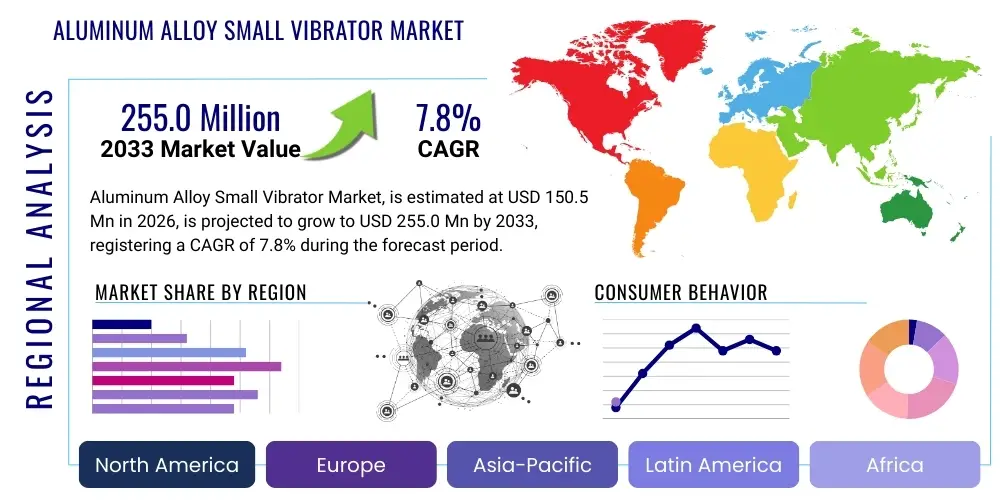

Aluminum Alloy Small Vibrator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438300 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Aluminum Alloy Small Vibrator Market Size

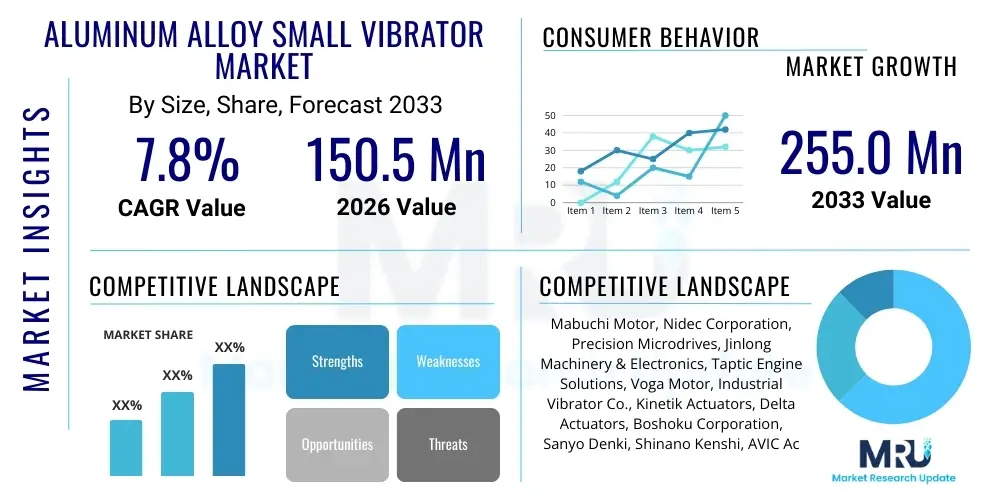

The Aluminum Alloy Small Vibrator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $150.5 Million in 2026 and is projected to reach $255.0 Million by the end of the forecast period in 2033.

Aluminum Alloy Small Vibrator Market introduction

The Aluminum Alloy Small Vibrator Market encompasses precision electromechanical devices designed to generate controlled vibrational forces for various end-use applications, ranging from consumer electronics haptics to highly demanding industrial processes. These devices utilize aluminum alloys—known for their high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance—in their housing and structural components. This selection ensures that the vibrators are lightweight yet durable, critical features for applications requiring high frequency, low energy consumption, and long operational life, particularly in portable or compact equipment. The core product provides kinetic energy conversion, often driven by brushed or brushless DC motors, optimized for specific frequency ranges and amplitudes.

Key applications driving the market expansion include the rapidly evolving field of haptic feedback systems in smartphones, gaming consoles, and medical diagnostics equipment, where precise and rapid tactile response is mandatory. Furthermore, in industrial sectors, these small vibrators are essential components in automated feeders, material conveyance systems, and precision screening machinery, especially where minimal footprint and reliable operation are non-negotiable. The inherent benefits of using aluminum alloy—such as superior heat dissipation compared to plastic casings—allow these components to operate continuously under higher stress levels, thereby increasing machine uptime and operational efficiency.

Major driving factors fueling the market growth include the global trend toward industrial automation and the increasing integration of Internet of Things (IoT) technologies in manufacturing processes, necessitating reliable, miniature actuators. The rising demand for enhanced user experience in consumer devices through advanced haptic effects, coupled with stringent quality control requirements in pharmaceutical and food processing industries (where precision material handling is vital), further cements the market trajectory. The transition towards energy-efficient components also favors aluminum alloy constructions due to their optimized mass distribution, leading to better mechanical efficiency.

Aluminum Alloy Small Vibrator Market Executive Summary

The Aluminum Alloy Small Vibrator Market is characterized by robust growth, primarily driven by the proliferation of automation technologies across diverse industrial and consumer sectors. Current business trends indicate a strong move toward customization and the development of specialized vibrators tailored for specific frequency and force outputs, particularly for high-precision applications like surgical robotics and sophisticated sorting systems. Manufacturers are heavily investing in material science research to further enhance alloy properties, focusing on vibration dampening within the housing structure while maximizing the output efficiency of the internal motor mechanism. This push for specialization is critical for maintaining competitive edge against standard magnetic actuators.

Regional trends reveal that the Asia Pacific (APAC) region maintains market dominance, propelled by its status as a global manufacturing hub for consumer electronics and automotive components, which are major end-users. North America and Europe, however, exhibit strong growth in high-value segments, specifically in precision medical devices and advanced industrial automation, demanding vibrators with highly accurate frequency control and superior durability. The European market, in particular, is influenced by stringent environmental regulations, favoring aluminum alloy solutions due to their recyclability and lighter weight, which contribute to overall energy savings in final products.

Segment-wise, the market is primarily segmented by motor type (Eccentric Rotating Mass (ERM) and Linear Resonant Actuator (LRA)), and application (Haptics, Industrial Processing, and Medical). The Haptics segment is experiencing the fastest expansion due to the constant iteration and improvement of tactile feedback in handheld devices. Furthermore, the industrial processing segment, driven by requirements in material handling and precise dosing systems, continues to provide a stable foundational revenue stream. Overall, the market outlook remains highly positive, contingent upon continuous innovation in lightweight motor technology and optimization of aluminum alloy fabrication techniques.

AI Impact Analysis on Aluminum Alloy Small Vibrator Market

User queries regarding the impact of Artificial Intelligence (AI) often center on how AI can optimize the performance and lifespan of small vibrators, particularly within complex automated systems. Key user concerns revolve around predictive maintenance—using AI to analyze vibration patterns and preempt component failure—and the integration of AI-driven control loops to achieve ultra-precise haptic feedback or material flow regulation. Users also inquire about AI's role in the design phase, specifically optimizing the geometry and material distribution of the aluminum alloy housing to maximize thermal efficiency and minimize unwanted harmonic vibrations. The general consensus is that AI is moving the market beyond simple mechanical actuation toward intelligent, self-monitoring systems, leading to higher efficiency and reduced downtime in critical applications like robotics and high-speed sorting.

AI's initial impact is felt predominantly in the manufacturing process itself, leveraging machine learning algorithms to optimize aluminum casting and CNC machining processes, ensuring tighter tolerances and enhanced consistency, crucial for high-frequency performance. Secondly, AI facilitates smarter integration at the system level. For instance, in automated feeding systems, AI algorithms can dynamically adjust the vibrator's frequency and amplitude based on real-time sensor data regarding material viscosity, density, or throughput rate, ensuring optimal flow without jamming or wastage. This transition from static, pre-set operational parameters to dynamic, intelligent control is a significant market shift.

In consumer electronics, particularly haptics, AI is essential for creating rich, context-aware tactile experiences. AI models analyze inputs (screen interaction, game state, notification type) and translate them into complex, nuanced vibration patterns that the aluminum alloy small vibrator executes. This level of complexity requires instantaneous processing and precise actuation control, capabilities that traditional control methods cannot match. Consequently, AI acts as a multiplier for the value proposition of high-quality aluminum alloy components, turning them from simple actuators into sophisticated interfaces.

- AI optimizes manufacturing yield by analyzing defects in aluminum alloy components during production.

- Predictive maintenance algorithms use vibration signature data to forecast vibrator failure, reducing industrial downtime.

- AI-driven control systems enable dynamic frequency and amplitude adjustments for precise material handling in automation.

- Machine Learning models enhance haptic fidelity by generating complex, context-specific tactile feedback patterns in consumer devices.

- AI assists in optimizing the mechanical design of the aluminum housing for improved thermal management and reduced parasitic vibration.

DRO & Impact Forces Of Aluminum Alloy Small Vibrator Market

The market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping the competitive landscape and technological evolution. Key drivers include the relentless global push towards compact and high-performance electronic devices, necessitating miniature, durable, and thermally efficient vibration mechanisms. The expansion of factory automation, particularly in sectors requiring sanitary or corrosion-resistant equipment (where aluminum alloys excel), further solidifies demand. Restraints primarily involve the high initial cost associated with precision aluminum machining and assembly compared to standard plastic or steel motor enclosures, alongside the continuous challenge of suppressing unwanted noise and harmonic vibrations generated during high-frequency operation. Opportunities emerge from the potential integration of these vibrators into advanced health monitoring wearables and the utilization of novel piezoelectric materials to supplement or replace traditional motor-driven systems, enhancing energy efficiency and responsiveness.

Drivers are strongly augmented by impact forces such as stringent quality standards in medical device manufacturing and the automotive industry’s shift toward advanced human-machine interfaces (HMI) requiring superior tactile feedback. The performance requirements necessitate the use of premium materials like specialized aluminum alloys, ensuring long-term reliability and precise force delivery. However, the market faces constraints related to technological maturity; while aluminum alloys offer thermal benefits, scaling down the size without compromising vibrational amplitude or lifespan remains a constant technical hurdle. Furthermore, the cyclical nature of the consumer electronics industry introduces demand volatility, impacting long-term investment planning for manufacturers.

Impact forces also include geopolitical stability influencing the supply chain of key raw materials (aluminum, copper for windings, and rare earth elements for magnets) and the pace of digitization globally. Opportunities for growth are strategically aligned with emerging applications in micro-robotics and 3D printing post-processing, where highly controllable, small-scale vibration is required for surface finish optimization or powder bed densification. Successfully navigating the high entry barriers related to precision engineering and securing strong intellectual property protections related to motor design and alloy formulation are critical for companies aiming to capitalize on these high-growth opportunities.

Segmentation Analysis

The Aluminum Alloy Small Vibrator Market is comprehensively segmented based on its fundamental operational characteristics, application area, and end-use industry, reflecting the diverse requirements of modern technology sectors. This segmentation allows manufacturers to tailor product specifications—such as frequency range, force output, and operational environment suitability—to meet specific customer needs, from low-power haptics to robust industrial sorting tasks. Key differentiators include the type of actuation mechanism employed, which dictates the performance profile, and the regional adoption rates of automation technologies, which heavily influence sales volume across different geographical markets.

- By Actuator Type:

- Eccentric Rotating Mass (ERM) Vibrators

- Linear Resonant Actuators (LRA)

- Piezoelectric Vibrators (Hybrid Aluminum Enclosures)

- By Frequency Range:

- Low Frequency (50 Hz - 150 Hz)

- Mid Frequency (150 Hz - 300 Hz)

- High Frequency (Above 300 Hz)

- By Application:

- Haptic Feedback (Consumer Electronics, Gaming)

- Industrial Automation and Material Handling (Feeders, Screeners)

- Medical Devices (Diagnostic, Surgical Tools)

- Automotive HMI and Safety

- Aerospace and Defense

- By End-Use Industry:

- Consumer Electronics and Telecommunications

- Machinery and Equipment Manufacturing

- Healthcare and Pharmaceuticals

- Construction and Mining

- Food Processing and Agriculture

Value Chain Analysis For Aluminum Alloy Small Vibrator Market

The value chain for the Aluminum Alloy Small Vibrator Market initiates with upstream activities focused on the sourcing and processing of raw aluminum, copper, and specialized magnetic materials. Upstream analysis highlights the dependence on primary aluminum smelters and the need for high-purity alloy compositions (e.g., 6000 series or specialized die-casting alloys) that offer optimal machinability and structural integrity required for precision vibrator housing. Key activities at this stage include refining, alloying, and primary casting processes, followed by precision CNC machining of the housing components to micron-level tolerances, which significantly impacts the vibrator's balance and operational life. Price volatility in base metals, particularly aluminum, poses a major risk at this initial stage, compelling manufacturers to implement robust inventory and hedging strategies.

The midstream segment involves the core manufacturing process: integrating the motor components (stator, rotor, magnet, windings) within the aluminum housing and balancing the eccentric mass or linear actuator mechanism. This phase requires specialized automated assembly lines and rigorous quality control protocols, including dynamic balancing tests, to ensure vibrational consistency and minimize acoustic noise. Distribution channels are bifurcated into direct sales to large Original Equipment Manufacturers (OEMs)—especially in the consumer electronics and automotive sectors—and indirect channels via specialized industrial component distributors and catalog resellers for smaller industrial maintenance, repair, and operations (MRO) requirements. The efficiency of the distribution network is crucial for timely delivery, especially for high-volume consumer product cycles.

Downstream analysis focuses on the end-user application and post-sale services. Direct distribution (D2C for OEMs) ensures tight technical collaboration and customization, vital for integrating vibrators into cutting-edge products like next-generation surgical robots or advanced mobile devices. Indirect channels, through regional distributors, provide accessibility to a broader range of smaller industrial users who rely on readily available, standardized components. Customer satisfaction is heavily reliant on the longevity and reliability of the vibrator in its intended harsh environment (e.g., high heat, dust, continuous operation), driving demand for comprehensive warranties and readily available technical support regarding frequency adjustment and fault diagnostics.

Aluminum Alloy Small Vibrator Market Potential Customers

Potential customers for aluminum alloy small vibrators are predominantly industrial Original Equipment Manufacturers (OEMs) and developers in the high-technology sectors who prioritize durability, thermal performance, and low weight in their final product designs. The primary buyer segments include major smartphone and tablet manufacturers, who require high-fidelity haptic feedback systems, making them critical, high-volume purchasers. Additionally, industrial automation companies designing feeding systems, small parts sorting machinery, and pharmaceutical dosing equipment represent a stable customer base, valuing the corrosion resistance and robust nature of aluminum alloy construction necessary for demanding 24/7 operational cycles and sanitary environments.

The medical and defense sectors constitute high-value, niche customer segments. Medical device manufacturers, particularly those involved in developing portable diagnostic tools, miniature surgical instruments, or rehabilitation equipment, purchase these vibrators based on their precision actuation capabilities and hypoallergenic properties (often achieved through specialized alloy coatings). Defense contractors utilize these components in communication equipment, portable surveillance gear, and specialized guidance systems where weight savings are paramount, justifying the higher unit cost associated with the aluminum alloy construction.

Furthermore, smaller enterprises involved in specialized machinery creation, such as custom 3D printer manufacturers requiring vibration platforms for powder stabilization, and automotive suppliers integrating sophisticated tactile alerts into steering wheels and dashboards, represent expanding buyer categories. These customers seek customized solutions, often requiring suppliers to meet stringent quality certifications (e.g., ISO 13485 for medical, or IATF 16949 for automotive), pushing the market toward high-specification, bespoke aluminum alloy vibrator solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $150.5 Million |

| Market Forecast in 2033 | $255.0 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mabuchi Motor, Nidec Corporation, Precision Microdrives, Jinlong Machinery & Electronics, Taptic Engine Solutions, Voga Motor, Industrial Vibrator Co., Kinetik Actuators, Delta Actuators, Boshoku Corporation, Sanyo Denki, Shinano Kenshi, AVIC Actuation, Dema Actuator Systems, Alps Alpine, Johnson Electric, Minibrations Inc., Haptic Technologies Ltd., Coreless Dynamics, Vibra-Tech Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Alloy Small Vibrator Market Key Technology Landscape

The technological landscape of the Aluminum Alloy Small Vibrator Market is defined by continuous innovation focused on enhancing power efficiency, precision control, and reducing physical size while maintaining high durability. A primary technological focus is on motor design, particularly the adoption of Brushless DC (BLDC) motors or coreless DC motors, which offer higher energy conversion efficiency and extended lifespan compared to traditional brushed motors, essential for battery-powered consumer applications. Aluminum alloys are critical here, as their superior thermal management capabilities allow these high-speed motors to operate efficiently without overheating, thereby preventing performance degradation and ensuring reliability in compact enclosures.

Another crucial technological advancement involves the integration of advanced control electronics and firmware, enabling highly sophisticated signal processing for haptic feedback. Modern systems utilize advanced algorithms to modulate the frequency and amplitude rapidly, moving beyond simple on/off vibration to create intricate tactile textures. Furthermore, the fabrication technology used for the aluminum components itself is advancing, utilizing processes like micro-die casting and advanced CNC machining to achieve exceptionally tight dimensional tolerances and surface finishes. This precision is vital for the dynamic balancing of the eccentric mass in ERM vibrators and ensuring smooth movement in LRA systems, directly impacting the quality and consistency of the vibration output.

Emerging technologies include the hybridization of traditional motor systems with piezoelectric actuators. While piezoelectric solutions offer ultra-fast response times and low power consumption, their force output is often limited. Integrating them into an aluminum alloy housing allows them to supplement mechanical vibrators, offering a broader spectrum of haptic responses or providing ultra-fine control for micro-positioning industrial tasks. Furthermore, research into novel aluminum matrix composites and specialized anodization techniques seeks to improve wear resistance and electrical isolation, opening avenues for use in harsher, electromagnetically sensitive environments.

Regional Highlights

The regional dynamics of the Aluminum Alloy Small Vibrator Market are heavily influenced by local manufacturing concentration, consumer technology adoption rates, and the maturity of industrial automation infrastructure.

- Asia Pacific (APAC): Dominates the market due to the concentration of major consumer electronics manufacturing centers (China, South Korea, Taiwan) and a rapidly expanding industrial automation sector, particularly in logistics and automotive assembly. APAC is the largest consumer of small vibrators for high-volume, cost-competitive applications.

- North America: Characterized by high investment in advanced industrial automation, high-precision medical devices, and military applications. Demand is focused on high-specification, reliable, and highly customizable aluminum alloy vibrators, justifying premium pricing for superior performance.

- Europe: Exhibits steady growth driven by the automotive industry (HMI features) and stringent quality requirements in machinery manufacturing (e.g., food and pharmaceutical processing). Emphasis is placed on energy efficiency, regulatory compliance (REACH), and high mechanical longevity.

- Latin America (LATAM): Represents an emerging market with gradual adoption of automation in manufacturing and mining sectors. Growth is constrained by fluctuating economic conditions but presents opportunities for industrial-grade, cost-effective solutions.

- Middle East and Africa (MEA): Primarily driven by infrastructure projects and oil and gas sector demands, requiring robust, corrosion-resistant vibrators (often utilizing aluminum alloys for environmental resilience). The market size remains relatively smaller but is showing potential in specialized industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Alloy Small Vibrator Market.- Mabuchi Motor Co., Ltd.

- Nidec Corporation

- Precision Microdrives Ltd.

- Jinlong Machinery & Electronics Co., Ltd.

- Johnson Electric Holdings Ltd.

- Taptic Engine Solutions Inc.

- Voga Motor Technology

- Industrial Vibrator Co. (IVC)

- Kinetik Actuators Group

- Delta Actuators Systems

- Boshoku Corporation

- Sanyo Denki Co., Ltd.

- Shinano Kenshi Co., Ltd.

- AVIC Actuation Systems

- Dema Actuator Systems GmbH

- Alps Alpine Co., Ltd.

- Minibrations Inc.

- Haptic Technologies Ltd.

- Coreless Dynamics Pvt. Ltd.

- Vibra-Tech Systems Engineering

Frequently Asked Questions

Analyze common user questions about the Aluminum Alloy Small Vibrator market and generate a concise list of summarized FAQs reflecting key topics and concerns.Why is aluminum alloy preferred over plastics or steel for small vibrator housing?

Aluminum alloy is preferred due to its superior strength-to-weight ratio, excellent thermal dissipation characteristics, and inherent corrosion resistance. These features are critical for maintaining performance consistency, especially in compact, high-frequency, and heat-sensitive applications like consumer electronics and medical devices.

Which application segment drives the highest growth rate in this market?

The Haptic Feedback application segment, primarily driven by the continuous innovation and integration of advanced tactile user interfaces in smartphones, wearables, and gaming controllers, is expected to exhibit the highest Compound Annual Growth Rate (CAGR) through 2033.

How does AI technology affect the operational efficiency of aluminum alloy vibrators?

AI significantly enhances operational efficiency through predictive maintenance, monitoring vibration signatures to anticipate failures, and enabling dynamic control systems that adjust frequency and amplitude in real-time for optimized performance in automated material handling or precise haptic responses.

What is the primary technical challenge restraining widespread adoption of these vibrators in industrial settings?

The primary restraint is the higher manufacturing cost associated with the precision machining and dynamic balancing of aluminum alloy components compared to standard magnetic or plastic-cased vibrators, making them less suitable for extremely cost-sensitive, low-specification industrial tasks.

Which regional market holds the largest share for Aluminum Alloy Small Vibrators and why?

The Asia Pacific (APAC) region holds the largest market share, attributed to its position as the global hub for high-volume manufacturing of consumer electronics and its rapidly accelerating investment in large-scale industrial automation infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager