Airgel Insulation Cotton Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432062 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Airgel Insulation Cotton Market Size

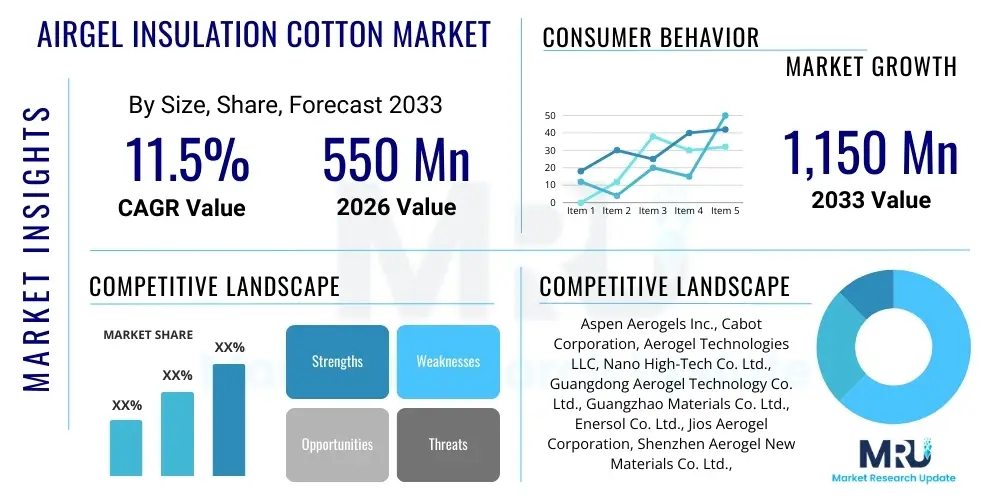

The Airgel Insulation Cotton Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 1,150 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the increasing global emphasis on energy efficiency, particularly in high-performance applications across the aerospace, industrial, and construction sectors. Airgel insulation cotton, recognized for its superior thermal properties compared to traditional materials, offers a unique blend of lightweight structure and exceptional insulating capability, making it indispensable for critical temperature control environments.

Airgel Insulation Cotton Market introduction

The Airgel Insulation Cotton Market encompasses the production, distribution, and application of flexible, lightweight thermal insulating materials derived from aerogels, typically reinforced with fibers like cotton or polyester to provide structural integrity and ease of handling. Aerogels are synthetically produced materials known for being the lightest solids, characterized by extremely low density and exceptionally high porosity, translating into unparalleled thermal resistance. Airgel insulation cotton leverages these properties, transforming brittle aerogels into durable, flexible blankets or sheets suitable for diverse industrial and consumer uses. This product primarily serves as a high-performance thermal barrier in scenarios where space is limited and extreme temperature differentials must be managed effectively.

Major applications for airgel insulation cotton span high-tech industries, including oil and gas pipelines, cryogenic storage systems, electric vehicle (EV) battery packs, and specialized building envelopes requiring minimal thickness yet maximum R-value. The primary benefits driving adoption include significantly reduced thermal conductivity, excellent fire resistance, hydrostatic compression resistance, and overall weight savings compared to conventional mineral wool or foam insulations. These characteristics are particularly valuable in sectors like aerospace, where minimizing mass is critical, and in industrial processes demanding continuous operation and safety under harsh thermal loads. The integration of aerogel technology with cotton or fibrous matrices enhances its flexibility and makes installation substantially easier across complex geometries.

Driving factors for the market expansion include stringent global energy conservation mandates, a surge in demand for high-efficiency insulation solutions in emerging economies, and the rapid technological advancements in material processing that lower production costs. Furthermore, the growing adoption of electric vehicles necessitates sophisticated thermal management systems for battery longevity and safety, positioning airgel insulation cotton as a key enabling material. The transition toward sustainable and green building practices also favors high-performance materials that reduce energy consumption over the lifecycle of structures, thus solidifying the airgel product's market position.

Airgel Insulation Cotton Market Executive Summary

The Airgel Insulation Cotton Market is experiencing robust growth fueled by technological innovation and escalating regulatory pressure for energy efficiency globally. Key business trends indicate a pivot towards customized product formulations designed specifically for niche applications, such as high-temperature industrial furnaces and next-generation cryogenics. Investment in scalable manufacturing processes, aimed at reducing the currently high production cost of aerogels, is a central theme among major market players, which directly impacts the material's accessibility across broader markets like residential construction. The convergence of material science and manufacturing automation is expected to accelerate product diversification and market penetration throughout the forecast period, emphasizing flexibility and durability in finished insulation forms.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, largely due to rapid industrialization, massive infrastructure projects, and significant governmental focus on sustainable energy and insulation standards, especially in China and India. North America and Europe maintain strong market shares, driven by established regulatory frameworks mandating stringent thermal performance standards in construction and the high demand from sophisticated end-use industries like aerospace and defense. These mature markets focus heavily on research and development to optimize performance characteristics and integrate airgel insulation into complex systems, such as subsea oil and gas infrastructure, where reliability is paramount.

Segmentation trends highlight that the blanket segment, owing to its flexibility and ease of installation, dominates the market based on form. By application, the oil and gas segment remains a primary revenue contributor due to the critical insulation needs of pipelines and deep-sea equipment operating under extreme conditions. However, the fastest growth is anticipated in the electric vehicle and general industrial insulation segments, reflecting global shifts towards electrification and the continuous necessity to upgrade aging industrial infrastructure to meet modern efficiency benchmarks. Market participants are focusing heavily on developing thinner, more water-resistant airgel compositions to cater to the stringent requirements of new mobility and construction standards.

AI Impact Analysis on Airgel Insulation Cotton Market

Common user questions regarding AI's impact on the Airgel Insulation Cotton Market typically revolve around optimizing material composition, predicting long-term performance under various environmental stresses, and enhancing manufacturing process efficiency. Users are concerned about how AI can lower the production cost of aerogel precursors and improve quality consistency. Key themes emerging from this analysis include the potential for AI-driven predictive maintenance in industrial applications utilizing airgel insulation, optimizing supply chain logistics for raw silica precursors, and simulating the thermal behavior of composite airgel products under extreme conditions. The overarching expectation is that AI will be the crucial tool enabling manufacturers to rapidly iterate on new product designs, significantly reducing the time-to-market for specialized, high-performance airgel insulation cotton tailored for specific industrial needs.

- AI-driven optimization of material synthesis processes, reducing energy input and maximizing yield of high-purity aerogel.

- Predictive modeling of thermal performance and degradation under varied pressures and temperatures, improving product warranties.

- Automation of quality control during fiber reinforcement and impregnation phases using computer vision systems.

- Enhanced supply chain management for sourcing critical silica precursors and optimizing global distribution networks.

- Development of smart airgel insulation systems integrated with sensors for real-time monitoring of temperature differentials and structural integrity in critical infrastructure.

- Accelerated research and development through machine learning algorithms that suggest novel composite material combinations for specific R-value targets.

DRO & Impact Forces Of Airgel Insulation Cotton Market

The Airgel Insulation Cotton Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO). Major drivers include the increasing global adoption of stringent energy conservation codes, particularly in construction and industrial sectors, alongside the robust demand from the rapidly expanding electric vehicle battery thermal management market. The need for lightweight, ultra-thin insulation in aerospace and specialized military applications further propels demand. However, the market faces considerable restraints, primarily the high initial manufacturing cost of airgel materials compared to conventional insulation, which limits widespread adoption in price-sensitive commercial markets. Handling challenges and the material's inherent dustiness during installation also pose minor hurdles that manufacturers must address through innovative product formulation.

Opportunities for market growth lie predominantly in technological breakthroughs that enable continuous, high-volume, and low-cost production methods, such as atmospheric drying techniques replacing supercritical fluid extraction. Furthermore, expanding the application scope into consumer electronics and household appliances, where space and energy efficiency are premium features, represents a lucrative avenue. The shift towards sustainable and bio-based aerogel precursors presents a substantial long-term opportunity, aligning the product with global green initiatives and improving its environmental profile.

The core impact forces shaping this market include intense competition from established insulation technologies like vacuum insulated panels (VIPs) and high-density polyurethane foams, regulatory mandates promoting high-R-value materials, and the volatility in raw material costs, specifically silica. Technological advancement in fiber reinforcement is a strong positive force, enhancing the material's durability and flexibility, thereby broadening its applicability in harsh environments. Overall, while cost remains a key barrier, the performance superiority of airgel insulation cotton in niche, high-value applications ensures sustained high growth rates, pushing manufacturers to overcome production challenges through scaling and automation.

Segmentation Analysis

The Airgel Insulation Cotton Market is comprehensively segmented based on its structural form, the type of reinforcing material used, the specific application area, and the geographical region. Analyzing these segments provides a clear understanding of market dynamics, revealing which product types are driving growth and which end-use sectors are exhibiting the highest propensity for adoption. The segmentation is critical for market players to tailor their production, distribution, and marketing strategies effectively, focusing on high-growth segments such as the increasing demand for blankets and sheets in industrial insulation and the emerging thermal management needs in the automotive sector.

- By Form:

- Blankets and Sheets

- Particles and Powders (Often used in composite structures)

- Panels

- By Reinforcement Material:

- Cotton Fibers

- Fiberglass

- Polyester Fibers

- Others (e.g., carbon fibers, specialized fabrics)

- By Application:

- Oil and Gas (Pipelines, Refining, Subsea Equipment)

- Industrial Insulation (Furnaces, Tanks, Heat Exchangers)

- Automotive and Transportation (EV Battery Thermal Management, Aerospace)

- Building and Construction (Residential, Commercial, HVAC)

- Apparel and Footwear

- Others (Medical devices, Electronics)

- By Region:

- North America (US, Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of LATAM)

- Middle East and Africa (Saudi Arabia, UAE, South Africa, Rest of MEA)

Value Chain Analysis For Airgel Insulation Cotton Market

The value chain for the Airgel Insulation Cotton Market begins with intensive upstream raw material procurement, primarily involving high-purity silica precursors (silicone alkoxides or waterglass) and the specific fibers used for reinforcement, such as specialized synthetic cotton or fiberglass mats. The complexity and proprietary nature of the aerogel synthesis process, often involving sol-gel reactions and subsequent drying techniques (supercritical or atmospheric), represent the most critical and capital-intensive stage of the value chain. Efficiency in this stage dictates the final product cost and scalability. Key players often invest heavily in backward integration to control precursor quality and ensure a steady supply of essential components.

The midstream operations involve the functionalization and composite formation, where the synthesized aerogel is impregnated into the fibrous cotton matrix to create the flexible insulation blanket or sheet. This manufacturing step requires specialized machinery to ensure uniform distribution and adhesion, guaranteeing the material’s structural integrity and minimizing dust formation. The distribution channel then handles the logistics, which can be direct, serving large industrial clients in oil and gas or aerospace with highly technical requirements, or indirect, moving products through specialized insulation distributors and wholesalers who cater to the construction and automotive aftermarket sectors. Due to the product’s relatively high value per volume, managing logistics efficiently is essential to maintaining competitive pricing.

Downstream activities center around the end-user application and installation. Direct customers, such as major shipbuilding yards or automotive manufacturers, purchase in bulk and integrate the material into their products. Indirect customers, often smaller construction firms or specialized contractors, rely on the detailed technical support and specific product formats offered by distributors. Crucially, the long-term value generated is tied to the energy savings realized by the end-user. Therefore, effective marketing emphasizes the lifecycle cost benefits and performance characteristics (R-value per inch) rather than just the initial purchase price, solidifying the importance of technical service and post-sale support within the value chain.

Airgel Insulation Cotton Market Potential Customers

Potential customers for Airgel Insulation Cotton are diverse, spanning multiple high-stakes industrial and commercial sectors where conventional insulation fails to meet stringent performance requirements regarding weight, thickness, or thermal resistance. The primary end-user/buyer groups include large multinational energy corporations requiring superior insulation for subsea pipelines, minimizing heat loss in deepwater operations, and optimizing flow assurance. Defense and aerospace contractors represent another critical segment, demanding lightweight, fire-resistant insulation for aircraft, spacecraft, and military vehicles where mass reduction is paramount to operational efficiency.

Furthermore, Original Equipment Manufacturers (OEMs) in the automotive industry, particularly those focused on electric vehicle battery manufacturing, are rapidly becoming major consumers. Airgel insulation cotton is essential for passive fire protection and maintaining optimal operating temperatures for EV battery packs, thereby extending battery life and ensuring passenger safety. The industrial sector, including petrochemical processing plants, power generation facilities, and manufacturing firms utilizing high-temperature processes, requires this material for insulating furnaces, kilns, and critical piping systems to improve energy efficiency and worker safety. The material's unique properties allow for the insulation of equipment in confined spaces where traditional materials are too bulky.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 1,150 Million |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aspen Aerogels Inc., Cabot Corporation, Aerogel Technologies LLC, Nano High-Tech Co. Ltd., Guangdong Aerogel Technology Co. Ltd., Guangzhao Materials Co. Ltd., Enersol Co. Ltd., Jios Aerogel Corporation, Shenzhen Aerogel New Materials Co. Ltd., American Aerogel Corporation, Basanite Industries LLC, Airgel Materials Inc., Techniks Inc., Aerotherm, Active Aerogels S.A., 3M Company, Dow Corning Corporation, Saint-Gobain, Morgan Advanced Materials, Zotefoams plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Airgel Insulation Cotton Market Key Technology Landscape

The Airgel Insulation Cotton Market is defined by sophisticated material science and advanced manufacturing techniques aimed at transforming fragile aerogel monoliths into flexible, durable composites. The core technological process is the Sol-Gel method, which dictates the quality and porosity of the silica aerogel precursor. The subsequent and most critical step is the drying phase. Historically, supercritical drying was necessary to prevent the collapse of the porous gel structure, but this method is highly expensive and complex. The current key technological trend involves the optimization of ambient pressure drying (APD) or freeze-drying techniques, which significantly reduce energy consumption and production costs, making the material more commercially viable for high-volume applications like construction.

Another pivotal area of technological innovation is the composite manufacturing process, focusing on integrating the aerogel matrix with the reinforcing cotton or fibrous material. This involves impregnation and lamination technologies designed to ensure maximum retention of aerogel particles within the structure, minimizing dust and improving mechanical resilience against compression and handling. Research and development efforts are concentrated on creating thinner blankets (less than 5mm) that maintain exceptional R-values, catering specifically to space-constrained applications like pipe insulation and battery casings. Furthermore, manufacturers are exploring hydrophobic treatments and specialized coatings to enhance the material’s water resistance, critical for outdoor and subsea applications where moisture absorption severely degrades insulating performance.

The development of next-generation aerogel precursors, moving beyond traditional silica to include carbon, alumina, or polymer-based structures, is also shaping the technology landscape. These new precursors allow for tailored material properties, such as enhanced flexibility, improved tensile strength, or superior conductivity blocking characteristics, expanding the material's use into extreme environments. The integration of continuous production lines, often utilizing AI and automation for real-time quality control and process parameter adjustments, is essential for achieving the scale required to meet growing industrial demand while maintaining competitive pricing against conventional insulation alternatives.

Regional Highlights

- Asia Pacific (APAC): APAC represents the highest growth potential, driven by extensive infrastructure development, particularly in China and India. Government policies promoting energy-efficient building standards and a rapidly expanding industrial base, especially the massive scale of EV battery manufacturing in countries like South Korea and China, fuel the demand for high-performance insulation solutions. Japan and Australia also contribute significantly, focusing on specialized, high-temperature industrial applications and energy retrofitting projects.

- North America: This region holds a significant market share, primarily due to the established presence of high-technology industries such as aerospace, defense, and oil and gas (especially deepwater exploration). Stringent safety and thermal performance regulations in the US and Canada mandate the use of premium insulation materials. The region is a leader in technological adoption and houses major R&D centers dedicated to aerogel innovation and application development.

- Europe: Europe is a mature market characterized by robust environmental and energy efficiency targets set by the European Union. Demand is stable and strong, particularly in the retrofit construction sector, where high-R-value, thin insulation is necessary for preserving historic building facades while meeting modern thermal requirements. Germany and the UK are key markets, driven by specialized cryogenics and industrial process insulation needs.

- Latin America (LATAM): The market in LATAM is emerging, focused mainly on insulating aging oil and gas infrastructure and supporting new industrial projects in Brazil and Mexico. Economic volatility and lower investment in high-cost materials sometimes limit adoption, but growing awareness of long-term energy savings is slowly increasing the market presence of airgel insulation cotton.

- Middle East and Africa (MEA): MEA exhibits strong demand from the massive regional oil and gas sector for pipeline and refining insulation, where extreme desert temperatures necessitate materials with superior long-term performance and durability. Investment in new energy projects, particularly solar and petrochemical facilities in Saudi Arabia and the UAE, acts as a primary market driver.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Airgel Insulation Cotton Market.- Aspen Aerogels Inc.

- Cabot Corporation

- Aerogel Technologies LLC

- Nano High-Tech Co. Ltd.

- Guangdong Aerogel Technology Co. Ltd.

- Guangzhao Materials Co. Ltd.

- Enersol Co. Ltd.

- Jios Aerogel Corporation

- Shenzhen Aerogel New Materials Co. Ltd.

- American Aerogel Corporation

- Basanite Industries LLC

- Airgel Materials Inc.

- Techniks Inc.

- Aerotherm

- Active Aerogels S.A.

- 3M Company

- Dow Corning Corporation

- Saint-Gobain

- Morgan Advanced Materials

- Zotefoams plc

Frequently Asked Questions

Analyze common user questions about the Airgel Insulation Cotton market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Airgel Insulation Cotton and what makes it superior to traditional insulation?

Airgel Insulation Cotton is a composite material combining highly porous, low-density silica aerogel particles with a flexible fibrous matrix, typically cotton or fiberglass. Its superiority stems from the extremely low thermal conductivity of aerogel, offering an R-value significantly higher per unit of thickness than traditional materials like mineral wool or foam, making it ideal for space-constrained, high-performance applications.

Which application sector drives the highest current demand for airgel insulation products?

The Oil and Gas sector currently represents the largest market share, utilizing airgel insulation cotton for critical applications such as subsea pipelines and industrial process equipment. This demand is driven by the need for flow assurance, minimized heat loss, and durable performance under extreme thermal and hydrostatic pressure conditions.

What are the primary factors restraining the widespread adoption of Airgel Insulation Cotton?

The principal restraint on widespread market adoption is the relatively high cost of production, primarily linked to the capital-intensive nature of aerogel synthesis and drying techniques (historically supercritical drying). While ambient pressure drying is reducing costs, the material still carries a premium price compared to conventional insulation alternatives.

How is the growth of Electric Vehicles (EVs) impacting the Airgel Insulation Cotton market?

The rapid growth of the EV market is significantly boosting demand, as airgel insulation cotton is a critical component for thermal runaway protection and efficient thermal management systems within EV battery packs. Its lightweight nature helps maximize vehicle range while its high thermal resistance ensures battery longevity and safety.

Which geographical region is expected to demonstrate the fastest growth rate for this market?

The Asia Pacific (APAC) region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR). This acceleration is attributed to massive industrialization, heightened infrastructure spending, and favorable governmental mandates pushing for energy efficiency in construction and the dominant global position in electric vehicle manufacturing within countries like China and India.

This comprehensive market research report on the Airgel Insulation Cotton Market provides deep insights into the current trends, future projections, and competitive landscape. The market analysis confirms a strong growth trajectory driven by unparalleled thermal performance requirements in specialized industries. The demand for lightweight, thin, and highly efficient insulation materials is escalating across the globe, especially in critical infrastructure, aerospace, and advanced mobility solutions like electric vehicle battery thermal management. The forecasted CAGR of 11.5% between 2026 and 2033 underscores the transformation occurring in material science and engineering aimed at achieving optimal energy efficiency. The market size, estimated at USD 550 Million in 2026 and projecting to reach USD 1,150 Million by 2033, reflects significant investment potential and technological maturation within the airgel manufacturing sector. Strategic regional growth in Asia Pacific, coupled with robust, established demand in North America and Europe, highlights the global nature of this high-performance insulation solution. Technological advancements in ambient pressure drying are key to unlocking broader commercial viability beyond high-value niche applications. The report meticulously covers segmentation based on Form (Blankets and Sheets dominating), Reinforcement Material (Fiberglass, Cotton, Polyester), and Application (Oil and Gas, Automotive, Industrial Insulation, Building and Construction). Key players like Aspen Aerogels, Cabot Corporation, and Nano High-Tech are profiled, illustrating the concentrated yet competitive nature of the industry. The impact analysis of Artificial Intelligence reveals its potential to revolutionize synthesis, quality control, and predictive performance modeling, further solidifying the material's role in future engineering projects. The detailed value chain analysis emphasizes the complexity of upstream silica precursor sourcing and the vital role of specialized distribution channels in reaching high-stakes end-users. Regulatory drivers promoting reduced carbon footprints and enhanced energy conservation remain the foundational stimuli for market evolution and product innovation. The market's future success hinges on overcoming the existing high production cost through scalable, sustainable manufacturing processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager