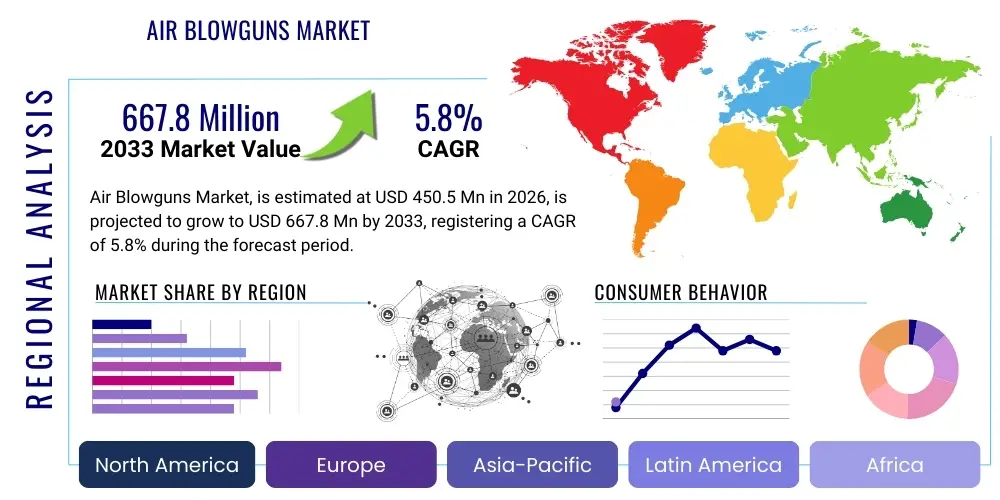

Air Blowguns Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438365 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Air Blowguns Market Size

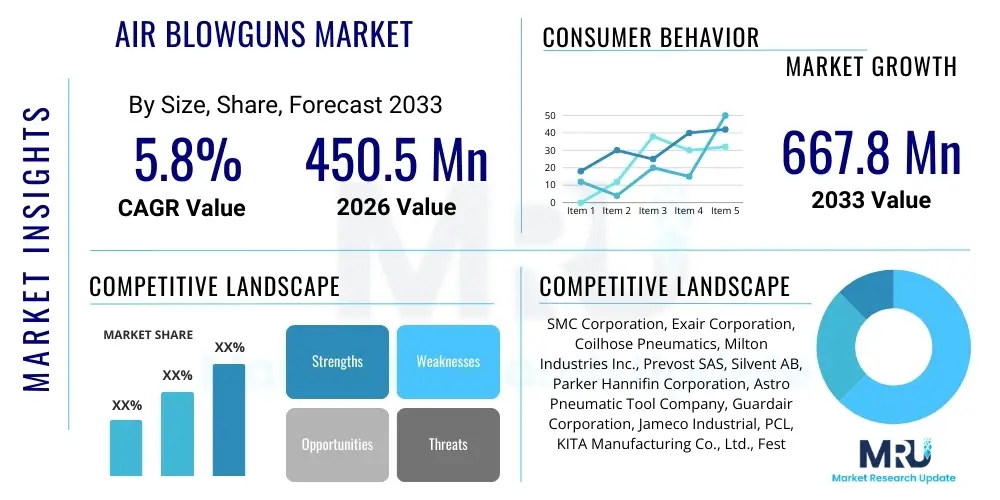

The Air Blowguns Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 667.8 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by rigorous industrial safety regulations mandating controlled air pressure devices in manufacturing environments and the continuous expansion of automated production lines globally, which require precise and efficient cleaning tools to maintain operational integrity and longevity of machinery. The focus on ergonomic designs and noise reduction technologies further contributes to market momentum across developed economies.

Air Blowguns Market introduction

The Air Blowguns Market comprises specialized pneumatic tools essential for diverse industrial and professional applications, primarily involving the targeted release of compressed air for cleaning, drying, cooling, and material ejection. These devices are crucial for maintaining clean work environments, clearing debris from machinery parts, and ensuring the quality control of finished goods across sectors like automotive, aerospace, electronics, and general manufacturing. Modern air blowguns are designed not only for performance but also increasingly prioritize operator safety and regulatory compliance, integrating features such as controlled output nozzles, pressure reducing systems, and ergonomic grips to minimize the risks associated with high-velocity air, such as noise exposure and potential tissue damage.

Product descriptions of contemporary air blowguns often emphasize durable construction using materials such as high-grade aluminum, zinc alloys, or robust composites, designed to withstand harsh industrial environments and frequent use. Key applications span across production line maintenance, where they quickly remove swarf and cooling lubricants; automotive garages for brake and engine cleaning; and woodworking shops for sawdust clearance. The versatility and efficiency of air blowguns, coupled with their relatively low operational cost compared to more complex cleaning systems, solidify their indispensable role in countless operational settings requiring rapid and precise debris removal, thereby driving sustained demand globally.

The primary benefits fueling the market include enhanced operational efficiency due to quick cleanup times, improved worker safety through compliance with Occupational Safety and Health Administration (OSHA) standards regarding maximum pressure output at the nozzle, and superior precision cleaning capabilities that cannot be matched by manual methods. Driving factors include the global expansion of manufacturing capacity, particularly in Asia Pacific, coupled with the necessity for high standards of cleanliness in sensitive industries like semiconductor fabrication and medical device manufacturing. Furthermore, innovation in nozzle design, focusing on vortex technology and sound dampening, continues to refresh the product landscape and stimulate replacements of older, non-compliant equipment, providing significant momentum to market expansion and technological adoption.

Air Blowguns Market Executive Summary

The Air Blowguns Market is characterized by robust business trends centered on technological innovation, compliance standardization, and supply chain resilience. Key business trends include the strong demand for safety-enhanced models that comply with increasingly stringent global regulations, driving manufacturers to invest heavily in specialized noise-reducing and pressure-regulating nozzles. Furthermore, consolidation within the market is occurring as major players seek to acquire specialized nozzle technology firms or expand their distribution networks to capture emerging industrial cleaning demands, particularly in high-precision manufacturing sectors where contaminant control is paramount for quality assurance and product reliability. The shift toward lightweight yet durable composite materials is also a defining trend, aiming to improve user ergonomics and reduce fatigue during prolonged operation.

Regional trends indicate that North America and Europe remain mature markets heavily focused on safety upgrades and replacement cycles, strongly influenced by established OSHA and equivalent EU safety directives that mandate specific air flow and pressure characteristics. Conversely, the Asia Pacific region, led by China, India, and Southeast Asian nations, is the highest growth contributor, fueled by rapid industrialization, extensive factory automation projects, and increasing infrastructure development. This region presents significant opportunities for standard and high-volume blowgun models, although regulatory compliance is rapidly becoming a more influential factor in purchasing decisions, aligning regional demands closer to Western standards over the forecast period.

Segment trends highlight the dominance of the pistol grip segment due to superior ergonomic comfort and ease of use, making it the preferred choice across general industrial applications. Simultaneously, the safety nozzle segment is experiencing the fastest growth, primarily because of regulatory pushes and corporate commitments to zero-accident policies. In terms of application, the automotive and general industrial cleaning sectors account for the largest market share, reflecting the high volume of pneumatic tool usage in vehicle maintenance, repair, and manufacturing. Material segment trends show a gradual shift away from purely metal construction towards hybrid metal-composite designs, balancing durability with reduced weight and improved heat dissipation characteristics, catering to the evolving demands of modern industrial operators for performance and long-term comfort.

AI Impact Analysis on Air Blowguns Market

Common user questions regarding AI's impact on the Air Blowguns Market typically revolve around whether intelligent systems will render manual blowguns obsolete, how AI can optimize compressed air usage, and if predictive maintenance (PdM) systems will incorporate blowgun efficiency metrics. Users are particularly interested in the intersection of Industry 4.0 principles, such as smart sensing and data analytics, with fundamental pneumatic tools. The prevailing theme is not replacement, but enhancement: users anticipate AI systems leveraging data from adjacent machinery (e.g., robotic arms or CNC machines) to precisely determine when and where cleaning is necessary, minimizing wasteful energy consumption and maximizing operational uptime, rather than replacing the fundamental cleaning function of the blowgun itself.

The key themes emerging from user concerns suggest that while the physical design of the blowgun may remain simple, its integration into larger smart factory ecosystems is paramount. Expectations are high that AI-driven monitoring systems could be applied to air compression networks, identifying patterns of excessive air consumption linked to blowgun misuse or leaks, thereby driving significant energy savings and justifying the adoption of more technologically advanced, instrumented blowgun systems. Furthermore, users anticipate AI playing a role in automating safety compliance checks, perhaps by analyzing video feeds of workstations to ensure operators use the correct type of safety nozzle for specific tasks, reducing human error and improving standardized procedures throughout complex manufacturing sites.

Overall, the analysis indicates that AI’s influence will manifest primarily in the optimization and regulatory compliance aspects of compressed air usage, rather than revolutionizing the blowgun's core function. AI systems will act as intelligent supervisors and efficiency consultants for pneumatic networks. This transformation drives demand for air blowguns that can integrate rudimentary sensing capabilities—such as flow meters or pressure gauges that transmit data to centralized AI analytics platforms—allowing factories to transition from reactive cleaning schedules to data-driven, predictive maintenance regimes focused on minimal energy expenditure and maximal production throughput, solidifying the market's trajectory towards smarter tools.

- AI-driven Predictive Maintenance (PdM) integration for monitoring compressed air system health and identifying leak sources, optimizing overall pneumatic network efficiency.

- Optimization of Cleaning Cycles: AI analytics determining optimal timing and duration for debris removal using blowguns, minimizing non-value-added time in automated production lines.

- Enhanced Safety Compliance Monitoring: Utilization of machine vision and AI algorithms to verify correct usage of safety-compliant blowgun nozzles in high-risk areas.

- Smart Inventory Management: AI forecasting demand for specific blowgun types and replacement parts based on industrial activity levels and usage intensity across facilities.

- Energy Consumption Reduction: Analysis of flow rate data from smart blowguns to identify and correct usage patterns leading to excessive or inefficient consumption of compressed air energy.

DRO & Impact Forces Of Air Blowguns Market

The dynamics of the Air Blowguns Market are dictated by a balanced interplay of Drivers (D), Restraints (R), Opportunities (O), and potent Impact Forces. A primary driver is the global increase in industrial automation and manufacturing output, especially within sectors requiring precise, non-contact cleaning, such as electronics assembly and medical manufacturing. This foundational demand is strongly supported by the increasingly stringent regulatory landscape, particularly OSHA standards in North America and similar directives in Europe, which enforce the use of safety-compliant blowguns designed to limit pressure at the nozzle tip to prevent air embolisms, thereby compelling regular equipment upgrades across all industrial users. The continuous push for better workplace safety and ergonomics also mandates the adoption of lightweight, low-noise blowgun models, driving product innovation and replacement sales across established markets.

However, the market faces significant restraints. A key restraint is the high operating cost associated with compressed air systems; generating compressed air is energy-intensive, making end-users constantly seek ways to minimize its use or adopt alternative, less expensive cleaning methods where feasible. Furthermore, the market is characterized by the relatively long lifespan of durable blowgun equipment, which slows down replacement cycles unless mandated by regulation or driven by significant technological leaps in safety or efficiency. The proliferation of low-quality, non-compliant blowgun models, often available at cheaper price points, poses a persistent challenge to premium manufacturers, as these products circumvent safety standards and dilute average market prices, especially in developing regions where regulatory enforcement may be less rigorous.

Significant opportunities exist in emerging markets, where rapid industrialization requires initial procurement of substantial volumes of pneumatic tools, offering high growth potential for manufacturers specializing in cost-effective, high-quality, and compliant products. Furthermore, the integration of smart features, such as embedded flow sensors and IoT connectivity for energy monitoring and predictive maintenance within larger pneumatic networks, presents a compelling opportunity for market premiumization and differentiation. The primary impact force on the market is the regulatory pressure exerted by governmental safety bodies, which not only drives the adoption of specific safety nozzle technologies but also influences material choice and design parameters. Technological advancements in noise reduction and efficiency also act as a crucial force, differentiating high-value products from commodity items and shaping the future competitive landscape by prioritizing energy efficiency alongside safety performance.

Segmentation Analysis

The Air Blowguns Market is comprehensively segmented based on product type, material composition, operating pressure capacity, and primary end-use application, allowing for a detailed understanding of diverse market needs and regional preferences. Segmentation provides crucial insights into which product categories are experiencing rapid technological advancements—such as the rapid uptake of safety nozzle technology—and which material compositions (e.g., metal versus composite) are gaining dominance based on durability requirements and weight reduction goals specific to various industrial environments. Analyzing these segments is essential for manufacturers tailoring product lines to meet niche demands, such as those found in sensitive environments like cleanrooms, or high-volume sectors like automotive body shops requiring robust tools.

The segmentation structure is vital for identifying current market trends and future growth vectors. For instance, the distinction between standard and high-pressure blowguns reflects the different power requirements across applications, where heavy machinery maintenance may demand high-pressure tools, while delicate electronics work requires precise, low-pressure control. Geographically, segmentation helps in allocating resources effectively, targeting regions experiencing rapid infrastructure build-out with the most relevant product mix. This granular analysis facilitates strategic pricing, marketing, and distribution efforts, ensuring that product features align accurately with the regulatory requirements and operational expectations of specific industry end-users, thereby maximizing market penetration and revenue potential.

The ongoing trend towards specialization means that segmentation is becoming increasingly focused on specific safety features and ergonomic improvements, moving beyond just basic classification. For example, within the application segment, the growth of the semiconductor industry necessitates ultra-clean, anti-static, and non-marring blowguns, creating a premium sub-segment. Similarly, the pressure requirements are leading to sub-segments based on adjustable flow and pressure control mechanisms integrated directly into the tool, providing users with unparalleled versatility and safety control. This detailed classification aids in benchmarking competitor performance and identifying underserved market niches for product development and strategic investment.

- By Product Type:

- Pistol Grip Blowguns

- Straight/Standard Blowguns

- Safety Tip/Nozzle Blowguns

- High Volume/High Thrust Blowguns

- By Material:

- Metal (Aluminum, Zinc Alloy)

- Plastic/Composite

- By Operating Pressure:

- Standard Pressure (Up to 90 PSI)

- High Pressure (Above 90 PSI)

- By Application/End-User:

- Automotive Maintenance and Repair

- General Industrial Cleaning and Maintenance

- Woodworking and Furniture Manufacturing

- Electronics and Semiconductor Manufacturing

- Aerospace and Heavy Equipment

Value Chain Analysis For Air Blowguns Market

The value chain for the Air Blowguns Market begins with the upstream activities centered on raw material procurement and component manufacturing. This stage involves sourcing high-grade metals (aluminum, brass, zinc for durability and corrosion resistance) and specialized engineering plastics/composites for lightweight bodies and ergonomic handles. Key upstream suppliers include metal foundries, plastic resin producers, and specialized manufacturers of internal components such as valves, springs, and seals which dictate the functionality and lifespan of the blowgun. The effectiveness of the upstream process is heavily reliant on maintaining consistent quality standards for materials that must withstand high internal pressure and external impact, influencing the final product's durability and price point in the market.

The core manufacturing and assembly phase involves precision machining, molding, and the final assembly of the blowgun body, nozzle, and trigger mechanisms. Manufacturers prioritize lean production methods and quality control to ensure strict adherence to international safety standards (like OSHA pressure restrictions) and ergonomic specifications. Direct distribution often involves sales teams targeting large industrial end-users, original equipment manufacturers (OEMs) who integrate these tools into larger pneumatic systems, and governmental bodies for compliance upgrades. Indirect distribution, which accounts for a substantial portion of sales volume, relies on a network of authorized distributors, industrial supply wholesalers, and increasingly, e-commerce platforms specializing in industrial equipment, providing broad market reach and inventory management support.

Downstream activities focus on reaching the end-user, including logistics, aftermarket service, and technical support. The effectiveness of the distribution channel—whether direct or indirect—is critical for market saturation. Major industrial distributors act as crucial intermediaries, providing localized inventory, technical expertise, and quick delivery, particularly essential for small to medium enterprises (SMEs). The aftermarket phase includes the supply of replacement nozzles, extension tips, and maintenance kits, ensuring prolonged product utility and maintaining manufacturer engagement with the installed base. The efficiency of the entire value chain is currently being optimized through digital platforms that connect manufacturers directly to large industrial buyers, bypassing some traditional layers and facilitating greater transparency in pricing and inventory management.

Air Blowguns Market Potential Customers

The primary potential customers and end-users of air blowguns span a broad range of industrial and professional sectors where cleanliness, drying, and precise debris removal are critical components of operational efficiency and product quality. The largest and most consistent buying segment is the automotive industry, encompassing both vehicle manufacturing plants (for clearing metal shavings and ensuring clean assembly surfaces) and the vast network of automotive maintenance and repair shops (for brake dust removal, engine bay cleaning, and drying surfaces after washing). These buyers prioritize durability, compliance with safety standards (especially OSHA tip pressure limits), and ergonomic design due to the high frequency of use in their demanding environments, often purchasing in bulk through specialized industrial wholesalers.

Another significant segment includes general industrial manufacturing and fabrication facilities, particularly those involved in metalworking, plastic molding, and machinery maintenance. In these environments, air blowguns are indispensable for clearing swarf, coolant residue, and dust accumulation on CNC machines, presses, and assembly lines to prevent equipment damage and ensure precise operation. These customers often seek high-thrust, robustly built blowguns designed for continuous heavy-duty use. The demand here is frequently driven by plant maintenance budgets and safety officers aiming to standardize compliant tools across multiple facilities, often purchasing based on total cost of ownership rather than initial unit price, valuing reliability and long warranty periods.

Specialized end-users represent high-value, niche markets. This includes the electronics and semiconductor industry, where contamination control is paramount; these customers require specialized, anti-static, non-marring plastic-tipped blowguns suitable for cleanroom environments and delicate circuit board work, necessitating specialized materials and ultra-precise airflow control. Similarly, the aerospace industry utilizes blowguns for critical component cleaning, often requiring specific material certifications. These buyers focus intensely on flow control accuracy, specialized nozzle configurations, and documented safety features, representing the segment most willing to pay a premium for technologically advanced, application-specific equipment that directly impacts product quality and compliance documentation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 667.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SMC Corporation, Exair Corporation, Coilhose Pneumatics, Milton Industries Inc., Prevost SAS, Silvent AB, Parker Hannifin Corporation, Astro Pneumatic Tool Company, Guardair Corporation, Jameco Industrial, PCL, KITA Manufacturing Co., Ltd., Festo, Chicago Pneumatic, Legacy Manufacturing, CEJN AB, Ingersoll Rand, Shinano Inc., Dixon Valve & Coupling Company, Lisle Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Air Blowguns Market Key Technology Landscape

The technology landscape of the Air Blowguns Market is heavily influenced by advancements in fluid dynamics and material science, driven primarily by the need for enhanced safety and greater energy efficiency. A core technological focus is on the design of safety nozzles, which utilize specialized internal structures, such as venturi passages or peripheral air inlets, to entrain ambient air. This design allows the output flow to remain strong for effective debris removal while ensuring that the dead-end pressure—the maximum pressure attainable if the tip is blocked—remains below the hazardous limits mandated by safety regulators (typically 30 PSI or 2 Bar). This fundamental technology is critical for mitigating the risk of air embolisms, thereby underpinning sales growth in highly regulated industrial environments globally, forcing older, non-compliant straight-tip blowguns out of professional settings.

Further technological innovation focuses heavily on acoustic performance and efficiency. Noise reduction technology utilizes specially designed nozzle geometries and internal sound-dampening materials to significantly reduce the decibel levels generated during operation, addressing long-term occupational health concerns related to noise-induced hearing loss. Simultaneously, efficiency technologies, often referred to as "air-saver" or "high-thrust" nozzles, maximize the kinetic energy of the output air stream using minimal input volume of compressed air. These optimized designs leverage principles of mass flow and air entrainment to deliver a powerful cleaning force while demonstrably lowering the energy consumption required from the compressor, offering a compelling return on investment for high-volume industrial users concerned with utility costs, and marking a key competitive differentiator for premium manufacturers in the market.

Material technology also plays a crucial role, with manufacturers increasingly adopting high-performance composites and lightweight polymers alongside traditional metals. This shift allows for the creation of durable, impact-resistant, yet significantly lighter blowgun bodies, enhancing operator ergonomics and reducing repetitive strain injuries over long shifts. Furthermore, for specialized applications like electronics or painting, advancements include anti-static materials and non-marring tips (often rubber or soft plastic) that prevent surface damage and electrostatic discharge. Future technological integration is expected to focus on incorporating low-cost micro-sensors for real-time monitoring of flow rate, pressure, and temperature, enabling full compatibility with Industry 4.0 monitoring systems and providing actionable data for preventive maintenance and air consumption optimization across the entire pneumatic network.

Regional Highlights

North America, particularly the United States and Canada, represents a mature yet highly valuable market segment for air blowguns, characterized by rigorous adherence to safety standards, most notably those established by the Occupational Safety and Health Administration (OSHA). The region's demand is driven primarily by replacement cycles focused on upgrading legacy equipment to modern, safety-compliant, and ergonomic models. The automotive, aerospace, and high-tech manufacturing sectors are the biggest consumers, demanding high-quality, durable, and energy-efficient tools. Regulatory enforcement acts as a powerful catalyst, ensuring continuous demand for specialized safety nozzles and noise-reduction features, thereby maintaining high average selling prices compared to other global regions.

The Asia Pacific (APAC) region is distinguished as the fastest-growing market globally, driven by large-scale investments in manufacturing infrastructure, factory automation, and industrial expansion in countries like China, India, Vietnam, and Indonesia. While the initial market penetration was characterized by a demand for basic, cost-effective models, rising labor standards and increasing foreign investment are rapidly escalating the demand for international-standard compliant equipment. The sheer volume of new factories coming online creates immense opportunities for high-volume sales. Manufacturers in this region are increasingly balancing cost-competitiveness with the need to meet localized, evolving safety regulations, making APAC a key battleground for both local and international manufacturers.

Europe maintains a strong market position, highly focused on sustainability, noise reduction, and advanced ergonomic requirements, driven by strict EU directives and national standards promoting worker health and safety. The European market prioritizes high-efficiency nozzles to address rising energy costs and environmental concerns associated with compressed air systems. The robust industrial base, including Germany’s advanced engineering and manufacturing sectors, drives consistent demand for premium, technologically advanced blowguns integrated with certified safety features. The Middle East and Africa (MEA) and Latin America (LATAM) markets, while smaller, are showing significant potential, linked to infrastructure projects, oil and gas maintenance, and growing regional manufacturing hubs. Demand in these regions is heavily influenced by large industrial projects and foreign investment driving the adoption of standardized international equipment.

- North America (US, Canada): Mature market dominated by safety-compliant replacements; strong influence of OSHA standards; high demand in automotive and aerospace.

- Europe (Germany, UK, France): Focus on ergonomic design, noise reduction technology, and high energy efficiency due to stringent EU environmental and labor regulations; stable demand from advanced manufacturing.

- Asia Pacific (China, India, Japan): Highest growth market driven by rapid industrialization and new facility construction; increasing emphasis on adopting international safety standards, leading to rising demand for specialized tools.

- Latin America (Brazil, Mexico): Growth driven by automotive manufacturing and mining sectors; market price sensitivity is higher, but safety compliance is gradually improving.

- Middle East and Africa (MEA): Demand tied to infrastructure development and heavy industry (Oil & Gas); focus on durable equipment capable of handling harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Air Blowguns Market.- SMC Corporation

- Exair Corporation

- Coilhose Pneumatics

- Milton Industries Inc.

- Prevost SAS

- Silvent AB

- Parker Hannifin Corporation

- Astro Pneumatic Tool Company

- Guardair Corporation

- Jameco Industrial

- PCL

- KITA Manufacturing Co., Ltd.

- Festo

- Chicago Pneumatic

- Legacy Manufacturing

- CEJN AB

- Ingersoll Rand

- Shinano Inc.

- Dixon Valve & Coupling Company

- Lisle Corporation

- A.V. Industrial Products

- ITW Global Brands

- Nitto Kohki

- Rexroth (Bosch Rexroth)

- Schunk GmbH

Frequently Asked Questions

Analyze common user questions about the Air Blowguns market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most crucial regulatory compliance factor affecting the Air Blowguns Market?

The most crucial regulatory compliance factor is the Occupational Safety and Health Administration (OSHA) 1910.242(b) standard in the US, or equivalent international safety directives, which mandate that compressed air used for cleaning must be reduced to less than 30 PSI (pounds per square inch) when the discharge opening is blocked (dead-end pressure). This regulation drives the mandatory adoption of engineered safety nozzles designed to release pressure laterally upon blockage, significantly impacting product design and procurement decisions globally.

How are advancements in ergonomics influencing the purchasing decisions for industrial Air Blowguns?

Ergonomic advancements significantly influence purchasing decisions, particularly in high-volume manufacturing environments. Buyers seek lightweight designs achieved through composite materials, cushioned pistol grips, and specialized trigger mechanisms that minimize operator fatigue and the risk of repetitive strain injuries (RSI). Improved ergonomics are directly linked to enhanced productivity and reduced long-term operational costs related to workplace injuries, driving demand for premium, user-focused models.

Which segment of the Air Blowguns Market is projected to experience the fastest growth rate?

The Safety Tip/Nozzle Blowguns segment is projected to experience the fastest growth rate. This accelerated growth is primarily attributed to the global reinforcement of industrial safety regulations and corporate mandates prioritizing worker protection. As non-compliant tools are phased out and replaced, the demand for certified, pressure-regulating safety nozzles that adhere strictly to international pressure limitations provides the highest market momentum throughout the forecast period.

What role does energy efficiency technology play in modern Air Blowgun design?

Energy efficiency technology, often utilizing advanced venturi or laminar flow nozzle designs, plays a critical role in modern air blowguns by maximizing thrust while minimizing the consumption of compressed air. Since generating compressed air is highly energy-intensive and costly, these air-saving nozzles offer significant utility cost reductions for industrial end-users, acting as a major incentive for upgrading older equipment and directly contributing to corporate sustainability and cost reduction initiatives across global manufacturing sites.

What distinguishes the Asia Pacific market dynamic compared to North America and Europe?

The Asia Pacific (APAC) market is primarily characterized by rapid new facility construction and initial procurement, leading to high volume demand and the fastest growth rate. In contrast to North America and Europe, which focus heavily on replacement cycles and premium safety upgrades based on long-established regulations, APAC’s growth is fueled by vast industrial expansion, though regional safety standards are quickly tightening, driving a shift from basic, inexpensive models toward internationally compliant, high-quality products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Air Blowguns Market Size Report By Type (Straight Nozzle, Angled Nozzle, Others), By Application (Industrial Machinery, Electronics, Automotive, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Air Blowguns Market Statistics 2025 Analysis By Application (Industrial Machinery, Electronics, Automotive), By Type (Straight Nozzle, Angled Nozzle), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager