Alkylated Naphthalene Sulfonate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434144 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Alkylated Naphthalene Sulfonate Market Size

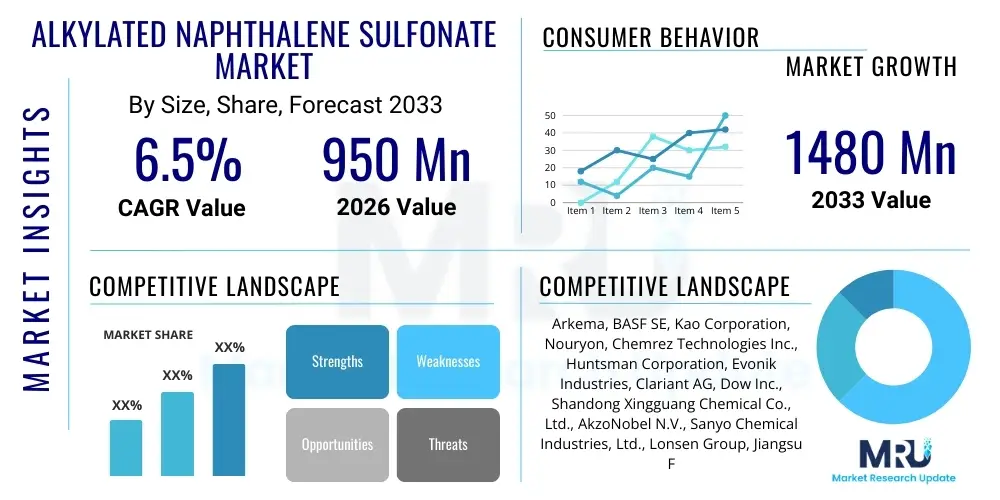

The Alkylated Naphthalene Sulfonate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 950 million in 2026 and is projected to reach USD 1480 million by the end of the forecast period in 2033.

Alkylated Naphthalene Sulfonate Market introduction

Alkylated Naphthalene Sulfonates (ANS) are a critical class of anionic surfactants widely recognized for their superior dispersing, wetting, and emulsifying properties, making them indispensable across various industrial applications. These compounds function primarily by reducing surface tension and stabilizing colloidal particles, which is particularly vital in environments demanding high chemical stability, such as cement mixing, textile processing, and pesticide formulations. The robust chemical structure of ANS, derived through the alkylation and subsequent sulfonation of naphthalene, imparts high resistance to hard water, high temperatures, and extreme pH conditions, distinguishing them from traditional sulfonate alternatives.

Major applications of Alkylated Naphthalene Sulfonates span construction, agrochemicals, and specialized industrial cleaning. In the construction sector, ANS are utilized as powerful superplasticizers and water-reducing admixtures, enhancing the workability of concrete without compromising strength, a factor crucial for large-scale infrastructure projects. Furthermore, in agriculture, they serve as excellent dispersants and wetting agents, improving the efficacy and shelf stability of wettable powders (WP) and suspension concentrates (SC) used in pesticide and herbicide formulations. The intrinsic benefits driving market growth include regulatory shifts favoring high-performance, low-dosage chemicals, and the accelerating demand for high-durability construction materials globally.

The primary driving factors sustaining the market expansion include rapid urbanization in emerging economies, particularly across the Asia Pacific region, leading to booming residential and commercial construction activities. The increasing adoption of advanced agrochemical formulations requiring superior dispersing agents to comply with stricter environmental standards also fuels demand. Furthermore, the specialized usage in the oil and gas sector, particularly in enhanced oil recovery (EOR) processes and drilling fluid formulations where high stability is paramount, solidifies the sustained market trajectory throughout the forecast period. Innovation focused on biodegradable ANS variants is also opening new avenues for environmentally conscious applications.

Alkylated Naphthalene Sulfonate Market Executive Summary

The global Alkylated Naphthalene Sulfonate market is characterized by robust growth driven primarily by expansion in infrastructure development and the increasing sophistication of the agrochemical industry. Current business trends indicate a strong focus on capacity expansion, especially in Asian manufacturing hubs, to meet the surging domestic demand from construction and textile industries. Companies are strategically investing in R&D to develop performance-optimized products, specifically those tailored for high-range water reduction in concrete and ultra-stable pesticide dispersion systems. Merger and acquisition activities remain steady, consolidating the supply chain and allowing key players to acquire specialized technology portfolios and regional market access, enhancing overall competitive resilience.

Regionally, the Asia Pacific continues to dominate the market share, led by China and India, due to massive governmental spending on infrastructure, burgeoning populations requiring housing, and being the largest global producers and consumers of agrochemicals. North America and Europe demonstrate mature market characteristics, focusing primarily on regulatory compliance, sustainability, and high-value niche applications, such as oilfield chemicals and specialized textile dyeing auxiliaries. Growth in these mature regions is moderate, driven predominantly by replacement demand and the shift towards premium, environmentally safer ANS grades. Latin America and the Middle East & Africa are emerging markets showing promising growth, particularly in construction chemicals, linked to oil revenue-fueled development projects and increasing adoption of modern farming techniques.

Segment trends highlight the dominance of the concrete admixture segment, which commands the largest volume share due to the global imperative to improve concrete durability and performance. However, the agrochemicals segment is expected to register the highest growth rate, fueled by the rising global population demanding efficient crop protection and the necessity for advanced formulation techniques. By product type, the high molecular weight ANS grades are gaining traction as they offer superior dispersing performance at lower dosages, aligning with industry objectives of cost efficiency and reduced environmental footprint. Overall market dynamism suggests sustained investment across all segments, ensuring stable supply and technological advancement.

AI Impact Analysis on Alkylated Naphthalene Sulfonate Market

User queries regarding AI's impact on the Alkylated Naphthalene Sulfonate market generally revolve around optimizing synthesis processes, predicting material performance under specific conditions, and streamlining complex supply chain logistics. Users are concerned with how AI tools, particularly machine learning (ML) and predictive modeling, can reduce raw material wastage, decrease production cycle times, and ensure consistent product quality across various batches. A key theme is the expectation that AI can drastically enhance R&D efficiency, allowing manufacturers to rapidly screen and optimize novel ANS molecular structures for specific end-use requirements, such as enhanced thermal stability for drilling operations or improved biodegrability characteristics.

In manufacturing, AI and advanced analytics are projected to revolutionize plant operations. By integrating sensor data from reactors and processing units, ML algorithms can monitor reaction kinetics in real-time, accurately adjust inputs like temperature, pressure, and catalyst concentration, thereby maximizing yield and minimizing energy consumption. This level of precision optimization is crucial for specialty chemicals where slight variations in synthesis parameters can significantly affect the final product's performance characteristics, such as particle size distribution and sulfonation degree. Furthermore, AI-driven demand forecasting provides manufacturers with enhanced visibility into future market needs, allowing for better inventory management and optimized distribution networks, reducing lead times and overall operational expenditure.

The application of AI extends significantly into formulation and quality control for end-user industries. For instance, in concrete admixture manufacturing, AI models can predict the optimal blend of ANS components required to achieve desired concrete properties (slump, setting time, strength) based on variable factors like ambient temperature, aggregate type, and cement composition. This moves the industry toward hyper-customization and away from trial-and-error methodologies. Consequently, while AI does not directly alter the chemical production of ANS, its strategic implementation enhances efficiency, boosts product consistency, accelerates innovation cycles, and provides a significant competitive advantage to firms adopting these digital transformation tools.

- AI-driven optimization of sulfonation and alkylation reaction parameters for improved yield and purity.

- Machine learning models used for predictive maintenance of specialized chemical processing equipment, reducing downtime.

- Enhanced supply chain management through AI forecasting of raw material prices (naphthalene, alkylbenzenes) and fluctuating demand from construction and agrochemical sectors.

- Accelerated R&D via computational chemistry and ML screening of novel ANS molecular structures for targeted performance characteristics.

- Real-time quality control and process monitoring ensuring adherence to stringent industry standards (e.g., concrete admixture specifications ASTM C494).

- AI integration in specialized formulation services for end-users, predicting optimal ANS dosage in complex chemical blends.

DRO & Impact Forces Of Alkylated Naphthalene Sulfonate Market

The Alkylated Naphthalene Sulfonate market dynamics are shaped by a complex interplay of strong demand drivers emanating from global infrastructure development and advanced farming techniques, countered by restraints related to environmental concerns and raw material volatility. Opportunities lie in developing high-performance, sustainable alternatives and expanding into specialized applications like enhanced oil recovery, while impact forces such as stringent environmental regulations and intense price competition dictate market profitability and entry barriers. The overall force vector indicates a moderate to high growth trajectory, provided manufacturers successfully navigate raw material price fluctuations and meet increasing sustainability mandates.

Key drivers include the global infrastructure boom, particularly the rapid urbanization in Asia and Africa, requiring vast quantities of high-performance concrete where ANS act as indispensable plasticizers. The parallel growth of the agrochemical industry, driven by the necessity for improved crop yields, increases the requirement for superior dispersing and wetting agents. However, the market faces significant restraints, notably the reliance on petrochemical feedstocks (naphthalene and crude oil derivatives), leading to price volatility and supply chain instability. Furthermore, environmental regulations, particularly concerning wastewater discharge and the inherent non-biodegradability of some ANS types, pressure manufacturers to invest heavily in sustainable manufacturing processes and bio-based alternatives.

Opportunities for market players are abundant, focusing primarily on product innovation. The development of readily biodegradable Alkylated Naphthalene Sulfonate variants, or those derived from renewable resources, presents a significant potential to capture premium market segments, especially in Europe. The expansion into niche, high-value applications such as gypsum board manufacturing, industrial cleaning degreasers, and specialized pigment dispersion further offers avenues for differentiation and margin enhancement. The overarching impact forces include the increasing consolidation among global chemical giants, leading to heightened competition and the need for significant scale economies, coupled with evolving international standards for chemical safety and formulation efficiency which necessitate continuous product refinement and certification.

Segmentation Analysis

The Alkylated Naphthalene Sulfonate market is broadly segmented based on Product Type, Application, and End-Use Industry. This stratification allows for detailed analysis of market dynamics, revealing specific growth pockets and demand shifts across various vertical markets. Product types are primarily differentiated by molecular weight and degree of sulfonation, which directly influences their performance characteristics, such as deflocculation capability and solubility in different solvents. The market is highly dependent on the performance requirements of the end-use application, necessitating a tailored approach to product development and distribution.

The primary segmentation by Application includes Concrete Admixtures, Agrochemicals, Textile Auxiliaries, Leather Tanning, and Oilfield Chemicals. Concrete admixtures historically constitute the largest application segment due to the vast volumes consumed in global construction projects. However, the fastest growth is observed in specialized segments like enhanced oil recovery (EOR) operations, where the thermal and chemical stability of ANS surfactants are highly valued. Geographically, the consumption patterns vary significantly; for instance, European demand is highly influenced by advanced textile and industrial cleaning formulations, while Asian markets prioritize construction and crop protection requirements.

Understanding the market by End-Use Industry (Construction, Agriculture, Textiles, etc.) allows for strategic targeting. Manufacturers need to align production capabilities with the specific regulatory and performance standards of each industry, such as compliance with REACH regulations for textiles in Europe or adhering to specific performance standards (e.g., API standards) for oilfield chemicals. This intricate segmentation confirms that while the core chemistry remains the same, the formulation, pricing, and distribution strategies must be optimized for each distinct market vertical.

- By Product Type:

- Sodium Salt of Alkylated Naphthalene Sulfonates (SNF/PNS)

- Calcium Salt of Alkylated Naphthalene Sulfonates

- Ammonium Salt of Alkylated Naphthalene Sulfonates

- Low Molecular Weight ANS

- High Molecular Weight ANS

- By Application:

- Concrete Admixtures (Superplasticizers, Water Reducers)

- Agrochemical Dispersants and Wetting Agents (for WP, SC, WDG formulations)

- Textile and Leather Processing Auxiliaries (Dyeing and Tanning Agents)

- Oilfield Chemicals (Drilling Fluids, Enhanced Oil Recovery)

- Industrial Cleaners and Detergents

- Pigment and Dyestuff Dispersants

- By End-Use Industry:

- Construction Industry

- Agriculture Sector

- Textile and Leather Industry

- Oil and Gas Industry

- Chemical Manufacturing

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, India, Japan, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (Saudi Arabia, UAE, South Africa)

Value Chain Analysis For Alkylated Naphthalene Sulfonate Market

The value chain for Alkylated Naphthalene Sulfonates begins with the upstream procurement of essential raw materials, primarily naphthalene (derived from coal tar or petrochemical sources) and alkylating agents (such as propylenes or butylenes). This stage is characterized by high capital intensity and significant sensitivity to crude oil price fluctuations, which directly influence the input costs for ANS manufacturers. Key activities in the upstream segment involve the highly complex chemical synthesis, including alkylation followed by sulfonation, requiring specialized pressurized reactors and efficient waste treatment facilities to handle acidic byproducts, ensuring compliance with environmental regulations during synthesis.

The midstream segment involves the core manufacturing process where raw ANS are synthesized, purified, dried, and formulated into various grades (powder, liquid concentrate). Manufacturers often specialize in optimizing the molecular weight distribution and sulfonation degree to cater to specific performance requirements demanded by downstream industries, such as high dispersion stability for agrochemicals or specific slump retention times for concrete admixtures. Following manufacturing, products are typically bagged, containerized, and transported via multimodal logistics. The distribution channel is crucial, relying on specialized chemical distributors who possess the technical expertise required to handle these products and provide localized inventory management and technical support to regional customers.

The downstream segment encompasses the blending and final application by end-users. Direct distribution channels are often employed for large volume purchases, such as major construction chemical formulators or international agrochemical giants, enabling stricter quality control and direct contractual pricing. Indirect distribution, leveraging regional specialized chemical distributors and agents, services smaller industrial users and allows for market penetration into geographically diverse areas. The value chain concludes with the final integration of ANS into finished goods—be it specialized concrete formulations, advanced pesticide mixtures, or high-end textile dyes—where the performance of the ANS is directly measured against the desired end-product quality and efficiency.

Alkylated Naphthalene Sulfonate Market Potential Customers

Potential customers for Alkylated Naphthalene Sulfonates are diverse, spanning multiple heavy industrial sectors that rely on high-performance dispersants and wetting agents. The primary buyers are large-scale construction chemical manufacturers who utilize ANS as superplasticizers (e.g., Melamine Sulfonate Resin replacements) to formulate high-strength, self-compacting concrete necessary for infrastructure projects, including bridges, high-rises, and dams. These buyers demand reliable supply, high purity, and consistent performance metrics, often purchasing in bulk quantities under long-term supply agreements. Their purchasing decisions are highly influenced by performance specifications, regulatory approvals, and cost-in-use efficiencies, seeking materials that reduce the overall cement-to-water ratio effectively.

A secondary, high-growth customer base resides in the global agrochemical industry. These customers include multinational pesticide and fertilizer manufacturers who require ANS for formulating wettable powders, granules, and suspension concentrates. ANS ensures the active ingredient is uniformly dispersed in water and adheres effectively to foliage, thereby maximizing biological efficacy and extending the shelf life of the formulation. These customers prioritize product stability, compatibility with various active ingredients, and compliance with stringent environmental and registration standards set by regulatory bodies globally. The demand here is cyclical, heavily influenced by planting seasons and global agricultural output forecasts, requiring flexible and responsive supply chains.

Furthermore, specialized industrial buyers form a significant potential customer group, including textile mills and dye manufacturers who use ANS as dyeing auxiliaries and dispersants to ensure level dyeing and prevent agglomeration of dyes. The oil and gas industry represents a niche, high-value customer segment, utilizing ANS in drilling muds and specialized injection fluids for enhanced oil recovery (EOR), demanding products capable of functioning under high-pressure and high-temperature downhole conditions. Overall, the end-users are sophisticated industrial entities that view ANS as a crucial performance enhancer, not merely a commodity chemical, placing a high premium on technical service and application expertise from their suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 950 million |

| Market Forecast in 2033 | USD 1480 million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arkema, BASF SE, Kao Corporation, Nouryon, Chemrez Technologies Inc., Huntsman Corporation, Evonik Industries, Clariant AG, Dow Inc., Shandong Xingguang Chemical Co., Ltd., AkzoNobel N.V., Sanyo Chemical Industries, Ltd., Lonsen Group, Jiangsu Feymer Technology Co., Ltd., Chemtall Co., Ltd., Tianjing Zhonghuan Chemical Co., Ltd., Enaspol a.s., Stepan Company, Croda International Plc, MUHU (China) Construction Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Alkylated Naphthalene Sulfonate Market Key Technology Landscape

The core technology surrounding Alkylated Naphthalene Sulfonates production involves a two-stage chemical synthesis process: alkylation and sulfonation. Alkylation, typically facilitated by Friedel–Crafts catalysts, introduces the desired alkyl chain onto the naphthalene ring. The length and branching of this alkyl chain are critical, as they dictate the final surfactant properties, such as hydrophobicity and wetting power. Continuous research is focused on optimizing catalyst systems and reactor designs—moving toward continuous flow reactors rather than batch processes—to enhance reaction yield, improve selectivity, minimize byproduct formation, and significantly reduce operational costs and energy consumption associated with the high temperatures and pressures required for synthesis.

The subsequent sulfonation process, where a sulfonic acid group is attached, is also being continually refined. Traditional batch sulfonation methods are being replaced by advanced continuous film reactors or falling film sulfonators, which allow for rapid heat dissipation and precise control over the degree of sulfonation, thereby ensuring batch-to-batch consistency—a non-negotiable requirement for high-performance applications like concrete admixtures. Furthermore, technological advancements are focusing on purification and drying technologies, such as spray drying and thin-film evaporation, to produce high-purity, low-salt ANS powders that are preferred in applications where residual inorganic salts can interfere with formulation stability, particularly in complex agrochemical systems or high-end pigments.

A significant technological push involves developing and scaling up production methods for highly dispersible, low-foam ANS variants. Low foaming characteristics are essential in applications like high-speed textile dyeing and certain industrial cleaning processes. Manufacturers are also exploring greener chemical routes, focusing on enzyme catalysis or utilizing bio-derived raw materials where feasible, aligning with global trends toward sustainable chemistry. Furthermore, specialized formulation technology, which involves micronization and surface modification of the final ANS product, is crucial for optimizing the performance of solid-state ANS products, such as those used in water-dispersible granules (WDG) for agricultural use, thereby maintaining the technological edge in a highly competitive dispersant market.

Regional Highlights

- Asia Pacific (APAC): APAC is the unequivocally dominant region, holding the largest market share in terms of volume and value, primarily due to the expansive construction sector in China, India, and Southeast Asian nations. The region benefits from lower manufacturing costs, high domestic consumption, and the presence of numerous localized ANS producers. The demand is also heavily supported by robust agricultural practices and thriving textile industries, making it the central hub for both production and consumption. Regulatory frameworks, while rapidly tightening, generally support manufacturing scale-up, positioning APAC as the primary driver of global ANS demand throughout the forecast period.

- North America: North America represents a mature, high-value market characterized by stringent environmental regulations (TSCA). Consumption is concentrated in specialized sectors such as oilfield chemicals (driven by shale extraction technologies), premium concrete admixtures, and high-performance industrial coatings. Market growth is stable, driven more by technological upgrades (e.g., using superior ANS grades in high-performance concrete) rather than sheer volume expansion. The region also exhibits strong R&D capabilities focused on developing sustainable and biodegradable naphthalene alternatives.

- Europe: Europe is a highly regulated market, with REACH compliance heavily influencing product development and trade. The focus is strongly skewed toward high-purity, environmentally compliant ANS grades used in specialized textile auxiliaries, industrial degreasers, and premium construction chemicals. Market growth is moderate, but profitability is high due to the premium pricing of compliant products. Manufacturers must continually innovate to meet evolving sustainability targets and restrict the use of certain chemicals, pushing demand for bio-derived surfactants.

- Latin America (LATAM): LATAM, particularly Brazil and Argentina, presents a significant emerging market, fueled by substantial investments in infrastructure (roads, housing) and robust agricultural activities. Brazil's vast agricultural sector drives considerable demand for ANS as agrochemical dispersants. Market penetration is expanding, yet distribution challenges and economic volatility remain factors that necessitate localized supply chain strategies for effective market capture.

- Middle East & Africa (MEA): The MEA region is demonstrating strong potential, largely driven by large-scale urban development projects in the GCC states (Saudi Arabia, UAE) and increasing exploration activities in the oil and gas sector. The high-temperature, harsh operating conditions prevalent in regional drilling operations necessitate the use of stable, high-performance ANS in drilling fluids, cementing, and EOR operations, driving specialized demand, especially for thermal-resistant grades.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Alkylated Naphthalene Sulfonate Market.- BASF SE

- Kao Corporation

- Nouryon

- Huntsman Corporation

- Evonik Industries

- Clariant AG

- Dow Inc.

- Shandong Xingguang Chemical Co., Ltd.

- AkzoNobel N.V.

- Sanyo Chemical Industries, Ltd.

- Lonsen Group

- Jiangsu Feymer Technology Co., Ltd.

- Chemtall Co., Ltd.

- Tianjing Zhonghuan Chemical Co., Ltd.

- Enaspol a.s.

- Stepan Company

- Croda International Plc

- MUHU (China) Construction Materials Co., Ltd.

- Arkema

- Chemrez Technologies Inc.

Frequently Asked Questions

Analyze common user questions about the Alkylated Naphthalene Sulfonate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary functions of Alkylated Naphthalene Sulfonates (ANS) in industrial applications?

ANS primarily function as high-performance anionic surfactants and dispersants. Their main roles include reducing surface tension, stabilizing colloidal systems, acting as wetting agents, and preventing the flocculation of fine particles. This makes them essential in concrete superplasticizing, agrochemical dispersion, and textile dyeing processes, particularly where high chemical and thermal stability is required.

Which end-use industry drives the highest demand volume for Alkylated Naphthalene Sulfonates?

The Construction Industry is the largest consumer by volume, utilizing ANS predominantly as water-reducing agents and superplasticizers in concrete admixtures. These compounds improve the workability and durability of concrete, which is crucial for major infrastructure and building projects globally, particularly in high-growth regions like Asia Pacific.

How does the volatility of raw material prices affect the ANS market?

The ANS market is highly sensitive to the price fluctuations of key petrochemical raw materials, mainly naphthalene (derived from coal tar or crude oil) and alkylating agents. Volatility in crude oil markets directly impacts manufacturing costs, posing a significant challenge for cost management and pricing stability throughout the ANS supply chain, necessitating forward hedging strategies.

Are there environmentally friendly or bio-based alternatives to traditional Alkylated Naphthalene Sulfonates?

Yes, driven by stringent environmental regulations, there is increasing market development and research focused on high-performance alternatives, including lignin-based sulfonates, polycarboxylate ethers (PCEs, especially in concrete), and developing biodegradable ANS variants or those synthesized using bio-derived feedstocks to improve sustainability profiles.

What are the key regional growth areas for the Alkylated Naphthalene Sulfonate market?

The Asia Pacific region, led by China and India, is the most significant growth area, driven by massive infrastructure spending and robust agricultural sectors. Emerging growth potential is also observed in the Middle East & Africa, tied to large-scale construction projects and specialized demand from the regional oil and gas industry.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager