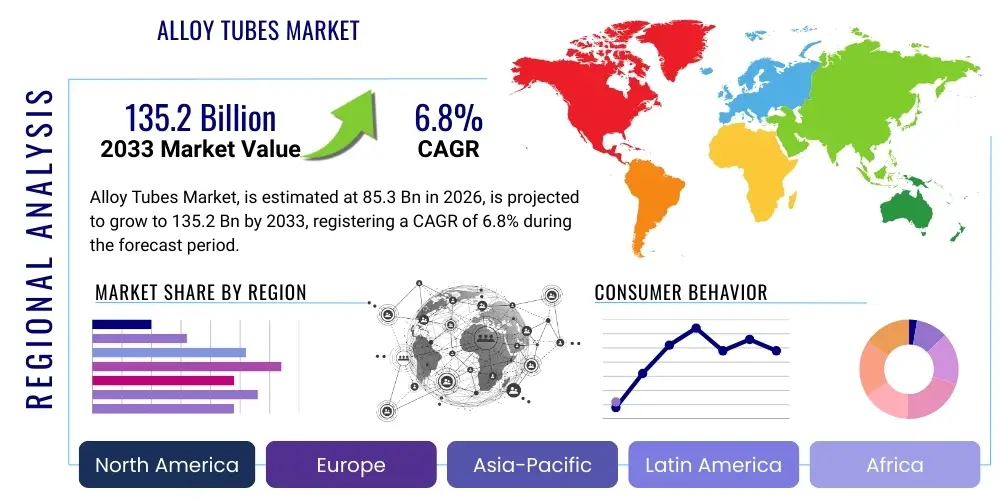

Alloy Tubes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440278 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Alloy Tubes Market Size

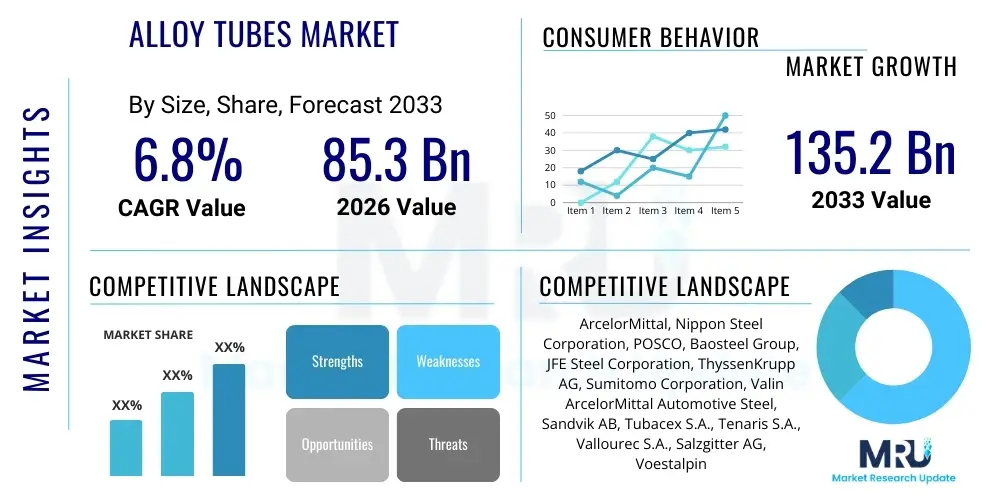

The Alloy Tubes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 85.3 Billion in 2026 and is projected to reach USD 135.2 Billion by the end of the forecast period in 2033. This robust growth trajectory is underpinned by increasing global industrialization, significant investments in energy infrastructure, and the continuous demand for high-performance materials across diverse critical applications. The market expansion is further fueled by the escalating need for corrosion-resistant and high-strength tubing solutions in sectors such as oil and gas, chemical and petrochemical processing, power generation, and advanced manufacturing. These industries are continuously seeking materials that can withstand extreme operating conditions, including high temperatures, pressures, and corrosive environments, making alloy tubes an indispensable component for maintaining operational integrity and efficiency. The demand from emerging economies, coupled with stringent safety and environmental regulations necessitating superior material performance, contributes substantially to the anticipated market value appreciation over the forecast period.

Alloy Tubes Market introduction

The alloy tubes market encompasses a broad spectrum of tubular products manufactured from various metal alloys, designed to offer superior mechanical properties, corrosion resistance, and high-temperature strength compared to traditional carbon steel. These alloys typically include combinations of iron with elements like nickel, chromium, molybdenum, titanium, and others, meticulously engineered to meet the demanding requirements of specific industrial applications. Products range from seamless tubes, known for their uniform structure and strength, to welded tubes, which provide cost-effective solutions for certain uses. The primary applications for alloy tubes are incredibly diverse and critical, spanning across industries such as oil and gas exploration and production, chemical and petrochemical processing plants, power generation facilities including nuclear and thermal power, automotive manufacturing, aerospace and defense, and even advanced construction. Their ability to perform reliably under harsh conditions, resist chemical degradation, and withstand significant mechanical stresses makes them indispensable in environments where failure is not an option, ensuring safety, efficiency, and longevity of industrial assets globally.

The intrinsic benefits of alloy tubes are multifarious, extending far beyond basic material containment. Key advantages include exceptional resistance to various forms of corrosion, such as pitting, crevice corrosion, and stress corrosion cracking, which is crucial in highly aggressive chemical environments. They also exhibit remarkable strength-to-weight ratios and maintain structural integrity at elevated temperatures and pressures, enabling more efficient and safer operations in high-performance systems. Furthermore, alloy tubes offer enhanced durability, reducing the frequency of maintenance and replacement, which translates into significant cost savings over the operational lifespan of industrial equipment. These superior properties lead to extended service life for critical infrastructure components, improved operational safety, and often contribute to higher process efficiency and reduced environmental impact due to less material degradation and fewer leaks. The ongoing innovation in alloy metallurgy continues to push the boundaries of performance, offering customized solutions for increasingly complex engineering challenges, thereby solidifying the market position of alloy tubes as a cornerstone of modern industrial infrastructure.

Driving factors for the alloy tubes market are profoundly linked to global economic growth and industrial development. A primary driver is the accelerating demand from the energy sector, particularly the oil and gas industry, which requires high-strength, corrosion-resistant tubing for drilling, exploration, and transportation in increasingly challenging environments, including deep-sea and shale gas operations. The expansion of chemical and petrochemical industries, driven by a growing global population and industrial output, also fuels demand for specialized alloy tubes capable of handling aggressive chemicals at high temperatures and pressures. Additionally, the power generation sector, especially with the construction of new thermal and nuclear power plants and the upgrading of existing infrastructure, relies heavily on alloy tubes for heat exchangers, boilers, and superheaters. Urbanization and infrastructure development, particularly in emerging economies, further contribute to market growth by increasing demand in construction and manufacturing. The stringent regulatory landscape for safety and environmental protection also compels industries to adopt higher-grade materials like alloy tubes to prevent failures and ensure compliance, thereby acting as a significant market driver across multiple end-use sectors, fostering innovation and greater adoption.

Alloy Tubes Market Executive Summary

The Alloy Tubes Market is experiencing dynamic shifts driven by a complex interplay of global business trends, evolving technological landscapes, and persistent industrial demands. A prominent business trend is the increasing emphasis on advanced material solutions that offer enhanced performance characteristics, such as superior corrosion resistance, heightened mechanical strength, and excellent thermal stability, particularly crucial in sectors like energy, defense, and chemical processing. This has led to substantial investments in research and development by manufacturers to innovate new alloy compositions and processing techniques, enabling them to meet increasingly stringent application requirements and maintain a competitive edge. Furthermore, there is a clear trend towards consolidation within the industry, as larger players acquire niche specialists to expand their product portfolios, technological capabilities, and global market reach. Supply chain optimization and strategic partnerships are also becoming critical, as companies seek to mitigate raw material price volatility and ensure a stable, efficient flow of specialized materials to their diverse customer base. The market is also witnessing a growing focus on sustainability and lifecycle management, with manufacturers exploring environmentally friendly production methods and recyclable alloy options, aligning with global corporate social responsibility initiatives and regulatory pressures.

Regional trends significantly shape the market dynamics, with distinct patterns emerging across key geographical areas. Asia Pacific, spearheaded by rapid industrialization in countries like China, India, and Southeast Asian nations, stands as the largest and fastest-growing market for alloy tubes. This growth is propelled by massive infrastructure projects, burgeoning manufacturing sectors, and increasing energy demands. North America and Europe, while more mature markets, exhibit steady demand driven by the modernization of existing industrial facilities, the replacement of aging infrastructure, and robust activity in the aerospace and defense sectors. These regions also lead in technological advancements and the adoption of high-value, specialized alloy products for critical applications. The Middle East and Africa (MEA) region shows considerable potential, primarily due to extensive investments in oil and gas exploration, production, and refining capacities, coupled with developing chemical industries. Latin America is also a growing market, spurred by investments in mining, oil and gas, and infrastructure development, though often subject to economic and political stability. Each region presents unique challenges and opportunities, requiring tailored market entry strategies and localized product offerings to effectively capture market share and cater to specific industrial needs.

Segmentation trends within the alloy tubes market reveal specific areas of growth and evolving preferences. By material type, nickel-based alloys and high-grade stainless steel alloys are projected to witness substantial demand due to their exceptional corrosion resistance and high-temperature performance, making them ideal for aggressive environments in chemical processing and power generation. Titanium alloys are also gaining traction, particularly in aerospace and medical applications, owing to their outstanding strength-to-weight ratio and biocompatibility. In terms of application, the oil and gas sector continues to be a dominant segment, requiring a vast array of alloy tubes for drilling, pipelines, and refineries, with increasing demand for superalloys in extreme downhole conditions. The chemical and petrochemical industry is another significant consumer, driven by the expansion of processing units and the need for materials resistant to diverse corrosive media. Power generation, especially in advanced nuclear and supercritical thermal plants, also commands high-performance alloy tubes for heat exchangers and boiler components. Furthermore, the automotive and aerospace industries are increasingly integrating lighter, stronger alloy tubes to enhance fuel efficiency and structural integrity, pointing towards continued diversification and specialization across end-use sectors, each demanding bespoke material solutions to optimize performance and adhere to stringent industry standards and safety protocols.

AI Impact Analysis on Alloy Tubes Market

The integration of Artificial Intelligence (AI) and machine learning technologies is poised to fundamentally transform various facets of the alloy tubes market, from raw material sourcing and manufacturing processes to quality control, supply chain management, and even demand forecasting. Common user questions related to AI's impact often revolve around how AI can enhance production efficiency, reduce waste, improve product quality, and potentially lower costs. There are significant concerns regarding the initial investment required for AI adoption, the need for skilled personnel to manage these advanced systems, and the data security implications of integrating AI across sensitive industrial operations. Users are also keen to understand how AI can help in predicting material failures, optimizing maintenance schedules for machinery, and streamlining complex logistical challenges. Expectations are high that AI will lead to more personalized alloy solutions, faster market response times, and ultimately, a more resilient and agile manufacturing ecosystem, enabling manufacturers to navigate market volatility with greater precision and leverage data-driven insights for strategic decision-making in a highly competitive global landscape, thereby driving a paradigm shift in operational methodologies and competitive advantages.

- Predictive Maintenance: AI algorithms analyze sensor data from manufacturing equipment to predict potential failures, enabling proactive maintenance and minimizing downtime in alloy tube production lines.

- Quality Control and Inspection: AI-powered vision systems detect defects in alloy tubes with higher accuracy and speed than traditional methods, ensuring superior product quality and reducing scrap rates.

- Process Optimization: Machine learning models optimize parameters for melting, extrusion, rolling, and heat treatment processes, leading to improved material properties, reduced energy consumption, and increased yield.

- Supply Chain Management: AI enhances demand forecasting, optimizes inventory levels, and improves logistics for raw materials and finished products, leading to more efficient supply chains and reduced operational costs.

- New Material Development: AI accelerates the discovery and design of novel alloy compositions with desired properties by simulating material behavior and predicting performance characteristics, speeding up R&D cycles.

- Energy Efficiency: AI systems monitor and adjust energy usage in manufacturing facilities in real-time, identifying opportunities for significant energy savings in energy-intensive processes like heating and cooling.

- Customization and Personalization: AI allows for rapid customization of alloy tube specifications based on customer requirements, facilitating agile manufacturing and quicker fulfillment of specialized orders.

- Market Trend Analysis: AI tools analyze vast datasets to identify emerging market trends, competitive landscapes, and potential new applications, providing strategic insights for business development.

- Worker Safety: AI can monitor workplace conditions and identify potential hazards, contributing to a safer manufacturing environment by predicting and preventing accidents.

- Environmental Impact Reduction: By optimizing processes and reducing waste, AI contributes to more sustainable manufacturing practices, aligning with global environmental objectives.

DRO & Impact Forces Of Alloy Tubes Market

The alloy tubes market is influenced by a comprehensive set of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that shape its trajectory. The primary drivers include the relentless expansion of industrial infrastructure globally, particularly in emerging economies, which necessitates high-performance materials for new construction and modernization projects. Crucially, the robust demand from critical end-use industries such as oil and gas, chemical and petrochemical processing, and power generation, all of which require tubes capable of withstanding extreme conditions and corrosive environments, consistently fuels market growth. Technological advancements in metallurgy, leading to the development of new alloys with enhanced properties, also act as a significant driver, enabling manufacturers to meet increasingly stringent performance requirements. Furthermore, global trends towards energy efficiency and stricter environmental regulations compel industries to adopt superior materials like alloy tubes to prevent leakages, reduce maintenance, and ensure operational integrity, thereby driving their adoption across diverse applications. The increasing complexity of industrial processes, demanding higher-strength and more resilient components, further underscores the indispensable role of alloy tubes in maintaining modern industrial operations at optimal levels.

Despite the strong growth drivers, the alloy tubes market faces several notable restraints. Volatility in raw material prices, particularly for key alloying elements such as nickel, chromium, molybdenum, and titanium, presents a significant challenge, leading to unpredictable production costs and impacting profitability margins for manufacturers. The capital-intensive nature of alloy tube manufacturing, requiring substantial investments in advanced machinery, furnaces, and processing facilities, can deter new entrants and limit expansion for smaller players. Additionally, stringent environmental regulations regarding industrial emissions and waste disposal during the manufacturing process add to operational costs and complexities, necessitating continuous investment in compliance technologies. The availability of substitute materials, albeit with often inferior performance characteristics for critical applications, can also pose a restraint in certain less demanding sectors. Furthermore, the global economic slowdowns or geopolitical uncertainties can impact industrial investment and project development, thereby temporarily suppressing demand for alloy tubes. These multifaceted restraints necessitate strategic planning and robust supply chain management by market participants to mitigate risks and ensure sustainable growth in a dynamic global environment.

Opportunities within the alloy tubes market are abundant and diverse, promising sustained growth and innovation. The emergence of new and advanced applications in niche sectors, such as hydrogen transportation and storage, carbon capture technologies, and concentrated solar power systems, presents significant growth avenues for specialized alloy tubes. The increasing adoption of high-strength, lightweight alloys in the automotive and aerospace industries, driven by the need for fuel efficiency and reduced emissions, offers substantial opportunities for market expansion. Furthermore, the growing demand for renewable energy infrastructure, including offshore wind turbines and geothermal power plants, requires durable and corrosion-resistant tubing solutions, creating new markets for specialized alloy tubes. Opportunities also arise from the global focus on upgrading aging industrial infrastructure, particularly in developed economies, which necessitates the replacement of older components with more robust and efficient alloy tubes. Manufacturers can also capitalize on the growing trend towards customization and value-added services, offering bespoke alloy solutions tailored to specific customer requirements and providing comprehensive technical support and after-sales services. Strategic collaborations with research institutions and end-use industries to co-develop innovative alloy solutions further enhance market opportunities, paving the way for advanced material applications and sustained market leadership.

Segmentation Analysis

The alloy tubes market is extensively segmented to reflect the diverse range of products, applications, and end-use industries it serves, providing a granular view of market dynamics and growth opportunities. This comprehensive segmentation allows for a deeper understanding of specific market niches, demand patterns, and competitive landscapes, enabling stakeholders to formulate targeted strategies. The market is primarily categorized by material type, which defines the chemical composition and inherent properties of the tubes; by application, detailing the specific industrial uses where these tubes are deployed; by end-use industry, identifying the broader sectors consuming these products; by outer diameter, differentiating tubes based on their physical dimensions; and by manufacturing process, distinguishing between seamless and welded production methods. Each segment possesses unique characteristics and growth drivers, influenced by technological advancements, regulatory environments, and specific industrial requirements. Analyzing these segments individually and in conjunction provides crucial insights into market trends, competitive positioning, and future growth potential across the global alloy tubes landscape.

- By Material Type:

- Stainless Steel Alloys: Comprising various grades like 304, 316, 321, and duplex stainless steels (e.g., 2205, 2507), known for excellent corrosion resistance and strength across a wide range of temperatures. Widely used in chemical, food processing, and architectural applications.

- Nickel Alloys: Including Inconel, Monel, Hastelloy, and Nimonic series, offering superior resistance to extreme temperatures, aggressive corrosive media, and high-pressure environments. Critical for aerospace, power generation, and highly corrosive chemical plants.

- Titanium Alloys: Renowned for high strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. Primary applications in aerospace, medical implants, marine, and chemical processing.

- Copper Alloys: Such as brass, bronze, and cupro-nickel, valued for excellent thermal conductivity, corrosion resistance, and ductility. Commonly used in heat exchangers, plumbing, and electrical applications.

- Other Alloys: Including zirconium alloys, aluminum alloys, and specialized low-alloy steels designed for specific high-performance applications in nuclear, automotive, and infrastructure sectors, offering unique property combinations.

- By Application:

- Oil & Gas: For upstream (drilling, exploration), midstream (pipelines, transportation), and downstream (refining, processing) operations, requiring high-strength and corrosion-resistant tubes for severe environments.

- Chemical & Petrochemical: Used in reactors, heat exchangers, and piping systems to handle corrosive chemicals at high temperatures and pressures, ensuring operational safety and efficiency.

- Power Generation: Critical for boilers, superheaters, heat exchangers, and condensers in thermal, nuclear, and renewable energy plants, demanding high-temperature strength and fatigue resistance.

- Automotive: For exhaust systems, fuel lines, braking systems, and structural components, focusing on lightweight, high-strength, and corrosion-resistant solutions.

- Aerospace & Defense: Employed in aircraft hydraulic systems, engine components, structural frames, and missile systems, where light weight, high strength, and reliability are paramount.

- HVAC: For refrigeration coils, heat pumps, and air conditioning units, utilizing alloys with good thermal conductivity and corrosion resistance.

- Construction: In structural applications, architectural designs, and durable piping systems for infrastructure projects.

- Other Industrial: Includes applications in marine, pulp & paper, mining, food & beverage, and pharmaceutical industries, each requiring specific alloy properties.

- By End-Use Industry:

- Energy: Encompassing oil & gas, power generation (fossil, nuclear, renewable), and related infrastructure projects.

- Manufacturing: Covering automotive, aerospace, machinery, and general industrial fabrication.

- Infrastructure: Pertaining to construction, water treatment, and public utility networks.

- Transportation: Including marine vessels, rail, and land transport systems.

- By Outer Diameter:

- Small Diameter (Below 2 Inches): Typically used for instrumentation, hydraulic lines, and smaller heat exchangers, requiring precision and flexibility.

- Medium Diameter (2-6 Inches): Common for process piping, general industrial applications, and some structural uses, balancing strength and flow capacity.

- Large Diameter (Above 6 Inches): Primarily for major pipelines, large structural components, and high-volume fluid transfer systems, emphasizing robustness and capacity.

- By Manufacturing Process:

- Seamless: Produced by piercing a solid billet, resulting in a tube with uniform wall thickness and superior strength, ideal for high-pressure and high-temperature applications.

- Welded: Formed from a flat strip and welded along the seam, offering cost-effectiveness and flexibility in dimensions, suitable for less demanding applications or where large diameters are required.

Value Chain Analysis For Alloy Tubes Market

The value chain for the alloy tubes market is a complex ecosystem involving multiple stages, from raw material extraction and primary metal production to fabrication, distribution, and end-use application. It begins with the upstream segment, which is crucial for defining the quality and cost structure of the final product. This initial phase involves the mining and processing of essential raw materials such as iron ore, nickel, chromium, molybdenum, titanium, and copper. These raw materials are then refined into pure metals or ferroalloys, which are the fundamental building blocks for producing various alloy compositions. Key suppliers in this upstream segment include large-scale mining companies and metal refiners, whose operations are often global and subject to significant geopolitical and economic influences. The availability, quality, and price volatility of these raw materials directly impact the manufacturing costs and lead times for alloy tube producers. Effective management of upstream activities, including long-term supply contracts and diversification of sourcing, is paramount for ensuring a stable and cost-efficient supply of essential alloying elements, directly influencing the competitiveness of downstream manufacturers.

Following the upstream activities, the core manufacturing phase involves the intricate processes of melting, casting, forming, and finishing. Primary alloy tube manufacturers procure the refined metals and ferroalloys, then combine them in precise ratios to create specific alloy compositions. This is followed by various hot and cold working processes, such as extrusion, pilgering, drawing, and rolling, to form the tubes to the desired dimensions and properties. Heat treatment, surface finishing, and rigorous quality control inspections are integral steps to ensure the tubes meet specified mechanical properties, corrosion resistance, and dimensional tolerances. This stage is highly capital-intensive, requiring advanced metallurgical expertise, sophisticated machinery, and adherence to stringent quality standards and certifications. Companies invest heavily in research and development to innovate new alloy grades and optimize manufacturing processes, aiming to enhance product performance, reduce production costs, and minimize environmental impact. The ability to produce a wide range of high-quality, specialized alloy tubes efficiently and reliably is a key differentiator for manufacturers in this competitive market, directly impacting their market share and profitability.

The downstream segment of the value chain focuses on distribution, sales, and end-use applications. Once manufactured, alloy tubes are distributed to end-users through various channels, which can be direct or indirect. Direct sales channels involve manufacturers selling directly to large industrial customers or project contractors, often for bespoke orders requiring specific technical consultation and support. This approach allows for closer customer relationships and a deeper understanding of specific application requirements. Indirect distribution channels typically involve a network of distributors, wholesalers, and specialized stockists who maintain inventories of standard alloy tube products and serve a broader base of smaller to medium-sized customers across different industries. These distributors play a critical role in providing logistical support, cutting services, and often, initial technical advice. The choice of distribution channel depends on factors such as market reach, customer segmentation, product specialization, and logistical capabilities. Effective downstream management is essential for ensuring timely delivery, providing technical support, and building strong customer relationships, which are crucial for maintaining market presence and fostering repeat business in the highly demanding industrial landscape of alloy tubes. After-sales support and technical services are also vital components in ensuring customer satisfaction and driving long-term loyalty and market reputation.

Alloy Tubes Market Potential Customers

The potential customers for alloy tubes represent a diverse and extensive array of industries, each with unique requirements driven by their operational demands, environmental conditions, and regulatory mandates. At the forefront are the colossal oil and gas exploration, production, and refining sectors. Companies involved in upstream activities, such as drilling and extraction from conventional and unconventional reserves, require ultra-strong and corrosion-resistant tubes for drill pipes, casings, and downhole components that can withstand extreme pressures, high temperatures, and corrosive fluids like hydrogen sulfide. Midstream operations, including pipelines for transporting crude oil and natural gas, necessitate robust alloy tubes capable of enduring harsh external environments and internal corrosive media over long distances. Downstream refineries and petrochemical plants depend on alloy tubes for heat exchangers, reaction vessels, and process piping systems that handle aggressive chemicals at elevated temperatures, where material integrity is paramount for safety and continuous operation. These customers prioritize reliability, durability, and compliance with stringent industry standards like API and ASTM, making them significant drivers of demand for high-grade alloy tubes.

Another major segment of potential customers includes power generation companies, encompassing thermal, nuclear, and rapidly expanding renewable energy sectors. Thermal power plants, particularly those operating at supercritical and ultra-supercritical conditions, require advanced alloy tubes for superheaters, reheaters, and boiler tubes that can withstand extremely high temperatures and pressures to maximize efficiency and minimize emissions. Nuclear power plants demand specialized zirconium alloys and high-nickel alloys for fuel cladding and heat exchanger applications, where radiation resistance, corrosion resistance, and long-term stability are critical for safety and operational longevity. The burgeoning renewable energy sector, including concentrated solar power (CSP) and geothermal energy, also presents significant opportunities, requiring durable alloy tubes capable of handling high-temperature heat transfer fluids and corrosive geothermal brines. Furthermore, the aerospace and defense industries are critical customers, utilizing lightweight, high-strength titanium and nickel alloys for aircraft hydraulic systems, engine components, structural frames, and missile systems, where performance under extreme stress, temperature variations, and fatigue resistance are non-negotiable for operational integrity and occupant safety, driving demand for premium, highly certified alloy tubes.

Beyond the energy and aerospace sectors, a broad range of manufacturing and infrastructure industries constitute significant potential customers. The chemical processing industry, encompassing a vast array of specialty chemical producers, pharmaceutical manufacturers, and food and beverage processing plants, consistently seeks alloy tubes resistant to specific corrosive agents and capable of maintaining product purity. Automotive manufacturers are increasingly integrating high-strength, lightweight alloy tubes into exhaust systems, braking lines, and structural components to improve fuel efficiency, reduce emissions, and enhance overall vehicle performance and safety. Construction and infrastructure development projects, especially in urban areas and for critical public utilities, require durable alloy tubes for water treatment facilities, structural supports, and architectural applications where longevity and aesthetic appeal are important. The marine industry, including shipbuilding and offshore structures, also demands corrosion-resistant alloy tubes for seawater piping systems and structural components to withstand harsh saline environments. Each of these diverse customer segments evaluates alloy tubes based on a complex matrix of factors including material cost, performance specifications, compliance with international standards, supplier reliability, and the availability of technical support and customization options, underscoring the necessity for manufacturers to offer tailored solutions and robust service offerings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.3 Billion |

| Market Forecast in 2033 | USD 135.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ArcelorMittal, Nippon Steel Corporation, POSCO, Baosteel Group, JFE Steel Corporation, ThyssenKrupp AG, Sumitomo Corporation, Valin ArcelorMittal Automotive Steel, Sandvik AB, Tubacex S.A., Tenaris S.A., Vallourec S.A., Salzgitter AG, Voestalpine AG, Outokumpu Oyj, Allegheny Technologies Incorporated (ATI), Kobe Steel, Ltd., Tata Steel Ltd., Corinth Pipeworks, Zekelman Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Alloy Tubes Market Key Technology Landscape

The alloy tubes market is characterized by a continuously evolving technological landscape, driven by the relentless pursuit of enhanced material properties, optimized manufacturing processes, and cost efficiency to meet the increasingly rigorous demands of industrial applications. A cornerstone of this landscape is advanced metallurgy, focusing on developing novel alloy compositions that offer superior performance characteristics, such as ultra-high corrosion resistance, exceptional strength-to-weight ratios, and enhanced thermal stability. This includes the development of superalloys capable of withstanding extreme temperatures and pressures in aerospace engines and power generation turbines, as well as duplex and super duplex stainless steels specifically designed for highly corrosive environments in oil and gas and chemical processing. Innovations in alloying elements and precise control over microstructure through advanced heat treatment processes are critical for achieving these desired properties, enabling tubes to perform reliably in environments previously deemed too harsh for conventional materials. The continuous investment in metallurgical research is fundamental to unlocking new applications and maintaining a competitive edge in a market where material performance is paramount.

Beyond material composition, manufacturing technologies play a pivotal role in shaping the alloy tubes market. Seamless tube manufacturing, utilizing processes like rotary piercing (Mannesmann process) for hot-rolled tubes and cold drawing or cold pilgering for cold-finished tubes, remains crucial for applications demanding high pressure and uniform structural integrity. Advancements in these processes focus on improving dimensional accuracy, surface finish, and reducing material waste. For welded tubes, technologies such as laser welding, plasma arc welding (PAW), and electron beam welding (EBW) are gaining traction due to their ability to produce high-quality, narrow, and deep welds with minimal heat-affected zones, ensuring mechanical properties close to those of the base material. Friction stir welding (FSW) is also an emerging technology, particularly for challenging-to-weld alloys, offering solid-state joining with excellent mechanical properties. Automation and robotics are increasingly integrated into tube manufacturing lines, from material handling and processing to quality inspection, enhancing operational efficiency, consistency, and worker safety while reducing manual labor requirements and associated human error, leading to higher throughput and reduced production costs across the board.

Furthermore, non-destructive testing (NDT) and advanced inspection technologies are indispensable within the alloy tubes market to ensure product integrity and compliance with stringent industry standards. Techniques such as ultrasonic testing (UT), eddy current testing (ECT), radiographic testing (RT), and magnetic particle inspection (MPI) are routinely employed to detect internal and surface flaws, ensuring the absence of defects that could compromise performance in critical applications. Modern NDT systems often incorporate automation and sophisticated data analysis, including AI and machine learning, to improve detection accuracy and speed, reducing inspection times and enhancing overall quality assurance. Digitalization and Industry 4.0 principles are also transforming the manufacturing landscape, with the adoption of IoT sensors for real-time monitoring of production parameters, big data analytics for process optimization, and digital twins for simulating manufacturing scenarios and predicting equipment behavior. These technologies facilitate predictive maintenance, optimize resource utilization, and enable more agile and responsive production cycles, positioning manufacturers to better adapt to market fluctuations and deliver high-quality, customized alloy tube solutions with greater efficiency and precision, further solidifying their role in supporting critical global industries.

Regional Highlights

- North America: This region represents a mature yet robust market for alloy tubes, characterized by significant demand from the oil and gas industry, particularly in shale extraction and offshore drilling operations, which require high-performance, corrosion-resistant materials. The United States and Canada are also strong markets for aerospace and defense applications, driving demand for specialized titanium and nickel alloys. Furthermore, ongoing modernization of aging infrastructure in power generation and chemical processing sectors contributes to steady growth. The region benefits from substantial investments in R&D and advanced manufacturing technologies, ensuring the production of high-quality, customized alloy solutions. Strict environmental regulations and safety standards also compel industries to adopt superior material grades, thereby fostering demand for premium alloy tubes. The market here is driven by technological innovation and a focus on high-value applications, with an emphasis on performance and reliability in critical industrial settings.

- Europe: Europe is a key market, driven by a strong industrial base in Germany, France, the UK, and Italy, with significant demand from chemical and petrochemical, power generation, and automotive sectors. The region is a leader in adopting advanced manufacturing techniques and sustainable practices, influencing the demand for innovative and eco-friendly alloy tube solutions. Investments in renewable energy infrastructure, such as offshore wind farms and advanced nuclear power facilities, further fuel the need for specialized alloy tubes. While some traditional industries are mature, there's a strong emphasis on upgrading existing facilities and developing high-tech applications. Stringent EU regulations concerning quality, safety, and environmental impact promote the use of high-grade alloy tubes, ensuring compliance and enhancing operational longevity across various European industries. The robust automotive industry, especially in Germany, also contributes significantly to the demand for lightweight and high-strength alloy tubes for enhanced vehicle performance and efficiency.

- Asia Pacific (APAC): APAC stands as the largest and fastest-growing market, primarily fueled by rapid industrialization, urbanization, and massive infrastructure development in countries like China, India, Japan, and South Korea. The region's burgeoning manufacturing sector, including automotive, electronics, and heavy industries, drives substantial demand. Significant investments in oil and gas exploration, refinery expansions, and power plant construction across the region are key growth engines. China, in particular, dominates in terms of consumption and production capacity, with India rapidly emerging as a major market due to its ambitious industrial growth plans and infrastructure projects. The increasing energy demand, coupled with governmental initiatives to boost industrial output and develop new industrial parks, creates a fertile ground for market expansion. While price sensitivity is a factor, the sheer scale of industrial activity and infrastructure development ensures a continuous and escalating demand for alloy tubes across a broad spectrum of applications, from basic industrial piping to highly specialized chemical processing equipment and power generation components.

- Latin America: This region presents a growing market opportunity, particularly in countries like Brazil, Mexico, and Argentina, driven by investments in the oil and gas sector, mining, and infrastructure development. Brazil, with its extensive offshore oil reserves, contributes significantly to the demand for high-strength, corrosion-resistant alloy tubes for exploration and production. Mexico's robust manufacturing sector, especially automotive, also drives demand. Economic growth and increased foreign direct investment are spurring industrial expansion, leading to higher consumption of alloy tubes across various applications. However, market growth can be influenced by economic volatility and political stability. Despite these challenges, the long-term prospects remain positive due to the region's rich natural resources and ongoing efforts to industrialize and modernize infrastructure, requiring reliable and durable material solutions for diverse industrial projects. The need for advanced materials in the processing of raw materials like minerals and agricultural products also contributes to the regional market for specialized tubing solutions.

- Middle East and Africa (MEA): The MEA region is characterized by substantial investments in its vast oil and gas reserves, which are the primary drivers for the alloy tubes market. Countries like Saudi Arabia, UAE, and Qatar are undertaking massive projects in upstream, midstream, and downstream sectors, requiring large quantities of high-performance alloy tubes for drilling, pipelines, refineries, and petrochemical complexes. Diversification efforts by many MEA economies into non-oil sectors, such as manufacturing, tourism infrastructure, and renewable energy, are also creating new avenues for market growth. Infrastructure development, including new cities and industrial zones, further contributes to demand. While the market is heavily influenced by global oil prices, the strategic importance of the region's energy sector ensures sustained demand for superior quality alloy tubes. Africa, though varied, shows emerging demand from new oil and gas discoveries and infrastructure development projects in select countries, indicating future growth potential in the long term, albeit with unique logistical and economic considerations for market entry and expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Alloy Tubes Market.- ArcelorMittal

- Nippon Steel Corporation

- POSCO

- Baosteel Group

- JFE Steel Corporation

- ThyssenKrupp AG

- Sumitomo Corporation

- Valin ArcelorMittal Automotive Steel

- Sandvik AB

- Tubacex S.A.

- Tenaris S.A.

- Vallourec S.A.

- Salzgitter AG

- Voestalpine AG

- Outokumpu Oyj

- Allegheny Technologies Incorporated (ATI)

- Kobe Steel, Ltd.

- Tata Steel Ltd.

- Corinth Pipeworks

- Zekelman Industries

Frequently Asked Questions

Analyze common user questions about the Alloy Tubes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of alloy tubes?

Alloy tubes are essential in critical industries such as oil and gas (for exploration, production, and refining), chemical and petrochemical processing (for aggressive fluid handling), power generation (for boilers and heat exchangers), automotive (for exhaust and structural components), and aerospace (for lightweight, high-strength parts). Their application spans any sector requiring superior resistance to corrosion, high temperatures, or extreme pressures, ensuring operational integrity and safety across diverse industrial environments.

How do raw material prices impact the alloy tubes market?

Raw material prices, particularly for nickel, chromium, molybdenum, and titanium, significantly influence the alloy tubes market. Volatility in these prices directly affects manufacturing costs, which can lead to fluctuating product prices and impact profit margins for producers. Manufacturers often employ strategies like long-term contracts and hedging to mitigate these risks, but substantial price swings can still affect market stability and investment decisions across the value chain, necessitating careful financial planning and agile supply chain management.

What are the key technological advancements in alloy tube manufacturing?

Key technological advancements include the development of new alloy compositions with enhanced properties (e.g., super duplex stainless steels, advanced nickel-based superalloys), improvements in seamless and welded manufacturing processes for greater precision and efficiency (e.g., laser welding, cold pilgering), and the increasing integration of automation, robotics, and Industry 4.0 concepts (IoT, AI for process optimization and quality control). These innovations lead to superior product quality, reduced production costs, and faster response times, enabling customized solutions for complex industrial demands.

Which regions are leading the growth in the alloy tubes market?

The Asia Pacific (APAC) region is currently leading the growth in the alloy tubes market, driven by rapid industrialization, extensive infrastructure development, and significant investments in manufacturing and energy sectors, particularly in China and India. North America and Europe, while mature, demonstrate steady demand fueled by industrial modernization and high-tech applications in aerospace and defense. The Middle East and Africa (MEA) also show strong potential, primarily due to substantial oil and gas investments and economic diversification initiatives.

What role does sustainability play in the alloy tubes industry?

Sustainability is increasingly important, driving manufacturers to adopt environmentally friendly production methods, reduce energy consumption, and minimize waste during alloy tube fabrication. This includes efforts to use recyclable materials, optimize processes for lower carbon footprints, and ensure products contribute to the longevity and efficiency of industrial systems, thereby reducing overall environmental impact. Compliance with environmental regulations and the growing demand for sustainable sourcing also shape purchasing decisions by end-users, pushing the industry towards greener practices and lifecycle assessment considerations for materials and products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Alloy Tubes Market Size Report By Type (Seamless Alloy Tubes, Welded Alloy Tubes), By Application (Oil and Gas, Food Industry, Automotive, Power Industry, Chemical Industry, Construction, Water Treatment, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Alloy Tubes Market Statistics 2025 Analysis By Application (Oil and Gas, Food Industry, Automotive, Power Industry, Chemical Industry, Construction, Water Treatment, Others), By Type (Seamless Alloy Tubes, Welded Alloy Tubes), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Alloy Tubes Market Statistics 2025 Analysis By Application (Oil and Gas, Food Industry, Automotive, Power Industry, Chemical Industry, Construction, Water Treatment), By Type (Seamless Alloy Tubes, Welded Alloy Tubes), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager