Aircraft Coffee Maker Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440026 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Aircraft Coffee Maker Market Size

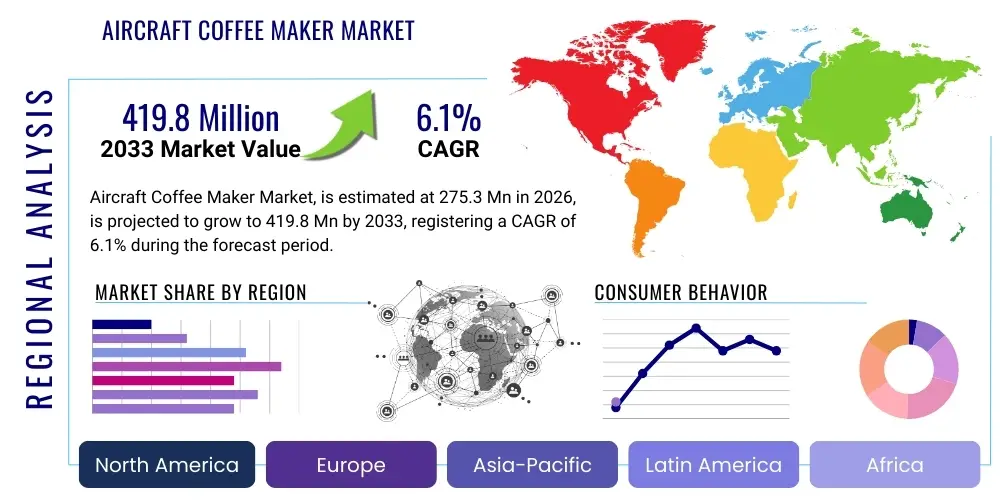

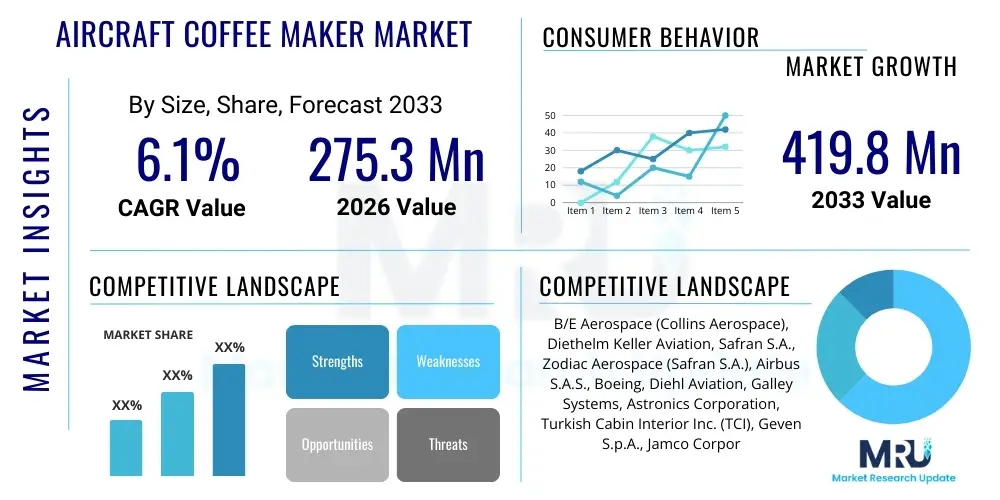

The Aircraft Coffee Maker Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.1% between 2026 and 2033. The market is estimated at USD 275.3 Million in 2026 and is projected to reach USD 419.8 Million by the end of the forecast period in 2033.

Aircraft Coffee Maker Market introduction

The Aircraft Coffee Maker Market encompasses the design, manufacturing, and distribution of specialized coffee brewing equipment tailored for aviation environments. These systems are engineered to operate reliably under unique conditions, including varying cabin pressures, altitudes, and stringent safety regulations. Unlike conventional coffee makers, aircraft models often feature robust construction, lightweight materials, and specific certifications for aerospace use, ensuring safe and efficient beverage service during flights. The primary goal is to provide passengers and crew with high-quality, freshly brewed coffee consistently, enhancing the overall in-flight experience and operational efficiency for airlines.

Product descriptions typically highlight features such as automatic brewing cycles, energy efficiency, ease of maintenance, and compliance with aviation standards like RTCA DO-160 and EASA/FAA regulations. Major applications span across commercial airlines, business jets, and even military transport aircraft, where consistent access to hot beverages is crucial for comfort and crew performance. The benefits derived from these advanced coffee makers include improved passenger satisfaction, reduced waste, optimized crew workflow, and enhanced brand perception for airlines.

Key driving factors for market expansion include the continuous growth in global air passenger traffic, an increasing demand for premium in-flight services, and the ongoing modernization of aircraft fleets. Airlines are investing in advanced cabin interiors to differentiate their offerings and cater to evolving passenger expectations for comfort and convenience. Furthermore, technological advancements in brewing mechanisms, material science, and connectivity are fueling innovation within this niche but critical segment of the aerospace industry, pushing for more efficient and customizable solutions.

Aircraft Coffee Maker Market Executive Summary

The Aircraft Coffee Maker Market is currently witnessing dynamic shifts driven by several overarching business, regional, and segment trends. Business trends highlight a strong emphasis on sustainability and operational efficiency, with manufacturers innovating to produce lighter, more energy-efficient units that reduce an aircraft's overall weight and fuel consumption. There's also a growing demand for integrated galley solutions that combine multiple functionalities, streamlining cabin services and optimizing space utilization. Airlines are increasingly looking for robust, low-maintenance systems that offer superior reliability, minimizing downtime and maintenance costs. Customization and brand alignment are also key, as airlines seek coffee makers that complement their cabin aesthetics and brand identity, enhancing the passenger experience.

Regionally, the market exhibits varied growth patterns. Asia Pacific, driven by rapid expansion of its airline fleets and increasing disposable incomes leading to higher air travel demand, is emerging as a significant growth hub. North America and Europe, while mature markets, continue to demonstrate steady demand for upgrades and replacements, spurred by technological advancements and the need to comply with evolving environmental regulations. Emerging economies in Latin America, the Middle East, and Africa are also contributing to market growth as their aviation sectors develop and expand, introducing new airlines and modernizing existing fleets, thereby creating fresh opportunities for aircraft coffee maker manufacturers.

Segment trends reveal a preference for automatic and semi-automatic coffee makers due to their ease of use, consistency in brewing, and minimal crew intervention requirements. Within aircraft types, commercial aircraft remain the largest segment, but the business jet sector is showing robust growth, driven by an increasing affluent traveler base demanding personalized and premium in-flight amenities. The aftermarket segment, including maintenance, repair, and overhaul (MRO) services, is crucial for market stability, ensuring the longevity and optimal performance of installed units. This segment benefits from regular servicing and part replacements, extending the lifecycle of existing coffee makers and contributing significantly to the overall market revenue.

AI Impact Analysis on Aircraft Coffee Maker Market

User questions related to the impact of AI on the Aircraft Coffee Maker Market often revolve around topics such as predictive maintenance, personalized beverage experiences, and operational efficiency gains. Users are keen to understand how AI can reduce unscheduled maintenance, optimize coffee consumption based on passenger profiles, and streamline galley operations. Concerns include data privacy, the complexity of integrating AI into existing galley systems, and the cost-benefit analysis of such advanced technologies. Expectations are high for AI to enhance reliability, minimize waste, and offer a more tailored service, transforming the traditional in-flight beverage preparation and delivery.

- AI-driven predictive maintenance can forecast potential equipment failures, reducing unscheduled downtime and improving operational efficiency.

- Personalized beverage recommendations powered by AI, leveraging passenger data, can enhance customer satisfaction and tailor in-flight service.

- Optimized inventory management through AI algorithms can predict coffee and ingredient consumption, minimizing waste and ensuring adequate supplies.

- Automation of brewing parameters using AI can ensure consistent coffee quality regardless of altitude or cabin conditions.

- AI integration with cabin management systems can allow for seamless ordering and delivery processes, improving crew workflow.

- Enhanced energy efficiency through AI-controlled brewing cycles can reduce power consumption and contribute to sustainable operations.

DRO & Impact Forces Of Aircraft Coffee Maker Market

The Aircraft Coffee Maker Market is influenced by a complex interplay of drivers, restraints, and opportunities, collectively known as DRO & Impact Forces. The market's growth is primarily propelled by the escalating demand for air travel globally, which directly correlates with an expansion of airline fleets and a concurrent need for modern, efficient galley equipment. Passengers' increasing expectations for high-quality in-flight amenities, including premium beverage services, further stimulate market demand. Continuous technological advancements in brewing technology, material science for lighter components, and smart connectivity features also serve as significant drivers, pushing manufacturers to innovate and offer more sophisticated solutions that enhance both crew efficiency and passenger satisfaction.

However, the market faces several inherent restraints. The high initial investment cost associated with certified aerospace equipment, due to stringent safety regulations and specialized manufacturing processes, can be a barrier for some airlines, particularly smaller regional carriers. Limited cabin space on aircraft imposes design constraints, requiring compact and highly integrated solutions, which can complicate development and increase costs. The complex regulatory environment, involving certifications from bodies like the FAA and EASA, adds layers of testing and compliance, extending product development cycles and further escalating expenses. Additionally, maintenance complexity and the need for specialized personnel to service these units can impact overall operational costs for airlines, posing a challenge to widespread adoption.

Despite these challenges, substantial opportunities exist for market players. The development of eco-friendly and energy-efficient coffee makers aligns with the aviation industry's sustainability goals, offering a compelling selling point. The integration of smart technology, such as IoT connectivity for remote monitoring and diagnostics, presents avenues for enhanced operational efficiency and predictive maintenance. Customization options, allowing airlines to brand and tailor coffee makers to their specific interior designs and service philosophies, offer competitive advantages. Furthermore, market expansion into emerging economies with burgeoning aviation sectors, coupled with extensive retrofit programs for older aircraft, provides robust growth potential. These opportunities incentivize continuous innovation and strategic partnerships within the industry.

Segmentation Analysis

The Aircraft Coffee Maker Market is meticulously segmented to provide a granular understanding of its diverse components and dynamics. This segmentation typically involves categorizing products based on their operational type, the specific aircraft they are designed for, and the sales channel through which they are distributed. Analyzing these segments helps stakeholders identify key growth areas, understand competitive landscapes, and tailor their strategies to specific market needs. The intricate nature of aviation requirements mandates specialized solutions, making these segmentation analyses crucial for both manufacturers and airlines.

Understanding the interplay between these segments is vital for strategic planning. For instance, the demand for automatic coffee makers in commercial aircraft through OEM channels represents a different market dynamic compared to manual units supplied via the aftermarket for general aviation. Each segment presents unique technological requirements, regulatory hurdles, and customer preferences. Manufacturers often specialize in certain segments, developing expertise in specific brewing technologies or aircraft integrations, while airlines evaluate solutions based on their fleet composition, route networks, and passenger service standards. This detailed approach ensures that market offerings are precisely aligned with industry demands.

- By Type:

- Automatic

- Semi-Automatic

- Manual

- By Aircraft Type:

- Commercial Aircraft

- Business Jets

- Military Aircraft

- General Aviation

- By Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket

Value Chain Analysis For Aircraft Coffee Maker Market

The value chain for the Aircraft Coffee Maker Market is characterized by a series of specialized activities, starting from raw material sourcing and extending to end-user consumption and aftermarket services. Upstream analysis involves the procurement of high-grade materials such as stainless steel, specialized plastics, advanced heating elements, and electronic components, all of which must meet stringent aerospace quality and safety standards. Suppliers in this phase are critical for providing components that ensure durability, lightweight properties, and performance under extreme conditions. Research and development activities, including material science and brewing technology innovation, are also foundational upstream processes, driving product differentiation and technological advancements.

Midstream activities encompass the design, manufacturing, assembly, and rigorous testing of the coffee makers. This phase requires specialized engineering expertise to integrate various components into compact, robust, and compliant units. Manufacturing processes must adhere to aviation industry certifications (e.g., AS9100) and strict quality control measures to ensure reliability and safety in flight environments. The complexity of these products necessitates precision manufacturing and thorough validation, including environmental testing for vibration, temperature, and pressure fluctuations. Collaboration between design engineers and regulatory bodies is crucial to ensure compliance throughout the development and production lifecycle.

Downstream analysis focuses on distribution channels and end-user engagement. Direct distribution is common, where manufacturers supply directly to aircraft OEMs for new installations or to airlines for fleet upgrades and replacements. Indirect channels involve MRO (Maintenance, Repair, and Overhaul) service providers, cabin interior integrators, or specialized distributors who facilitate sales and provide ongoing support. Aftermarket services, including spare parts supply, maintenance, and technical support, represent a significant part of the downstream value chain, ensuring the long-term operational integrity of the coffee makers. Effective post-sales support is critical for maintaining customer satisfaction and fostering long-term relationships within the aviation industry.

Aircraft Coffee Maker Market Potential Customers

The primary potential customers and end-users of aircraft coffee makers are broadly categorized within the aviation ecosystem, ranging from major commercial airlines to private aircraft operators. Commercial airlines represent the largest segment, continually seeking to equip their fleets with reliable, efficient, and aesthetically pleasing galley equipment that enhances the passenger experience and crew productivity. These airlines often procure units directly from manufacturers or through major aircraft OEMs during new aircraft acquisition or cabin refurbishment programs. Their purchasing decisions are driven by factors such as durability, ease of maintenance, energy efficiency, and compliance with strict aviation safety regulations. The sheer volume of their operations necessitates robust and scalable solutions.

Beyond commercial aviation, business jet operators and private aircraft owners constitute a growing and highly lucrative customer base. For this segment, customization, premium features, and design integration are paramount. Business jet owners often demand bespoke coffee maker solutions that align with the luxury interiors of their aircraft, offering sophisticated brewing options and high-end aesthetics. The focus here is on delivering a personalized and exclusive in-flight experience, where quality and convenience are non-negotiable. Manufacturers targeting this niche often emphasize compact designs, advanced functionalities, and premium finishes to meet the discerning tastes of their clientele, which include corporations, high-net-worth individuals, and charter companies.

Moreover, military and government aircraft, though a smaller segment, also require specialized coffee makers designed for rugged environments and mission-critical applications. These units must be exceptionally durable, resistant to extreme conditions, and capable of reliable operation during long-haul transport or special operations. The purchasing decisions for this segment are driven by reliability, compliance with military specifications, and ease of field maintenance, rather than passenger luxury. Furthermore, MRO facilities and aircraft refurbishment centers are indirect but significant customers, as they source replacement units and parts for ongoing maintenance and upgrade projects across various aircraft types, ensuring the operational longevity of existing coffee maker installations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 275.3 Million |

| Market Forecast in 2033 | USD 419.8 Million |

| Growth Rate | 6.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | B/E Aerospace (Collins Aerospace), Diethelm Keller Aviation, Safran S.A., Zodiac Aerospace (Safran S.A.), Airbus S.A.S., Boeing, Diehl Aviation, Galley Systems, Astronics Corporation, Turkish Cabin Interior Inc. (TCI), Geven S.p.A., Jamco Corporation, KID-Systeme GmbH, Lufthansa Technik AG, RECARO Aircraft Seating GmbH & Co. KG, Bucher Aerospace, Duni AB, E.I.S. Aircraft GmbH, Rockwell Collins, MGR foamtex Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aircraft Coffee Maker Market Key Technology Landscape

The technology landscape for aircraft coffee makers is continuously evolving, driven by the need for enhanced performance, reliability, and passenger experience, while adhering to strict aviation standards. Modern aircraft coffee makers leverage advanced brewing technologies to ensure consistent quality regardless of altitude or cabin pressure fluctuations. This includes precision temperature control systems, optimized water heating elements, and pressure-equalization mechanisms that mimic ground-level brewing conditions. Furthermore, innovations in filtration systems are crucial for maintaining coffee purity and reducing mineral build-up, thus extending the lifespan of the equipment and minimizing maintenance requirements. The emphasis is on delivering a cafe-quality beverage in a challenging operational environment.

Material science plays a pivotal role in the technological advancement of these units. Manufacturers are increasingly utilizing lightweight, high-strength composite materials and aerospace-grade alloys to reduce the overall weight of the coffee makers, directly contributing to fuel efficiency for airlines. These materials also need to be highly durable, resistant to corrosion, and capable of withstanding the rigorous demands of frequent use and varying cabin conditions. Ergonomic design and modular construction are also key technological aspects, facilitating easier installation, maintenance, and integration into compact galley spaces, which are a premium on any aircraft.

Connectivity and smart features are rapidly becoming integral to the next generation of aircraft coffee makers. This includes the implementation of IoT capabilities for remote monitoring, allowing airlines to track usage patterns, predict maintenance needs, and manage inventory more efficiently. Touchscreen interfaces, intuitive controls, and integration with broader cabin management systems are enhancing usability for cabin crew. Some advanced systems also incorporate self-cleaning cycles and diagnostic tools, further streamlining operations and reducing manual intervention. These technological integrations aim to create a more autonomous, efficient, and user-friendly experience, aligning with the broader trend of digital transformation within aviation.

Regional Highlights

- North America: A mature market with consistent demand for advanced and replacement units, driven by significant commercial airline fleets and a robust business jet sector. Focus on technological upgrades and adherence to FAA regulations.

- Europe: Characterized by a strong presence of major aircraft manufacturers and airlines, leading to continuous demand for innovative, high-quality, and environmentally compliant coffee makers. Emphasis on EASA certifications and efficiency.

- Asia Pacific (APAC): The fastest-growing region, fueled by expanding air travel, new airline ventures, and significant investments in fleet expansion and modernization. Emerging economies are key growth drivers, creating substantial opportunities for new installations.

- Latin America: Growing aviation sector with increasing air passenger traffic, leading to moderate demand for new and refurbished aircraft galley equipment, including coffee makers.

- Middle East and Africa (MEA): Marked by substantial investments in aviation infrastructure and luxury air travel, particularly in the Middle East, driving demand for high-end, customizable coffee maker solutions for premium cabins. Africa's developing aviation market offers future growth potential.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aircraft Coffee Maker Market.- B/E Aerospace (Collins Aerospace)

- Diethelm Keller Aviation

- Safran S.A.

- Zodiac Aerospace (Safran S.A.)

- Airbus S.A.S.

- Boeing

- Diehl Aviation

- Galley Systems

- Astronics Corporation

- Turkish Cabin Interior Inc. (TCI)

- Geven S.p.A.

- Jamco Corporation

- KID-Systeme GmbH

- Lufthansa Technik AG

- RECARO Aircraft Seating GmbH & Co. KG

- Bucher Aerospace

- Duni AB

- E.I.S. Aircraft GmbH

- Rockwell Collins

- MGR foamtex Ltd.

Frequently Asked Questions

What factors are driving the growth of the aircraft coffee maker market?

The market is primarily driven by increasing global air passenger traffic, expansion and modernization of aircraft fleets, rising passenger expectations for premium in-flight services, and ongoing technological advancements in brewing and material efficiency. Airlines are also focused on enhancing operational efficiency and crew convenience.

How do aircraft coffee makers differ from standard coffee machines?

Aircraft coffee makers are specifically designed to meet stringent aviation safety standards and operate reliably under unique conditions such as varying cabin pressures, altitudes, and limited space. They feature robust, lightweight construction, specialized brewing technology for consistent quality, and certifications like RTCA DO-160, unlike standard household or commercial machines.

What are the latest technological advancements in aircraft coffee makers?

Recent advancements include precision temperature control, optimized water heating and filtration systems, use of lightweight composite materials for reduced weight, and the integration of smart features like IoT connectivity for remote monitoring, predictive maintenance, and seamless cabin management system integration. Eco-friendly designs are also a growing trend.

Which regions are experiencing significant growth in this market?

Asia Pacific is witnessing the most significant growth due to rapid fleet expansion and increased air travel demand. North America and Europe remain key markets for upgrades and replacements, while the Middle East shows strong demand for luxury and customized solutions, and Latin America and Africa are emerging growth areas.

What impact do regulatory standards have on aircraft coffee maker design?

Regulatory standards from bodies like the FAA and EASA heavily influence aircraft coffee maker design, demanding rigorous testing for safety, flammability, electromagnetic compatibility, and operational reliability. These regulations dictate material choices, electrical components, and overall system integration, ensuring the units function safely and effectively in an aerospace environment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager