Aircraft Manufacturing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439842 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Aircraft Manufacturing Market Size

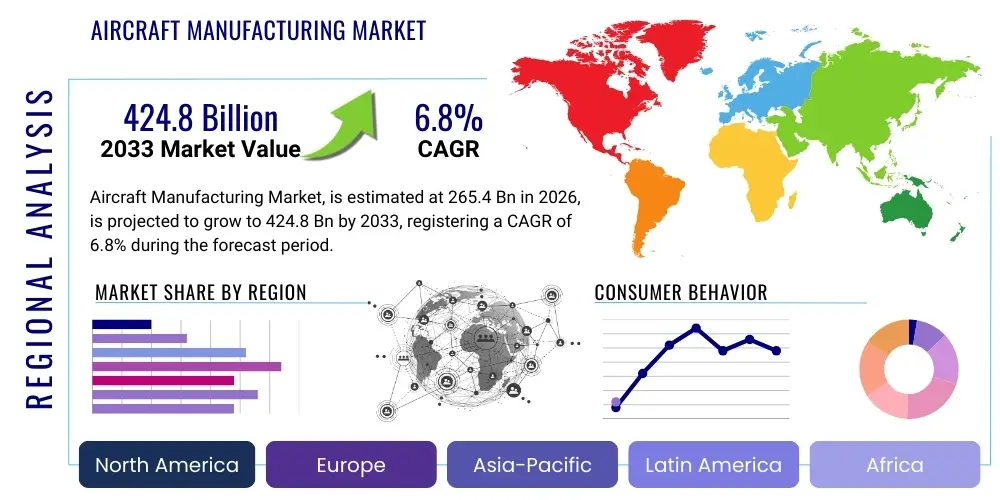

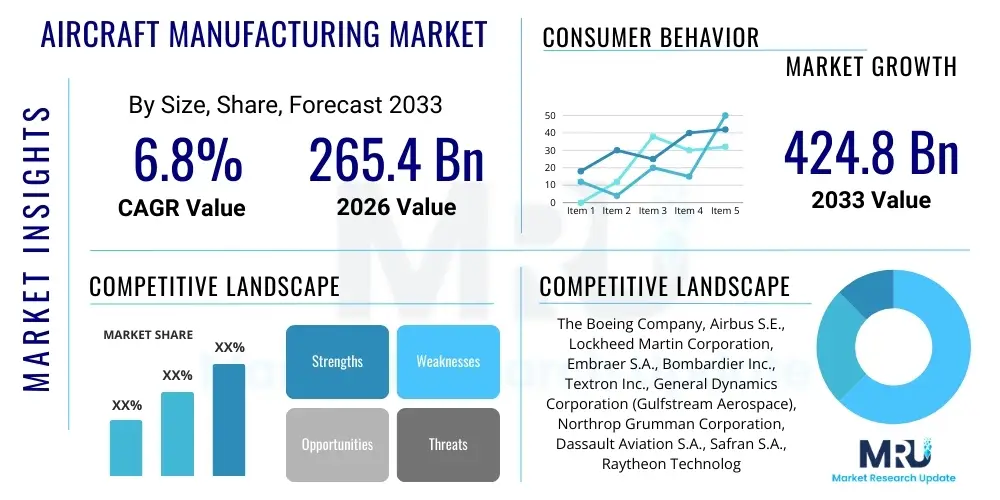

The Aircraft Manufacturing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 265.4 billion in 2026 and is projected to reach USD 424.8 billion by the end of the forecast period in 2033.

Aircraft Manufacturing Market introduction

The aircraft manufacturing market encompasses the global industry dedicated to the design, development, production, assembly, and maintenance of all types of aircraft, ranging from commercial airliners and cargo planes to military jets, business aircraft, helicopters, and unmanned aerial vehicles (UAVs). Products include advanced aerostructures, sophisticated propulsion systems, and integrated avionics, serving a diverse set of applications such as commercial passenger and cargo transport, national defense and security operations, executive travel, and specialized services like search and rescue or agricultural spraying. This pivotal industry significantly contributes to global connectivity, economic growth, and technological advancement, enabling efficient movement of people and goods while also playing a critical role in national security. The market is primarily driven by increasing global air passenger traffic, rising defense expenditures, the ongoing need for fleet modernization, and continuous innovation in aerospace technologies aimed at improving fuel efficiency, safety, and operational capabilities.

Aircraft Manufacturing Market Executive Summary

The aircraft manufacturing market is characterized by several key business trends, including a strong emphasis on sustainability through the development of electric, hybrid-electric, and hydrogen-powered aircraft, alongside a growing focus on sustainable aviation fuels (SAF). Digital transformation, incorporating advanced manufacturing techniques like additive manufacturing and the implementation of digital twins, is reshaping production processes, while supply chain resilience remains a critical concern post-global disruptions. Regional dynamics show North America and Europe maintaining leadership in research, development, and high-value manufacturing, with the Asia-Pacific region emerging as a significant growth engine driven by expanding air travel demand and new regional manufacturing capabilities. Segment trends indicate robust demand in the commercial aircraft sector, particularly for narrow-body jets, supported by increasing passenger numbers and fleet renewal cycles, while military aircraft demand is sustained by geopolitical tensions and modernization initiatives, and the business jet and general aviation segments are experiencing a steady recovery.

AI Impact Analysis on Aircraft Manufacturing Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the aircraft manufacturing market frequently center on themes of operational efficiency, cost reduction, innovation acceleration, and the transformation of traditional manufacturing processes. Common questions explore how AI can optimize design and engineering, streamline production lines, enhance predictive maintenance, and manage complex supply chains. There is also significant interest in AI's role in improving aircraft safety and performance through advanced analytics, as well as its potential to drive the development of next-generation autonomous flight systems and urban air mobility solutions. Furthermore, users often express curiosity about the implications of AI for workforce development, requiring new skills and collaborative human-AI interfaces.

The collective sentiment reflects an expectation that AI will be a transformative force, enabling manufacturers to address challenges such as reducing development cycles, improving product quality, and meeting stringent environmental regulations. Concerns also surface around the integration complexities, data security, regulatory frameworks for AI-driven systems, and the ethical considerations associated with increased automation and potential job displacement. The overarching expectation is for AI to serve as a catalyst for a smarter, more efficient, and more sustainable future in aircraft manufacturing, fundamentally altering how aircraft are conceived, built, and maintained throughout their lifecycle. This technological evolution is anticipated to enhance decision-making across all operational levels, from strategic planning to real-time production adjustments, thereby maximizing resource utilization and minimizing waste.

Ultimately, the user landscape indicates a strong desire for clarity on the practical applications and tangible benefits of AI in this high-stakes industry. Manufacturers are expected to leverage AI for everything from advanced materials discovery and generative design to optimizing factory floor layouts and robotic automation. The potential for AI to personalize manufacturing processes, predict component failures with greater accuracy, and manage vast datasets generated during flight operations for continuous improvement is seen as paramount. This deep integration of AI is not merely about incremental improvements but about fostering a paradigm shift in how the industry operates, fostering unprecedented levels of innovation, precision, and responsiveness to market demands.

- Enhanced Generative Design and Engineering: AI algorithms accelerate the design process, optimize aerodynamics, structural integrity, and material usage, leading to lighter, more efficient aircraft.

- Optimized Production and Assembly: AI-powered robotics and automation improve precision, speed, and safety in manufacturing, reducing human error and production bottlenecks.

- Predictive Maintenance and Quality Control: AI analyzes sensor data to predict component failures, enabling proactive maintenance, reducing downtime, and ensuring higher quality standards throughout the aircraft lifecycle.

- Supply Chain Optimization: AI systems manage and predict supply chain disruptions, optimize inventory levels, and enhance logistics, ensuring timely delivery of parts and materials.

- Autonomous Systems and Urban Air Mobility (UAM): AI is crucial for developing autonomous flight capabilities, supporting navigation, decision-making, and control for next-generation aircraft and UAM platforms.

- Simulation and Testing Efficiency: AI-driven simulations allow for rapid virtual prototyping and testing, significantly reducing the need for costly physical prototypes and accelerating certification processes.

- Sustainable Manufacturing Practices: AI helps optimize energy consumption in factories, reduce waste, and manage the lifecycle of materials, contributing to more environmentally friendly production.

DRO & Impact Forces Of Aircraft Manufacturing Market

The Aircraft Manufacturing Market is primarily driven by the escalating demand for air travel, both passenger and cargo, propelled by global economic growth, increasing urbanization, and expanding international trade. This demand necessitates extensive fleet modernization and expansion programs by airlines worldwide, further bolstered by rising defense budgets globally in response to evolving geopolitical landscapes and the continuous need for advanced military aircraft. Additionally, relentless technological advancements, particularly in fuel efficiency, lightweight materials, and digital manufacturing, serve as key drivers, compelling manufacturers to innovate and airlines to upgrade. However, the market faces significant restraints, including exceptionally high research and development costs, prolonged product development cycles stretching over years, and a highly stringent regulatory environment that imposes rigorous certification processes. Supply chain vulnerabilities, exacerbated by recent global events, and the industry's substantial environmental footprint, alongside the capital-intensive nature of operations, further impede growth.

Despite these challenges, substantial opportunities exist, particularly in the realm of sustainable aviation, encompassing electric, hybrid-electric, and hydrogen propulsion systems, as well as the adoption of Sustainable Aviation Fuels (SAF). The burgeoning Urban Air Mobility (UAM) and Advanced Air Mobility (AAM) sectors, coupled with the rapid evolution of Unmanned Aerial Vehicles (UAVs) for diverse commercial and defense applications, present new avenues for market expansion. Digitalization across the value chain, from additive manufacturing to digital twins and advanced analytics, offers opportunities for greater efficiency and innovation. The market is subject to various impact forces, where the bargaining power of buyers (airlines and governments) is significant due to large-volume procurements and long-term contracts. The bargaining power of suppliers, especially for specialized components like engines and avionics, is also high. The threat of new entrants is low due to immense capital requirements, technological barriers, and regulatory hurdles, while the threat of substitutes is minimal given the unique advantages of air travel. Competitive rivalry remains intense among a few dominant global players, driving continuous innovation and market consolidation.

Segmentation Analysis

The Aircraft Manufacturing Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics, reflecting the multifaceted nature of aerospace production. This segmentation allows for precise analysis of market trends, competitive landscapes, and growth opportunities across various aircraft types, applications, structural components, and technological adoptions. Understanding these distinct segments is crucial for stakeholders to tailor strategies, identify niche markets, and respond effectively to evolving industry demands. The market structure highlights the specialization required within different manufacturing domains, from the intricate assembly of commercial jets to the robust construction of military aircraft, and the innovative development of future aerial mobility solutions.

- By Aircraft Type

- Commercial Aircraft (Narrow-body, Wide-body, Regional Jets)

- Military Aircraft (Fighters, Bombers, Transport Aircraft, Surveillance Aircraft, Trainers)

- General Aviation Aircraft (Piston, Turboprop, Business Jets)

- Helicopters (Commercial, Military)

- Unmanned Aerial Vehicles (UAVs)/Drones (Military, Commercial, Consumer)

- By Component/System

- Aerostructures (Fuselage, Wings, Empennage, Landing Gear Systems)

- Engines (Turbofan, Turboprop, Turboshaft, Piston)

- Avionics (Navigation, Communication, Flight Control, Surveillance Systems)

- Aircraft Interiors (Seats, Galleys, Lavatories, Cabin Management Systems)

- Other Systems (Hydraulics, Electrical, Environmental Control)

- By Application/End-Use

- Passenger Transport

- Cargo Transport

- Military & Defense

- Business & General Aviation

- Special Mission (e.g., Search & Rescue, Surveillance, Agriculture)

- By Technology

- Traditional Manufacturing

- Advanced Manufacturing (Additive Manufacturing, Automated Assembly)

- Digital Systems Integration (IoT, AI/ML, Digital Twin)

- Sustainable Aviation Technologies (Electric/Hybrid-Electric Propulsion, Hydrogen, SAF-compatible)

- By Material

- Aluminum Alloys

- Titanium Alloys

- Composite Materials (Carbon Fiber, Fiberglass)

- Steel Alloys

Value Chain Analysis For Aircraft Manufacturing Market

The aircraft manufacturing value chain is an intricate ecosystem, beginning with upstream activities focused on the procurement and processing of highly specialized raw materials and complex sub-components. This segment involves advanced metallurgy for aluminum, titanium, and steel alloys, along with the sophisticated production of composite materials by specialized suppliers, which are then integrated into larger structural elements by tier-2 and tier-1 component manufacturers. These include engine producers, avionics system developers, and landing gear manufacturers, forming the foundational inputs for aircraft assemblers. The core manufacturing stage involves the complex assembly of these thousands of components into a finished aircraft by major OEMs, requiring extensive engineering, automation, and stringent quality control processes. Downstream activities primarily involve direct sales and delivery of completed aircraft to end-users such as commercial airlines, cargo operators, and government defense agencies.

Post-delivery, the downstream segment extends into extensive aftermarket services, including maintenance, repair, and overhaul (MRO), spare parts supply, and aircraft modifications, ensuring the operational longevity and safety of the fleet. Distribution channels in this market are predominantly direct, particularly for large commercial and military aircraft, where OEMs engage in direct negotiations and long-term contracts with airlines and national governments due to the high value and customization involved. For smaller general aviation aircraft or specific components, indirect channels through authorized dealers and distributors may play a role. The relationship between direct and indirect channels is often blurred, with OEMs frequently providing direct support and parts through their own service networks while also leveraging a network of approved MRO providers for regional services. The entire chain is characterized by deep partnerships, stringent quality requirements, and significant regulatory oversight, ensuring the highest standards of safety and performance from raw material to end-of-life services.

Aircraft Manufacturing Market Potential Customers

The primary potential customers and end-users of the aircraft manufacturing market are diverse, reflecting the broad utility of aviation across various sectors. Commercial airlines represent the largest segment, consistently investing in new aircraft for fleet expansion and modernization to meet the growing global demand for passenger and cargo air travel. Cargo operators, including major logistics companies, constitute another significant customer base, requiring dedicated freighter aircraft to support global supply chains and e-commerce growth. National governments and defense organizations are pivotal customers, procuring military aircraft such as fighters, bombers, transport planes, and surveillance aircraft to enhance their defense capabilities and ensure national security.

Beyond these large institutional buyers, the market also caters to business corporations and high-net-worth individuals who purchase business jets for executive travel, valuing efficiency, privacy, and convenience. General aviation enthusiasts and flight schools form a customer segment for smaller piston and turboprop aircraft, supporting recreational flying, pilot training, and localized transport needs. Additionally, specialized service providers and government agencies (e.g., coast guards, border patrols, forestry services) acquire aircraft for specific missions like search and rescue, law enforcement, disaster response, and environmental monitoring. Aerospace leasing companies also play a crucial intermediary role, purchasing aircraft from manufacturers and leasing them to airlines, thereby facilitating fleet acquisition without substantial upfront capital investment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 265.4 billion |

| Market Forecast in 2033 | USD 424.8 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | The Boeing Company, Airbus S.E., Lockheed Martin Corporation, Embraer S.A., Bombardier Inc., Textron Inc., General Dynamics Corporation (Gulfstream Aerospace), Northrop Grumman Corporation, Dassault Aviation S.A., Safran S.A., Raytheon Technologies Corporation (Collins Aerospace, Pratt & Whitney), BAE Systems plc, Leonardo S.p.A., Hindustan Aeronautics Limited (HAL), Mitsubishi Heavy Industries, Co., Ltd., Commercial Aircraft Corporation of China, Ltd. (COMAC), Sukhoi Company, Kawasaki Heavy Industries, Ltd., Pilatus Aircraft Ltd., Cirrus Aircraft. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aircraft Manufacturing Market Key Technology Landscape

The aircraft manufacturing market is characterized by a dynamic and continually evolving technology landscape, with innovation driving advancements across all stages of the product lifecycle, from design to end-of-life. Advanced materials are at the forefront, with a significant shift towards lightweight composites such as carbon fiber reinforced polymers (CFRPs) and advanced metallic alloys (e.g., titanium, aluminum-lithium) to improve fuel efficiency, reduce weight, and enhance structural integrity. Additive manufacturing, or 3D printing, is gaining traction for producing complex components with optimized geometries, reducing material waste, and accelerating prototyping and production times. Digital transformation technologies, including the Internet of Things (IoT), Artificial Intelligence (AI), Machine Learning (ML), and Digital Twins, are revolutionizing factory operations, enabling predictive maintenance, real-time quality control, and highly efficient, automated assembly lines. These technologies facilitate a more connected and intelligent manufacturing ecosystem, enhancing decision-making and operational agility.

Furthermore, the industry is heavily investing in sustainable aviation technologies to meet stringent environmental targets. This includes research and development into electric and hybrid-electric propulsion systems for shorter-range aircraft, hydrogen-powered concepts for longer-range applications, and the widespread adoption of Sustainable Aviation Fuels (SAFs) to drastically reduce carbon emissions. Advanced avionics and sophisticated flight control systems continue to evolve, integrating features like enhanced automation, improved navigation accuracy, and robust cybersecurity measures to ensure safety and operational reliability in increasingly complex airspaces. Robotics and automation are becoming pervasive, not only in assembly but also in quality inspection and material handling, significantly boosting efficiency and precision. The convergence of these technologies is not only redefining how aircraft are built but also shaping the future capabilities and environmental footprint of the entire aerospace sector, fostering a new era of innovation and sustainability.

Regional Highlights

- North America: Dominates the aircraft manufacturing market, driven by significant defense spending, robust commercial aviation demand, and a strong presence of major OEMs and technology innovators. The region is a hub for R&D in advanced aerospace technologies, including next-generation military aircraft and commercial jets, with substantial investments in new materials and digital manufacturing processes.

- Europe: A key player with major commercial aircraft manufacturers (e.g., Airbus) and a strong network of aerospace suppliers. The region focuses heavily on sustainable aviation initiatives, including electric propulsion and SAFs, and boasts significant capabilities in military aircraft, helicopters, and general aviation, supported by extensive collaborative R&D programs.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapidly increasing air passenger traffic, fleet expansion by emerging airlines, and significant investments in aviation infrastructure. Countries like China and India are developing indigenous manufacturing capabilities and becoming major consumers of both commercial and military aircraft, with a growing focus on regional jet development.

- Latin America: Features a notable presence with specialized manufacturers (e.g., Embraer) primarily in regional jets and business aviation. The region's market growth is tied to economic development, leading to increased air travel demand and potential for fleet modernization, although it often relies on imports for larger commercial and military aircraft.

- Middle East and Africa (MEA): Characterized by substantial investments in new aircraft by rapidly expanding airlines in the Middle East, driven by strategic geographic locations and robust tourism sectors. African countries are gradually investing in fleet upgrades and aviation infrastructure, with defense spending also contributing to military aircraft procurement in select nations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aircraft Manufacturing Market.- The Boeing Company

- Airbus S.E.

- Lockheed Martin Corporation

- Embraer S.A.

- Bombardier Inc.

- Textron Inc.

- General Dynamics Corporation (Gulfstream Aerospace)

- Northrop Grumman Corporation

- Dassault Aviation S.A.

- Safran S.A.

- Raytheon Technologies Corporation (Collins Aerospace, Pratt & Whitney)

- BAE Systems plc

- Leonardo S.p.A.

- Hindustan Aeronautics Limited (HAL)

- Mitsubishi Heavy Industries, Co., Ltd.

- Commercial Aircraft Corporation of China, Ltd. (COMAC)

- Sukhoi Company

- Kawasaki Heavy Industries, Ltd.

- Pilatus Aircraft Ltd.

- Cirrus Aircraft

Frequently Asked Questions

What is the projected growth rate for the Aircraft Manufacturing Market?

The Aircraft Manufacturing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, reaching an estimated USD 424.8 billion by the end of the forecast period.

How is AI impacting the aircraft manufacturing process?

AI is transforming aircraft manufacturing by enabling generative design, optimizing production with robotics, enhancing predictive maintenance, streamlining supply chains, and driving the development of autonomous flight systems for improved efficiency, safety, and innovation.

What are the primary drivers for growth in the aircraft manufacturing market?

Key growth drivers include increasing global air passenger and cargo traffic, rising defense budgets, the ongoing need for fleet modernization by airlines, and continuous technological advancements aimed at improving fuel efficiency and operational performance.

Which regions are leading in aircraft manufacturing and market growth?

North America and Europe currently lead in aircraft manufacturing with established OEMs and R&D capabilities, while the Asia Pacific region is projected to be the fastest-growing market due to expanding air travel demand and significant investment in aviation infrastructure.

What role do sustainable aviation technologies play in the market?

Sustainable aviation technologies, including electric/hybrid-electric propulsion, hydrogen power, and Sustainable Aviation Fuels (SAFs), are crucial for meeting environmental regulations, reducing carbon footprint, and driving future innovation in the aircraft manufacturing market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager