperatives and contractors also form a crucial customer group, as they often purchase and operate advanced pneumatic equipment to provide services to multiple smaller farms, thereby democratizing access to modern agricultural technologies. Beyond traditional farming, research institutions and universities involved in agricultural science and technology are also key buyers, utilizing these integrated systems for experimental purposes, developing new farming techniques, and training the next generation of agricultural professionals. Furthermore, food processing companies with backward integration into farming or those establishing controlled environment agriculture operations may also invest in these advanced pneumatic systems to ensure consistent supply and quality control from cultivation to processing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.8 Billion |

| Market Forecast in 2033 | USD 3.0 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | John Deere, CNH Industrial, AGCO Corporation, Kubota Corporation, CLAAS Group, Mahindra & Mahindra Ltd., Iseki & Co., Ltd., SDF Group, Yanmar Co., Ltd., PÖTTINGER Landtechnik GmbH, Amazone-Werke H. Schöttler GmbH, Kverneland Group (Kubota), Bucher Industries AG, Buhler Industries Inc., Roskilde Landbrugsmaskiner (Kongskilde Industries A/S), Festo SE & Co. KG, SMC Corporation, Parker Hannifin Corporation, Bosch Rexroth AG, Norgren (IMI Precision Engineering). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Agricultural Pneumatic Integrated Equipment Market Key Technology Landscape

The Agricultural Pneumatic Integrated Equipment Market is continuously evolving, driven by a dynamic key technology landscape that seeks to enhance precision, efficiency, and sustainability in farming. At its core, the market leverages advanced pneumatic technologies, including high-performance compressors, precise actuators, and intelligent valve systems, which are crucial for the accurate movement, control, and application of agricultural inputs. Beyond foundational pneumatic components, the integration of cutting-edge sensor technology is paramount. This includes GPS for precise positioning, ultrasonic sensors for object detection, spectral sensors for crop health monitoring, and soil moisture sensors, all providing real-time data critical for informed decision-making and automated adjustments of pneumatic equipment. These sensors feed information into sophisticated control systems, often based on Programmable Logic Controllers (PLCs) or embedded microcontrollers, which interpret data and send precise commands to pneumatic components.

The broader technological ecosystem significantly impacting this market includes the Internet of Things (IoT), which enables seamless connectivity between pneumatic equipment, other farm machinery, and central management platforms. IoT allows for remote monitoring, diagnostics, and control, facilitating predictive maintenance and optimized operational scheduling. Artificial Intelligence (AI) and Machine Learning (ML) algorithms are increasingly being integrated to process the vast amounts of data collected by sensors and IoT devices. AI models can predict crop yields, identify disease outbreaks, optimize irrigation schedules, and most importantly, autonomously adjust pneumatic system parameters for tasks like variable rate seeding and targeted spraying, thus minimizing waste and maximizing efficiency. Robotics and autonomous vehicle technology are also critical, particularly for self-driving tractors and specialized robots equipped with pneumatic manipulators for tasks like automated harvesting, pruning, and sorting, significantly reducing labor dependency and increasing operational precision. Cloud computing platforms support the storage and analysis of agricultural data, while advanced material science contributes to the development of more durable, lightweight, and corrosion-resistant pneumatic components, enhancing the longevity and performance of agricultural equipment in harsh farming environments. These combined technological advancements are transforming agricultural pneumatic integrated equipment into smart, connected, and highly efficient farming solutions.

Regional Highlights

- North America: This region is a frontrunner in the adoption of agricultural pneumatic integrated equipment, driven by large-scale commercial farming, high labor costs, and significant investments in precision agriculture technologies. Countries like the United States and Canada exhibit high demand for advanced machinery that offers automation, data integration, and optimized resource utilization. Government initiatives and robust R&D infrastructure further support market growth.

- Europe: Characterized by a strong emphasis on sustainable farming practices, environmental regulations, and advanced agricultural research, Europe is a key market for pneumatic integrated equipment. Countries such as Germany, France, and the Netherlands lead in adopting sophisticated precision farming solutions, with a focus on reducing chemical inputs and improving efficiency. Subsidies for technological upgrades and a skilled agricultural workforce contribute to its prominent market position.

- Asia Pacific (APAC): This region is experiencing the fastest growth, primarily fueled by increasing population, rising food demand, and government efforts to modernize agriculture. Countries like China, India, and Australia are investing heavily in farm mechanization, driven by labor shortages and the need to enhance productivity. The gradual shift from traditional farming to advanced techniques presents immense opportunities for pneumatic integrated equipment manufacturers.

- Latin America: With vast agricultural lands and a growing commercial farming sector, Latin America represents a significant market. Countries such as Brazil and Argentina are witnessing increased adoption of pneumatic planters and sprayers to boost crop yields and operational efficiency. The expansion of export-oriented agriculture further propels demand for advanced integrated equipment in the region.

- Middle East and Africa (MEA): This region is an emerging market, driven by food security concerns, increasing mechanization efforts, and government investments in agricultural development. While adoption rates are currently lower compared to developed regions, there is substantial potential for growth as modern farming practices are introduced and implemented to overcome climatic challenges and improve agricultural output.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Agricultural Pneumatic Integrated Equipment Market.- John Deere

- CNH Industrial N.V.

- AGCO Corporation

- Kubota Corporation

- CLAAS Group

- Mahindra & Mahindra Ltd.

- Iseki & Co., Ltd.

- SDF Group

- Yanmar Co., Ltd.

- PÖTTINGER Landtechnik GmbH

- Amazone-Werke H. Schöttler GmbH

- Kverneland Group (Kubota)

- Bucher Industries AG

- Buhler Industries Inc.

- Roskilde Landbrugsmaskiner (Kongskilde Industries A/S)

- Festo SE & Co. KG

- SMC Corporation

- Parker Hannifin Corporation

- Bosch Rexroth AG

- Norgren (IMI Precision Engineering)

Frequently Asked Questions

What is agricultural pneumatic integrated equipment?

Agricultural pneumatic integrated equipment refers to farming machinery and systems that utilize compressed air technology for precise actuation, control, and power transmission in various agricultural operations. These systems combine pneumatic components with electronics and sensors to enhance efficiency, accuracy, and automation in tasks like planting, spraying, and harvesting.

What are the primary benefits of using pneumatic equipment in agriculture?

The primary benefits include enhanced precision in seed placement and chemical application, significant reduction in labor costs through automation, improved operational speed and efficiency, optimized utilization of agricultural inputs (seeds, fertilizers, pesticides), and ultimately, increased crop yields and improved product quality.

What challenges does the market for agricultural pneumatic integrated equipment face?

Key challenges include the high initial investment costs for advanced systems, a shortage of skilled labor required for operation and maintenance, the technical complexity of integrated pneumatic equipment, and the fragmentation of landholdings in many agricultural regions, which can hinder large-scale adoption.

How is AI impacting the agricultural pneumatic integrated equipment market?

AI is transforming the market by enabling predictive maintenance, optimizing equipment settings based on real-time data, enhancing precision in application tasks, automating complex decision-making, and facilitating the development of fully autonomous farming solutions, leading to greater efficiency and resource optimization.

Which regions are leading in the adoption of agricultural pneumatic integrated equipment?

North America and Europe are currently leading in adoption due to mature precision agriculture markets, high labor costs, and robust government support. However, the Asia Pacific region, particularly countries like China and India, is experiencing rapid growth due to increasing mechanization and modernization efforts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager