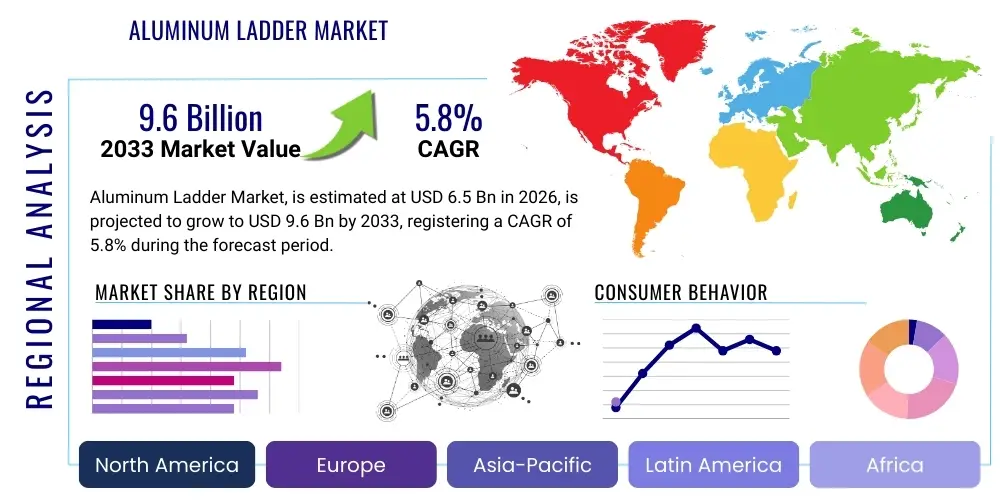

Aluminum Ladder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438476 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Aluminum Ladder Market Size

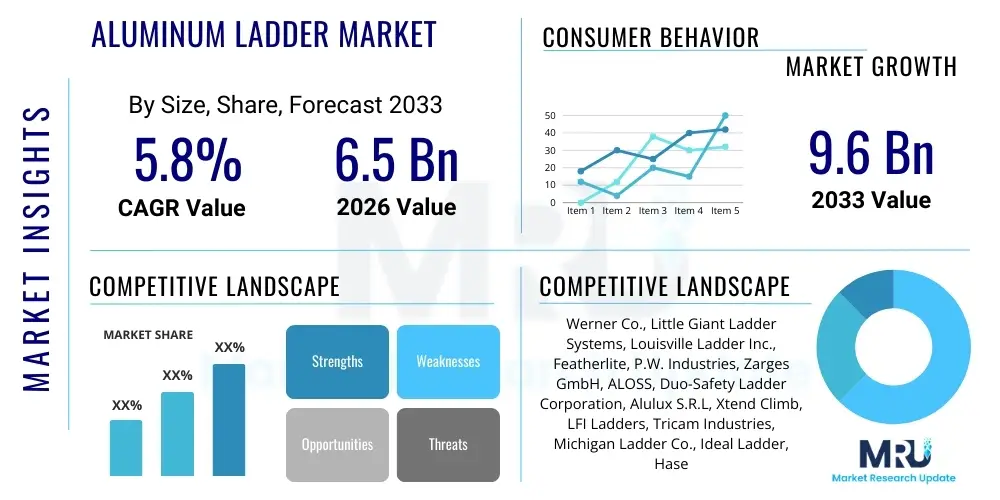

The Aluminum Ladder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 6.5 Billion in 2026 and is projected to reach USD 9.6 Billion by the end of the forecast period in 2033.

Aluminum Ladder Market introduction

The Aluminum Ladder Market encompasses the manufacturing, distribution, and sale of various types of portable ladders primarily constructed from aluminum alloys. These products, ranging from step ladders and extension ladders to multipurpose and specialized industrial platforms, serve a crucial function across residential, commercial, and heavy industrial sectors. The inherent characteristics of aluminum—light weight, high strength-to-weight ratio, corrosion resistance, and relative cost efficiency compared to materials like fiberglass (in certain applications) or wood—make it the material of choice for users seeking mobility, durability, and compliance with modern safety standards. The primary application drivers include extensive residential repair and renovation activities, large-scale infrastructure projects such as road construction and utility maintenance, and sustained growth in the global warehousing and logistics industries where accessibility at height is constantly required for inventory management and racking systems.

The core product description revolves around standardized designs compliant with international safety bodies like OSHA, ANSI, and EN. Aluminum ladders are often differentiated by load capacity (Type I, IA, IAA), height specifications, and feature sets such as non-slip feet, integrated tool holders, and stabilizing outriggers, enhancing user safety and productivity. The shift towards lightweight but robust designs is a continuous innovation priority, driven by the need for easier transport and reduced ergonomic strain on the user. Furthermore, the increasing complexity of architectural designs and the need for high-reach access in commercial building maintenance fuel demand for specialized aluminum scaffold ladders and telescopic models which offer superior adaptability compared to traditional fixed-height alternatives.

Key driving factors supporting market expansion include robust growth in the construction sector globally, especially in emerging economies undergoing rapid urbanization, coupled with stringent occupational safety regulations mandating certified equipment. The replacement cycle for ladders, particularly in heavy industrial environments where wear and tear is significant, provides a stable revenue stream. Additionally, the proliferation of DIY (Do-It-Yourself) culture, particularly in North America and Europe, further stimulates the residential segment. The market dynamic is intensely competitive, relying heavily on supply chain efficiencies, pricing strategies, and continuous compliance with evolving international safety protocols, which act as a high barrier to entry for non-compliant manufacturers.

Aluminum Ladder Market Executive Summary

The global Aluminum Ladder Market is characterized by moderate but steady growth, heavily influenced by cyclical patterns in residential housing starts and governmental infrastructure spending. Current business trends indicate a strong focus on premiumization, driven by consumer willingness to invest more in high-specification, safety-enhanced ladders, leading manufacturers to integrate features like wider rungs, improved locking mechanisms, and better stability systems. Consolidation among major market participants is observed, as large companies acquire specialized regional manufacturers to gain access to proprietary designs or niche distribution networks, particularly in the multi-position and telescopic segments. Furthermore, supply chain resilience remains a key theme, with companies actively diversifying raw material sourcing options to mitigate price volatility inherent in global aluminum markets and geopolitical instability.

Regional trends highlight the Asia Pacific (APAC) region as the fastest-growing market, primarily fueled by massive infrastructural development and the ongoing commercial real estate boom in countries like India and China. North America maintains its position as the largest revenue generator, distinguished by high consumer awareness regarding safety regulations and a mature home improvement market that encourages frequent product replacement and upgrades. Europe presents a mature but highly regulated environment, where demand is stable and innovation is often centered around meeting rigorous European Norms (EN) safety standards. The Middle East and Africa (MEA) and Latin America show promising growth prospects linked to burgeoning construction activity, though adoption rates can be volatile depending on local economic conditions and regulatory enforcement.

Segment-wise, the market sees significant strength in the extension ladder category due to its indispensable use in high-reach professional applications, though the standard step ladder segment commands the largest volume due to its ubiquitous residential and light commercial use. The industrial end-user segment, comprising utility companies, telecommunications, and heavy manufacturing, offers the highest profitability due to the requirement for heavy-duty, certified equipment (Type IA and IAA). Future segment growth is anticipated in specialized products, such as non-conductive hybrid ladders utilizing fiberglass components alongside aluminum for enhanced safety in electrical environments, catering to a niche but high-value market.

AI Impact Analysis on Aluminum Ladder Market

Common user inquiries concerning the influence of AI on the Aluminum Ladder Market typically center on how technology can enhance safety features, optimize manufacturing processes, and improve supply chain forecasting. Users often ask if AI can lead to "smart ladders" capable of detecting instability or overload, and how machine learning optimizes material usage to reduce waste and cost in highly competitive manufacturing environments. The consensus from analyzed queries suggests key themes revolving around predictive maintenance of high-volume stamping and welding machinery, automated visual inspection systems (AI-powered cameras) for immediate quality control checks on weld integrity and rivet placement, and sophisticated demand sensing algorithms that drastically reduce inventory holding costs by accurately predicting seasonal shifts in regional construction and DIY activity.

- AI-driven Predictive Maintenance: Minimizing downtime on crucial manufacturing machinery through real-time sensor data analysis.

- Automated Quality Control (AQC): Utilizing computer vision to ensure compliance with strict dimensional and structural safety standards, improving overall product reliability.

- Supply Chain Optimization: Machine learning algorithms forecasting demand fluctuations, optimizing raw aluminum procurement schedules, and managing global logistics routes efficiently.

- Ergonomic Design Simulation: AI modeling tools assisting engineers in designing safer, lighter, and more stable ladder structures, adhering to biomechanical limits.

- Smart Safety Integration: Developing IoT-enabled ladders linked to AI systems for real-time instability alerts, weight capacity monitoring, and logging usage history for fleet management.

DRO & Impact Forces Of Aluminum Ladder Market

The Aluminum Ladder Market is propelled by structural drivers, primarily global urbanization and escalating residential renovation spending, while being constrained significantly by increasing regulatory stringency regarding workplace safety and raw material price volatility. Opportunities arise through the development of specialized, smart, and ergonomic ladder systems and market penetration in undeveloped regions requiring basic infrastructure access equipment. The market faces impact forces primarily from the substitution threat posed by alternative access equipment like scissor lifts and scaffolding for high-reach tasks, and the constant pressure on pricing due to the commoditized nature of basic aluminum ladder types.

Segmentation Analysis

The Aluminum Ladder Market is segmented based on product type, material composition (though predominantly aluminum, variations in alloy type are key), end-user application, and distribution channel. The complexity of segmentation allows manufacturers to target specific safety and load requirements, particularly differentiating between heavy-duty industrial applications requiring extreme durability and lightweight residential models designed for ease of use. Understanding these segments is crucial for strategic pricing and optimized inventory management, especially given the diverse geographic regulatory requirements for each application type.

- Product Type

- Step Ladders (Single-Sided, Twin/Double Step)

- Extension Ladders (Sectional, Straight)

- Multi-Position/Telescopic Ladders

- Platform Ladders/Work Platforms

- Scaffold Ladders and Components

- End-User

- Residential (DIY and Home Maintenance)

- Commercial (Retail, Offices, Light Maintenance)

- Industrial (Construction, Utilities, Telecommunications, Manufacturing)

- Load Capacity (ANSI/OSHA Classification)

- Type III (Light Duty - 200 lbs)

- Type II (Medium Duty - 225 lbs)

- Type I (Heavy Duty - 250 lbs)

- Type IA (Extra Heavy Duty - 300 lbs)

- Type IAA (Special Duty - 375 lbs)

- Distribution Channel

- Offline (Hardware Stores, Specialty Retailers, Wholesalers)

- Online (E-commerce Platforms, Direct Sales)

Value Chain Analysis For Aluminum Ladder Market

The value chain for the Aluminum Ladder Market begins with the upstream sourcing of primary aluminum and specialized alloys, a phase highly susceptible to global commodity price fluctuations and energy costs associated with smelting. Key activities include extrusion, casting, and sheet forming necessary to create the ladder components. Midstream activities involve high-precision manufacturing processes such, including robotic welding, riveting, and component assembly, focusing intensely on quality assurance and compliance testing to meet rigorous safety standards. Downstream, the value chain is dominated by highly structured distribution channels, including direct sales to major construction companies and utility providers, and indirect sales through large big-box retailers (DIY chains) and e-commerce platforms. The efficiency of logistics, including managing the transportation of bulky, irregularly shaped goods, significantly impacts the final cost and market competitiveness.

Aluminum Ladder Market Potential Customers

Potential customers for aluminum ladders span a wide demographic, categorized mainly by the frequency of use, necessary load rating, and procurement volume. The largest volume buyers are residential consumers, particularly homeowners engaged in light repair, painting, and maintenance tasks, who prioritize affordability and basic safety features. Professional end-users, including General Contractors (G.C.s), roofing specialists, painters, and HVAC technicians, constitute the highest value customers, demanding robust, high-load capacity (Type IA/IAA) extension and multi-position ladders that meet strict job site safety requirements. Additionally, large institutional buyers such as utility companies, telecom providers, government maintenance departments, and warehouse operators represent consistent, high-volume purchasers who often require customized or specialized rolling platform ladders and prioritize long-term durability and corporate fleet management compatibility.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 9.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Werner Co., Little Giant Ladder Systems, Louisville Ladder Inc., Featherlite, P.W. Industries, Zarges GmbH, ALOSS, Duo-Safety Ladder Corporation, Alulux S.R.L, Xtend Climb, LFI Ladders, Tricam Industries, Michigan Ladder Co., Ideal Ladder, Hase Safety. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Ladder Market Key Technology Landscape

The technological landscape in the Aluminum Ladder Market is characterized by material science advancements and the integration of digital features designed primarily to enhance user safety and structural integrity. Key developments include the utilization of proprietary high-strength aluminum alloys, such as aerospace-grade variants, which allow for lighter product weight without compromising load capacity, appealing directly to professional users needing easy transportability. Furthermore, manufacturers are increasingly implementing advanced manufacturing techniques, specifically hydroforming and robotic welding, to ensure superior consistency and durability across high-volume production lines. These automated processes minimize human error, which is critical in maintaining compliance with stringent global safety standards, thereby reducing liability risks.

A significant trend involves the development of hybrid ladder designs that strategically combine aluminum frames with fiberglass elements, primarily in the stiles, to offer non-conductivity for electrical work while maintaining the lightweight nature of aluminum for the rungs and bracing. This provides a crucial balance between versatility and specialized safety requirements. Additionally, the nascent field of 'Smart Ladders' incorporates technology through integrated sensors, Bluetooth connectivity, and accelerometer modules. These features can track usage patterns, monitor tilt angles to warn against improper setup, detect overload conditions, and even initiate geo-fencing to ensure the ladder is only used in authorized areas or by certified personnel, transforming the ladder from a simple tool into an integrated safety asset managed digitally.

Innovations also extend to user-centric features, such as advanced anti-slip mechanisms for feet and rungs, incorporating specialized rubber and composite materials that offer improved grip on diverse surfaces like concrete, decking, and ice. The design focus also includes quick-locking hinge systems for multi-position ladders, minimizing pinch points and simplifying deployment, thereby addressing long-standing ergonomic and safety concerns voiced by professional users. Adoption of these technologies is driving differentiation in the market, shifting competitive focus away from mere price towards value derived from enhanced safety, durability, and compliance capabilities.

Regional Highlights

North America, particularly the United States and Canada, represents the most mature and significant revenue contributor to the Aluminum Ladder Market. This dominance is attributable to high per capita spending on residential home improvement, a large existing base of professional contractors, and the widespread adoption and strict enforcement of workplace safety standards mandated by organizations like OSHA and ANSI. The demand here is characterized by a strong preference for high-quality, Type IA and IAA rated products, often favoring specialized models like multi-position and extension ladders for both commercial construction and the established DIY sector. Economic stability and sustained low interest rates have historically supported robust housing markets, leading to steady demand for replacement and new construction access equipment. Manufacturers in this region often emphasize lifetime warranties and superior design features as primary differentiators over cost.

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period. This accelerated growth is primarily underpinned by massive governmental investments in infrastructural development (roads, railways, public utilities) and rapid urbanization leading to immense growth in residential and commercial building construction across major economies like China, India, and Southeast Asian nations. While the pricing sensitivity is higher in APAC compared to North America, the sheer volume of construction projects drives substantial demand for standard and extension aluminum ladders. As disposable incomes rise and awareness regarding workplace safety gradually improves, there is a measurable shift from cheaper, often uncertified ladders towards compliant, quality products, presenting significant long-term growth opportunities for established international brands.

Europe holds a substantial market share, defined by its rigorous regulatory environment governed by European Norms (EN 131 standards), which necessitates continuous compliance and specialized product testing. The European market demand is stable, driven by steady industrial maintenance, renovation activities in older building stock, and a strong manufacturing base. Countries like Germany and the UK show high demand for aluminum scaffolding components and platform ladders, prioritizing equipment that supports efficient working at height while ensuring strict adherence to worker safety laws. Latin America and the Middle East & Africa (MEA) are emerging markets, where demand is currently volatile but promising, contingent upon oil price stability and the execution of planned mega-projects, particularly in the UAE, Saudi Arabia, and Qatar, which require vast amounts of high-reach industrial equipment.

- North America: Dominant market share due to mature DIY culture, high safety standards (OSHA/ANSI), and sustained professional construction activity.

- Asia Pacific (APAC): Highest growth rate driven by urbanization, infrastructure mega-projects, and increasing awareness of occupational safety standards, particularly in China and India.

- Europe: Stable market characterized by stringent EN 131 regulations, focus on specialized platforms, and demand driven by industrial maintenance and renovation.

- Middle East & Africa (MEA): Emerging demand fueled by large-scale construction and industrial diversification projects, requiring heavy-duty access solutions.

- Latin America: Growth potential linked to economic recovery and investment in public infrastructure, with increasing adoption of standard, cost-effective aluminum models.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Ladder Market.- Werner Co.

- Little Giant Ladder Systems

- Louisville Ladder Inc.

- Featherlite

- P.W. Industries

- Zarges GmbH

- ALOSS

- Duo-Safety Ladder Corporation

- Alulux S.R.L

- Xtend Climb

- LFI Ladders

- Tricam Industries

- Michigan Ladder Co.

- Ideal Ladder

- Hase Safety

- Bauer Corporation

- Kenko Corporation

- Gomarus

- Jiawang Aluminum

Frequently Asked Questions

Analyze common user questions about the Aluminum Ladder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of aluminum ladders over fiberglass alternatives?

Aluminum ladders offer a superior strength-to-weight ratio, making them significantly lighter and easier to transport and position compared to similarly rated fiberglass models. While fiberglass is non-conductive and preferred for electrical work, aluminum provides better corrosion resistance in many environments and is generally more cost-effective for general use applications.

How do safety regulations, such as OSHA and ANSI, impact the purchase decisions for aluminum ladders?

OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) compliance is mandatory for professional and industrial users in North America. These regulations dictate required load capacities (e.g., Type I, IA, IAA), structural integrity, and proper usage guidelines. Non-compliant ladders pose severe legal risks and insurance issues, making certification the primary filtering factor for commercial purchases.

Which end-user segment drives the highest volume demand in the Aluminum Ladder Market?

The residential and light commercial segments drive the highest volume demand, primarily for standard step ladders and smaller extension ladders used for routine maintenance and DIY projects. However, the industrial and construction segments, while lower in volume, generate the highest revenue value due to the required purchase of specialized, high-load capacity (heavy-duty) equipment.

What technological innovations are currently trending in aluminum ladder design?

Current trends focus heavily on integrating smart safety features, including IoT sensors for monitoring stability and load capacity in real time, enhanced ergonomic designs (quick-locking hinges, wider rungs), and material science improvements utilizing proprietary high-strength aluminum alloys to reduce weight while maintaining the required Type IA and IAA industrial ratings.

How does the volatility of aluminum prices affect the manufacturing costs and final market price of ladders?

Aluminum is the primary raw material, and its price volatility, driven by global commodity markets and energy costs, directly impacts the upstream manufacturing cost. Manufacturers often manage this through long-term hedging contracts or passing marginal increases to the consumer, leading to fluctuating retail prices, especially for high-volume, commoditized standard ladder types.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager