Aluminum Liquid Cold Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439632 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Aluminum Liquid Cold Plate Market Size

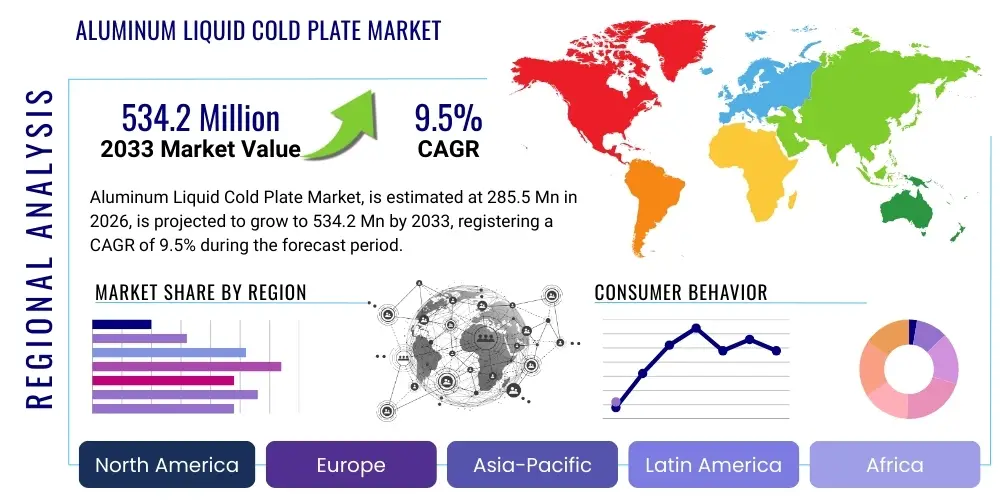

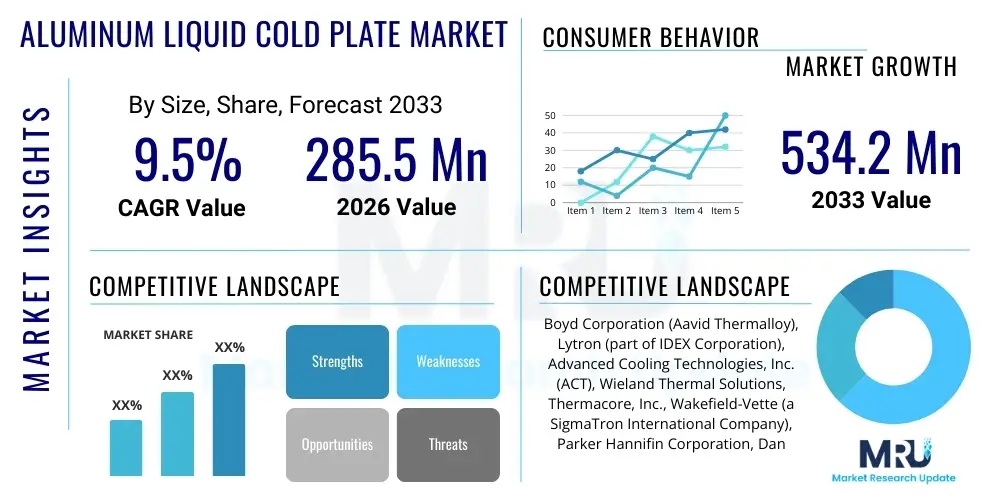

The Aluminum Liquid Cold Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 285.5 Million in 2026 and is projected to reach USD 534.2 Million by the end of the forecast period in 2033.

Aluminum Liquid Cold Plate Market introduction

The Aluminum Liquid Cold Plate Market is a critical segment within the broader thermal management industry, providing highly efficient cooling solutions for demanding electronic and power applications. Aluminum liquid cold plates are specialized heat exchangers designed to transfer heat from high-power components to a circulating liquid coolant, such as water or a dielectric fluid, which then dissipates the heat elsewhere. These plates are engineered to offer superior thermal conductivity, excellent corrosion resistance, and a lightweight profile, making them ideal for applications where heat dissipation is paramount and space is often restricted. Their robust construction and ability to handle high heat fluxes position them as an indispensable component in modern high-performance systems.

The product, an aluminum liquid cold plate, typically consists of a machined aluminum base with internal channels through which a liquid coolant flows. These channels are designed to maximize surface area contact with the coolant and ensure efficient heat absorption from the attached components. Major applications span a diverse range of industries, including data centers and high-performance computing (HPC), electric vehicles (EVs) and automotive power electronics, industrial automation, medical imaging equipment, and aerospace and defense systems. The adaptability of aluminum cold plates to various form factors and thermal loads contributes significantly to their widespread adoption across these sectors.

The primary benefits of utilizing aluminum liquid cold plates include their exceptional thermal performance, which enables higher power densities for electronic devices without compromising reliability. Their lightweight nature contributes to overall system efficiency, particularly in mobile or weight-sensitive applications like EVs and aerospace. Key driving factors propelling market growth include the relentless increase in heat generation from advanced processors and power electronics, the expansion of data center infrastructure, the rapid electrification of the automotive industry, and the growing demand for compact and efficient cooling solutions across industrial and medical sectors. These factors collectively underscore the vital role aluminum liquid cold plates play in enabling technological advancement.

Aluminum Liquid Cold Plate Market Executive Summary

The Aluminum Liquid Cold Plate Market is currently experiencing robust growth, driven by an escalating demand for efficient thermal management solutions across various high-power applications. Key business trends indicate a strong focus on customization and integration, with manufacturers developing bespoke cold plate designs to meet specific thermal and geometric requirements of diverse end-user industries. There is a noticeable shift towards advanced manufacturing techniques, such as friction stir welding and vacuum brazing, to enhance plate integrity, improve thermal performance, and reduce manufacturing costs. Furthermore, strategic collaborations between cold plate manufacturers and original equipment manufacturers (OEMs) are becoming more prevalent, fostering innovation and ensuring seamless integration into complex systems. The emphasis on sustainability and energy efficiency is also shaping business strategies, prompting the development of more environmentally friendly manufacturing processes and lighter, more efficient designs.

Regionally, the market exhibits dynamic growth patterns. Asia Pacific stands out as a dominant and rapidly expanding region, fueled by burgeoning data center construction, extensive electronics manufacturing, and significant investments in electric vehicle production, particularly in countries like China, Japan, and South Korea. North America maintains a strong market presence, driven by its robust high-performance computing (HPC) sector, advanced aerospace and defense industries, and a growing emphasis on electric vehicle infrastructure. Europe is also a significant market, propelled by its stringent environmental regulations driving EV adoption, advanced industrial automation, and expanding renewable energy installations. Emerging markets in Latin America and the Middle East & Africa are showing promising growth, albeit from a smaller base, as industrialization and digital transformation initiatives gain momentum.

In terms of segment trends, the data centers and high-performance computing (HPC) segment continues to be a primary revenue driver, owing to the increasing power density of server racks and the critical need for reliable cooling to prevent downtime. The electric vehicles (EVs) and automotive power electronics segment is projected to witness the highest growth rate, propelled by the global push towards vehicle electrification and the associated demand for efficient cooling of batteries, inverters, and motors. Industrial power electronics, including applications in renewable energy and industrial automation, represent another substantial segment experiencing steady growth. The medical imaging and equipment segment also contributes significantly, requiring precise and quiet thermal management for sensitive diagnostic devices. These segmentation trends highlight the diverse and expanding application landscape for aluminum liquid cold plates.

AI Impact Analysis on Aluminum Liquid Cold Plate Market

The advent and widespread adoption of Artificial Intelligence (AI) are fundamentally reshaping the demand landscape for aluminum liquid cold plates. Users frequently inquire about how the escalating computational power requirements of AI processors, graphics processing units (GPUs), and specialized AI accelerators directly translate into increased thermal management needs. Concerns often revolve around the ability of existing cooling technologies to keep pace with the exponential heat generation from AI workloads, leading to expectations that liquid cooling, particularly using efficient aluminum cold plates, will become a standard rather than an exception in AI data centers and edge computing infrastructure. There is a strong user interest in understanding the role of advanced cooling solutions in enabling the next generation of AI hardware, ensuring optimal performance, preventing thermal throttling, and improving the energy efficiency of AI systems. The key themes revolve around scalability, reliability, and the potential for cold plates to facilitate denser, more powerful AI deployments.

- Increased demand for high-performance cooling due to higher power densities of AI processors (GPUs, TPUs, FPGAs).

- Necessity for liquid cooling to prevent thermal throttling and ensure sustained optimal performance of AI hardware.

- Enhanced focus on energy efficiency in AI data centers, where liquid cold plates can significantly reduce power consumption compared to air cooling.

- Development of specialized cold plate designs optimized for AI accelerator modules and compact edge AI devices.

- Growth in custom cold plate solutions to integrate seamlessly with proprietary AI hardware architectures.

- Expansion of market opportunities in AI-driven data centers, supercomputers, and autonomous vehicle platforms.

- Requirement for reliable and scalable cooling infrastructure to support the continuous growth of AI training and inference workloads.

- Potential for AI algorithms to optimize cold plate design and manufacturing processes for improved efficiency.

DRO & Impact Forces Of Aluminum Liquid Cold Plate Market

The Aluminum Liquid Cold Plate Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and impact forces. A primary driver is the pervasive trend of increasing heat flux in modern electronics, necessitating more efficient and compact thermal management solutions. Components in data centers, high-performance computing (HPC), and power electronics are generating unprecedented levels of heat, which conventional air cooling struggles to dissipate effectively. The rapid expansion of data center infrastructure globally, coupled with the escalating adoption of electric vehicles (EVs) and hybrid vehicles, further fuels demand for liquid cold plates due to their superior heat transfer capabilities. Additionally, the proliferation of 5G technology and industrial automation requiring robust and reliable cooling for critical components also acts as a significant market driver. These factors collectively create a strong pull for advanced liquid cooling technologies.

Despite these strong drivers, the market faces several notable restraints. The relatively high manufacturing cost associated with precision-machined and vacuum-brazed aluminum cold plates can be a barrier to entry for some applications or smaller-scale projects. The design complexity involved in integrating liquid cooling systems, including pumps, reservoirs, and heat exchangers, adds to the overall system cost and requires specialized expertise. Furthermore, potential issues related to material compatibility between the cold plate and the coolant, as well as the risk of leakage, remain significant concerns for end-users, potentially hindering broader adoption. The initial capital investment for implementing liquid cooling infrastructure can also be higher compared to traditional air-cooling methods, which may deter some organizations from making the transition immediately. Addressing these restraints through innovation in manufacturing and system design is crucial for market expansion.

However, substantial opportunities exist for market growth and innovation. The ongoing trend towards miniaturization and higher power density in electronic devices creates new niches for compact and efficient liquid cold plates, particularly in advanced consumer electronics and portable high-performance systems. The burgeoning adoption of renewable energy systems, such as solar inverters and wind turbine converters, presents a significant opportunity for cold plates to manage heat in critical power electronics. Moreover, advanced applications in aerospace, defense, and space exploration require extremely reliable and lightweight cooling solutions, where aluminum liquid cold plates offer a distinct advantage. Integrating these cold plates with smart thermal management systems and IoT technologies for real-time monitoring and predictive maintenance represents another avenue for innovation, enhancing efficiency and reliability. The continuous evolution of manufacturing technologies, such as additive manufacturing for complex channel geometries, also opens doors for more customized and optimized cold plate designs.

Segmentation Analysis

The Aluminum Liquid Cold Plate Market is comprehensively segmented to provide granular insights into its diverse components and application areas. This segmentation allows for a detailed understanding of market dynamics across different product types, end-use applications, and geographic regions. Analyzing these segments helps in identifying key growth drivers, emerging trends, and potential market opportunities, enabling stakeholders to make informed strategic decisions. The market can be broadly categorized by the manufacturing technology used for the plates, the specific industries they serve, and the end-users integrating these critical cooling components into their systems.

- By Type:

- Brazed Cold Plates

- Vacuum Brazed Cold Plates

- Friction Stir Welded Cold Plates

- CNC Machined Cold Plates

- Extruded Cold Plates

- By Application:

- Data Centers & High-Performance Computing (HPC)

- Electric Vehicles (EVs) & Automotive

- Industrial Power Electronics

- Medical Imaging & Equipment

- Aerospace & Defense

- Renewable Energy Systems

- Others (e.g., Lasers, Test Equipment)

- By End-User:

- OEM (Original Equipment Manufacturers)

- ODM (Original Design Manufacturers)

- System Integrators

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Aluminum Liquid Cold Plate Market

The value chain for the Aluminum Liquid Cold Plate Market encompasses several critical stages, beginning with upstream activities related to raw material procurement and extending through manufacturing, assembly, distribution, and ultimately, to the end-users. Upstream analysis focuses on the sourcing of primary materials, predominantly high-grade aluminum alloys, which are selected for their thermal conductivity, lightweight properties, and corrosion resistance. Suppliers of aluminum billets and sheets play a crucial role here, as the quality and availability of these materials directly impact the production capabilities and cost structure of cold plate manufacturers. Other upstream components include coolants (e.g., de-ionized water, glycols, dielectric fluids), seals, gaskets, and connection fittings from specialized component manufacturers. Effective supplier management and quality control at this stage are paramount to ensuring the reliability and performance of the final cold plate products.

Midstream activities involve the design, fabrication, and assembly of the cold plates themselves. This stage often includes sophisticated processes such as CNC machining to create precise internal channels, brazing (including vacuum brazing) for hermetic sealing, friction stir welding for robust joints, and specialized surface treatments to enhance corrosion resistance and thermal performance. Manufacturers invest heavily in R&D to optimize plate designs for specific thermal loads and form factors, focusing on fluid dynamics and heat transfer efficiency. Quality assurance and testing are integral parts of this stage to guarantee leak-proof operation and consistent thermal performance. Downstream analysis then examines how these finished cold plates reach the market. This involves direct sales to large Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs) who integrate the cold plates into their final products, as well as sales through a network of distributors and system integrators who provide complete thermal management solutions to end-users.

The distribution channel for aluminum liquid cold plates can be broadly categorized into direct and indirect routes. Direct distribution involves cold plate manufacturers selling directly to major OEMs in industries such as data centers, automotive, and industrial power electronics. This approach allows for close collaboration, customization, and technical support tailored to specific project requirements. Indirect distribution, on the other hand, relies on a network of specialized distributors, value-added resellers, and system integrators. These intermediaries often provide additional services such as system design, installation, and maintenance, making cold plates accessible to a wider range of smaller or more specialized end-users. The choice between direct and indirect channels often depends on the scale of the customer, the complexity of the solution required, and the geographic reach desired by the manufacturer. Both channels are vital for comprehensive market penetration and ensuring that advanced thermal management solutions reach diverse applications efficiently.

Aluminum Liquid Cold Plate Market Potential Customers

The Aluminum Liquid Cold Plate Market serves a diverse array of potential customers, primarily composed of end-users and system integrators who require high-efficiency thermal management for their critical electronic and power components. A significant segment of these customers includes operators and infrastructure providers in the Data Center and High-Performance Computing (HPC) sectors. These entities are constantly upgrading their server racks, supercomputers, and AI accelerators, all of which generate immense heat, making liquid cold plates indispensable for maintaining optimal operating temperatures and ensuring system reliability. The need for compact, energy-efficient, and high-density computing solutions drives continuous demand from this customer base, which is focused on maximizing processing power while minimizing energy consumption and footprint.

Another rapidly expanding customer segment comprises Electric Vehicle (EV) manufacturers and automotive power electronics suppliers. As the global automotive industry shifts towards electrification, there is an urgent need for robust and efficient cooling solutions for EV battery packs, inverters, motors, and charging systems. Aluminum liquid cold plates offer the lightweight design, high thermal conductivity, and durability required to manage the significant heat generated in these critical EV components, contributing to extended battery life, improved performance, and enhanced safety. Similarly, industrial power electronics producers, including those in renewable energy (solar inverters, wind turbine converters), industrial automation, and heavy machinery, represent a substantial customer base. These industries demand reliable cooling for components like IGBTs, rectifiers, and motor drives, often operating in harsh environments where precise thermal control is vital for equipment longevity and operational efficiency.

Furthermore, medical imaging and equipment manufacturers are key potential customers, requiring advanced cooling for devices such as MRI scanners, CT scanners, and high-power lasers, where silent operation, precision, and reliability are paramount. The aerospace and defense sector also presents a strong customer segment, driven by the need for lightweight, rugged, and high-performance cooling for avionics, radar systems, and embedded electronics in extreme conditions. Test and measurement equipment manufacturers, semiconductor fabrication plants, and even specialized consumer electronics developers designing ultra-high-performance devices also contribute to the customer base. These diverse end-users and their integrators share a common need for superior, custom-engineered thermal solutions that aluminum liquid cold plates are uniquely positioned to provide.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.5 Million |

| Market Forecast in 2033 | USD 534.2 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Boyd Corporation (Aavid Thermalloy), Lytron (part of IDEX Corporation), Advanced Cooling Technologies, Inc. (ACT), Wieland Thermal Solutions, Thermacore, Inc., Wakefield-Vette (a SigmaTron International Company), Parker Hannifin Corporation, Danfoss A/S, Fujikura Ltd., Celsia Technologies, Aspinity (part of Laird Thermal Systems), Wolverine Tube, Inc., AMETEK Inc. (Sunpower), Daikin Industries Ltd., Mitsubishi Electric Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Liquid Cold Plate Market Key Technology Landscape

The Aluminum Liquid Cold Plate Market is characterized by a dynamic and evolving technology landscape, driven by the continuous demand for enhanced thermal performance, reliability, and cost-effectiveness. A crucial aspect of this landscape involves advanced manufacturing techniques. Precision Computer Numerical Control (CNC) machining is foundational for creating intricate internal flow channels and complex geometries within the aluminum plates, optimizing fluid dynamics and heat transfer efficiency. Beyond traditional machining, processes like vacuum brazing are widely employed to create hermetically sealed, high-integrity cold plates, especially for applications requiring superior reliability and corrosion resistance. Friction Stir Welding (FSW) is emerging as a critical technology, offering a solid-state joining process that creates strong, defect-free bonds without melting the aluminum, leading to cold plates with excellent thermal and mechanical properties, particularly advantageous for high-volume production and complex designs.

Material science and surface engineering also play a significant role in the technological advancement of aluminum liquid cold plates. Research into novel aluminum alloys with improved thermal conductivity and enhanced corrosion resistance is ongoing, allowing for more robust and long-lasting products. Surface treatments, such as anodizing and specialized coatings, are applied to further improve corrosion resistance, especially when using aggressive coolants or in challenging environmental conditions, thereby extending the lifespan and reliability of the cold plates. The integration of advanced coolants, beyond conventional water-glycol mixtures, includes dielectric fluids and phase-change materials that offer superior heat absorption capabilities and electrical isolation, opening up new application possibilities in electrically sensitive environments like high-voltage power electronics and direct-to-chip cooling systems for AI accelerators.

Furthermore, the technological landscape extends to the holistic integration of cold plates within broader thermal management systems. This includes innovations in pump technology for efficient coolant circulation, advanced heat exchanger designs for ultimate heat rejection, and sophisticated sensor arrays for real-time temperature and flow monitoring. Predictive maintenance capabilities, often leveraging AI and IoT, are increasingly being integrated to monitor system health, detect potential issues early, and optimize cooling performance dynamically. The development of modular and scalable cold plate solutions that can be easily configured for various applications and upgraded to meet future thermal demands is also a key technological trend. These combined advancements ensure that aluminum liquid cold plates remain at the forefront of high-efficiency thermal management solutions for the most demanding electronic and power applications.

Regional Highlights

- North America: A mature market characterized by significant demand from the data center, high-performance computing (HPC), and aerospace & defense sectors. The region benefits from substantial R&D investments in advanced cooling technologies and the presence of major technology hubs. Growing electric vehicle (EV) manufacturing and infrastructure development also contribute to sustained market growth.

- Europe: Driven by stringent environmental regulations promoting energy efficiency and the rapid adoption of electric vehicles. Germany, France, and the UK are key markets with strong industrial automation, renewable energy, and automotive industries. Emphasis on precision engineering and high-reliability components further boosts the market.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by extensive electronics manufacturing, rapid expansion of data centers, and massive investments in EV production, particularly in China, Japan, South Korea, and India. The region's industrialization and urbanization fuel demand across various applications, including consumer electronics and industrial power.

- Latin America: An emerging market with increasing investments in data center infrastructure and industrial development. While smaller than other regions, it offers significant growth potential as digitalization initiatives and manufacturing capabilities expand across countries like Brazil and Mexico.

- Middle East and Africa (MEA): A nascent but growing market influenced by diversification efforts away from oil economies, leading to investments in technology infrastructure, smart cities, and industrial sectors. Opportunities are emerging in localized data centers, renewable energy projects, and specialized industrial applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Liquid Cold Plate Market.- Boyd Corporation (Aavid Thermalloy)

- Lytron (part of IDEX Corporation)

- Advanced Cooling Technologies, Inc. (ACT)

- Wieland Thermal Solutions

- Thermacore, Inc.

- Wakefield-Vette (a SigmaTron International Company)

- Parker Hannifin Corporation

- Danfoss A/S

- Fujikura Ltd.

- Celsia Technologies

- Aspinity (part of Laird Thermal Systems)

- Wolverine Tube, Inc.

- AMETEK Inc. (Sunpower)

- Daikin Industries Ltd.

- Mitsubishi Electric Corporation

Frequently Asked Questions

What is an aluminum liquid cold plate and its primary function?

An aluminum liquid cold plate is a specialized heat exchanger designed to efficiently transfer heat from high-power electronic components to a circulating liquid coolant. Its primary function is to maintain optimal operating temperatures for sensitive electronics, preventing overheating and ensuring system reliability and performance by rapidly dissipating high heat fluxes.

Which industries are the major end-users of aluminum liquid cold plates?

Major end-user industries include data centers and high-performance computing (HPC), electric vehicles (EVs) and automotive power electronics, industrial automation, medical imaging and equipment, and aerospace and defense. These sectors rely on cold plates for effective thermal management of high-heat-generating components.

How does the growth of AI influence the demand for aluminum liquid cold plates?

The growth of AI significantly boosts demand for aluminum liquid cold plates by driving the need for more powerful, densely packed processors (GPUs, AI accelerators) that generate immense heat. Liquid cooling, enabled by cold plates, is essential to manage these high heat fluxes, ensure peak AI hardware performance, and improve energy efficiency in AI data centers.

What are the key manufacturing technologies used for aluminum liquid cold plates?

Key manufacturing technologies include precision CNC machining for internal channels, vacuum brazing for hermetic sealing, and friction stir welding (FSW) for robust, defect-free joints. These techniques are crucial for producing high-performance, reliable, and leak-proof cold plates tailored to specific thermal requirements.

What are the main drivers and restraints impacting the aluminum liquid cold plate market?

Main drivers include increasing heat flux in electronics, rapid growth of data centers and EVs, and advancements in 5G and industrial automation. Restraints involve high manufacturing costs, design complexity, and concerns over material compatibility and potential leakage. Opportunities arise from miniaturization, renewable energy applications, and advanced aerospace/defense systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager