Aircraft Washing Trucks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432707 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Aircraft Washing Trucks Market Size

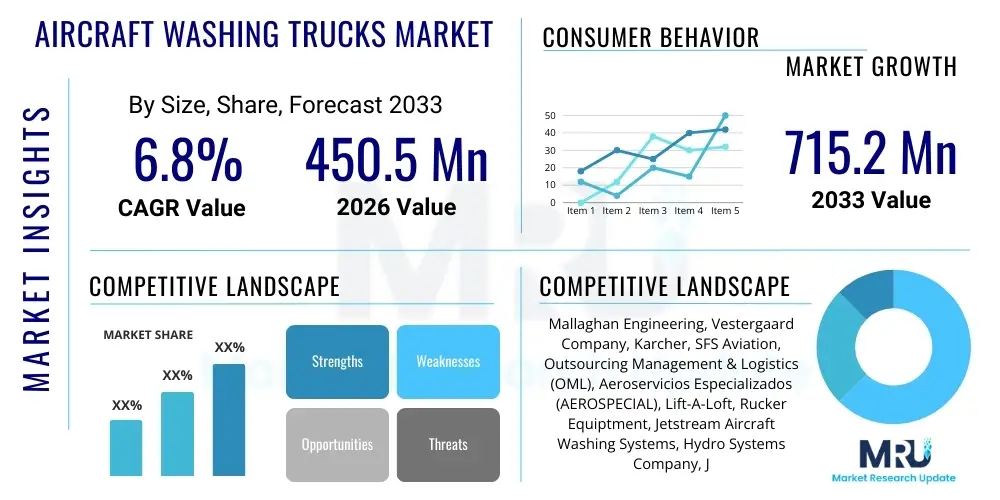

The Aircraft Washing Trucks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 million in 2026 and is projected to reach USD 715.2 million by the end of the forecast period in 2033.

Aircraft Washing Trucks Market introduction

The Aircraft Washing Trucks Market encompasses specialized heavy-duty ground support equipment (GSE) designed for the routine and deep cleaning of commercial, military, and private aircraft. These highly sophisticated vehicles are crucial for maintaining the operational integrity and aesthetic condition of aviation assets. The core functionality includes the ability to apply specialized, often non-toxic, cleaning agents and water using precision delivery systems, such as hydraulic booms and automated nozzle assemblies, capable of reaching high fuselage sections and wingspans of wide-body aircraft. Routine cleaning is essential not only for visual inspection and corrosion prevention but critically for aerodynamic performance; a clean aircraft experiences less drag, directly resulting in significant savings in aviation fuel consumption. Consequently, these trucks represent a vital investment for airlines and maintenance facilities focused on operational efficiency and compliance.

The product portfolio within this market ranges from smaller, truck-mounted units primarily used for regional jets and narrow-body aircraft, to large, custom-built robotic systems designed to service the largest wide-body planes, such as the Airbus A380 or Boeing 747. Key features often include onboard water heating capabilities, integrated filtration systems for water recycling, and advanced control interfaces that allow operators to precisely manage water pressure and chemical dilution ratios. Major applications span high-volume international airports, which require rapid turnaround cleaning between flights, dedicated Maintenance, Repair, and Overhaul (MRO) facilities where deep structural cleaning precedes inspections, and governmental airbases requiring specialized procedures for military aircraft. The benefits derived from using these trucks include standardized cleaning quality, enhanced safety compared to manual methods, and reduction in environmental impact through optimized chemical usage and advanced water conservation technologies.

The primary driving factors propelling market expansion are the rapid global expansion of commercial aircraft fleets, particularly in emerging economies of the Asia Pacific region, and the escalating cost of aviation fuel, which intensifies the focus on drag reduction through immaculate external surfaces. Furthermore, the stringent and evolving regulatory environment, particularly concerning environmentally sound maintenance practices, favors manufacturers that offer closed-loop water recycling systems and biodegradable cleaning solutions. The move away from labor-intensive manual methods towards fast, automated, truck-based systems offers clear operational advantages, including reduced labor costs, minimization of cleaning time, and higher consistency, ensuring the market maintains a robust growth trajectory throughout the forecast period of 2026 to 2033.

Aircraft Washing Trucks Market Executive Summary

The Aircraft Washing Trucks Market is currently undergoing a significant technological transformation, shifting from semi-manual brush-based systems to highly automated, robotic, and brushless cleaning solutions. Business trends indicate a preference among end-users for service-based models, including leasing and full-service cleaning contracts, rather than outright capital purchase, particularly among medium-sized MROs seeking to reduce upfront expenditure while securing access to the latest technology. Manufacturers are focusing R&D on sustainability, notably integrating multi-stage water recycling units that achieve high reuse rates, and developing integrated telematics systems for predictive maintenance and optimized fleet management. The competitive landscape is marked by specialist Ground Support Equipment (GSE) manufacturers differentiating themselves through proprietary automation software and specialized chemical compatibility for composite aircraft materials.

Geographically, market growth is distinctly polarized. Mature markets in North America and Europe lead in the adoption of high-cost, advanced autonomous technologies and stringent environmental compliance, driving demand for technologically superior replacement equipment. Conversely, the Asia Pacific region is the global hotspot for volume growth, driven by massive increases in commercial fleet size and the concurrent development of new airport and MRO infrastructure. Regional differences in regulatory requirements significantly influence product design; for example, European specifications often emphasize noise reduction and zero wastewater discharge, while Middle Eastern market demands prioritize features combating sand and dust contamination common in arid environments. This regional divergence requires manufacturers to maintain highly flexible and adaptable product lines.

Segmentation analysis reveals that the robotic/automated systems segment is expanding at the fastest pace, reflecting the aviation industry's deep commitment to minimizing maintenance downtime and maximizing cleaning accuracy. The wide-body aircraft category commands premium pricing and specialized engineering due to the complex access requirements and high volumes of water needed for coverage. In terms of application, MRO facilities represent a stable revenue stream for deep cleaning units, while commercial airports drive demand for rapid, high-throughput washing solutions. Overall market momentum is strongly positive, underpinned by the indispensable nature of the equipment for flight safety and operational cost management.

AI Impact Analysis on Aircraft Washing Trucks Market

User inquiries concerning AI's integration into the Aircraft Washing Trucks Market primarily center on transforming washing from a mechanical process into an intelligent, data-driven operation. Key questions often relate to the feasibility of achieving full autonomy on the apron, the accuracy of computer vision systems in detecting subtle damage during washing, and how AI can dynamically optimize resource usage—specifically water and specialized detergents—based on real-time surface assessment. Users seek assurance regarding the safety protocols and fail-safes implemented in AI-guided systems operating in close proximity to expensive aircraft structures. The analysis confirms strong user interest in solutions that not only automate labor but also enhance quality control and reduce the environmental footprint. The core expectation is that AI will standardize cleaning consistency, eliminate potential human errors resulting from fatigue or varied skill levels, and ultimately deliver a higher return on investment (ROI) through optimized operational logistics.

The practical application of AI in this domain spans machine learning algorithms applied to predictive maintenance for the washing truck's complex mechanical components, and advanced computer vision systems integrated into the cleaning booms. These vision systems use deep learning models trained on vast datasets of contamination types, allowing the system to instantly classify surface debris (e.g., soot, bird strike residue, de-icing fluid) and precisely adjust parameters like water temperature, nozzle angle, and pressure for specific areas. This granular control minimizes the risk of damage, reduces water consumption by avoiding unnecessary high-pressure cleaning on light contamination, and ensures regulatory compliance by tracking chemical run-off metrics in real-time. This integration shifts the washing process from a standardized routine into a tailored, aircraft-specific, intelligent procedure.

Furthermore, AI algorithms are critical for path planning and anti-collision systems. By integrating data from LiDAR, ultrasonic sensors, and aircraft CAD models, AI generates optimized, three-dimensional washing paths that cover every surface efficiently while maintaining safe clearances. This capability is paramount for fully autonomous operations. The cumulative impact is a substantial increase in operational efficiency, a reduction in the required crew size, and a decrease in the overall cost per wash cycle. As AI capabilities mature, the market is expected to see a proliferation of software-as-a-service (SaaS) models bundled with the trucks, providing continuous updates to the cleaning algorithms and expanded diagnostic capabilities. This ensures the washing truck remains aligned with the needs of ever-evolving aircraft materials and maintenance requirements.

- AI-driven optimization of washing parameters: Computer vision systems analyze aircraft contamination levels (e.g., soot, fluid residue) to adjust water pressure, detergent concentration, and washing duration dynamically, minimizing resource waste and optimizing chemical usage.

- Autonomous Navigation and Positioning: AI algorithms enable autonomous docking and precise maneuvering of the washing truck and boom around complex aircraft geometries, using LiDAR and 3D mapping to eliminate human error and potential surface damage.

- Predictive Maintenance for Washing Systems: Machine learning analyzes sensor data from pumps, filters, and hydraulic systems to predict component failure, scheduling proactive maintenance and ensuring high operational readiness of the washing fleet through reduced unexpected downtime.

- Defect Detection Integration: High-resolution cameras combined with AI image recognition software detect minor paint chips, signs of corrosion, or superficial structural damage during the washing process, seamlessly integrating maintenance checks directly into the routine cleaning cycle for improved inspection efficiency.

- Optimized Water Recycling Management: AI systems enhance the efficiency of onboard water treatment and recycling units by analyzing the composition of collected greywater and predicting the optimal chemical dosage needed for purification, maximizing reuse rates and minimizing environmental discharge impact.

DRO & Impact Forces Of Aircraft Washing Trucks Market

The Aircraft Washing Trucks Market is significantly influenced by a powerful confluence of economic incentives and regulatory necessities. Key drivers include the direct correlation between a clean aircraft surface and optimal aerodynamic efficiency, resulting in measurable reductions in fuel burn, which is a major operating cost for airlines. This economic driver is amplified by continuous global fleet expansion, particularly the rise of low-cost carriers demanding rapid turnaround and minimal maintenance downtime. Furthermore, stringent aviation safety bodies worldwide mandate regular, standardized cleaning procedures to prevent corrosion, inspect structural integrity, and ensure the effective functioning of vital components, thereby embedding routine washing as a critical, non-discretionary operational activity.

Conversely, market growth is restrained by several factors, chief among them being the extremely high initial capital expenditure required for purchasing advanced, specialized washing trucks, which poses a barrier, especially for smaller MRO operations or regional airports. The operational environment also imposes restraints; outdoor washing activities are often highly dependent on favorable weather conditions, particularly temperature and wind, leading to periods of downtime. Moreover, the complexity and cost associated with training personnel to safely and effectively operate these sophisticated hydraulic and automated systems, coupled with securing operating permits in regulated airport environments, further temper the rate of market penetration in certain geographies.

Opportunities for future expansion are substantial, primarily driven by the global imperative for sustainable aviation operations. Manufacturers offering advanced water recycling technologies and innovative, environmentally benign chemical solutions stand to capture significant market share as global environmental standards tighten. The increasing adoption of advanced composite materials in new generation aircraft (e.g., Boeing 787, Airbus A350) creates a specialized opportunity for highly precise, non-contact robotic washing systems that mitigate the risk of surface damage associated with traditional mechanical brushes. The integration of IoT and cloud-based fleet management solutions presents an opportunity to optimize truck deployment and maintenance schedules across vast airport operational landscapes, enhancing service delivery and profitability for contractors.

Segmentation Analysis

Market segmentation for Aircraft Washing Trucks provides a detailed view of product diversity and specific customer needs, catering to the distinct requirements of different aviation stakeholders. Segmentation by aircraft type is foundational, as the size, reach, and capacity of the washing system must be precisely tailored to service narrow-body or wide-body aircraft, affecting the truck’s overall specifications and cost. The technological segmentation, specifically the division between brushing and non-contact robotic systems, highlights the industry's shift toward high-speed, damage-preventive cleaning methods crucial for modern composite airframes. Furthermore, distinguishing between end-user applications—commercial airports, MROs, and military bases—allows manufacturers to customize durability, regulatory compliance features, and operational capacity to align with the unique demands and utilization rates characteristic of each customer group.

- By Aircraft Type:

- Narrow-Body Aircraft Washing Trucks: Designed for high maneuverability and fast turnaround times for common commercial jets (e.g., A320, B737).

- Wide-Body Aircraft Washing Trucks: Feature extensive boom reach and high-capacity water tanks, specialized for large transports (e.g., B777, A380).

- Regional Jet/Turboprop Aircraft Washing Trucks: Smaller, more compact units optimized for regional airport operations.

- By Washing Mechanism:

- Brushing Systems (Manual/Semi-Automated): Traditional methods using rotating brushes, often integrated with a water spray, suitable for robust surfaces.

- Brushless/High-Pressure Water Systems: Utilize high-velocity water and specialized chemicals, favored for sensitive surfaces and efficient rinsing.

- Robotic/Automated Cleaning Systems: Advanced systems using AI and precision robotics for non-contact, highly customized cleaning paths, minimizing labor.

- By Application:

- Commercial Airports: Demand rapid, high-frequency washing services, often managed by centralized ground handling services.

- Maintenance, Repair, and Overhaul (MRO) Facilities: Require specialized deep-cleaning capabilities prior to structural inspections and component replacement.

- Military Bases and Government Aviation Centers: Demand ruggedized, often self-contained systems with specialized features for tactical aircraft.

- Private and General Aviation Services: Smaller, flexible units for exclusive FBO (Fixed Base Operator) services.

- By Component/System:

- Water Supply and Recycling Units: Focusing on filtration, treatment, and maximizing water reuse rates.

- Chemical and Detergent Dosing Systems: Precision dispensing units for complex, biodegradable cleaning agents.

- Boom and Lift Systems: Hydraulic assemblies that dictate the reach, height, and stability of the cleaning apparatus.

- Control and Navigation Systems: Software and hardware interfaces for autonomous control and operator guidance, including anti-collision sensors.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Aircraft Washing Trucks Market

The value chain begins in the upstream segment with the procurement of essential raw materials and specialized sub-components. This phase involves acquiring heavy-duty commercial truck chassis from established automotive manufacturers, specialized high-pressure pumping systems, advanced membrane filters, and complex hydraulic components for the booms. Success in the upstream market depends on securing reliable supply chains for these durable, high-specification parts that must withstand harsh operating conditions and frequent chemical exposure. Suppliers must adhere to stringent aerospace standards for safety and reliability, requiring close collaborative relationships between the truck manufacturer and component providers to ensure system integration compatibility.

The midstream phase, involving manufacturing and assembly, is where the core value is added. This includes the custom design of the washing module, integrating the water tanks, heating elements, filtration systems, and the dynamic control software onto the chassis. Manufacturers focus heavily on optimizing the system layout for weight distribution, stability during high-reach operations, and ease of maintenance. Distribution channels for Aircraft Washing Trucks are typically highly specialized. Direct sales are common due to the high capital cost, complexity, and customization required by large airlines and MRO groups. This allows manufacturers to provide direct technical consultation, customized financing, and integrated long-term service agreements. Indirect channels utilize specialized Ground Support Equipment (GSE) distributors who offer regional support, especially in markets where regulatory hurdles or language barriers necessitate local expertise.

The downstream activities center on the end-user operations, including installation, commissioning, training, and robust after-sales support. This market phase is characterized by significant revenue generation from maintenance contracts, spare parts supply, and chemical consumable distribution. Potential customers, including major international airports and flagship airlines, evaluate purchases based not only on initial cost but heavily on reliability, mean time between failures (MTBF), and the manufacturer's ability to provide swift global service support. The trend toward leasing models also places increased responsibility on manufacturers and service providers to maintain high operational readiness, strengthening the focus on predictive maintenance and rapid deployment of technical teams.

Aircraft Washing Trucks Market Potential Customers

The primary customer base for Aircraft Washing Trucks consists of organizations with significant capital assets in aircraft and a critical need to maximize operational efficiency and aircraft lifespan. Major global airline groups and national flag carriers are key end-users, requiring dedicated fleets of washing trucks stationed at their main operational and maintenance hubs to ensure their aircraft are cleaned on defined schedules, crucial for adherence to warranty requirements and fuel efficiency optimization. These customers typically demand high-throughput, technologically advanced automated systems capable of servicing diverse fleet types, placing a high value on reliability and after-sales service quality.

A second major segment comprises third-party Maintenance, Repair, and Overhaul (MRO) service providers. These facilities handle extensive contract work for multiple airlines and require flexible, robust washing trucks capable of accommodating large aircraft volumes and different cleaning specifications. MROs often seek trucks that are adaptable to deep cleaning protocols, including specific chemical application required before non-destructive testing (NDT) inspections. Their purchase decisions are heavily influenced by the equipment's versatility, longevity, and the ability to minimize water and chemical consumption to manage operating expenses.

Finally, large international airport authorities and military organizations represent substantial customer segments. Airports often purchase or contract the washing service centrally, requiring vehicles that meet strict airport apron safety and environmental regulations. Military bases require specialized, ruggedized washing trucks often designed for rapid deployment and operation in varied environmental conditions, focusing on durability and self-sufficiency, including specialized systems for handling hazardous materials sometimes found on military aircraft.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 715.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mallaghan Engineering, Vestergaard Company, Karcher, SFS Aviation, Outsourcing Management & Logistics (OML), Aeroservicios Especializados (AEROSPECIAL), Lift-A-Loft, Rucker Equiptment, Jetstream Aircraft Washing Systems, Hydro Systems Company, JBT Corporation, TLD Group, Guangtai Airports Equipment, Schopf Maschinenbau, Weihai Guangtai Airport Equipment, Toyota Industries Corporation, Global Ground Support, Aviatron, Inc., WASP Engineering, ITW GSE. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aircraft Washing Trucks Market Key Technology Landscape

The contemporary technology landscape of the Aircraft Washing Trucks Market is defined by the confluence of robust mechanical engineering and highly sophisticated digital control systems. Central to this evolution is the design and integration of multi-articulated hydraulic booms, which must provide extreme reach and stability while maintaining precision control in varied environmental conditions. These booms are increasingly equipped with inertial guidance systems and laser-based sensors to ensure the cleaning head maintains a safe, consistent distance from the aircraft surface throughout the cleaning cycle, crucial for preventing localized pressure damage or abrasion, especially on vulnerable areas like wing leading edges and engine cowlings. The power systems are also evolving, with increasing interest in hybrid and electric chassis configurations to meet strict air quality and noise regulations within airport environments.

A pivotal technological shift involves resource management and environmental compliance, driven by the scarcity of water and strict regulatory discharge standards globally. Modern washing trucks feature highly advanced, integrated water reclamation systems that employ multi-stage processes including chemical flocculation, ultrafiltration, and sometimes reverse osmosis, enabling the recycling of a significant majority of the water used (often exceeding 85%). This technology minimizes the environmental footprint and drastically reduces operational dependency on external water sources. Simultaneously, chemical dosing systems have become digitized, using flow meters and precision pumps to ensure the optimal, minimal amount of specialized, eco-friendly detergent is used, enhancing cleaning effectiveness while protecting aircraft paint and composite structures.

The most disruptive technological innovation is the adoption of robotics and artificial intelligence (AI) to facilitate non-contact cleaning. Robotic systems utilize 3D scanning technology (LiDAR or structured light) to create a precise digital twin of the aircraft’s external geometry. AI algorithms then generate the most efficient cleaning path, executing the washing process via high-pressure jets without physical brushing. This robotic automation significantly reduces the time required for a full wash, enhances safety, minimizes labor costs, and provides unparalleled consistency, positioning it as the future standard, particularly for wide-body fleet maintenance. Connectivity via IoT sensors allows for continuous performance monitoring and remote diagnostics, ensuring the high complexity of these systems is matched by maximized operational uptime.

Regional Highlights

- Asia Pacific (APAC): The APAC region commands attention as the leading growth market due to massive capital expenditure on aviation infrastructure and an unprecedented rate of commercial fleet deliveries. Countries like China, India, and Southeast Asian economies are rapidly expanding their MRO capabilities and international airport capacity. The demand profile in APAC favors high-throughput, often custom-built washing trucks that can handle the sheer volume of aircraft and the high utilization rates of regional fleets, driving robust market expansion for both automated and traditional systems.

- North America: Representing a technologically mature market, North America focuses on equipment replacement, technology upgrades, and automation integration. Key market drivers include stringent environmental regulations necessitating closed-loop water systems and the high cost of labor, which accelerates the transition toward semi-autonomous and robotic washing solutions. Large airline operators frequently utilize fleet management software integrated with washing trucks (telematics) to optimize maintenance schedules and ensure regulatory compliance.

- Europe: The European market is characterized by high demand for sustainability and efficiency, driven by strong regulatory frameworks from entities like EASA. European buyers prioritize low-emission chassis, superior noise damping, and market-leading water recycling capabilities. The market is stable, with growth stemming primarily from technological substitution—replacing aging fleets with environmentally superior, automated models—and service contracts supporting major hub airports.

- Latin America (LATAM): Growth in LATAM is promising but often constrained by economic volatility and infrastructure investment timelines. While fleet expansion drives underlying demand, price sensitivity means that used or refurbished high-quality equipment is often considered alongside new purchases. The focus is on reliable, durable, and relatively simple-to-maintain units, particularly in developing aviation centers in countries such as Brazil, Mexico, and Chile.

- Middle East and Africa (MEA): Dominated by major aviation hubs in the Gulf Cooperation Council (GCC) nations, this region demands highly specialized equipment designed to counter severe environmental challenges, primarily intense heat and abrasive sand/dust. These operators invest heavily in premium, high-capacity trucks featuring advanced filtration and climate control systems. Demand is consistent due to the strategic importance of these global transit hubs and their high fleet utilization rates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aircraft Washing Trucks Market.- Mallaghan Engineering

- Vestergaard Company

- Karcher

- SFS Aviation

- Outsourcing Management & Logistics (OML)

- Aeroservicios Especializados (AEROSPECIAL)

- Lift-A-Loft

- Rucker Equiptment

- Jetstream Aircraft Washing Systems

- Hydro Systems Company

- JBT Corporation

- TLD Group

- Guangtai Airports Equipment

- Schopf Maschinenbau

- Weihai Guangtai Airport Equipment

- Toyota Industries Corporation

- Global Ground Support

- Aviatron, Inc.

- WASP Engineering

- ITW GSE

- Houchin Aerospace

- Tronair

- Unitron

- Doosan Industrial Vehicle

Frequently Asked Questions

Analyze common user questions about the Aircraft Washing Trucks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for advanced aircraft washing trucks?

The key drivers include regulatory mandates for maintaining aircraft structural integrity, the economic necessity for fuel efficiency improvement (as cleanliness reduces aerodynamic drag and operating costs), the high cost of labor, and the rising adoption of automated systems to minimize aircraft ground time and maximize operational readiness.

How do brushless and robotic washing systems differ from traditional mechanical methods?

Brushless and robotic systems utilize non-contact methods, employing high-pressure water jets, specialized chemicals, and AI-guided precision mapping to clean surfaces without physical abrasion. This offers superior speed, consistency, and significantly reduces the risk of damage to modern composite materials compared to older mechanical brushing techniques.

What role does water recycling play in the modern aircraft washing truck market?

Water recycling is a critical industry requirement, driven by environmental sustainability goals and operational cost reduction. Modern trucks feature sophisticated closed-loop filtration and treatment systems (often including reverse osmosis) that enable the reuse of 85% to 90% of the wash water, minimizing discharge and resource consumption.

Which geographical region is expected to show the highest growth rate and why?

Asia Pacific (APAC) is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR). This rapid growth is driven by substantial investment in new airport infrastructure, accelerated commercial fleet expansion, and the establishment of major Maintenance, Repair, and Overhaul (MRO) centers across the region.

What are the main technological challenges facing autonomous aircraft washing trucks?

The main challenges involve achieving guaranteed, highly accurate navigation and anti-collision safety in dynamic airport environments, ensuring reliable sensor performance under diverse weather conditions, and developing AI algorithms capable of rapidly adapting the washing path to highly complex and non-standardized aircraft geometries.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager