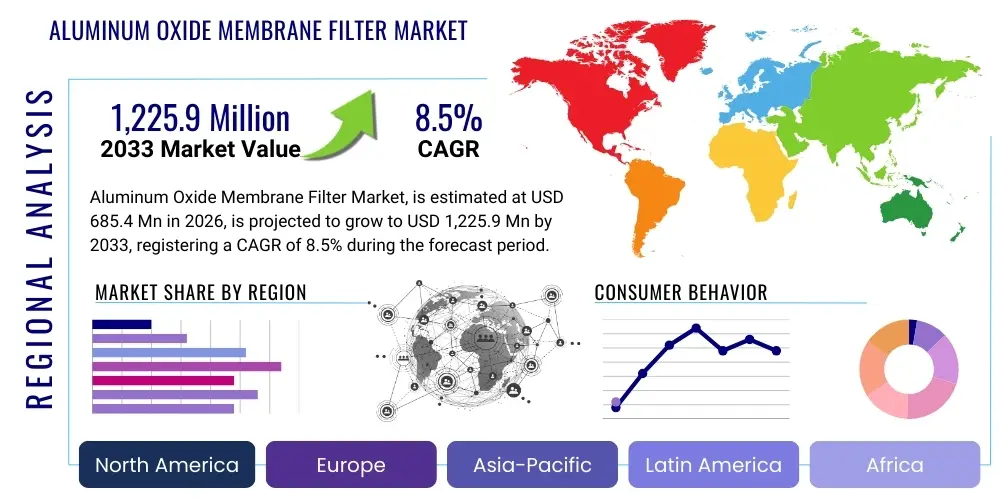

Aluminum Oxide Membrane Filter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437043 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Aluminum Oxide Membrane Filter Market Size

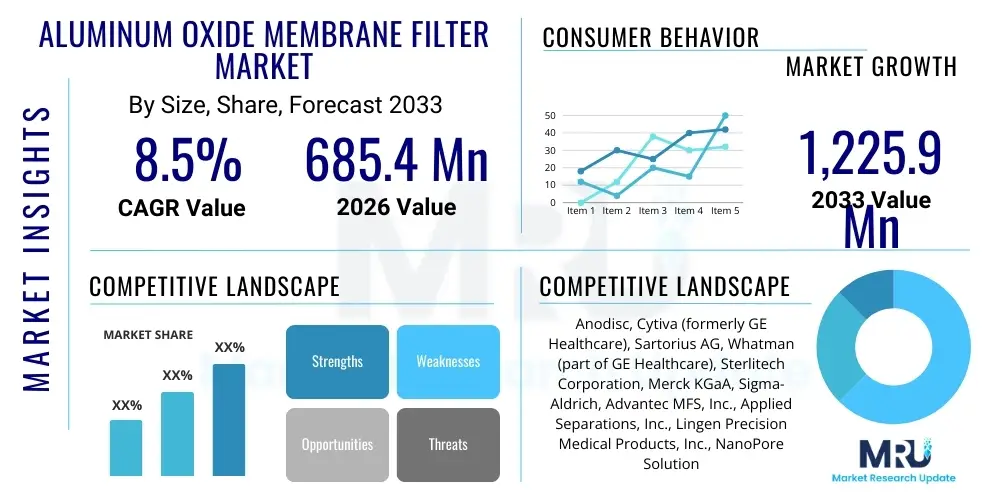

The Aluminum Oxide Membrane Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 685.4 Million in 2026 and is projected to reach USD 1,225.9 Million by the end of the forecast period in 2033.

Aluminum Oxide Membrane Filter Market introduction

The Aluminum Oxide Membrane Filter Market encompasses the global sale and distribution of filters characterized by highly ordered, uniform, nanoporous structures made from anodic aluminum oxide (AAO). These filters are engineered through electrochemical anodization processes, resulting in membranes with precisely tunable pore diameters, high pore density, and exceptional mechanical stability. Unlike traditional polymer membranes, aluminum oxide filters offer superior resistance to harsh chemicals, extreme temperatures, and provide highly reproducible results, making them indispensable in demanding scientific and industrial applications where precision filtration and separation are paramount.

The primary applications driving the market include high-resolution microfiltration, separation of biological macromolecules, sample preparation in analytical laboratories (such as HPLC and GC), and advanced materials synthesis, particularly as templates for producing nanowires and nanotubes. In the biomedical sector, AAO membranes are critical for drug delivery systems, cell culture substrates, and advanced biosensors due to their biocompatibility and controllable surface chemistry. The increasing focus on nanotechnology research and development globally, coupled with stringent quality control requirements in pharmaceutical and semiconductor manufacturing, fuels the demand for these high-specification filters.

Key benefits of aluminum oxide membrane filters include their high surface area-to-volume ratio, narrow pore size distribution, and intrinsic hydrophilicity, which facilitates high flux rates and minimal non-specific binding. Driving factors for market expansion are the rapid growth of the biopharmaceutical industry, which necessitates ultra-clean separation technologies, continuous innovation in diagnostics, and the ongoing miniaturization trend in analytical devices. Furthermore, the rising awareness regarding water quality and environmental monitoring in developing economies is creating new opportunities for membrane adoption in environmental filtration and monitoring applications, expanding the traditional user base.

Aluminum Oxide Membrane Filter Market Executive Summary

The Aluminum Oxide Membrane Filter Market is characterized by robust growth, primarily driven by technological convergence in materials science and biotechnology. Current business trends indicate a strong shift towards customization, where manufacturers are focusing on producing tailored pore geometries and surface modifications to meet specific application needs, particularly in advanced diagnostics and microelectronics. Strategic collaborations between academic research institutions and commercial filter providers are accelerating product innovation, leading to membranes optimized for rapid point-of-care testing and large-scale industrial purification. Investment in automated manufacturing processes is also a prevailing trend, aiming to reduce the high production costs historically associated with AAO filters and thus improving market accessibility across different end-user segments.

Regionally, North America and Europe currently dominate the market due to the presence of established pharmaceutical and biotechnology clusters, coupled with high R&D spending in government and private sectors. However, the Asia Pacific (APAC) region is projected to exhibit the highest growth trajectory throughout the forecast period. This rapid expansion in APAC is fueled by the burgeoning semiconductor industry in countries like South Korea and Taiwan, increasing investments in healthcare infrastructure in China and India, and supportive government policies promoting nanotechnology applications. Emerging markets in Latin America and MEA are showing steady, albeit slower, adoption rates, mainly concentrated in academic research and environmental monitoring initiatives.

Segment-wise, the Membrane Type segment, specifically filters with pore sizes in the nanofiltration range, is anticipated to witness substantial growth, owing to their utility in protein separation and viral clearance applications within the biopharmaceutical sector. By End-User, the Pharmaceutical & Biotechnology segment maintains the largest market share, driven by stringent regulatory requirements for product purity and the increasing pipeline of complex biologics. The Technology segment is seeing rapid advancement in deposition techniques and surface functionalization methods, enhancing the filter's versatility and performance in novel applications like fuel cells and high-capacity battery separators.

AI Impact Analysis on Aluminum Oxide Membrane Filter Market

Common user questions regarding AI's impact on the Aluminum Oxide Membrane Filter Market frequently center on how machine learning can optimize the complex anodization process, whether predictive analytics can improve filter lifespan and purity consistency, and the role of AI in analyzing filtration data derived from high-throughput screening applications. Users are concerned about maintaining the ultra-precise nanostructure integrity while seeking cost reduction through automation. The consensus expectation is that AI will primarily serve as an optimization tool, enhancing manufacturing efficiency, accelerating new product development (by simulating ideal pore structures), and enabling smart quality control systems that can detect minute structural defects in real-time, thereby reducing material waste and ensuring compliance with strict regulatory standards required in biomedical and microelectronics fields.

- AI-driven optimization of AAO synthesis parameters (voltage, temperature, acid concentration) to ensure uniform pore distribution and reduced batch variability.

- Implementation of Computer Vision and Machine Learning algorithms for automated defect detection during the fabrication process, significantly improving quality control and yield rates.

- Predictive maintenance schedules for filtration systems utilizing aluminum oxide membranes in industrial settings, minimizing downtime and extending operational life.

- Development of smart membrane systems integrated with AI for real-time performance monitoring and dynamic adjustment of flow rates based on contaminant load and fouling prediction.

- Accelerated discovery of new surface functionalization coatings through AI-guided combinatorial chemistry simulations, enhancing specificity for target molecules.

- Data analysis tools utilizing machine learning to interpret complex separation data generated by AAO membranes in drug screening and diagnostics applications.

- Supply chain optimization using AI for demand forecasting and inventory management of specialized raw materials needed for filter production.

DRO & Impact Forces Of Aluminum Oxide Membrane Filter Market

The Aluminum Oxide Membrane Filter market dynamics are shaped by a strong combination of technological drivers and stringent regulatory restraints, balanced by substantial opportunities arising from emerging industrial sectors. The primary driving force is the relentless demand for higher resolution separation techniques in biopharma and nanotechnology, necessitating the use of highly uniform nanoporous structures. Restraints largely revolve around the high capital investment required for AAO manufacturing equipment and the inherent fragility of ceramic-based filters, which limits handling and large-scale, rugged industrial deployment. Opportunities are vast, particularly in environmental remediation, where the filter's stability makes it ideal for harsh chemical separation, and in energy storage, where it functions as a critical separator component in advanced batteries, offering new revenue streams beyond traditional life science applications. These forces collectively dictate the strategic direction and competitive intensity within the market.

Key drivers include the global expansion of the injectable drug and vaccine market, which relies heavily on sterile, particle-free liquids achievable through AAO membranes. Additionally, governments worldwide are increasing funding for nanotechnology and materials science research, driving academic and industrial exploration into novel uses for these membranes, such as advanced gas sensors and catalytic converters. The filters’ inherent thermal and chemical stability is a significant advantage over polymeric alternatives, accelerating their adoption in high-temperature or aggressive chemical environments prevalent in petrochemical and specialty chemical manufacturing. The regulatory landscape, specifically the need to comply with Good Manufacturing Practice (GMP) standards in pharmaceuticals, further mandates the use of reliable, non-leaching filtration media, favoring aluminum oxide.

Conversely, significant restraints hinder wider adoption. The complexity of the anodization process makes mass production difficult and costly, resulting in higher unit prices compared to conventional filters, thereby limiting penetration in price-sensitive markets. Furthermore, the brittleness of AAO membranes requires specialized module designs and careful handling during integration into filtration systems, increasing the risk of mechanical failure. To overcome these constraints, manufacturers are actively pursuing opportunities in composite membrane development, integrating aluminum oxide structures onto supportive polymeric or metallic substrates to enhance durability while retaining precision. New opportunities also lie in the rapid growth of the decentralized water treatment market, where robust membranes are essential for removal of trace contaminants and microbial pathogens.

Segmentation Analysis

The Aluminum Oxide Membrane Filter Market is segmented based on critical performance characteristics, material properties, and end-user requirements, providing a granular view of demand patterns. Segmentation by Pore Size (e.g., Microfiltration, Ultrafiltration, Nanofiltration) reflects the application specificity, with smaller pore sizes addressing high-precision tasks like viral clearance and larger pores focused on general particulate removal. Segmentation by Membrane Type often differentiates between unsupported, rigid AAO membranes and supported, composite structures. End-user classification is crucial, detailing consumption across highly regulated sectors like Pharmaceuticals & Biotechnology, advanced fields such as Semiconductor & Microelectronics, and emerging areas like Environmental & Water Treatment, allowing manufacturers to tailor marketing and product development strategies effectively.

- By Pore Size

- Microfiltration (Pore Size > 0.1 µm)

- Ultrafiltration (Pore Size 0.01 µm to 0.1 µm)

- Nanofiltration (Pore Size 0.001 µm to 0.01 µm)

- By Application

- Sample Preparation and Analysis

- Sterilization and Clarification

- Nanofabrication and Template Synthesis

- Air and Gas Filtration

- Drug Delivery Systems

- By End-User

- Pharmaceutical and Biotechnology Companies

- Academic and Research Institutions

- Semiconductor and Microelectronics Industry

- Chemical and Petrochemical Industry

- Food and Beverage Industry

- Environmental Monitoring and Water Treatment

- By Membrane Type

- Standard (Unsupported) AAO Membranes

- Composite and Supported AAO Membranes

Value Chain Analysis For Aluminum Oxide Membrane Filter Market

The value chain for the Aluminum Oxide Membrane Filter Market begins with upstream activities focused on securing high-purity aluminum stock and necessary chemical precursors, such as electrolytic solutions and acids required for the highly sensitive anodization process. Suppliers in this segment must adhere to strict quality controls, as the purity of the starting materials directly impacts the uniformity and performance metrics of the final membrane structure. Manufacturing involves complex, energy-intensive electrochemical processes, including cleaning, anodizing, pore widening, and functionalization. This stage requires specialized equipment and highly skilled technical labor, representing the highest value-addition point due to the intellectual property surrounding pore structure control and surface modification techniques.

Downstream activities include system integration, where membrane manufacturers sell the filters as components to system integrators who incorporate them into larger analytical instruments, filtration systems (e.g., tangential flow filtration units), or specialized microfluidic devices. The distribution channel is bifurcated: direct sales channels are employed for large-volume, customized orders, particularly to major pharmaceutical or semiconductor fabrication plants where technical support and customization are critical. Indirect distribution involves specialized scientific distributors and catalog retailers who service the vast global network of academic research laboratories, smaller biotech firms, and quality control departments, providing rapid access to standard catalog products.

The commercial success heavily relies on the efficiency of the distribution network and the provision of specialized technical support to end-users, ensuring correct membrane selection and system integration, especially given the filters’ specialized nature. The final stage involves the end-user applying the filter in their respective processes, such as sterilizing media, clarifying biologics, or using the membrane as a template for synthesizing nanomaterials. Feedback from these critical end-users directly influences upstream R&D and manufacturing adjustments, emphasizing the interconnectedness of all value chain components in maintaining product relevance and quality within this niche, high-precision market.

Aluminum Oxide Membrane Filter Market Potential Customers

Potential customers for Aluminum Oxide Membrane Filters represent a highly specialized group requiring filtration, separation, or structural templates at the nano- and micro-scale, where standard polymer membranes are insufficient due to limitations in thermal stability, chemical resistance, or pore uniformity. The primary end-users are concentrated within the Pharmaceutical and Biotechnology sectors, specifically companies involved in vaccine production, monoclonal antibody purification, virus filtration, and complex drug formulation where purity levels must be exceptionally high and validated under strict regulatory standards. These customers rely on AAO filters for critical sterile filtration steps and specialized sample preparation prior to highly sensitive analytical techniques like mass spectrometry or electron microscopy.

Another major customer segment includes the Semiconductor and Microelectronics industry, particularly firms engaged in advanced lithography, circuit fabrication, and high-purity chemical supply. In these environments, even minute particulate contamination can ruin high-value components, making the highly uniform pore structure of AAO membranes essential for filtering solvents, etchants, and gases used in cleanroom processes. Furthermore, the inherent stability and precise geometry of aluminum oxide makes these membranes invaluable for advanced materials research, where scientists use them as templates to grow ordered arrays of nanowires, carbon nanotubes, or magnetic nanostructures, positioning academic and industrial R&D centers as consistent, long-term buyers.

Emerging potential customers are found within the advanced energy sector, particularly manufacturers of lithium-ion batteries and fuel cells seeking stable, porous separators that can withstand aggressive chemical environments and high operating temperatures. Environmental monitoring laboratories and water treatment facilities also represent a growing customer base, utilizing AAO filters for demanding applications such as heavy metal removal from industrial effluent or precise analysis of trace organic pollutants in drinking water sources. Ultimately, any industry prioritizing ultra-high separation resolution, chemical resilience, and thermal stability in their critical processes constitutes a key potential customer.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 685.4 Million |

| Market Forecast in 2033 | USD 1,225.9 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Anodisc, Cytiva (formerly GE Healthcare), Sartorius AG, Whatman (part of GE Healthcare), Sterlitech Corporation, Merck KGaA, Sigma-Aldrich, Advantec MFS, Inc., Applied Separations, Inc., Lingen Precision Medical Products, Inc., NanoPore Solutions, Synder Filtration, Inc., Axiva Sichem Biotech, Osmonics, Inc., Alfa Aesar (Thermo Fisher Scientific), Porous Materials, Inc., Membrane Solutions, GVS S.p.A., Fuji Film Corporation, AASTOCKS.com. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Oxide Membrane Filter Market Key Technology Landscape

The technological foundation of the Aluminum Oxide Membrane Filter market is anchored in the precise control of the electrochemical anodization process. Current technological advances focus on optimizing the three main stages: the initiation of pore formation, the steady-state growth of the porous layer, and the subsequent pore widening or modification. Innovations in anodization techniques include pulse anodization and hard anodization methods, which allow for greater control over pore morphology, enabling the fabrication of tapered pores or filters with complex, multi-layered structures. Furthermore, the development of large-area anodization techniques is crucial for scaling up production to meet industrial demand while maintaining the nanometer-scale precision required, addressing a historical bottleneck in commercial viability.

Another significant technological focus area is surface functionalization, which dramatically enhances the utility of AAO membranes beyond simple mechanical sieving. Techniques such as Atomic Layer Deposition (ALD) are increasingly used to deposit ultra-thin, conformal layers of materials (like metal oxides or polymers) inside the pores. This functionalization can alter the membrane’s surface charge, hydrophobicity/hydrophilicity, or introduce specific binding sites, allowing the filter to act as a highly selective adsorber or a catalytic surface, expanding its application space into advanced chemical separation and sensing. These advancements transform the membrane from a passive filter into an active component in complex chemical processes.

Furthermore, the integration of AAO membranes into composite structures represents a key evolutionary step. Technologies like casting or direct deposition onto polymer supports (e.g., PVDF, PES) or rigid stainless steel meshes significantly improve the mechanical robustness and handling capacity of the filters, mitigating the primary restraint of brittleness. This composite approach facilitates easier integration into standard industrial filtration modules, such as spiral-wound or flat-sheet configurations, making them viable for high-flow, large-scale industrial applications previously inaccessible to unsupported ceramic membranes. The combination of structural reinforcement and surface engineering is defining the next generation of high-performance aluminum oxide membrane filters.

Regional Highlights

- North America: This region holds the largest market share, driven by substantial government and private sector investment in life sciences R&D, particularly in the US. The presence of major pharmaceutical, biotechnology, and semiconductor manufacturing hubs necessitates high-quality, reproducible filtration media. The stringent regulatory environment for drug purity and manufacturing standards (FDA requirements) mandates the use of reliable separation technologies like AAO membranes. The market growth here is stabilized by continuous innovation and early adoption of advanced nanofabrication techniques utilizing these membranes as templates.

- Europe: Europe is a mature market exhibiting steady growth, supported by strong academic research infrastructure and robust pharmaceutical sectors in Germany, Switzerland, and the UK. The European Union’s Framework Programmes fund materials science and nanotechnology projects, directly boosting the demand for high-specification AAO filters. Focus areas include advanced medical diagnostics, personalized medicine, and strict environmental regulations that encourage the use of high-efficiency filtration for water and air quality monitoring.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market. This growth is primarily fueled by rapid industrialization, massive investments in the semiconductor and microelectronics supply chain (especially in Taiwan, South Korea, and China), and significant expansion of the domestic pharmaceutical and biotech manufacturing bases. Government initiatives promoting domestic R&D and manufacturing capacity, coupled with the need for clean processes in high-tech industries, are key accelerators for AAO membrane adoption in the region.

- Latin America (LATAM): The market in LATAM is emerging, characterized by increasing, albeit selective, adoption, mainly centered in Brazil and Mexico. Demand stems primarily from academic research institutions and growing domestic pharmaceutical generic manufacturers focusing on quality control and basic life science research. Economic fluctuations and lower average R&D spending compared to developed regions present moderate growth challenges, but opportunities exist in water purification and specialty chemical processing.

- Middle East and Africa (MEA): MEA represents a niche market, with growth concentrated in technologically advanced economies like the UAE and Saudi Arabia. The primary drivers are investments in water desalination and petrochemical industries, where the chemical and thermal stability of aluminum oxide membranes provides a distinct advantage. Market expansion is dependent on diversification efforts away from oil economies and increased funding for regional biotechnology initiatives and environmental sustainability projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Oxide Membrane Filter Market.- Cytiva (a Danaher company)

- Sartorius AG

- Merck KGaA

- Advantec MFS, Inc.

- Sterlitech Corporation

- Anodisc (a specialist membrane producer)

- General Electric (GE) Healthcare (Whatman brand)

- Lingen Precision Medical Products, Inc.

- NanoPore Solutions

- Synder Filtration, Inc.

- GVS S.p.A.

- Fuji Film Corporation

- Applied Separations, Inc.

- Porous Materials, Inc.

- Axiva Sichem Biotech

- W. L. Gore & Associates

- Donaldson Company, Inc.

- Alpha Analytical, Inc.

- Osmonics, Inc.

- Alfa Aesar (Thermo Fisher Scientific)

Frequently Asked Questions

Analyze common user questions about the Aluminum Oxide Membrane Filter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Aluminum Oxide Membrane Filters over polymeric membranes?

Aluminum Oxide (AAO) membranes offer superior chemical inertness, high thermal stability (allowing use in harsh environments), and a highly uniform, reproducible pore structure, which is critical for precision filtration and nanofabrication applications where polymer stability or pore distribution is inadequate.

In which industries are AAO filters most critically applied?

The most critical applications are concentrated in the Pharmaceutical and Biotechnology industries for sterile filtration and protein separation, and in the Semiconductor and Microelectronics sector for ultra-pure chemical filtration necessary to prevent component contamination.

How is the pore size of Aluminum Oxide Membranes controlled and verified?

Pore size is controlled precisely during the electrochemical anodization process by varying voltage and electrolyte composition. Verification is typically performed using advanced techniques such as Scanning Electron Microscopy (SEM) and specialized gas or liquid permeation porosimetry to ensure uniformity and compliance with specifications.

What challenges are limiting the widespread adoption of AAO membrane filters?

Major limitations include the high cost of production due to the complexity of the anodization process, and the inherent mechanical fragility and brittleness of the ceramic material, which demands careful handling and specialized system integration compared to flexible polymer filters.

Which geographical region exhibits the strongest growth potential for this market?

The Asia Pacific (APAC) region is forecasted to show the highest growth rate, driven by accelerating investments in regional semiconductor manufacturing capacity and rapid expansion of the domestic biopharmaceutical and advanced R&D sectors across major economies like China and South Korea.

The Aluminum Oxide Membrane Filter Market is experiencing a pivotal transition driven by nanotechnology advancements and the need for precision separation technologies across high-value industries. The market's future expansion is heavily reliant on manufacturers successfully mitigating current constraints—namely high production costs and material brittleness—through process automation and the creation of durable, composite membrane structures. Integration with AI and advanced analytics is expected to be a major catalyst, moving the industry toward 'smart filtration' solutions capable of real-time monitoring and adaptive performance. The convergence of demand from biopharma, microelectronics, and sustainable energy solutions reinforces the long-term, specialized requirement for AAO filters. Continued research into surface functionalization techniques will unlock further niche applications, particularly in highly selective sensing and drug delivery, cementing aluminum oxide membranes as indispensable tools for 21st-century material science and life science innovation.

Technological improvements in the manufacturing scale-up, specifically in large-area anodization and roll-to-roll processing for supported membranes, are critical for making these filters economically viable for large-scale industrial use, such as high-volume water purification. Currently, the high cost limits use mostly to high-margin, precision laboratory and specialized industrial applications. Addressing the cost-efficiency gap while maintaining ultra-high quality standards will be the central competitive battleground for market leaders over the next decade. Furthermore, standardization and regulatory harmonization across global markets will facilitate easier market entry and adoption of new, composite AAO products designed for robust performance under continuous operational stress. Investment trends indicate a clear pivot towards optimizing existing filter structures for bio-specific applications (e.g., cell sorting, viral concentration) and high-temperature environments, ensuring steady market growth.

The market also faces competition from other high-performance filtration media, including specialized ceramics like silicon carbide or advanced polymeric fibers that are continually improving their thermal and chemical resistance profiles. However, the unique, perfectly uniform channel geometry intrinsic to AAO remains a difficult feature to replicate with high fidelity in other materials, preserving its competitive edge in ultra-high precision fields like nanofabrication templates and certain advanced diagnostic assays. Strategic market penetration will increasingly focus on vertical integration, where manufacturers partner closely with end-users in the development cycle to ensure the filter specifications perfectly match the application requirements, minimizing waste and maximizing process yields in complex operations.

Geographically, while North America and Europe retain technical leadership, the sheer volume potential of the APAC region, especially given the monumental scale of its semiconductor and pharmaceutical investments, signals a future dominance in market consumption. Companies are therefore strategically positioning their R&D and manufacturing bases closer to these high-growth Asian markets to capitalize on evolving local needs and regulatory frameworks. The long-term outlook for the Aluminum Oxide Membrane Filter Market is highly positive, conditional on successfully transitioning specialized lab-scale technologies into cost-effective, durable industrial solutions adaptable across diverse high-tech sectors globally.

Finally, environmental sustainability requirements are acting as a subtle yet powerful market driver. The robust nature of AAO filters makes them suitable for multiple cleaning and reuse cycles, offering a significant sustainability benefit over single-use polymer filters in certain industrial contexts. This factor is becoming increasingly important for corporations aiming to reduce their environmental footprint and comply with circular economy principles. As regulatory pressure for sustainable manufacturing intensifies globally, the longevity and potential for regeneration inherent in ceramic-based filtration systems, including those made from aluminum oxide, will further enhance their appeal in green technology applications, reinforcing market resilience against alternative disposable filtration methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager