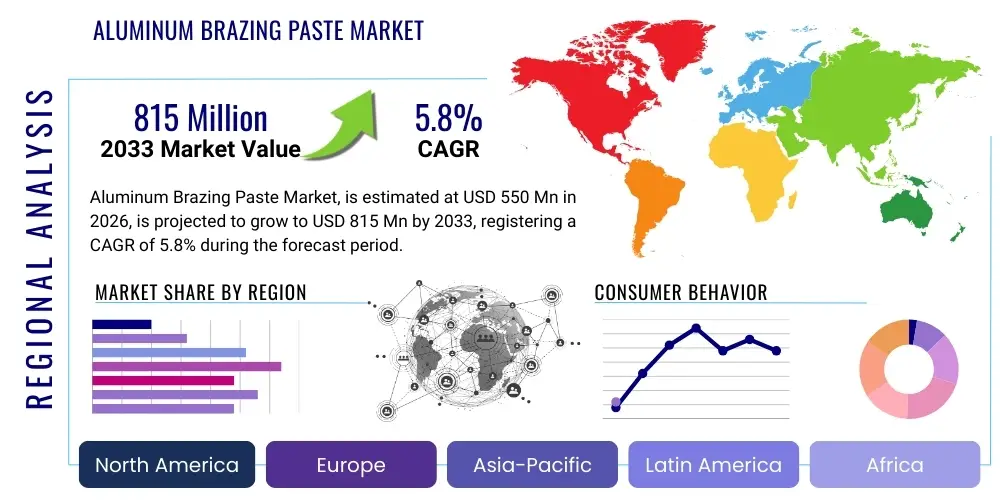

Aluminum Brazing Paste Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434935 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Aluminum Brazing Paste Market Size

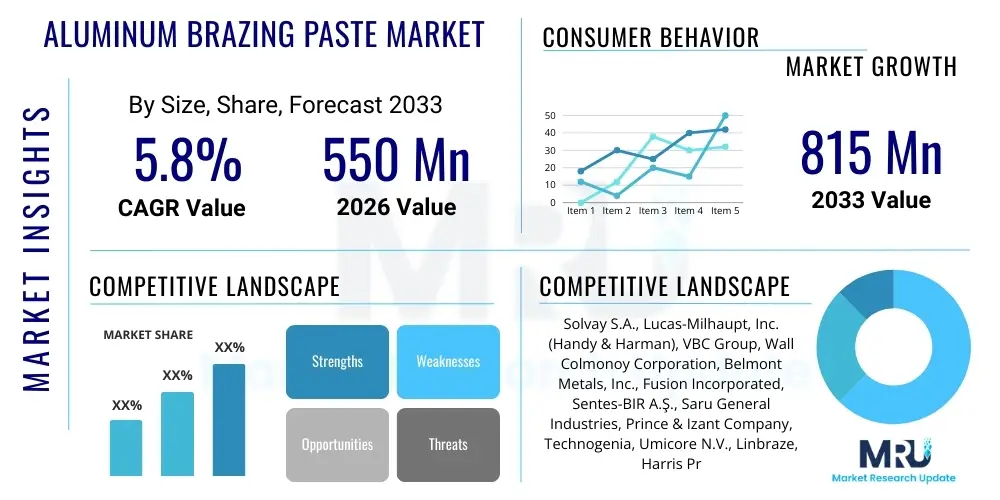

The Aluminum Brazing Paste Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 815 Million by the end of the forecast period in 2033.

Aluminum Brazing Paste Market introduction

Aluminum Brazing Paste is a specialized composite material consisting of aluminum alloy filler metal powder mixed with fluxing agents and a binder system, designed for joining aluminum components through a metallurgical process below the melting point of the base metal. This paste offers a highly precise and efficient method for automated and high-volume brazing applications, particularly in complex geometries where traditional methods prove challenging. Major applications span critical sectors such as the automotive industry, specifically for manufacturing radiators, condensers, and heat exchangers; the HVAC&R sector for coils and evaporators; and increasingly in electronic thermal management systems due to aluminum's favorable strength-to-weight ratio and high thermal conductivity. The primary benefits of utilizing brazing paste include superior joint strength, excellent leak tightness essential for fluid handling systems, and the ability to join multiple points simultaneously (multi-joint brazing). Driving factors propelling market growth include the global push for vehicle lightweighting to enhance fuel efficiency, the stringent regulatory environment necessitating high-performance thermal management systems, and the rapid expansion of electric vehicle (EV) manufacturing which heavily relies on efficient battery and power electronics cooling solutions.

Aluminum Brazing Paste Market Executive Summary

The global Aluminum Brazing Paste market is characterized by robust business trends driven by technological advancements in flux chemistry and automation integration. Key manufacturers are focusing on developing non-corrosive, low-residue pastes compatible with No-Bake, vacuum, and Controlled Atmosphere Brazing (CAB) processes, catering to the increasing demand for high-quality, clean joints in sensitive applications like aerospace and electronics. Segment trends indicate the Powder Type sub-segment, particularly potassium fluoroaluminate-based fluxes, maintaining dominance due to their efficacy and environmental advantages over traditional corrosive fluxes. Geographically, the Asia Pacific region, led by China and India, is expected to exhibit the highest growth rate, fueled by massive investment in automotive production, infrastructure development, and the rapid industrialization of the HVAC manufacturing base. North America and Europe, while mature, demonstrate stable growth driven by strict performance standards and the rapid adoption of specialized thermal management solutions required for advanced hybrid and electric vehicles, necessitating specialized aluminum joining solutions that ensure durability and thermal efficiency in extreme operating conditions.

AI Impact Analysis on Aluminum Brazing Paste Market

User queries regarding AI's influence in the brazing domain commonly center on predictive quality control, optimization of production parameters, and automated material handling. Users seek to understand how machine learning can analyze real-time sensor data from brazing furnaces (temperature profiles, atmosphere composition) to predict potential joint defects before they occur, thus minimizing scrap rates and ensuring superior metallurgical integrity. Furthermore, there is significant interest in using AI algorithms to optimize paste dispensing volumes and patterns based on component geometry, leading to material savings and enhanced application precision. The core concern revolves around the initial investment required for integrating vision systems and data infrastructure necessary for effective AI implementation, balanced against the potential return on investment from improved operational efficiency and consistency, particularly within high-stakes, high-volume production lines characteristic of automotive heat exchanger manufacturing.

- AI-driven Predictive Maintenance: Monitoring furnace parameters and component behavior to anticipate equipment failure or process drift, ensuring consistent brazing cycles.

- Quality Control Automation: Utilizing machine vision and deep learning algorithms to inspect brazed joints instantly, identifying micro-defects or flux residues with greater accuracy than human inspection.

- Process Optimization: Employing machine learning to fine-tune paste composition mixing ratios and dispensing rheology for optimal flow characteristics during complex multi-pass brazing operations.

- Supply Chain Forecasting: AI models assist manufacturers in forecasting demand for specific paste types (e.g., specialized low-temperature alloys) based on automotive and HVAC production schedules, optimizing inventory levels of raw materials like aluminum powder and specialized flux chemicals.

- Robot-Assisted Application: Enhancing the accuracy of automated paste dispensing robots by using AI to adapt application speed and trajectory in real-time, compensating for minor variations in component placement or tolerance stack-up.

DRO & Impact Forces Of Aluminum Brazing Paste Market

The Aluminum Brazing Paste market is fundamentally driven by the escalating demand for lightweight materials in transportation sectors, primarily propelled by global emission regulations and the proliferation of electric vehicles, which require advanced thermal management components (Drivers). However, the market faces significant restraints, including the high initial capital investment required for specialized Controlled Atmosphere Brazing (CAB) furnaces and the technical challenges associated with maintaining precise moisture and oxygen levels during the brazing process, which is critical for achieving defect-free joints. Opportunities abound in the development of novel flux systems that offer lower processing temperatures or are completely residue-free, broadening the applicability of aluminum brazing into more sensitive electronics packaging and microchannel components. The key impact forces influencing market dynamics include the rapidly changing technological landscape in flux chemistry, requiring continuous Research and Development (R&D) investment, and the fierce competition among Tier 1 suppliers in the automotive sector who mandate stringent quality and cost controls from their brazing paste providers, thereby putting pressure on manufacturers to innovate rapidly while maintaining competitive pricing structures.

Segmentation Analysis

The Aluminum Brazing Paste market is comprehensively segmented based on its core components, the technology utilized in the brazing process, and the critical end-use applications it serves. Analyzing these segments provides strategic insights into the most lucrative growth avenues and prevailing market dynamics. Segmentation by technology—particularly the controlled atmosphere brazing (CAB) versus vacuum brazing segments—reveals shifts toward CAB due to its cost-effectiveness and scalability for high-volume automotive production, while segmentation by end-user highlights the dominance and future growth potential of the automotive sector, driven by the shift towards efficient, compact, and lightweight heat exchange systems across all vehicle platforms, including internal combustion engine vehicles, hybrids, and electric mobility solutions.

- By Brazing Technology:

- Controlled Atmosphere Brazing (CAB)

- Vacuum Brazing

- By Product Type (Flux Type):

- Non-Corrosive Flux (Potassium Fluoroaluminate based)

- Corrosive Flux (Traditional Chloride based)

- By Application:

- Automotive (Radiators, Condensers, Heater Cores, Intercoolers)

- HVAC&R (Evaporators, Coils)

- Aerospace & Defense

- Electronics Cooling/Thermal Management

- By Filler Metal Alloy:

- Aluminum-Silicon Alloys (e.g., 4047)

- Specialty Alloys

Value Chain Analysis For Aluminum Brazing Paste Market

The value chain for Aluminum Brazing Paste begins with upstream activities involving the sourcing and processing of specialized raw materials. This includes high-purity aluminum powder, which forms the filler metal component, and critical fluxing agents, such as potassium fluoroaluminate salts, sourced from chemical suppliers. The quality, purity, and particle size distribution of both the aluminum powder and the fluxing salts are paramount, as they directly influence the rheology, shelf life, and ultimate performance of the paste during the brazing cycle. Manufacturers of brazing paste must employ specialized compounding and mixing equipment to ensure a highly homogeneous distribution of these fine particles within the organic binder system. This manufacturing step is technically challenging, requiring strict control over moisture content and temperature to prevent premature activation or degradation of the reactive flux components, thereby maintaining the desired viscosity for automated dispensing applications.

Midstream activities involve the formulation, testing, and packaging of the final paste product. Extensive quality control protocols are implemented here, including rheological testing (viscosity, yield stress) to ensure consistency for dispensing equipment and thermal testing to verify the melting characteristics and flux activity range. The distribution channel analysis highlights a dual approach: direct sales are common for large volume customers, particularly major automotive OEMs or Tier 1 heat exchanger manufacturers who require technical support and customized formulations specific to their production lines. Indirect distribution utilizes specialized chemical distributors or industrial consumables providers, particularly for smaller users or maintenance, repair, and overhaul (MRO) applications, offering wider geographic reach but often handling standard, off-the-shelf formulations. Maintaining the cold chain and proper storage conditions is crucial throughout the distribution process due to the sensitivity of the flux components.

The downstream segment focuses on the application and end-user consumption. Primary end-users, such as automotive heat exchanger manufacturers, integrate the paste into highly automated production lines, often involving robotic dispensing followed by processing in specialized CAB furnaces. Customer feedback loop integration is essential; issues related to flux residue, poor wetting, or inconsistent joint strength are relayed back to the manufacturers to refine paste compositions. The efficiency of the paste—measured by reduction in scrap rates, improvement in leak test reliability, and suitability for multi-pass brazing cycles—is the ultimate determinant of value capture for end-users, underscoring the necessity for close collaboration between the paste supplier and the manufacturing engineer responsible for brazing operations.

Aluminum Brazing Paste Market Potential Customers

The primary consumers and buyers of Aluminum Brazing Paste are large-scale manufacturers within the transportation and thermal management industries that require high-integrity, leak-proof joints in aluminum assemblies. Leading potential customers include Tier 1 and Tier 2 automotive suppliers specializing in heating, ventilation, air conditioning, and cooling (HVAC&R) systems, such as Behr, Denso, and Valeo, who utilize massive quantities of paste for manufacturing vehicle condensers, evaporators, and complex radiator structures. These customers demand pastes that offer exceptional dispensing accuracy suitable for robotic systems, minimal post-braze residue to avoid contamination of refrigerants, and compatibility with specific aluminum alloys, ensuring that the finished components meet stringent performance and durability standards mandated by original equipment manufacturers (OEMs).

Another crucial segment of potential customers resides in the industrial and commercial HVAC&R sectors. Manufacturers of commercial air conditioners, industrial chillers, and refrigeration units constitute a stable demand base. As efficiency standards for commercial buildings globally become more rigorous, the demand for high-performance, compact aluminum heat exchangers increases, consequently driving the need for reliable, production-friendly brazing pastes. These customers prioritize pastes that facilitate high production throughput and guarantee leak tightness over long operational lifecycles, often requiring non-corrosive fluxes to minimize post-cleaning requirements, thereby reducing overall manufacturing costs and environmental impact associated with chemical cleaning agents necessary for traditional brazing methods.

Emerging high-growth customers include manufacturers focused on electric vehicle (EV) battery cooling plates and power electronics thermal management modules. The sophisticated thermal needs of EVs necessitate lightweight, complex aluminum cooling circuits where precise material application is paramount. Aerospace and defense contractors also represent high-value potential customers, albeit for lower volumes, requiring extremely high-specification pastes suitable for brazing lightweight airframe components and critical heat exchangers used in avionics and satellite thermal control systems. These customers demand the highest quality certifications, often favoring vacuum brazing pastes or highly specialized CAB pastes that guarantee zero porosity and exceptional metallurgical cleanliness for safety-critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 815 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Solvay S.A., Lucas-Milhaupt, Inc. (Handy & Harman), VBC Group, Wall Colmonoy Corporation, Belmont Metals, Inc., Fusion Incorporated, Sentes-BIR A.Ş., Saru General Industries, Prince & Izant Company, Technogenia, Umicore N.V., Linbraze, Harris Products Group, Shenzhen Xinbaili Industrial Co., Ltd., Shanghai Al-Fin Brazing Materials Co., Ltd., Shaanxi Tiande Brazing Materials Co., Ltd., Bohler Welding, Metglas Inc., Brazing & Soldering Technologies Co., Ltd., P.R. China, H.C. Starck Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Brazing Paste Market Key Technology Landscape

The technological landscape of the Aluminum Brazing Paste market is fundamentally defined by advancements in flux chemistry and rheology engineering aimed at improving performance, environmental compliance, and compatibility with automated systems. The dominant technology remains Controlled Atmosphere Brazing (CAB), which relies heavily on non-corrosive flux materials, predominantly based on potassium fluoroaluminate (KAlF4). Technological innovation in this area focuses on developing fluxes with lower melting points and enhanced activity ranges to minimize the thermal stress on thin-walled aluminum components, crucial for modern, lightweight heat exchangers. Furthermore, optimization of the binder system—the organic carrier that holds the metal powder and flux in suspension—is critical to ensuring the paste exhibits thixotropic properties necessary for consistent application via robotic dispensing nozzles, preventing clogging, and ensuring the paste maintains its structural integrity prior to the bake-out stage in the furnace.

A significant technological focus is directed toward developing “green” brazing solutions and residue management. Traditional corrosive chloride fluxes required intensive post-braze cleaning, adding cost and environmental complexity. The transition to non-corrosive fluoroaluminate fluxes has dramatically reduced this requirement, but R&D is ongoing to achieve truly residue-free or low-residue pastes that simplify the overall manufacturing process, particularly important for systems like refrigeration units where internal cleanliness is paramount. This involves developing binder systems that volatilize cleanly during the heating cycle and flux formulations that encapsulate impurities effectively without leaving chemically active residues that could lead to subsequent corrosion or component fouling, thereby improving the long-term reliability of the finished product.

Moreover, the integration of brazing pastes with advanced manufacturing techniques is a growing trend. This includes compatibility with complex, multi-port, and microchannel aluminum components used in modern thermal management. Manufacturers are developing pastes specifically optimized for precision deposition techniques, such as screen printing or highly controlled jet dispensing, allowing for intricate application patterns on small surfaces with high tolerance requirements. The filler alloy composition itself is also subject to continuous refinement; while Aluminum-Silicon (e.g., AA4047) remains standard, specialty pastes are being formulated using optimized alloy particle sizes and distributions to ensure better gap filling and enhanced metallurgical bonds in increasingly diverse aluminum base materials, accommodating the wide variety of alloys used across automotive and aerospace applications.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, primarily due to the massive scale of automotive manufacturing in China and the rapid expansion of industrialization across Southeast Asia, driving exponential demand for HVAC&R equipment. China dominates regional consumption, driven by high production volumes of radiators and condensers, compounded by significant government investment in electric vehicle infrastructure and manufacturing, mandating advanced aluminum joining techniques.

- North America: This region is characterized by high technical specification requirements, particularly within the aerospace and high-performance automotive sectors. Growth is stable, propelled by regulatory pressure for increased vehicle fuel economy and the ongoing shift toward complex aluminum structures in military and commercial aviation, requiring premium, high-reliability brazing paste formulations suitable for both CAB and vacuum processes.

- Europe: The European market demonstrates mature demand, focusing intensely on environmental compliance and manufacturing efficiency. Strict EU regulations regarding materials and processes accelerate the adoption of non-corrosive, low-residue fluoroaluminate pastes. Germany and France are key consumers, driven by high-end automotive production (premium vehicles) and rigorous industrial heating and cooling applications, emphasizing quality assurance and consistent material performance.

- Latin America: This region offers moderate growth potential, tied primarily to the local automotive assembly and replacement parts market (aftermarket HVAC). Market expansion is constrained by economic volatility and reliance on imported technology, but increasing industrialization, particularly in Brazil and Mexico, ensures a steady, albeit sensitive, demand for cost-effective and standard aluminum brazing paste formulations.

- Middle East and Africa (MEA): Growth in MEA is largely concentrated in infrastructure projects and the robust demand for air conditioning systems, driven by high ambient temperatures. The construction and commercial refrigeration sectors are significant end-users. Demand tends to focus on durable, reliable paste products that can withstand challenging environmental conditions, ensuring leak integrity in large-scale HVAC installations across the Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Brazing Paste Market.- Solvay S.A.

- Lucas-Milhaupt, Inc. (Handy & Harman)

- VBC Group

- Wall Colmonoy Corporation

- Belmont Metals, Inc.

- Fusion Incorporated

- Sentes-BIR A.Ş.

- Saru General Industries

- Prince & Izant Company

- Technogenia

- Umicore N.V.

- Linbraze

- Harris Products Group

- Shenzhen Xinbaili Industrial Co., Ltd.

- Shanghai Al-Fin Brazing Materials Co., Ltd.

- Shaanxi Tiande Brazing Materials Co., Ltd.

- Bohler Welding

- Metglas Inc.

- Brazing & Soldering Technologies Co., Ltd., P.R. China

- H.C. Starck Solutions

Frequently Asked Questions

Analyze common user questions about the Aluminum Brazing Paste market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using Aluminum Brazing Paste over traditional aluminum welding or flux application methods?

Aluminum Brazing Paste offers significant advantages in high-volume production due to its suitability for automated dispensing, ensuring precise and consistent filler metal and flux placement. Unlike welding, brazing minimizes thermal distortion, resulting in superior dimensional accuracy and integrity, which is critical for complex geometries like multi-port tubes in heat exchangers. The paste format also facilitates simultaneous brazing of multiple joints (multi-joint brazing) in controlled atmosphere furnaces (CAB), drastically increasing production efficiency and ensuring high-quality, leak-tight connections essential for fluid systems.

How does Controlled Atmosphere Brazing (CAB) affect the choice of aluminum brazing paste and its performance?

CAB technology requires non-corrosive aluminum brazing paste, typically utilizing potassium fluoroaluminate (KAlF4) flux rather than traditional chloride-based fluxes. The inert nitrogen atmosphere in the furnace, combined with precise control over oxygen and moisture levels, allows the non-corrosive flux to effectively remove aluminum oxides without leaving residues that require post-braze cleaning. This results in cleaner components, improved long-term reliability, and a significantly reduced environmental impact, making CAB and its specialized pastes the standard for high-volume automotive and HVAC aluminum component manufacturing globally.

Which end-use application segments are expected to drive the highest growth for specialized aluminum brazing pastes?

The highest growth is anticipated from the Electric Vehicle (EV) and high-performance electronics cooling segments. The increasing adoption of EVs requires highly efficient, lightweight battery cooling plates and power electronics heat sinks, often constructed from complex aluminum alloys. These components demand specialized, highly reliable aluminum brazing pastes capable of precision application in microchannel structures and ensuring robust thermal transfer, surpassing the growth rate observed in the traditional automotive radiator and conventional HVAC&R sectors.

What role does rheology play in the selection and application of aluminum brazing paste in automated systems?

Rheology, which defines the flow and deformation characteristics of the paste, is paramount for automated dispensing systems. Paste manufacturers engineer specific rheological properties, such as viscosity and thixotropy, to ensure the paste can be consistently and accurately dispensed through robotic nozzles without stringing or clogging. High thixotropy is essential to prevent the paste from slumping after application, ensuring it maintains its geometry on the joint prior to entering the furnace, thereby guaranteeing sufficient material is present for forming a reliable metallurgical bond during the heat cycle.

Are there environmental concerns associated with modern aluminum brazing fluxes, and what innovations address these?

While traditional chloride fluxes posed significant environmental challenges due to corrosive residue and waste water treatment requirements, modern non-corrosive fluoroaluminate fluxes (used in CAB) have largely mitigated these concerns. Current innovation focuses on developing low-VOC (Volatile Organic Compound) binder systems and advancing towards "no-residue" flux compositions. These advancements seek to minimize all chemical byproducts, further simplifying manufacturing processes, reducing energy consumption associated with post-braze treatment, and enhancing worker safety, aligning with stringent global environmental standards like REACH.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager