Airbrush Gun Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438809 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Airbrush Gun Market Size

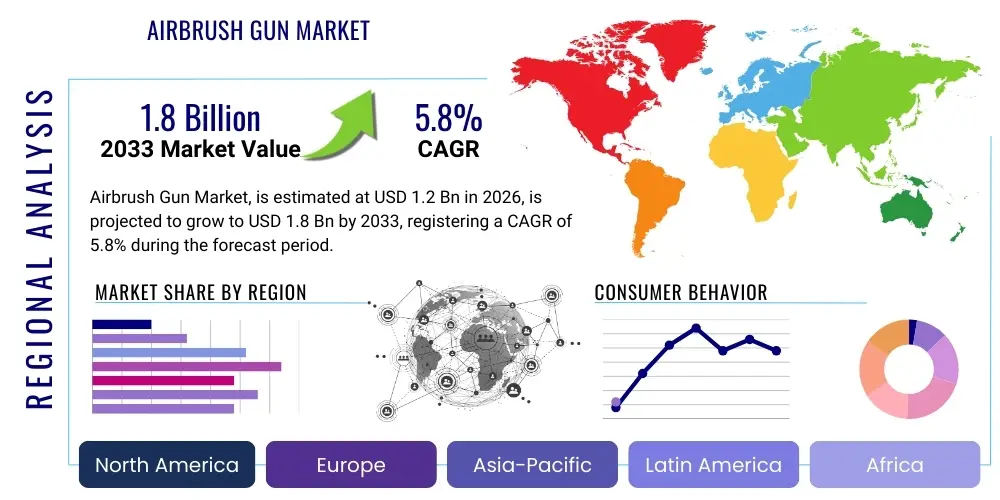

The Airbrush Gun Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.8 Billion by the end of the forecast period in 2033.

Airbrush Gun Market introduction

The Airbrush Gun Market encompasses the global trade of precision instruments designed for atomizing and spraying various mediums, including paints, inks, and cosmetics, onto surfaces. Airbrush guns, often consisting of a compressor, a hose, and the brush mechanism itself, are utilized across a wide spectrum of specialized applications where fine detail, smooth coverage, and minimal overspray are critical requirements. These instruments are categorized primarily by feed type (gravity, siphon, or side feed) and action type (single or dual action), enabling users to achieve varied results from broad coverage to micro-fine lines. The evolution of materials science, particularly in nozzle and needle design, continues to enhance the reliability and performance of modern airbrush systems, expanding their adoption in industrial and artistic domains.

Major applications driving market demand include the burgeoning professional cosmetics industry, particularly for flawless foundation and body art; the thriving creative sector, encompassing fine arts, illustration, and mural painting; and the expansive hobby segment, dominated by scale model building, custom garment design, and cake decoration. Furthermore, airbrush technology holds significant importance in the automotive sector for custom painting, pinstriping, and touch-up work, demanding tools capable of handling specialized automotive-grade coatings with high precision. The versatility and capability of airbrush systems to handle complex gradient transitions and extremely thin layers of material position them as indispensable tools across these high-value segments, influencing procurement decisions based on quality and durability.

The key benefits associated with airbrush guns include superior finish quality, precise control over material flow, reduced wastage compared to conventional spraying methods, and the ability to work with highly viscous or very thin media effectively. Driving factors for market growth include the rising global interest in high-definition makeup application, the increasing sophistication of the scale model and custom hobbyist community demanding professional-grade tools, and technological advancements leading to more ergonomic and maintenance-friendly airbrush designs. Furthermore, the growing use of airbrush technology in specialized fields like medical tattooing (areola reconstruction) and specialized industrial coating applications contributes significantly to sustained market expansion.

Airbrush Gun Market Executive Summary

The Airbrush Gun Market is characterized by robust growth, primarily propelled by the integration of airbrushing into mainstream consumer and professional applications, specifically in makeup and custom automotive design. Business trends indicate a strong move towards dual-action, gravity-feed airbrushes due to their superior control and efficiency, favoring high-end manufacturers focused on ergonomic designs and durable materials such as stainless steel components. The competitive landscape is moderately fragmented, with specialized manufacturers maintaining dominance through innovation in compressor technology—specifically the shift toward quieter, oil-less miniature compressors—and strategic partnerships with educational institutions and professional artists to promote brand loyalty and technical skill development globally. Sustainability is also emerging as a minor trend, with some focus on reducing volatile organic compound (VOC) emissions by optimizing paint atomization.

Regionally, the market exhibits dynamic growth, with Asia Pacific (APAC) emerging as the fastest-growing region, fueled by expanding manufacturing hubs, rising disposable incomes driving consumer spending on luxury cosmetics, and a deeply entrenched culture of hobbyist model building, particularly in Japan, South Korea, and China. North America and Europe remain key revenue contributors, maintaining strong demand across professional applications, fine arts, and high-performance custom automotive paint jobs. These mature markets are demanding advanced features such as solvent-resistant seals and modular components for easy cleaning and maintenance. Regulatory standards regarding paint application and safety, while stricter in Europe, also influence design specifications across these regions.

Segment trends highlight the dominance of the Application segment, specifically Cosmetics and Hobby & Arts, which together account for the largest share of market revenue. Within product type, gravity-feed airbrushes lead the market due to their suitability for detailed work and lower operational pressure requirements, making them ideal for high-viscosity mediums. The distribution segment is witnessing rapid transformation, with e-commerce platforms experiencing accelerated growth, providing niche manufacturers access to a global consumer base and simplifying the procurement process for specialized accessories and spare parts. This digital shift necessitates optimized logistics and robust online technical support from market leaders to maintain competitive advantage and customer satisfaction.

AI Impact Analysis on Airbrush Gun Market

Common user questions regarding AI’s impact on the airbrush market center on whether automation will replace skilled artists, how AI can assist in color matching and workflow efficiency, and the potential for AI-driven maintenance and diagnostics of high-precision tools. Users frequently query the role of computer vision and machine learning in enhancing the consistency of mass production processes utilizing automated airbrush systems (such as in electronics coating or automotive component finishing). There is a significant interest in AI tools that can simulate complex artistic effects or aid in the preliminary design phase, suggesting that users view AI not as a replacement, but as an advanced assistant capable of reducing error rates and accelerating complex creative tasks. The overall expectation is that AI will improve the precision and reliability of industrial airbrushing while providing new digital tools for professional artists.

The influence of Artificial Intelligence, particularly in conjunction with robotics and machine vision, is primarily transformative in industrial and high-volume production environments. Automated airbrush systems, leveraging AI algorithms, can analyze surface topology, calculate optimal spray patterns in real-time to ensure uniform coating thickness, and dynamically adjust pressure and paint volume based on environmental conditions or material characteristics. This level of optimization significantly reduces material waste, enhances quality consistency across large batches, and lowers the need for continuous human supervision in repetitive coating tasks, such as aerospace component priming or precise medical device coating.

For the professional artist and hobbyist segments, AI impact is manifesting through enhanced digital design tools. AI-powered software can suggest optimized color palettes, predict how specific paint mixtures will behave under varying airbrush settings, and even generate complex stencils or patterns suitable for airbrush application based on textual or visual inputs. Furthermore, AI is beginning to be integrated into equipment diagnostics; smart compressors and airbrush modules are capable of monitoring usage metrics, detecting potential mechanical failures (like needle wear or nozzle blockage) before they occur, and proactively suggesting maintenance schedules. This predictive maintenance enhances tool longevity and minimizes costly downtime for professional users.

- AI-driven optimization of industrial spray patterns, maximizing material efficiency.

- Machine learning algorithms enhancing color matching and consistency in large-scale production.

- Predictive maintenance features integrated into smart airbrush compressors and modules.

- AI assistance in digital art and design, generating complex stencils and patterns for physical transfer.

- Computer vision systems ensuring defect detection and quality control during automated coating processes.

- Automation replacing repetitive tasks in electronics coating and small part finishing, increasing throughput.

DRO & Impact Forces Of Airbrush Gun Market

The Airbrush Gun Market is simultaneously driven by technological advancements in precision manufacturing and the expansive growth of end-user application fields, particularly in high-definition aesthetics and custom arts. Restraints mainly revolve around the steep learning curve required for mastering advanced airbrushing techniques and the necessary investment in high-quality ancillary equipment, such as reliable compressors and ventilation systems. Opportunities are significant in emerging markets where disposable income is increasing, coupled with untapped potential in niche industrial applications requiring ultra-fine coatings. These forces create a dynamic environment where precision, quality, and user accessibility are the critical factors determining market trajectory and competitive success over the forecast period.

Key drivers include the global expansion of the beauty and cosmetics industry, where airbrush makeup provides a superior, long-lasting, and hygienic application sought after by professional makeup artists and consumers alike. The sustained popularity of elaborate scale modeling, demanding high levels of paint detail, acts as another major catalyst. Furthermore, continuous product innovation, particularly the development of high-performance, solvent-resistant airbrushes and quiet, portable compressor units powered by modern battery technology, lowers the barrier to entry for hobbyists and mobile professionals, thereby significantly expanding the user base globally and boosting sales volumes for specialized equipment.

Restraints impeding market growth primarily include the required expertise and initial cost of setup. High-end, dual-action airbrushes coupled with quality compressors represent a substantial investment, deterring casual hobbyists. Moreover, the maintenance of airbrush guns—requiring thorough cleaning after every use to prevent clogging—is time-consuming and often intimidating for beginners, leading to slower initial adoption rates. External impact forces, such as fluctuating raw material costs (e.g., stainless steel and specialized plastics used in construction) and increasing environmental regulations concerning paint disposal and VOC emissions, necessitate constant R&D investment from manufacturers to ensure compliance and cost-effective production, potentially impacting retail prices.

Segmentation Analysis

The Airbrush Gun Market segmentation provides crucial insights into targeted product development and strategic market penetration, dissecting the total addressable market based on product characteristics, usage context, and end-user requirements. Primary segmentation revolves around Type (Gravity Feed, Siphon Feed, Side Feed), which dictates the tool's performance profile, and Application (Hobby & Arts, Cosmetics, Automotive, Medical), reflecting the diverse end-user demand patterns. Analyzing these segments helps manufacturers tailor specific models—for instance, developing robust, high-volume siphon feeds for automotive priming versus delicate, gravity feeds for cosmetic application—optimizing features for defined user groups.

The dominance of the Gravity Feed segment underscores the market's focus on precision and low-pressure operation, favored heavily by fine artists and cosmetic professionals who prioritize detailed work and controlled material flow. Conversely, the Siphon Feed segment retains relevance in applications requiring larger quantities of material or where visibility is not obscured by a top-mounted cup. Understanding these structural dynamics is essential for market players to diversify their product portfolio to capture maximum revenue across varied professional and consumer needs, ensuring that specific models are optimized for viscosity and volume handling.

Application analysis confirms that the Hobby & Arts sector remains the backbone of the market, driven by millions of global enthusiasts dedicated to model painting and illustration. However, the Cosmetics segment is experiencing the fastest growth, primarily due to the rapid adoption of airbrush makeup techniques in bridal, theatrical, and high-end consumer settings. Manufacturers are thus increasingly investing in developing specialized, hypoallergenic airbrush solutions and ergonomic, quiet compressors tailored specifically for personal and salon use, signifying a strategic pivot towards high-growth, high-margin consumer niches alongside established industrial demands.

- By Type:

- Gravity Feed Airbrush Guns

- Siphon Feed Airbrush Guns

- Side Feed Airbrush Guns

- By Action:

- Single-Action Airbrush Guns

- Dual-Action Airbrush Guns

- By Application:

- Hobby and Fine Arts (Model Building, Illustration, Custom T-shirts)

- Cosmetics and Beauty (Makeup, Nail Art, Body Art)

- Automotive and Custom Coatings (Vehicular Graphics, Pinstriping)

- Medical and Technical (Tattooing, Areola Reconstruction, Specialized Coatings)

- Industrial and Manufacturing (Electronics Coating, Prototypes)

- By Distribution Channel:

- Online Retail (E-commerce Platforms)

- Offline Retail (Specialty Stores, Art Supply Stores, Direct Distribution)

Value Chain Analysis For Airbrush Gun Market

The Airbrush Gun market value chain begins with upstream activities involving the sourcing and processing of raw materials, predominantly high-grade metals such as brass, stainless steel, and specialized polymers for seals and handles, along with precision components like needles and nozzles. Manufacturers often rely on specialized suppliers for CNC machining and ultra-fine fabrication necessary to meet the demanding tolerances required for consistent atomization. Effective upstream management focuses on ensuring material quality, minimizing supply chain disruptions, and maintaining cost efficiency, as the precision of these components is directly correlated with the final product's performance and market reputation, particularly for premium brands like Iwata and Harder & Steenbeck.

The midstream stage involves the core manufacturing, assembly, quality assurance, and branding of the airbrush guns and their accompanying accessories, such as compressors and hoses. This stage is capital-intensive, requiring specialized assembly techniques and rigorous testing to ensure optimal air pressure consistency and paint flow control. Distribution channels then move the finished goods towards the downstream market. This includes a blend of direct sales to large industrial clients and indirect distribution through a network of wholesalers, regional distributors, and specialized retail chains (like art supply stores and hobby shops). The increasing prevalence of global e-commerce platforms has fundamentally altered indirect distribution, allowing manufacturers to bypass traditional intermediaries and reach niche consumer bases worldwide.

The downstream analysis focuses on the interaction with the end-users—hobbyists, professional artists, makeup artists, and industrial operators. For high-precision tools, post-sale support, including technical training, availability of spare parts (needles, nozzles, seals), and reliable warranty service, becomes a critical differentiator and a significant component of the value proposition. Direct distribution often facilitates stronger customer feedback loops, allowing manufacturers to rapidly integrate user-driven improvements into future product designs. The efficiency of both direct and indirect channels is paramount; direct channels ensure high margins and control, while indirect channels provide the necessary breadth of market coverage, particularly in geographically diverse regions like APAC and Latin America.

Airbrush Gun Market Potential Customers

Potential customers for the Airbrush Gun Market are highly diversified, ranging from individual consumers and small-scale entrepreneurs to large multinational corporations requiring precision coating solutions. The largest segment of end-users are professional and amateur artists and hobbyists, including scale modelers, illustrators, textile designers, and custom bike/helmet painters, who require high-control tools for detailed aesthetic applications. These users typically prioritize dual-action capabilities, fine nozzle sizes (0.2 mm to 0.5 mm), and reliable long-term performance, often opting for gravity-feed systems for maximum control and efficiency with small paint volumes.

The fastest-growing customer segment is the professional beauty and cosmetic industry, which includes makeup artists specializing in bridal, cinematic, and theatrical makeup, and salon professionals offering temporary tattoos and nail art. These buyers demand sterile, lightweight, and easy-to-clean equipment, favoring specialized cosmetic airbrush kits that include small, quiet compressors optimized for mobility and low-pressure operation. For this segment, the quality of the atomization and the compatibility with water-based, specialized cosmetic formulations are key purchasing criteria, often leading to brand loyalty towards manufacturers known for cosmetic-specific lines.

Furthermore, significant potential lies within specialized industrial and technical domains, encompassing manufacturers in electronics, aerospace, and medical devices that require ultra-thin, highly consistent protective or functional coatings. These B2B customers seek robust, automated, or semi-automated airbrush systems (often siphon or pressure feed due to high volume needs) capable of integrating seamlessly into robotic arms and production lines. Procurement decisions in this area are driven by repeatability, durability under chemical exposure, compliance with industrial safety standards, and documented statistical process control (SPC) capabilities to ensure zero-defect output for critical components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Iwata, Paasche Airbrush, Badger Air-Brush Co., Harder & Steenbeck GmbH, Sata GmbH & Co. KG, Grex Airbrush, Olympos, DeVilbiss (ITW), Master Airbrush, Sparmax, Tamiya, Testor Corporation, NEO for Iwata, Fengda, VEDA, Royalmax, AirGo, Z-Art, GSI Creos, ABEST. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Airbrush Gun Market Key Technology Landscape

The contemporary Airbrush Gun Market is heavily influenced by advancements in nozzle and needle manufacturing, focusing on achieving finer atomization and greater durability. High-precision CNC machining is crucial for producing internal components with exceptionally tight tolerances (often measured in microns), which directly impacts spray pattern consistency and material efficiency. Manufacturers are increasingly utilizing corrosion-resistant materials, such as specific grades of stainless steel and Teflon (PTFE) seals, to handle aggressive, modern solvent-based and UV-cured paints without degradation. This material technology focus ensures the longevity of dual-action mechanisms and maintains performance across diverse media types, including highly viscous metallic paints or thin cosmetic foundations.

Another significant technological driver is the evolution of air compression systems. Traditional large, loud, oil-lubricated compressors are being supplanted by quiet, oil-less miniature diaphragm and piston compressors. These compact units are highly favored by mobile professionals and hobbyists due to their portability, reduced maintenance needs, and significantly lower noise footprint, which is critical for studio or residential use. Furthermore, integrated air regulators and moisture traps are standard features, enhancing paint consistency by ensuring clean, dry airflow, thus mitigating issues such as sputtering and tip dry, which traditionally plagued airbrush users and required specialized techniques to manage.

Digital integration, though nascent, is starting to reshape the high-end segment. This includes the development of smart airbrush systems featuring digital pressure gauges, electronic micro-valves for precise air and fluid regulation, and in some cases, Bluetooth connectivity to monitor usage statistics or interface with companion apps. These technological enhancements are particularly valuable in industrial settings where precise control and real-time data logging are mandatory for quality assurance. The continuous research into modularity—allowing users to easily swap out components like paint cups, needles, and nozzles—further improves user experience, simplifying the crucial cleaning process and enabling rapid customization for different tasks without needing multiple dedicated airbrush units.

Regional Highlights

Regional dynamics play a crucial role in shaping the Airbrush Gun Market, driven by differential application maturity and economic development levels. North America and Europe historically represent the largest revenue share, primarily due to established and sophisticated industries in custom automotive finishing, professional fine arts, and high-end cosmetic applications. These regions feature mature distribution networks, strong consumer purchasing power, and a high demand for premium, durable airbrush equipment characterized by high levels of precision and ergonomic design. Regulatory environments regarding solvent use and safety standards also drive technological innovation towards water-based, low-VOC paint systems and enhanced ventilation technology in these areas.

Asia Pacific (APAC) is projected to be the fastest-growing region over the forecast period. This rapid expansion is attributed to the burgeoning scale model hobbyist community, particularly in East Asia (Japan, China), where meticulous detail work is highly valued. Simultaneously, the accelerating growth of the middle class in emerging economies such as India and Southeast Asian nations is stimulating demand for cosmetic airbrushing and localized custom manufacturing services. Market penetration in APAC is often facilitated through strong partnerships with local distributors and the development of cost-effective, yet reliable, airbrush kits that cater to mass market consumers alongside high-end professional users.

Latin America (LATAM), and the Middle East and Africa (MEA), while currently smaller contributors, offer significant untapped market potential. Growth in these regions is supported by increasing infrastructure development, boosting the need for specialized industrial coatings, and the gradual adoption of airbrush techniques in local art and customization scenes. However, market development in MEA and LATAM often faces challenges related to unstable distribution logistics, fluctuating currency exchange rates impacting import costs, and the need for region-specific marketing strategies to overcome language and cultural barriers in tool adoption.

- North America: Dominant market share driven by professional arts, custom automotive, and established cosmetic airbrush industry. High demand for premium dual-action models.

- Europe: Strong revenue from fine arts and demanding industrial applications; stringent environmental regulations pushing the adoption of eco-friendly airbrush media and systems.

- Asia Pacific (APAC): Highest CAGR, fueled by the massive hobbyist market, increasing disposable income, and rapid expansion of the professional beauty sector in key economies (China, Japan, South Korea).

- Latin America (LATAM): Emerging market, focusing on specialized local art and small-scale custom work; market development constrained by economic volatility and reliance on imports.

- Middle East and Africa (MEA): Growth potential in aesthetic applications (body art) and niche industrial coating sectors, though overall market size remains relatively small.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Airbrush Gun Market.- Iwata

- Paasche Airbrush

- Badger Air-Brush Co.

- Harder & Steenbeck GmbH

- Sata GmbH & Co. KG

- Grex Airbrush

- Olympos

- DeVilbiss (ITW)

- Master Airbrush

- Sparmax

- Tamiya

- Testor Corporation

- NEO for Iwata

- Fengda

- VEDA

- Royalmax

- AirGo

- Z-Art

- GSI Creos

- ABEST

Frequently Asked Questions

Analyze common user questions about the Airbrush Gun market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between gravity-feed and siphon-feed airbrush guns?

Gravity-feed airbrushes, dominant in the market, use gravity to pull paint downward from a top-mounted cup, requiring less air pressure, making them ideal for fine detail and small volumes. Siphon-feed airbrushes draw paint upward from a container mounted below, requiring higher air pressure but accommodating larger paint volumes, suitable for large area coverage like murals or automotive base coats.

Which airbrush type is recommended for beginners in the hobby segment?

Beginners are generally recommended to start with a single-action, gravity-feed airbrush due to its simpler operation and easier control over the paint flow. While dual-action offers better control for advanced users, the single-action mechanism simplifies the cleaning process and reduces the initial learning curve, providing a smoother transition into airbrushing techniques for scale modeling or basic illustration.

How is the growth of the cosmetic industry impacting the demand for specialized airbrush equipment?

The cosmetic industry significantly drives demand, especially for specialized, quiet, and portable airbrush systems optimized for liquid foundation and body art. This segment requires hygienic, ergonomic tools compatible with water-based and hypoallergenic makeup formulations, spurring innovation in small, oil-less compressors and dedicated cosmetic airbrush lines from major manufacturers, contributing substantially to market value.

What are the main technological innovations in airbrush compressors?

Key technological innovations focus on portability and noise reduction. Modern compressors are predominantly oil-less piston or diaphragm designs, offering quiet operation, minimal maintenance, and compact size suitable for home or studio use. Battery-powered, rechargeable compressors are also growing in popularity, enabling mobile use for makeup artists and outdoor muralists, addressing a critical need for professional flexibility.

What are the major restraints limiting the broader adoption of airbrush guns?

The primary restraints include the relatively high initial investment required for high-quality guns and compressors, which can be prohibitive for casual users. Additionally, the necessity for meticulous and frequent cleaning to prevent clogging, alongside the complex technique required to master dual-action control for detailed work, presents a significant barrier to entry, often necessitating professional training.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager