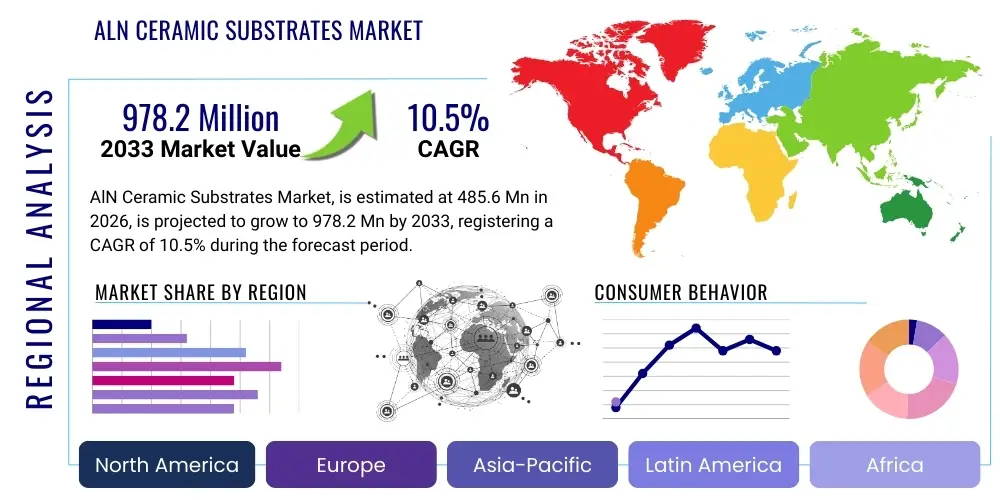

AlN Ceramic Substrates Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439421 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

AlN Ceramic Substrates Market Size

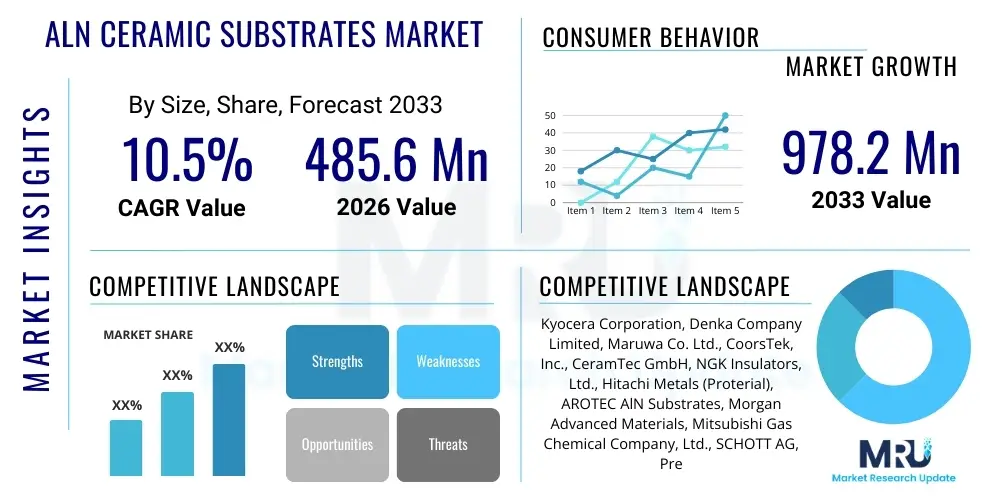

The AlN Ceramic Substrates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 485.6 Million in 2026 and is projected to reach USD 978.2 Million by the end of the forecast period in 2033.

AlN Ceramic Substrates Market introduction

The AlN Ceramic Substrates Market encompasses the production and distribution of aluminum nitride (AlN) based ceramic materials, primarily utilized as heat sinks and electrical insulators in high-performance electronic applications. AlN ceramic substrates are renowned for their exceptional thermal conductivity, electrical insulation properties, and mechanical strength, making them indispensable in environments demanding efficient heat dissipation and robust dielectric characteristics. These substrates serve as foundational components in various advanced electronic devices, particularly where silicon-based materials fall short in thermal management.

Major applications for AlN ceramic substrates span across critical industries including power electronics, LED lighting, automotive electronics, and high-frequency communication devices. In power electronics, they facilitate the efficient operation of inverters, converters, and power modules by preventing overheating. For LED lighting, AlN substrates enhance lumen output and extend device lifespan by effectively managing heat generated by high-power LEDs. Their utility in automotive electronics, particularly for electric and hybrid vehicles, is growing due to the increasing demand for high-reliability components in challenging thermal environments.

The primary benefits of AlN ceramic substrates include superior thermal conductivity (significantly higher than alumina), excellent electrical insulation, a coefficient of thermal expansion (CTE) closely matched to silicon, and high mechanical strength. These attributes contribute to enhanced device performance, reliability, and miniaturization capabilities. Driving factors for market growth include the escalating demand for high-power density electronic devices, the rapid proliferation of 5G technology, the expansion of the electric vehicle market, and the increasing adoption of wide-bandgap semiconductors like GaN and SiC, which operate at higher temperatures and require advanced thermal management solutions.

AlN Ceramic Substrates Market Executive Summary

The AlN Ceramic Substrates Market is experiencing robust growth driven by an accelerating need for advanced thermal management solutions across multiple high-tech industries. Business trends indicate a strong focus on innovation in manufacturing processes to reduce costs and improve material purity, alongside strategic collaborations between substrate manufacturers and device integrators to develop application-specific solutions. The market is characterized by increasing investment in research and development aimed at enhancing thermal performance and exploring new metallization techniques to support complex circuit designs, while also addressing environmental sustainability concerns through more energy-efficient production methods.

Regionally, the Asia Pacific (APAC) stands out as the dominant market, largely attributed to its established electronics manufacturing ecosystem, significant investments in 5G infrastructure, and the rapidly expanding electric vehicle production hubs in countries like China, Japan, and South Korea. North America and Europe also represent significant markets, driven by stringent performance requirements in aerospace and defense, medical devices, and high-reliability industrial applications. Emerging economies within APAC, Latin America, and the Middle East and Africa are expected to demonstrate substantial growth opportunities, fueled by increasing industrialization and technological adoption.

In terms of segment trends, the power electronics segment continues to be a primary revenue driver, witnessing high demand for AlN substrates in IGBT modules, MOSFETs, and rectifiers for industrial power supplies and renewable energy systems. The automotive electronics segment is poised for accelerated growth due to the electrification of vehicles and the subsequent need for robust thermal management in power inverters and battery management systems. Furthermore, advancements in packaging technologies, such as Chip-on-Board (COB) and System-in-Package (SiP), are increasingly leveraging AlN substrates for their superior thermal properties, indicating a strong trend towards integration and miniaturization across various electronic device categories.

AI Impact Analysis on AlN Ceramic Substrates Market

User questions regarding AI's impact on the AlN Ceramic Substrates Market often center on its role in optimizing manufacturing processes, influencing demand for high-performance computing (HPC) hardware, and potentially enabling new material discovery or design methodologies. Key themes revolve around how AI can enhance efficiency, reduce defects in complex AlN substrate production, and drive the need for more sophisticated thermal management in AI accelerators and data centers. There are also expectations about AI's ability to predict material properties and accelerate R&D cycles for next-generation AlN composites, alongside concerns about the initial investment required for AI integration and the need for specialized data infrastructure.

- AI-driven process optimization: Enhances manufacturing efficiency, reduces defects, and improves yield rates in AlN substrate production through predictive analytics and machine learning algorithms.

- Increased demand from AI hardware: High-performance AI processors, GPUs, and data center components require superior thermal management, directly boosting the demand for AlN substrates in advanced packaging.

- Accelerated material R&D: AI and machine learning tools can simulate and predict material properties, speeding up the discovery and development of novel AlN formulations or composite structures with improved performance.

- Supply chain optimization: AI can optimize AlN ceramic substrate supply chains, predicting demand fluctuations, managing inventory, and streamlining logistics to reduce costs and improve responsiveness.

- Enhanced quality control: AI-powered vision systems and sensor data analysis can perform real-time, high-precision quality checks during production, ensuring the integrity and reliability of AlN substrates.

- Predictive maintenance: AI algorithms can monitor manufacturing equipment, forecasting potential failures and enabling proactive maintenance, thereby minimizing downtime and increasing production throughput.

- Customization and design flexibility: AI can facilitate the rapid design and customization of AlN substrates for specific applications, optimizing thermal pathways and electrical characteristics based on complex performance requirements.

DRO & Impact Forces Of AlN Ceramic Substrates Market

The AlN Ceramic Substrates Market is significantly shaped by a confluence of Drivers, Restraints, and Opportunities, all operating under various Impact Forces. Key drivers include the escalating demand for highly efficient thermal management solutions in modern electronics, propelled by the continuous pursuit of miniaturization and increased power density in devices. The widespread adoption of 5G technology, the rapid growth of electric vehicles (EVs) and hybrid electric vehicles (HEVs), and the expanding market for LED lighting and wide-bandgap (WBG) semiconductors (such as SiC and GaN) are major catalysts. These technologies inherently operate at higher temperatures and require superior heat dissipation capabilities that AlN substrates uniquely provide, ensuring device reliability and extending operational lifespans.

However, several restraints challenge the market's full potential. The high manufacturing cost associated with AlN substrates, primarily due to complex sintering processes and the purity requirements of raw materials, presents a significant barrier to wider adoption, especially in cost-sensitive applications. Competition from alternative substrate materials like alumina (Al2O3), silicon carbide (SiC), and even direct bonded copper (DBC) or active metal brazed (AMB) technologies, although often with lower thermal performance, can limit AlN market penetration. Furthermore, the intricate and energy-intensive production process for high-purity AlN can lead to supply chain vulnerabilities and environmental concerns, requiring continuous innovation in sustainable manufacturing.

Despite these challenges, substantial opportunities exist for market expansion. The growing investment in advanced packaging technologies, such as 3D integration and System-in-Package (SiP), creates new avenues for AlN substrates where their thermal properties are critical for densely packed components. Untapped potential in emerging applications like medical implants, aerospace and defense electronics, and high-frequency communication modules (e.g., radar systems) offers diversification. Furthermore, ongoing research into novel manufacturing techniques, such as additive manufacturing for complex geometries and advanced metallization processes, promises to reduce costs and enhance performance, making AlN more competitive. Impact forces, including technological advancements in material science, evolving regulatory frameworks for electronic waste and energy efficiency, geopolitical dynamics influencing raw material supply, and fluctuating global economic conditions, collectively shape the market trajectory by influencing investment, demand, and production strategies.

Segmentation Analysis

The AlN Ceramic Substrates Market is extensively segmented to provide a detailed understanding of its diverse applications and material types. These segmentations are crucial for identifying specific market niches, understanding competitive landscapes, and tailoring product development strategies. The market can be broadly categorized based on the type of substrate, its primary application, and the end-user industry it serves, reflecting the varied requirements of different electronic systems and manufacturing processes. Each segment presents unique growth drivers, technological challenges, and opportunities for manufacturers and suppliers.

- By Type:

- High Purity AlN Substrates

- Standard Grade AlN Substrates

- Thin Film AlN Substrates

- Thick Film AlN Substrates

- By Application:

- Power Electronics

- LED Lighting

- Automotive Electronics

- High-Frequency Devices

- Medical Devices

- Aerospace & Defense

- Consumer Electronics

- By End-User Industry:

- Semiconductor Industry

- Telecommunications

- Automotive

- Energy

- Healthcare

- Industrial

Value Chain Analysis For AlN Ceramic Substrates Market

The value chain for AlN ceramic substrates begins with the upstream procurement of high-purity raw materials, primarily aluminum powder and nitrogen gas, which are foundational for synthesizing aluminum nitride powder. This stage involves specialized chemical suppliers who ensure the quality and consistency of these precursor materials, as impurities can significantly impact the final thermal and electrical properties of the AlN substrate. Following raw material processing, AlN powder manufacturers convert these precursors into high-grade AlN powder suitable for ceramic fabrication, often involving advanced synthesis techniques to control particle size and morphology.

The midstream segment of the value chain involves the actual fabrication of AlN ceramic substrates. This typically includes processes like pressing, tape casting, sintering at high temperatures, and subsequent machining and metallization. Substrate manufacturers utilize advanced equipment and precise control mechanisms to produce substrates with specific dimensions, surface finishes, and circuit patterns, catering to diverse application requirements. This stage requires significant technological expertise and capital investment, making it a critical bottleneck and a source of competitive differentiation within the market.

Downstream, the manufactured AlN substrates are integrated into electronic devices. This involves semiconductor manufacturers, power module assemblers, LED package manufacturers, and automotive electronics suppliers who mount semiconductor chips and other components onto the AlN substrates. The distribution channel can be direct, where substrate manufacturers supply directly to large-scale device integrators, or indirect, involving distributors and agents who cater to smaller manufacturers or provide value-added services like customization and logistics. The final stage involves the sale of finished electronic products incorporating AlN substrates to end-users, underscoring the indirect but vital role of AlN in enhancing product performance and reliability across numerous industries.

AlN Ceramic Substrates Market Potential Customers

Potential customers for AlN ceramic substrates are primarily industries and manufacturers involved in the production of high-performance electronic devices that demand superior thermal management and robust electrical insulation. The core base includes companies operating within the semiconductor manufacturing sector, particularly those fabricating power devices, integrated circuits, and advanced sensor technologies. These buyers seek AlN for its ability to dissipate heat generated by densely packed components, thereby ensuring operational stability and prolonging device lifespan. The rising complexity and power density of chips for AI, 5G, and high-performance computing further amplify this demand.

Another significant segment of potential customers is the automotive electronics industry. As electric vehicles (EVs) and hybrid vehicles become more prevalent, the need for efficient thermal management in power inverters, converters, battery management systems, and charging infrastructure components intensifies. Automotive manufacturers and their tier-1 suppliers require substrates that can withstand harsh operating conditions, including high temperatures and vibrations, while reliably managing heat from high-power modules. AlN's thermal properties and mechanical strength make it an ideal choice for these critical automotive applications.

Furthermore, manufacturers in the LED lighting, telecommunications, and industrial power supply sectors represent substantial end-users. LED lighting companies utilize AlN to enhance the performance and longevity of high-power LED modules by effectively drawing heat away from the semiconductor junctions. In telecommunications, especially with the rollout of 5G infrastructure, AlN is crucial for base stations and RF modules operating at higher frequencies and power levels. Industrial applications, such as power converters for renewable energy systems, industrial lasers, and factory automation equipment, also rely on AlN ceramic substrates for their thermal and electrical stability, ensuring robust and reliable operation in demanding industrial environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 485.6 Million |

| Market Forecast in 2033 | USD 978.2 Million |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kyocera Corporation, Denka Company Limited, Maruwa Co. Ltd., CoorsTek, Inc., CeramTec GmbH, NGK Insulators, Ltd., Hitachi Metals (Proterial), AROTEC AlN Substrates, Morgan Advanced Materials, Mitsubishi Gas Chemical Company, Ltd., SCHOTT AG, Precision Ceramics, Suruga Seiki Co., Ltd., Tokuyama Corporation, Remtec Inc., Micropac Technology, Inc., KCC Corporation, Zhejiang Sino Microelectronics Co., Ltd., Hebei Sinopack Electronic Technology Co., Ltd., Beijing Century Hi-Tech Ceramic Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

AlN Ceramic Substrates Market Key Technology Landscape

The AlN Ceramic Substrates Market is characterized by a dynamic technological landscape that constantly evolves to meet the stringent demands of advanced electronics. Central to this landscape is the continuous improvement in manufacturing processes, particularly in powder synthesis and sintering techniques. High-purity AlN powder production is critical, with ongoing research focused on reducing impurities and controlling particle morphology to achieve optimal thermal conductivity and mechanical properties in the final substrate. Advanced sintering methods, such as hot pressing, hot isostatic pressing (HIP), and pressureless sintering with various additives, are continuously refined to achieve high-density, void-free substrates at lower temperatures and costs, enhancing throughput and yield.

Metallization technology is another pivotal aspect of the AlN substrate market. Since AlN is an electrical insulator, conductive patterns must be applied to its surface to create functional circuits. Common metallization techniques include thin-film technologies (e.g., sputtering, evaporation for Ti/W/Au, Ni/Au layers), thick-film technologies (e.g., screen printing of Ag, Au, or Cu pastes), and direct bonded copper (DBC) or active metal brazed (AMB) processes. Advances in these areas aim to improve adhesion strength, electrical conductivity, and thermal cycle reliability of the metallized layers, which are critical for power electronics and high-frequency applications. Development of novel metallization schemes that are lead-free and compatible with wider ranges of operating temperatures is also a key focus.

Furthermore, the integration of AlN substrates into sophisticated electronic packages drives innovation in bonding and interconnection technologies. Techniques such as eutectic bonding, transient liquid phase (TLP) bonding, and advanced polymeric adhesives are being developed to create reliable interfaces between the AlN substrate and semiconductor chips or other package components. Miniaturization trends also push for finer line/space patterning capabilities on AlN, requiring advanced lithography and etching processes. The adoption of additive manufacturing techniques, like 3D printing of AlN ceramics, is an emerging technology that promises to create complex geometries and integrated cooling channels, potentially revolutionizing thermal management solutions in the long term by enabling designs previously impossible with traditional methods.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to its robust electronics manufacturing base, significant investments in 5G infrastructure, and rapid growth in electric vehicle production in countries like China, Japan, South Korea, and Taiwan. These countries are major producers and consumers of high-power density electronic devices, driving substantial demand for AlN ceramic substrates.

- North America: A significant market driven by technological innovation in aerospace and defense, advanced medical devices, and high-performance computing. Strong R&D capabilities and a focus on high-reliability applications contribute to steady demand for premium AlN substrates.

- Europe: Characterized by strong automotive and industrial electronics sectors, particularly in Germany, France, and Italy. The region's emphasis on renewable energy technologies and stringent performance standards also fuels the adoption of AlN ceramic substrates for power modules and converters.

- Latin America: An emerging market with growing industrialization and increasing adoption of electronics. While smaller, the region shows potential, particularly in automotive manufacturing and basic industrial power applications.

- Middle East and Africa (MEA): Currently a smaller market but poised for growth due to infrastructure development, increasing urbanization, and expanding telecommunications networks. Demand is primarily concentrated in specific industrial projects and specialized electronics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the AlN Ceramic Substrates Market.- Kyocera Corporation

- Denka Company Limited

- Maruwa Co. Ltd.

- CoorsTek, Inc.

- CeramTec GmbH

- NGK Insulators, Ltd.

- Hitachi Metals (Proterial)

- AROTEC AlN Substrates

- Morgan Advanced Materials

- Mitsubishi Gas Chemical Company, Ltd.

- SCHOTT AG

- Precision Ceramics

- Suruga Seiki Co., Ltd.

- Tokuyama Corporation

- Remtec Inc.

- Micropac Technology, Inc.

- KCC Corporation

- Zhejiang Sino Microelectronics Co., Ltd.

- Hebei Sinopack Electronic Technology Co., Ltd.

- Beijing Century Hi-Tech Ceramic Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the AlN Ceramic Substrates market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are AlN ceramic substrates and why are they used?

AlN (Aluminum Nitride) ceramic substrates are advanced ceramic materials known for their exceptional thermal conductivity, electrical insulation, and mechanical strength. They are primarily used in high-performance electronics to efficiently dissipate heat from semiconductor devices, ensuring optimal operating temperatures, enhancing reliability, and extending device lifespan, especially in applications with high power density or demanding thermal environments.

What are the primary applications of AlN ceramic substrates?

AlN ceramic substrates are extensively used across various high-tech sectors. Key applications include power electronics (e.g., IGBT modules, rectifiers in inverters and converters), LED lighting (for high-power LED packages), automotive electronics (in electric vehicle power modules and battery management systems), high-frequency communication devices (5G base stations, RF modules), medical devices, and aerospace & defense electronics where thermal stability and reliability are paramount.

How do AlN substrates compare to other ceramic substrates like Alumina (Al2O3)?

AlN substrates offer significantly higher thermal conductivity (typically 170-200 W/mK) compared to alumina (Al2O3), which is around 20-30 W/mK. This superior thermal performance makes AlN ideal for heat-intensive applications. Additionally, AlN has a coefficient of thermal expansion (CTE) that is closely matched to silicon, reducing thermal stress on bonded components, a key advantage over Al2O3 in many semiconductor applications.

What are the main drivers for the growth of the AlN Ceramic Substrates market?

The market is driven by several factors, including the increasing demand for high-power density electronics, the proliferation of 5G technology, the rapid growth of electric vehicles (EVs) requiring robust power modules, and the widespread adoption of wide-bandgap (WBG) semiconductors (like GaN and SiC) which operate at higher temperatures and necessitate advanced thermal management solutions for optimal performance and longevity.

What challenges does the AlN Ceramic Substrates market face?

Key challenges include the high manufacturing cost of AlN substrates due to complex sintering processes and the requirement for high-purity raw materials. Competition from alternative, often lower-cost, substrate materials also poses a restraint. Furthermore, managing the intricate supply chain for specialized raw materials and ensuring sustainable production methods are ongoing challenges for market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager