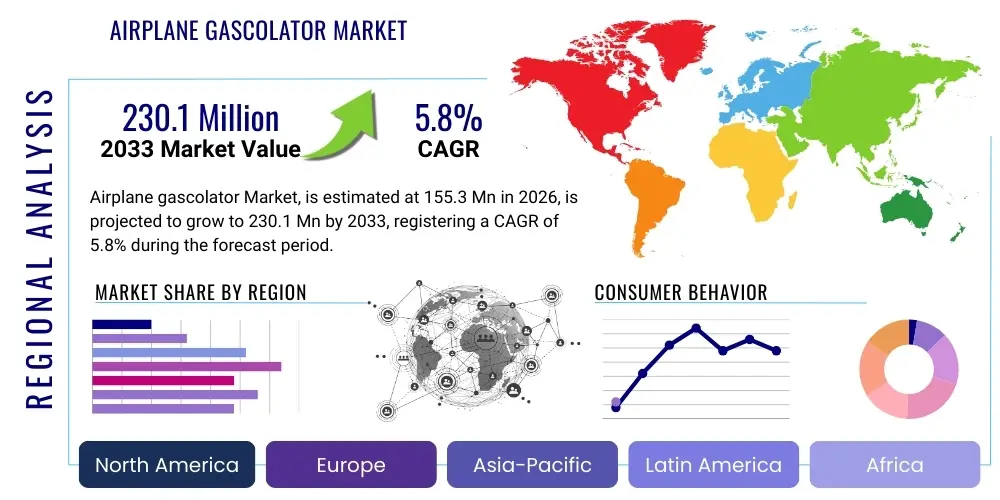

Airplane gascolator Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439587 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Airplane gascolator Market Size

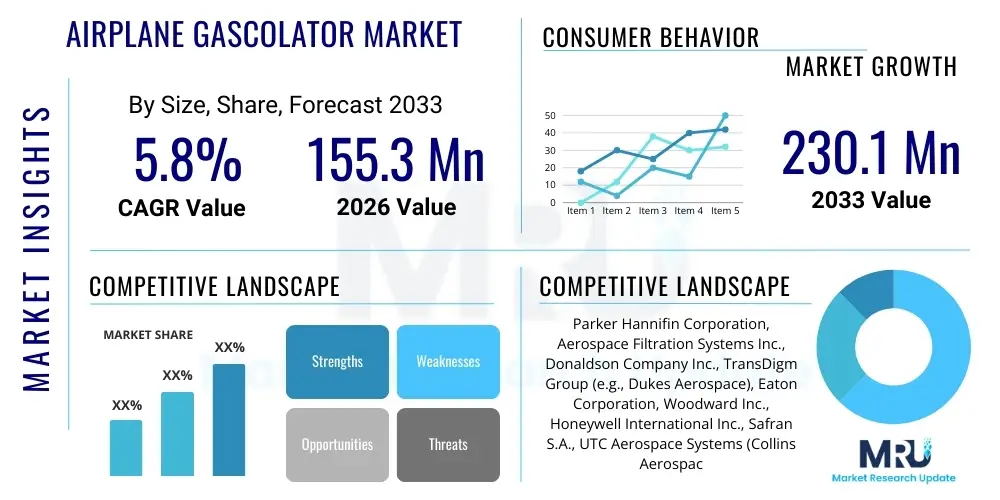

The Airplane gascolator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 155.3 million in 2026 and is projected to reach USD 230.1 million by the end of the forecast period in 2033. This growth is primarily driven by an expanding global aircraft fleet, stringent aviation safety regulations demanding reliable fuel system components, and continuous maintenance and replacement cycles within both commercial and general aviation sectors. The increasing demand for air travel and the modernization of military aircraft also contribute significantly to the market's upward trajectory, ensuring a stable yet dynamic growth outlook for gascolator manufacturers and service providers across the globe.

Airplane gascolator Market introduction

The Airplane gascolator Market encompasses the manufacturing, distribution, and maintenance of essential components designed to filter fuel in aircraft systems. A gascolator, a critical safety device, is integrated into an aircraft's fuel line, typically located at the lowest point of the fuel system or before the carburetor/fuel injection system. Its primary function is to trap and collect water, sediment, and other foreign particles from the fuel, preventing them from reaching the engine and causing potential damage or failure during flight. This proactive filtration ensures optimal engine performance and, more importantly, enhances flight safety by preventing fuel contamination-related issues.

The product's description highlights its robust construction, often involving precision-machined metal housing with a transparent bowl for visual inspection, and an internal screen or filter element. Major applications span across various aircraft types, including general aviation aircraft, commercial passenger and cargo planes, military aircraft, and increasingly, unmanned aerial vehicles (UAVs). Key benefits include enhanced engine longevity, reduced maintenance costs associated with fuel system issues, and critical compliance with aviation safety standards set by regulatory bodies worldwide. Driving factors for this market include the global expansion of aircraft fleets, the rising demand for air transport, stringent regulatory frameworks emphasizing flight safety, ongoing technological advancements in materials and filtration, and the perpetual need for replacement and maintenance of existing aircraft components to ensure operational reliability.

Airplane gascolator Market Executive Summary

The Airplane gascolator market is currently experiencing robust growth, propelled by several key business trends including the increasing production of new aircraft, significant activity in the aftermarket MRO (Maintenance, Repair, and Overhaul) sector, and advancements in component design. Manufacturers are focusing on developing gascolators with improved filtration efficiency, lighter materials, and enhanced durability to meet evolving industry demands. Strategic collaborations and partnerships between gascolator manufacturers and aircraft OEMs, as well as MRO providers, are becoming more prevalent, aiming to streamline supply chains and ensure component availability.

Regionally, North America continues to hold a dominant share, driven by a large general aviation fleet, a well-established commercial aviation sector, and significant military aviation expenditures. However, the Asia Pacific region is rapidly emerging as a high-growth market, attributed to its burgeoning commercial airline industry, extensive infrastructure development in aviation, and increasing disposable incomes fueling air travel demand. Europe also maintains a strong market presence due to its mature aerospace industry and stringent regulatory environment. Segment-wise, the aftermarket segment accounts for a substantial portion of revenue, driven by routine maintenance and replacement cycles. By aircraft type, general aviation remains a significant consumer, while commercial aviation is expected to witness accelerated growth due to fleet expansion and modernization initiatives. The shift towards more advanced filtration technologies and composite materials is a prominent trend across all segments, indicating a move towards greater efficiency and longevity in gascolator design.

AI Impact Analysis on Airplane gascolator Market

Users frequently inquire about how artificial intelligence (AI) can enhance the reliability and maintenance of critical aircraft components like gascolators. Common questions revolve around predictive maintenance capabilities for fuel systems, the role of AI in quality control during manufacturing, and its potential to optimize supply chain logistics for spare parts. The overarching themes suggest a strong user expectation for AI to reduce unexpected failures, streamline maintenance operations, and improve overall aircraft safety and operational efficiency through data-driven insights. There is also interest in AI's capacity to analyze flight data for early detection of fuel system anomalies that could impact gascolator performance.

- AI-powered predictive maintenance can forecast potential gascolator failures based on sensor data analysis, reducing unscheduled downtime and improving safety.

- AI algorithms can optimize manufacturing processes for gascolators, leading to higher precision, improved material utilization, and enhanced quality control.

- Supply chain optimization using AI can ensure timely availability of gascolator components for OEMs and MRO providers, minimizing inventory costs and lead times.

- AI in advanced sensor integration allows for real-time monitoring of fuel contaminants and gascolator efficiency, enabling proactive maintenance interventions.

- Data analytics driven by AI can identify patterns in gascolator performance across various aircraft types and operational conditions, feeding into design improvements.

DRO & Impact Forces Of Airplane gascolator Market

The Airplane gascolator market is profoundly shaped by a confluence of drivers, restraints, opportunities, and competitive forces. Key drivers include the ever-expanding global aircraft fleet across commercial, general, and military aviation sectors, which inherently increases the demand for new installations and replacement parts. Stringent aviation safety regulations, enforced by bodies like the FAA and EASA, mandate regular inspection and maintenance of fuel systems, including gascolators, thus sustaining aftermarket demand. Additionally, an aging global aircraft fleet necessitates frequent component replacements, further fueling market growth. Technological advancements in filtration efficiency, material science for durability, and integration of smart features are also acting as significant drivers, pushing for continuous product innovation.

However, the market faces several restraints. The high cost associated with research, development, and certification of new aviation components poses a barrier to entry for new players and limits innovation for smaller manufacturers. Economic downturns and geopolitical instability can negatively impact air travel demand and aircraft production, thereby reducing the overall market size. Furthermore, the market for standard gascolators is relatively mature, leading to intense price competition among established players. Opportunities for growth are abundant, particularly in the development of "smart" gascolators equipped with sensors for real-time monitoring of fuel purity and system health, integration with advanced composite materials for weight reduction and corrosion resistance, and expansion into emerging markets with rapidly growing aviation sectors, such as Asia Pacific and Latin America. The MRO market also presents significant opportunities for service providers specializing in gascolator maintenance and overhaul. The impact forces within the market, as described by Porter's Five Forces, include a moderate bargaining power of buyers due to standardization but also specific OEM requirements, significant bargaining power of suppliers for specialized materials, a low threat of substitutes given the critical nature of the component, a moderate threat of new entrants due to high certification barriers, and a high degree of competitive rivalry among existing manufacturers striving for market share and technological leadership.

Segmentation Analysis

The Airplane gascolator Market is broadly segmented based on several key characteristics to provide a granular view of market dynamics and opportunities. These segmentations allow for a detailed analysis of market trends, consumer behavior, and competitive landscapes across different product types, applications, and sales channels. Understanding these segments is crucial for stakeholders to develop targeted strategies and identify high-growth areas within the aviation fuel system component industry.

- By Type

- Metal Gascolators

- Plastic/Composite Gascolators

- With Filter Element

- Filterless Gascolators

- By Aircraft Type

- General Aviation

- Commercial Aviation (Passenger, Cargo)

- Military Aviation

- UAVs/Drones

- By Sales Channel

- Original Equipment Manufacturer (OEM)

- Aftermarket (MRO, Independent Distributors)

Value Chain Analysis For Airplane gascolator Market

The value chain for the Airplane gascolator market involves several critical stages, beginning with the sourcing of raw materials and extending through manufacturing, assembly, distribution, and ultimate end-use. Upstream analysis focuses on the suppliers of fundamental components and materials required for gascolator production. This includes precision metal alloys like aluminum, stainless steel, and brass for the housing, as well as specialized polymers and composites for lightweight variations. Suppliers of filter media, O-rings, seals, and transparent bowl materials also form a crucial part of the upstream segment, demanding high quality and certified materials to meet aviation standards. The innovation and reliability of these upstream suppliers directly impact the quality and performance of the final gascolator product.

Moving downstream, the manufactured gascolators are supplied to two primary channels: Original Equipment Manufacturers (OEMs) and the aftermarket. OEMs represent direct sales to aircraft manufacturers who integrate gascolators into new aircraft production lines. This segment requires strong relationships, adherence to specific design specifications, and rigorous quality assurance. The aftermarket segment, on the other hand, involves sales to Maintenance, Repair, and Overhaul (MRO) facilities, independent distributors, and individual aircraft owners for replacement and maintenance purposes. This channel is characterized by a demand for readily available parts, competitive pricing, and efficient logistics. Distribution channels typically involve a mix of direct sales from manufacturers to large OEMs or airlines, and indirect sales through a network of specialized aviation parts distributors who cater to smaller MROs and private aircraft owners, ensuring widespread product availability and service support across the global aviation ecosystem.

Airplane gascolator Market Potential Customers

The potential customers for Airplane gascolators are diverse, spanning the entire spectrum of the aviation industry, reflecting both new aircraft production and ongoing operational maintenance. The primary end-users or buyers include major aircraft manufacturers (OEMs) such as Boeing, Airbus, Textron Aviation, Cirrus Aircraft, and various military aircraft producers, who integrate gascolators into newly assembled aircraft. These customers require components that meet stringent design specifications, performance standards, and regulatory certifications, often forming long-term supply contracts with manufacturers.

Beyond OEMs, a substantial portion of the market is driven by the aftermarket segment. This includes Maintenance, Repair, and Overhaul (MRO) organizations worldwide, ranging from large airline-affiliated MROs to independent service providers specializing in general aviation. These entities purchase gascolators for routine maintenance, component replacement due to wear and tear, or upgrades during scheduled overhaul intervals. Airlines, cargo operators, charter companies, and private aircraft owners also represent direct or indirect end-users, requiring reliable gascolators to ensure the safety and operational efficiency of their fleets. Military aviation units globally are also significant consumers, demanding robust and specialized gascolators for their diverse range of aircraft, often under long-term government contracts. The continued operation and expansion of global aircraft fleets ensure a consistent and growing demand from this broad customer base.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.3 million |

| Market Forecast in 2033 | USD 230.1 million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Parker Hannifin Corporation, Aerospace Filtration Systems Inc., Donaldson Company Inc., TransDigm Group (e.g., Dukes Aerospace), Eaton Corporation, Woodward Inc., Honeywell International Inc., Safran S.A., UTC Aerospace Systems (Collins Aerospace), Crane Aerospace & Electronics, Triumph Group, Wescor Inc., Air-Maze Corporation, Champion Aerospace, RAPCO Inc., Spruce Aircraft Supply, BendixKing (a Honeywell business), Zephyr Aircraft Products, STC (Standard Aero), Aerodyne Research |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Airplane gascolator Market Key Technology Landscape

The Airplane gascolator market is undergoing continuous technological evolution driven by demands for enhanced safety, improved performance, and reduced maintenance. One significant area of advancement is in materials science, where traditional metallic gascolators are being complemented or replaced by lightweight, corrosion-resistant composite materials and advanced polymers. These materials offer benefits such as weight reduction, extended service life, and resistance to modern aviation fuels which can sometimes be more aggressive. Developments in manufacturing processes, including precision casting and additive manufacturing (3D printing), enable the creation of more complex geometries and integrated designs, leading to improved flow dynamics and filtration efficiency.

Another crucial technological trend is the integration of smart features and sensor technologies into gascolators. This involves incorporating sensors capable of detecting water or sediment accumulation in real-time, monitoring fuel flow, pressure, and temperature, and transmitting this data to the aircraft’s avionics system. Such smart gascolators provide pilots and maintenance crews with immediate, actionable insights, enabling proactive maintenance and preventing potential engine issues before they escalate. Furthermore, advancements in filtration media technology are leading to gascolators with finer micron ratings, greater dirt-holding capacity, and longer service intervals, ensuring cleaner fuel delivery and reducing the frequency of component replacements. The emphasis on sustainability also drives research into more environmentally friendly materials and easier recyclability of components at the end of their lifecycle, aligning with broader industry goals for reduced environmental impact.

Regional Highlights

- North America: Dominates the global market due to the presence of a vast general aviation fleet, a well-established commercial aviation sector, and significant defense spending on military aircraft. Stringent regulatory bodies like the FAA ensure high demand for certified components and regular maintenance.

- Europe: A mature market with a strong aerospace manufacturing base and a high number of active commercial and general aviation aircraft. Strict EASA regulations and a focus on operational safety drive consistent demand for quality gascolators.

- Asia Pacific (APAC): Emerging as the fastest-growing market, propelled by rapid expansion in commercial aviation, increasing air passenger traffic, and significant investments in airport infrastructure and fleet modernization, particularly in China and India.

- Latin America: Experiences moderate growth, driven by increasing regional air connectivity, fleet renewals, and the expansion of general aviation, though economic volatility can impact market stability.

- Middle East and Africa (MEA): Represents a growing market with significant investments in new airlines, fleet expansion, and military aviation modernization, especially in the UAE and Saudi Arabia, alongside infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Airplane gascolator Market.- Parker Hannifin Corporation

- Aerospace Filtration Systems Inc.

- Donaldson Company Inc.

- TransDigm Group (e.g., Dukes Aerospace)

- Eaton Corporation

- Woodward Inc.

- Honeywell International Inc.

- Safran S.A.

- UTC Aerospace Systems (Collins Aerospace)

- Crane Aerospace & Electronics

- Triumph Group

- Wescor Inc.

- Air-Maze Corporation

- Champion Aerospace

- RAPCO Inc.

- Spruce Aircraft Supply

- BendixKing (a Honeywell business)

- Zephyr Aircraft Products

- STC (Standard Aero)

- Aerodyne Research

Frequently Asked Questions

Analyze common user questions about the Airplane gascolator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an airplane gascolator and why is it important?

An airplane gascolator is a critical component in an aircraft's fuel system designed to filter out water, sediment, and other contaminants from the fuel before it reaches the engine. Its importance lies in preventing engine damage or failure due to contaminated fuel, thereby ensuring flight safety and optimal engine performance.

What are the key factors driving the growth of the gascolator market?

The market is primarily driven by the expanding global aircraft fleet across commercial, general, and military aviation, coupled with stringent aviation safety regulations mandating reliable fuel system components. Additionally, the continuous need for maintenance, repair, and replacement of gascolators in aging fleets significantly contributes to market growth.

How is technology influencing gascolator design and functionality?

Technology is driving advancements in gascolator design through the use of lightweight, corrosion-resistant materials (composites), improved filtration media for higher efficiency, and the integration of smart sensors. These sensors enable real-time monitoring of fuel purity and system health, facilitating predictive maintenance and enhancing overall safety.

Which regions are leading the airplane gascolator market?

North America currently leads the airplane gascolator market due to its large general and commercial aviation fleets. However, the Asia Pacific region is rapidly emerging as a high-growth market, propelled by its expanding commercial airline industry and increasing investments in aviation infrastructure.

Who are the primary end-users or customers for airplane gascolators?

Primary end-users include aircraft Original Equipment Manufacturers (OEMs) for new aircraft installations, Maintenance, Repair, and Overhaul (MRO) organizations for aftermarket replacements, airlines, cargo operators, and individual aircraft owners or operators for fleet maintenance and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager