Aircraft Propeller Governors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439894 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Aircraft Propeller Governors Market Size

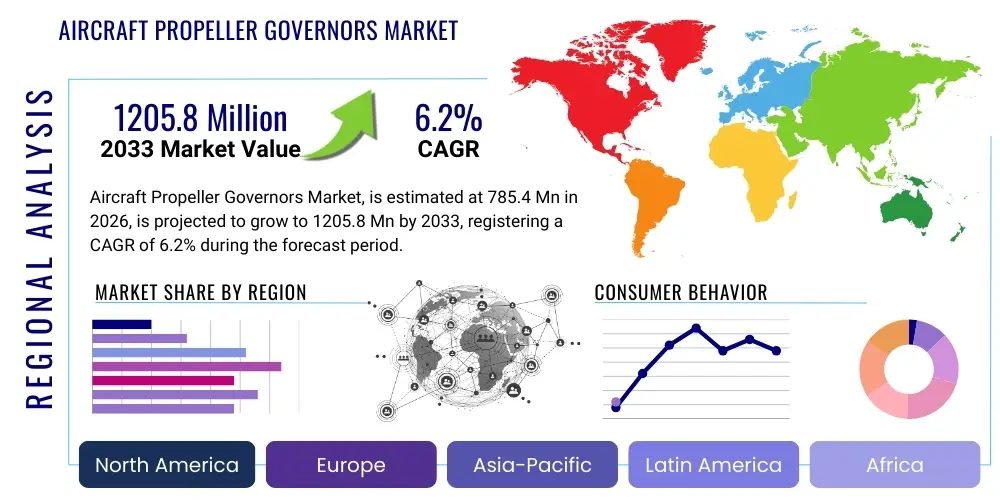

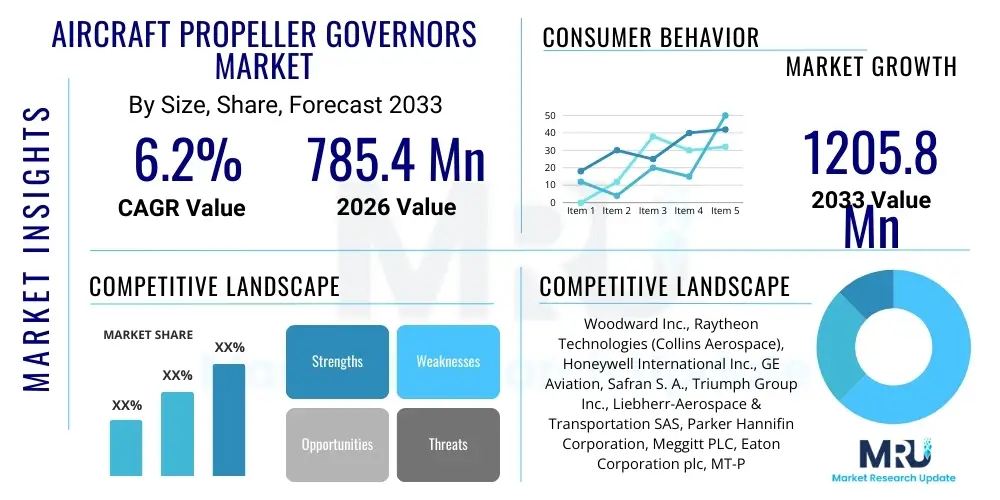

The Aircraft Propeller Governors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 785.4 Million in 2026 and is projected to reach USD 1205.8 Million by the end of the forecast period in 2033.

Aircraft Propeller Governors Market introduction

The Aircraft Propeller Governors Market plays a pivotal role in the aerospace industry, underpinning the efficient and safe operation of a vast array of propeller-driven aircraft, ranging from small general aviation planes to large turboprops and military transports. These sophisticated devices are integral to the propulsion system, meticulously controlling the pitch of the propeller blades to maintain a constant engine speed (RPM) regardless of flight conditions or engine power settings. This critical function ensures optimal engine performance, maximizes fuel efficiency, and significantly reduces operational noise, thereby enhancing overall aircraft performance and passenger comfort. The technological evolution of propeller governors, from purely hydro-mechanical systems to advanced electronic and FADEC-integrated solutions, has consistently aimed at improving precision, reliability, and responsiveness. Major applications span commercial aviation, where they are essential for regional turboprops; general aviation, providing critical control for private and training aircraft; and military aviation, where robust performance and adaptability are paramount for transport and special mission aircraft. The primary benefits derived from these systems include superior thrust management, reduced pilot workload, enhanced operational safety, and considerable cost savings through optimized fuel burn. Key driving factors propelling market expansion encompass the escalating global demand for air travel, the continuous modernization and expansion of commercial and military aircraft fleets, and a persistent industry focus on achieving greater fuel economy and compliance with increasingly stringent environmental regulations.

Aircraft Propeller Governors Market Executive Summary

The Aircraft Propeller Governors Market is experiencing robust growth, driven by dynamic shifts across global aviation sectors. Business trends highlight a strong emphasis on aftermarket services and MRO (Maintenance, Repair, and Overhaul) activities, as existing fleets require ongoing support, upgrades, and component replacements to extend their operational lifespans and meet new performance standards. Original Equipment Manufacturers (OEMs) are focused on developing integrated propeller control systems that leverage advanced digital technologies, often incorporating Full Authority Digital Engine Control (FADEC) for enhanced precision and automation. There is a discernible trend towards lighter, more durable materials and modular designs, simplifying maintenance and improving overall system reliability. Regional trends demonstrate North America and Europe as historically dominant markets, largely due to their mature aerospace industries, significant installed aircraft bases, and strong defense expenditures. However, the Asia Pacific region is rapidly emerging as a high-growth market, propelled by substantial investments in aviation infrastructure, a booming demand for air travel, and expanding regional aircraft fleets. Latin America and the Middle East and Africa are also showing promising growth, albeit from a smaller base, driven by increasing connectivity and strategic defense modernizations. Segment trends indicate a sustained demand for both traditional hydro-mechanical governors, particularly in legacy and general aviation aircraft, and a burgeoning demand for advanced electronic governors in new generation aircraft. The aftermarket segment, encompassing both components and services, continues to hold a substantial share, while the OEM segment is driven by new aircraft deliveries and technological innovation. The military aviation segment remains a consistent demand source, influenced by global geopolitical dynamics and defense spending cycles, requiring highly resilient and adaptable propeller control solutions.

AI Impact Analysis on Aircraft Propeller Governors Market

Artificial Intelligence is poised to significantly transform the Aircraft Propeller Governors Market by introducing unprecedented levels of optimization, predictive capability, and autonomous functionality. Common user questions related to AI's impact often revolve around how it can enhance maintenance predictability, improve flight performance, facilitate integration with emerging autonomous flight systems, and streamline the design and manufacturing processes. Users are keenly interested in AI's potential to move beyond traditional scheduled maintenance to highly accurate predictive analytics, minimizing downtime and reducing operational costs. There is also significant anticipation regarding AI's ability to fine-tune propeller pitch and RPM in real-time, adapting to dynamic atmospheric conditions for optimal fuel efficiency and reduced emissions. Furthermore, the aerospace community is exploring how AI can contribute to more resilient and intelligent control algorithms for next-generation aircraft, including UAVs and potentially urban air mobility vehicles, where autonomous decision-making for propulsion systems will be critical. Concerns frequently raised include the robustness of AI algorithms in safety-critical systems, data security implications for flight parameters, and the regulatory frameworks required to certify AI-driven components. Ultimately, AI is expected to revolutionize not only the operational aspects but also the lifecycle management and developmental pathways for propeller governors, pushing the boundaries of what these systems can achieve in terms of intelligence and adaptability.

- Predictive Maintenance and Diagnostics: AI algorithms analyze vast datasets from sensors on propeller governors to predict potential failures before they occur, enabling proactive maintenance, reducing unscheduled downtime, and optimizing component lifespan. This shifts maintenance from time-based or reactive approaches to condition-based strategies, significantly improving operational efficiency and safety.

- Real-time Performance Optimization: AI can process real-time flight data, environmental conditions, and engine parameters to continuously adjust propeller governor settings for optimal thrust, fuel efficiency, and noise reduction. This dynamic optimization surpasses static programming, adapting to changing flight envelopes and maximizing performance across diverse operational scenarios.

- Autonomous Control and Integration: As autonomous flight systems advance, AI will play a critical role in integrating propeller governor controls with wider aircraft autonomy. This includes intelligent decision-making for propulsion adjustments during complex maneuvers, emergency situations, or in uncrewed aerial vehicle (UAV) operations, enhancing mission success and reducing reliance on human input.

- Advanced Design and Simulation: AI-powered simulation tools can rapidly iterate through countless design variations for propeller governors, optimizing for weight, material properties, durability, and aerodynamic efficiency. Machine learning algorithms can identify optimal configurations for specific aircraft types and operational requirements, accelerating the development cycle and reducing R&D costs.

- Supply Chain and Manufacturing Efficiency: AI can optimize the manufacturing processes of propeller governors by identifying bottlenecks, predicting equipment failures, and improving quality control. Furthermore, AI-driven supply chain management can forecast demand more accurately, manage inventory levels efficiently, and mitigate disruptions, ensuring timely delivery of components.

DRO & Impact Forces Of Aircraft Propeller Governors Market

The Aircraft Propeller Governors Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities, alongside broader Impact Forces that shape its trajectory. Key drivers include the consistent growth in global air passenger traffic and freight volumes, necessitating an expansion of both commercial and general aviation fleets, many of which utilize propeller-driven aircraft. The increasing focus on fuel efficiency and reduced emissions across the aerospace industry acts as a significant catalyst, pushing for advanced propeller governor designs that can offer superior performance optimization. Moreover, the ongoing modernization of aging military and commercial aircraft fleets worldwide drives demand for upgrades and replacements of existing propeller governor systems. Conversely, the market faces several restraints, notably the inherently high costs associated with research, development, and stringent certification processes for new aerospace components, which can be a significant barrier to entry for new players and slow down innovation cycles. The long operational lifespan of aircraft means that replacement cycles for components like propeller governors are infrequent, leading to a demand curve primarily driven by new aircraft deliveries and aftermarket maintenance rather than rapid turnover. Furthermore, the market is susceptible to global economic downturns, which can negatively impact air travel demand and airline profitability, subsequently affecting aircraft orders and maintenance budgets. Opportunities for growth are plentiful, particularly in the burgeoning market for Unmanned Aerial Vehicles (UAVs) and Urban Air Mobility (UAM) platforms, many of which will rely on sophisticated propeller control systems. The adoption of advanced materials such as composites and alloys offers the potential for lighter, more durable, and more efficient governors. Retrofitting existing aircraft with technologically superior governors presents another significant opportunity, allowing older fleets to meet modern performance and environmental standards. The expansion of aviation infrastructure and fleet growth in emerging economies, particularly in Asia Pacific, Latin America, and parts of Africa, also provides fertile ground for market expansion. Impact forces such as evolving international aviation regulations, including noise and emissions standards, directly influence product development and market demand. Geopolitical stability or instability can impact military aviation spending, a key segment for propeller governors, while technological advancements in propulsion systems continue to redefine performance expectations and integration requirements for governors. Environmental concerns also pressure manufacturers to innovate cleaner and more efficient solutions, further shaping market dynamics.

Segmentation Analysis

The Aircraft Propeller Governors Market is comprehensively segmented to provide a detailed understanding of its diverse components and underlying dynamics. This segmentation allows for precise analysis of market trends, identification of high-growth areas, and strategic planning based on specific product characteristics, application areas, aircraft types, and end-user demands. The market is primarily divided by the type of technology employed in the governor system, the specific application within the aviation sector, the class of aircraft in which it is installed, and the end-user or point of sale, whether for new aircraft assembly or aftermarket maintenance. Each segment exhibits unique growth drivers and competitive landscapes, reflecting the varied requirements of modern aviation. Understanding these segments is crucial for market participants to tailor their offerings and strategies effectively, addressing the specific needs of commercial airlines, military operators, general aviation pilots, and maintenance organizations. The interplay between these segments also highlights the technological advancements and service demands that are shaping the future of propeller control systems in aircraft.

- By Type

- Hydro-mechanical Governors: Traditional systems relying on oil pressure and mechanical linkages for pitch control.

- Electronic Governors: Advanced systems using digital electronics for precise control, often integrated with FADEC.

- FADEC-integrated Electronic Governors: Fully digital systems that integrate propeller control with overall engine management.

- Standalone Electronic Governors: Digital governors that operate independently of a full FADEC system but offer electronic precision.

- By Application

- Commercial Aviation: Governors for regional turboprops, commuter aircraft, and other commercial propeller-driven aircraft.

- Military Aviation: Robust governors for military transport, surveillance, and training aircraft.

- General Aviation: Governors for private planes, business aircraft, and flight training aircraft.

- By Aircraft Type

- Fixed-Wing Aircraft: Propeller governors designed for conventional airplanes.

- Rotary-Wing Aircraft: Governors for helicopters and other rotorcraft, managing rotor RPM.

- By End-Use

- Original Equipment Manufacturer (OEM): Sales to aircraft manufacturers for new aircraft installation.

- Aftermarket (MRO): Sales of replacement parts, upgrades, and maintenance services for existing aircraft.

Value Chain Analysis For Aircraft Propeller Governors Market

The value chain for the Aircraft Propeller Governors Market is intricate, involving a series of sequential activities from raw material sourcing to final end-user application and ongoing support. At the upstream end, the process begins with the procurement of specialized raw materials, including high-grade metals such as aluminum alloys, steel, and titanium, as well as advanced composites and polymers essential for manufacturing durable and lightweight components. These materials are supplied by a specialized network of vendors to component manufacturers who produce critical sub-assemblies like valves, bearings, gears, sensors, actuators, and electronic control units. Precision engineering and adherence to stringent aerospace quality standards are paramount at this stage. Moving downstream, these manufactured components and sub-assemblies are then supplied to propeller governor system integrators or directly to aircraft propulsion system manufacturers. These entities assemble the complete governor units, often integrating them with propeller systems and engine control units, especially in the case of FADEC-integrated solutions. The finished propeller governors are then distributed through various channels. Direct distribution is common for OEM sales, where governor manufacturers supply directly to major aircraft manufacturers like Boeing, Airbus, Embraer, and Cessna for installation in new aircraft. For the aftermarket segment, distribution channels include authorized distributors, third-party MRO providers, and increasingly, direct sales from manufacturers to airlines, private operators, or military logistics departments. Indirect channels leverage a network of global distributors and regional service centers to ensure prompt availability of spare parts and maintenance support. This multifaceted value chain emphasizes the collaborative nature of the aerospace industry, where quality, reliability, and efficient logistics are critical at every stage, from material genesis to final operational deployment and through-life support for the aircraft.

Aircraft Propeller Governors Market Potential Customers

The potential customers for the Aircraft Propeller Governors Market are diverse, encompassing a broad spectrum of entities within the global aerospace and defense industries. Primarily, major aircraft manufacturers represent a significant customer base, requiring governors for integration into their new production lines for commercial, general, and military aircraft. This includes global giants such as Airbus, Boeing, Embraer, Textron Aviation (Cessna, Beechcraft), Pilatus, and other regional jet and turboprop manufacturers who require reliable and high-performance propeller control systems for their new aircraft models. Beyond initial equipment, a substantial portion of the market caters to the aftermarket segment. Here, airlines operating propeller-driven fleets, regional carriers, and cargo operators are crucial customers, purchasing replacement governors, spare parts, and seeking maintenance and overhaul services to ensure their aircraft remain airworthy and efficient. Independent Maintenance, Repair, and Overhaul (MRO) facilities worldwide also constitute a vital customer segment, acting as intermediaries or direct service providers for aircraft owners and operators, procuring components for repairs and scheduled maintenance. Furthermore, military and defense organizations globally are key end-users, requiring highly robust and specialized propeller governors for military transport aircraft, surveillance platforms, and training aircraft, often prioritizing durability, mission-readiness, and security of supply. Government agencies involved in search and rescue, law enforcement, and environmental monitoring also operate propeller-driven fleets, making them potential customers. Lastly, private aircraft owners and charter companies in the general aviation sector represent a consistent, albeit fragmented, demand for propeller governors and associated services, driven by safety, performance, and regulatory compliance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 785.4 Million |

| Market Forecast in 2033 | USD 1205.8 Million |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Woodward Inc., Raytheon Technologies (Collins Aerospace), Honeywell International Inc., GE Aviation, Safran S. A., Triumph Group Inc., Liebherr-Aerospace & Transportation SAS, Parker Hannifin Corporation, Meggitt PLC, Eaton Corporation plc, MT-Propeller Entwicklung GmbH, Sensenich Propeller Manufacturing Co. Inc., Hartzell Propeller Inc., McCauley Propeller Systems, Dowty Propellers. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aircraft Propeller Governors Market Key Technology Landscape

The Aircraft Propeller Governors Market is continuously evolving, driven by significant advancements in aerospace technology, a relentless pursuit of efficiency, and increasingly stringent regulatory demands. At the forefront of this technological landscape is the widespread adoption of electronic propeller governors, which offer substantially greater precision, reliability, and integration capabilities compared to their traditional hydro-mechanical counterparts. These electronic systems are frequently integrated with Full Authority Digital Engine Control (FADEC) systems, creating a seamless, centralized digital platform for managing both engine and propeller parameters. FADEC integration allows for optimal propeller pitch adjustments in real-time, adapting to varying flight conditions for maximum fuel efficiency, reduced emissions, and enhanced engine performance, while simultaneously reducing pilot workload through automated and precise control. Another critical area of development involves the use of advanced materials, including lightweight composites and high-strength alloys, which contribute to the reduction of overall system weight, improve durability, and extend the lifespan of propeller governor components. This material innovation also enhances resistance to harsh operational environments. Furthermore, there is a growing emphasis on incorporating advanced sensing and diagnostic technologies into governors. These intelligent sensors provide real-time data on system health, enabling sophisticated predictive maintenance capabilities through prognostics and health management (PHM) systems. This shift allows for condition-based maintenance, minimizing unscheduled downtime and optimizing maintenance schedules, thereby reducing operational costs and improving aircraft availability. Additive manufacturing, or 3D printing, is also gaining traction for producing complex internal components of governors, offering design flexibility, rapid prototyping, and the ability to create intricate geometries that enhance performance and reduce assembly complexity. The development of more robust and secure software for these digital control systems is also paramount, ensuring resilience against cyber threats and guaranteeing the integrity of flight-critical functions. Additionally, advancements in hydraulic actuation systems for hydro-mechanical governors, even as electronic systems gain prominence, continue to focus on improving responsiveness, reliability, and reducing hydraulic fluid contamination for legacy and general aviation applications. These interconnected technological advancements collectively define the cutting edge of propeller governor design and functionality, addressing the industry's demand for smarter, more efficient, and safer aircraft propulsion systems.

Regional Highlights

- North America: This region historically dominates the Aircraft Propeller Governors Market due to the presence of major aircraft manufacturers, a substantial installed base of commercial and general aviation aircraft, and significant defense spending. The demand is driven by fleet modernization, robust MRO activities, and a strong emphasis on technological innovation. The United States, in particular, leads in both production and consumption, reflecting its mature aerospace industry and extensive air travel network.

- Europe: A key market distinguished by the presence of prominent aerospace companies like Airbus and various engine manufacturers, Europe exhibits strong demand for advanced propeller governors. The region's focus on environmental regulations, particularly regarding noise and emissions, drives the adoption of more efficient and technologically sophisticated propeller control systems. Germany, France, and the UK are major contributors to market growth, with a strong emphasis on both OEM and aftermarket segments.

- Asia Pacific (APAC): Emerging as the fastest-growing market, APAC is fueled by booming air travel demand, significant investments in aviation infrastructure, and rapid expansion of both commercial and general aviation fleets. Countries like China, India, and Southeast Asian nations are adding numerous propeller-driven aircraft, driving both OEM and aftermarket demand for governors. Increasing defense budgets in several countries also contribute to military aircraft procurement.

- Latin America: This region represents an emerging market with steady growth, primarily driven by increasing regional air connectivity, the expansion of low-cost carriers, and the modernization of existing aircraft fleets. While smaller in comparison to North America or Europe, the demand for propeller governors is expected to rise with the ongoing development of aviation infrastructure and economic growth encouraging air travel. Brazil and Mexico are key markets within this region.

- Middle East and Africa (MEA): The MEA region demonstrates consistent growth, particularly influenced by strategic defense spending and the development of major aviation hubs. Investments in new airports and fleet expansion in key countries like the UAE, Saudi Arabia, and South Africa contribute to the demand for propeller governors. The region also sees significant MRO activity for both commercial and military aircraft.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aircraft Propeller Governors Market.- Woodward Inc.

- Raytheon Technologies (Collins Aerospace)

- Honeywell International Inc.

- GE Aviation

- Safran S. A.

- Triumph Group Inc.

- Liebherr-Aerospace & Transportation SAS

- Parker Hannifin Corporation

- Meggitt PLC

- Eaton Corporation plc

- MT-Propeller Entwicklung GmbH

- Sensenich Propeller Manufacturing Co. Inc.

- Hartzell Propeller Inc.

- McCauley Propeller Systems

- Dowty Propellers (part of GE Aviation)

Frequently Asked Questions

Analyze common user questions about the Aircraft Propeller Governors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an aircraft propeller governor?

The primary function of an aircraft propeller governor is to automatically regulate the pitch of the propeller blades to maintain a constant engine Revolutions Per Minute (RPM) regardless of varying flight conditions, engine power settings, or airspeeds. This ensures optimal engine performance, maximizes fuel efficiency, and enhances overall aircraft control and safety by providing constant speed operation.

How does a propeller governor contribute to aircraft fuel efficiency?

A propeller governor contributes to fuel efficiency by maintaining the engine at its most efficient operating RPM. By constantly adjusting the propeller blade angle to match engine load, it prevents the engine from over-revving or under-revving, allowing it to operate in its "sweet spot" where fuel consumption is minimized for the thrust produced, leading to significant operational cost savings over time.

What are the main types of propeller governors used in aviation?

The main types of propeller governors are hydro-mechanical and electronic. Hydro-mechanical governors use engine oil pressure and mechanical components to adjust blade pitch, common in older and general aviation aircraft. Electronic governors, often integrated with Full Authority Digital Engine Control (FADEC) systems, utilize digital signals for precise and responsive control, predominant in modern turboprop and military aircraft due to their superior accuracy and integration capabilities.

What factors are driving the growth of the Aircraft Propeller Governors Market?

The growth of the Aircraft Propeller Governors Market is primarily driven by the increasing global demand for air travel, leading to expansion and modernization of commercial and general aviation fleets. Other key drivers include a growing emphasis on fuel efficiency and reduced emissions, the need for advanced propeller control in military aircraft, and robust aftermarket demand for maintenance and upgrades of existing systems. Emerging applications in UAVs also present significant growth opportunities.

How does FADEC technology impact modern propeller governor systems?

FADEC (Full Authority Digital Engine Control) technology profoundly impacts modern propeller governor systems by integrating their functions into a centralized, digital engine management platform. This allows for highly precise, automated, and optimized control of both engine and propeller parameters, leading to enhanced performance, improved fuel efficiency, reduced pilot workload, advanced diagnostics, and greater system reliability compared to standalone or purely mechanical governor systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager