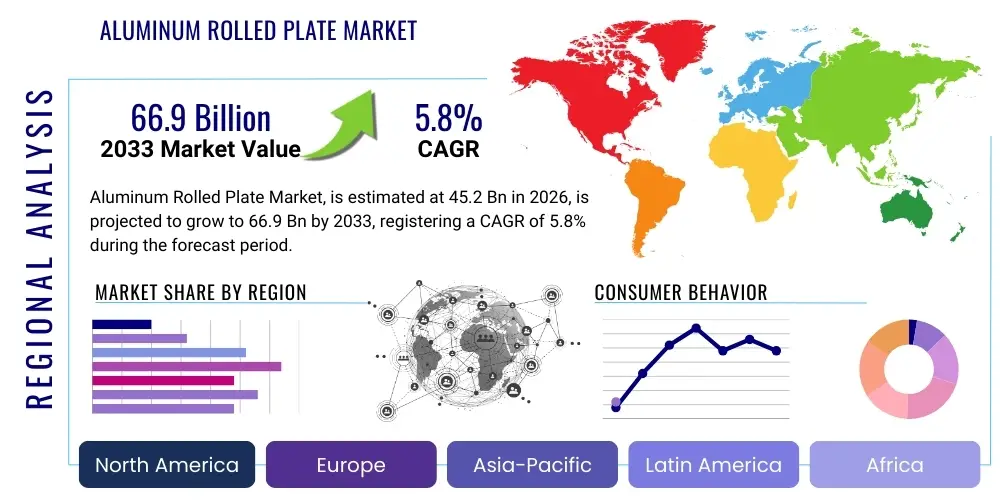

Aluminum Rolled Plate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440553 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Aluminum Rolled Plate Market Size

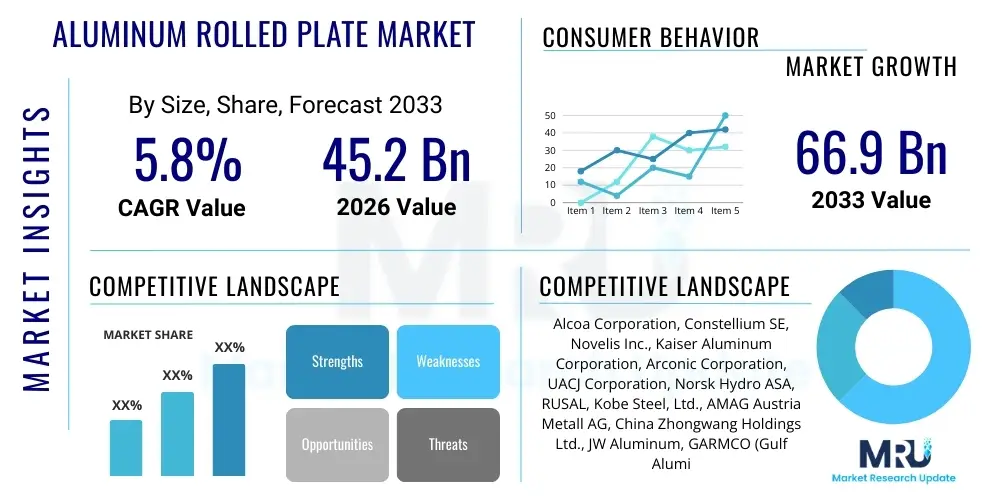

The Aluminum Rolled Plate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 45.2 billion in 2026 and is projected to reach USD 66.9 billion by the end of the forecast period in 2033.

Aluminum Rolled Plate Market introduction

The Aluminum Rolled Plate Market encompasses the global production and consumption of aluminum in various plate forms, manufactured through hot or cold rolling processes from aluminum ingots or slabs. These plates are characterized by their strength, lightweight properties, corrosion resistance, and high recyclability, making them indispensable across a multitude of industrial applications. The rolling process transforms primary or recycled aluminum into sheets or plates of varying thicknesses and specific alloy compositions, tailored to meet precise performance requirements for diverse end-use sectors.

Major applications for aluminum rolled plates span critical industries such as aerospace and defense, where high strength-to-weight ratios are paramount for aircraft structures; automotive and transportation, supporting the drive for lightweight vehicles and enhanced fuel efficiency, particularly in electric vehicles (EVs); and building and construction, used for facades, roofing, and structural components due to its durability and aesthetic versatility. Furthermore, the packaging sector utilizes rolled aluminum for containers, cans, and foils, benefiting from its barrier properties and recyclability, while the marine industry relies on it for shipbuilding due to its corrosion resistance in harsh environments. Industrial machinery, electrical equipment, and consumer goods also represent significant demand segments.

The core benefits of aluminum rolled plates, including their superior strength-to-weight ratio, excellent formability, robust corrosion resistance, and inherent sustainability through extensive recyclability, act as fundamental driving factors for market expansion. Global industrialization, rapid urbanization, increasing demand for sustainable materials, and the continuous technological advancements in manufacturing processes collectively underscore the market's trajectory. These plates are crucial for modern infrastructure development and for industries seeking to optimize performance while minimizing environmental impact, cementing their status as a foundational material in the global economy.

Aluminum Rolled Plate Market Executive Summary

The Aluminum Rolled Plate Market is experiencing dynamic growth driven by multifaceted business trends, including the robust demand from the electric vehicle (EV) sector for lightweighting solutions, the persistent expansion of the aerospace industry, and significant infrastructure development projects worldwide. Sustainability initiatives and the increasing adoption of recycled aluminum in production are also shaping business strategies, pushing manufacturers towards more eco-friendly processes and products. Mergers and acquisitions, along with strategic collaborations, are common as companies seek to consolidate market share, enhance technological capabilities, and expand their geographical footprint to meet evolving global demands for high-performance aluminum materials.

Regional trends highlight Asia Pacific (APAC) as the leading and fastest-growing market, primarily fueled by rapid industrialization, burgeoning construction activities, and substantial automotive production in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate mature markets, characterized by advanced manufacturing capabilities, stringent environmental regulations, and a strong focus on high-end applications in aerospace, defense, and specialized automotive components. Emerging markets in Latin America, the Middle East, and Africa are showing promising growth trajectories, supported by investments in infrastructure and industrial diversification, albeit from a smaller base, contributing significantly to future market expansion.

Segmentation trends indicate a strong preference for specific alloy types tailored for high-strength applications, particularly 5xxx and 6xxx series alloys for automotive and marine, and 7xxx series for aerospace, given their superior performance characteristics. The demand for medium and thick plates is escalating due to their critical use in structural components across heavy industries. Furthermore, the increasing adoption of aluminum rolled plates in novel applications such as renewable energy infrastructure (solar panel frames, wind turbine components) and advanced packaging solutions underscores the market's adaptability and potential for diversification, with a consistent push towards lighter, stronger, and more energy-efficient products.

AI Impact Analysis on Aluminum Rolled Plate Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Aluminum Rolled Plate Market often revolve around how AI can enhance operational efficiency, improve product quality, and contribute to sustainable manufacturing practices. Users are keen to understand AI's role in automating complex rolling processes, optimizing material usage, predicting equipment failures, and developing new advanced alloys. Key themes that emerge include the potential for AI-driven insights to revolutionize manufacturing workflows, reduce production costs, and accelerate innovation in material science, while also addressing concerns about data security, integration challenges, and the need for a skilled workforce capable of leveraging these advanced technologies. The overarching expectation is for AI to usher in a new era of precision, efficiency, and intelligence in the production of aluminum rolled plates.

- Enhanced Process Optimization: AI algorithms analyze vast datasets from rolling mills to fine-tune parameters such as speed, temperature, and pressure in real-time, leading to reduced energy consumption, minimized waste, and improved yield rates.

- Predictive Maintenance: AI-powered analytics monitors sensor data from machinery to anticipate equipment malfunctions or failures, enabling proactive maintenance scheduling that significantly reduces unplanned downtime and extends the lifespan of critical assets.

- Automated Quality Control: AI-driven vision systems and machine learning models detect surface defects, dimensional inaccuracies, and material inconsistencies with unparalleled precision and speed, ensuring consistent product quality and reducing the need for manual inspection.

- Supply Chain Optimization: AI predicts demand fluctuations, optimizes inventory levels for raw materials and finished goods, and streamlines logistics across the entire supply chain, enhancing resilience and responsiveness to market changes.

- Advanced Material Design and Discovery: AI accelerates the research and development of new, high-performance aluminum alloys by simulating material properties and predicting optimal compositions, significantly shortening the innovation cycle for tailor-made rolled plate solutions.

DRO & Impact Forces Of Aluminum Rolled Plate Market

The Aluminum Rolled Plate Market is primarily driven by the escalating demand for lightweight, high-strength materials across critical industries. The global automotive sector, particularly the rapid growth of electric vehicles (EVs), heavily relies on aluminum for structural components, body panels, and battery enclosures to enhance energy efficiency and extend range. Similarly, the aerospace and defense industries require advanced aluminum alloys for aircraft manufacturing due to their superior strength-to-weight ratio. Furthermore, extensive infrastructure development projects in emerging economies, alongside urbanization trends, fuel demand for aluminum in construction, while the packaging industry continues its shift towards sustainable and recyclable aluminum solutions, all serving as powerful market growth catalysts.

Despite robust growth drivers, the market faces significant restraints. Volatility in raw material prices, particularly for primary aluminum and alloying elements, alongside fluctuating energy costs, directly impacts production expenses and profit margins. High capital investment required for modern rolling mills and advanced processing technologies poses a barrier to entry for new players and limits expansion for smaller entities. Moreover, stringent environmental regulations regarding emissions and waste management, alongside potential trade protectionism and geopolitical instabilities, can disrupt supply chains and hinder market accessibility, collectively posing challenges to consistent market growth and stability.

Opportunities for market players are abundant, particularly in the realm of sustainable packaging solutions, which leverage aluminum's infinite recyclability and lightweight properties. The expansion of renewable energy infrastructure, including solar panel frames and wind turbine components, presents a growing niche for specialized aluminum plates. Technological advancements in advanced manufacturing, such as additive manufacturing and smart factory integration, offer avenues for innovative product development and optimized production processes. Geopolitical stability, evolving consumer preferences for eco-friendly products, and sustained economic growth in key regions represent additional positive impact forces, enabling market participants to expand their product portfolios and explore new application areas, driving future market evolution and profitability.

Segmentation Analysis

The Aluminum Rolled Plate Market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, consumption patterns, and growth opportunities across various product types, dimensions, applications, and end-use industries. This segmentation facilitates targeted strategies for manufacturers, suppliers, and investors, reflecting the complex interplay of material science, industrial demand, and geographical influences.

- By Type:

- 1xxx Series (Pure Aluminum)

- 3xxx Series (Aluminum-Manganese Alloys)

- 5xxx Series (Aluminum-Magnesium Alloys)

- 6xxx Series (Aluminum-Magnesium-Silicon Alloys)

- 7xxx Series (Aluminum-Zinc Alloys)

- Other Alloys

- By Thickness:

- Thin Plate (< 6 mm)

- Medium Plate (6 mm - 150 mm)

- Thick Plate (> 150 mm)

- By Application:

- Aerospace and Defense

- Automotive and Transportation

- Building and Construction

- Packaging

- Industrial Machinery and Equipment

- Electrical and Electronics

- Marine

- Other Applications

- By End-Use Industry:

- Manufacturing

- Consumer Goods

- Infrastructure

- Energy

- Military

- Commercial

Value Chain Analysis For Aluminum Rolled Plate Market

The value chain for the Aluminum Rolled Plate Market begins with extensive upstream activities, primarily involving the extraction of bauxite ore, followed by its refinement into alumina (aluminum oxide). This alumina is then processed through energy-intensive electrolysis in smelters to produce primary aluminum. Alongside primary production, a significant and growing component of the upstream segment is aluminum scrap collection and recycling, which feeds secondary aluminum into the production stream, contributing to sustainability efforts and reducing raw material costs and energy consumption. Key players in this stage include bauxite miners, alumina refiners, and primary aluminum smelters, along with scrap collection and processing enterprises.

The midstream phase of the value chain focuses on the transformation of primary or secondary aluminum ingots and slabs into rolled plates. This involves sophisticated hot rolling and cold rolling processes, where the metal is progressively reduced in thickness and improved in surface quality and mechanical properties. Further processing includes heat treatment, annealing, surface finishing (such as anodizing or coating), and cutting to precise dimensions and specifications as required by various end-use applications. This stage is dominated by specialized aluminum rolling mills and plate manufacturers who possess advanced machinery and metallurgical expertise to produce high-quality rolled plates with specific alloy compositions and properties tailored for diverse industrial demands.

The downstream segment encompasses the distribution and end-use of aluminum rolled plates. Distribution channels are varied, including direct sales from manufacturers to large-scale industrial customers (e.g., automotive OEMs, aerospace companies), as well as indirect sales through a network of distributors, wholesalers, and service centers that provide smaller quantities, custom cutting, and value-added services to a broader range of end-users. Fabricators and processors then transform these plates into finished or semi-finished components for specific applications in industries such as aerospace, automotive, construction, marine, and packaging. The efficiency and reliability of these distribution networks are crucial for ensuring timely delivery and meeting the specialized requirements of a diverse customer base globally.

Aluminum Rolled Plate Market Potential Customers

Potential customers for aluminum rolled plates represent a broad spectrum of industries, primarily comprising manufacturers and fabricators who require lightweight, high-strength, and corrosion-resistant materials for their end products. A significant segment includes automotive original equipment manufacturers (OEMs) and their suppliers, driven by the imperative to reduce vehicle weight for improved fuel efficiency and enhanced performance, particularly crucial in the rapidly expanding electric vehicle (EV) market for battery enclosures, body structures, and chassis components. The aerospace and defense sectors are also prime customers, utilizing advanced aluminum alloys for aircraft fuselages, wings, and other structural parts due to their superior strength-to-weight ratio and fatigue resistance, ensuring both safety and operational efficiency in demanding environments.

The building and construction industry constitutes another substantial customer base, with demand stemming from architects and construction companies for applications such as roofing, facades, curtain walls, decorative elements, and structural frameworks in both commercial and residential projects. The marine industry, including shipbuilders and offshore platform constructors, procures aluminum rolled plates for various vessel types and marine structures, benefiting from aluminum’s excellent corrosion resistance in saltwater environments and reduced maintenance requirements. Furthermore, manufacturers of industrial machinery and equipment, electrical components, and consumer durable goods like appliances also frequently incorporate aluminum rolled plates for their durability, thermal conductivity, and aesthetic appeal.

The packaging industry remains a consistently robust market for aluminum rolled plates, with beverage can manufacturers, food container producers, and foil suppliers relying on aluminum for its barrier properties, recyclability, and lightweight nature, contributing to sustainable packaging solutions. Beyond these major sectors, the energy industry utilizes aluminum plates for components in renewable energy systems, such as solar panel frames and heat exchangers. Each of these customer segments often has specific requirements regarding alloy composition, plate thickness, surface finish, and mechanical properties, necessitating a diverse product offering from aluminum rolled plate manufacturers to cater effectively to these specialized needs and preferences.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.2 Billion |

| Market Forecast in 2033 | USD 66.9 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alcoa Corporation, Constellium SE, Novelis Inc., Kaiser Aluminum Corporation, Arconic Corporation, UACJ Corporation, Norsk Hydro ASA, RUSAL, Kobe Steel, Ltd., AMAG Austria Metall AG, China Zhongwang Holdings Ltd., JW Aluminum, GARMCO (Gulf Aluminium Rolling Mill B.S.C.), Hulamin Ltd., SAFIN S.p.A., Gränges AB, Precision Rolled Products, Inc., Henan Mingtai Aluminum Industrial Co., Ltd., Shandong Nanshan Aluminum Co., Ltd., Yunnan Aluminum Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Rolled Plate Market Key Technology Landscape

The aluminum rolled plate market is characterized by a dynamic technology landscape, constantly evolving to meet demands for higher strength, lighter weight, improved formability, and enhanced sustainability. Core to this landscape are advanced rolling technologies, including hot rolling mills, which process thick aluminum slabs into thinner plates, and sophisticated cold rolling mills, which further reduce thickness and improve surface finish, dimensional accuracy, and mechanical properties. Innovations in these processes focus on optimizing roll design, lubrication systems, and process control algorithms to achieve greater efficiency, minimize energy consumption, and produce plates with superior metallurgical characteristics and tighter tolerances, crucial for high-performance applications.

Beyond the primary rolling processes, the market heavily relies on advanced metallurgical techniques and alloy development. This includes the creation of new high-strength aluminum alloys, particularly from the 5xxx, 6xxx, and 7xxx series, tailored for specific industry requirements such as extreme temperatures, high fatigue resistance, or superior weldability. Heat treatment technologies, like solution treatment and artificial aging, are critical for enhancing the mechanical properties of these alloys. Furthermore, surface treatment technologies, such as anodizing, various coating applications (e.g., paint, polymer films), and specialized surface texturing, are employed to improve corrosion resistance, wear resistance, and aesthetic appeal, extending the lifespan and functionality of the rolled plates in diverse environments.

The integration of Industry 4.0 principles, digitalization, and automation is transforming the production landscape, ushering in smart factories where data analytics, artificial intelligence (AI), and machine learning optimize every stage of manufacturing. Predictive maintenance systems leverage AI to monitor equipment health, minimizing downtime and maintenance costs. Automated quality control systems, utilizing computer vision and sensors, ensure consistent product quality by rapidly detecting defects. Additionally, sustainability technologies play a pivotal role, encompassing innovations in recycling processes to increase the use of secondary aluminum, energy-efficient rolling operations, and waste heat recovery systems, all contributing to a reduced environmental footprint and improved resource utilization across the aluminum rolled plate manufacturing sector.

Regional Highlights

- North America: A mature market characterized by robust demand from the aerospace and defense sectors, along with a growing automotive industry driven by lightweighting mandates for fuel efficiency and EV production. The region benefits from advanced manufacturing capabilities and significant investments in research and development for high-performance alloys.

- Europe: Known for its stringent environmental regulations and strong focus on sustainability, the European market shows significant demand from the automotive (especially premium and electric vehicles), construction, and industrial sectors. Emphasis on recycling and circular economy principles drives innovation in aluminum production and usage.

- Asia Pacific (APAC): The largest and fastest-growing market globally, propelled by rapid industrialization, urbanization, and substantial infrastructure development in countries like China, India, Japan, and South Korea. The region's expanding automotive production, thriving construction industry, and increasing demand for consumer goods are key growth drivers.

- Latin America: An emerging market with growing demand influenced by infrastructure projects, expanding automotive manufacturing, and mining activities. Economic development and foreign investments are gradually boosting the consumption of aluminum rolled plates in the region.

- Middle East and Africa (MEA): This region is witnessing significant investments in industrial diversification, urban development, and construction projects, leading to an increasing demand for aluminum rolled plates. The presence of major primary aluminum producers also supports regional supply.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Rolled Plate Market.- Alcoa Corporation

- Constellium SE

- Novelis Inc.

- Kaiser Aluminum Corporation

- Arconic Corporation

- UACJ Corporation

- Norsk Hydro ASA

- RUSAL

- Kobe Steel, Ltd.

- AMAG Austria Metall AG

- China Zhongwang Holdings Ltd.

- JW Aluminum

- GARMCO (Gulf Aluminium Rolling Mill B.S.C.)

- Hulamin Ltd.

- SAFIN S.p.A.

- Gränges AB

- Precision Rolled Products, Inc.

- Henan Mingtai Aluminum Industrial Co., Ltd.

- Shandong Nanshan Aluminum Co., Ltd.

- Yunnan Aluminum Co., Ltd.

Frequently Asked Questions

What drives the growth of the aluminum rolled plate market?

The market's growth is primarily driven by increasing demand from the automotive industry (especially electric vehicles for lightweighting), the expanding aerospace and defense sectors, global infrastructure development, and the growing preference for sustainable packaging solutions due to aluminum's recyclability.

What are the key applications for aluminum rolled plates?

Key applications include aerospace (aircraft structures), automotive (body panels, chassis), building and construction (facades, roofing), packaging (cans, foils), marine (shipbuilding), and industrial machinery, leveraging aluminum's strength, lightness, and corrosion resistance.

How does AI impact the aluminum rolled plate industry?

AI significantly impacts the industry by enhancing process optimization in rolling mills, enabling predictive maintenance for machinery, improving automated quality control, streamlining supply chain logistics, and accelerating the design of new, advanced aluminum alloys, leading to greater efficiency and innovation.

What are the main challenges faced by the market?

Primary challenges include the volatility of raw material prices and energy costs, the high capital investment required for advanced production facilities, stringent environmental regulations, and potential disruptions from global trade policies and geopolitical instabilities.

Which region dominates the aluminum rolled plate market?

The Asia Pacific (APAC) region currently dominates the aluminum rolled plate market, driven by rapid industrialization, extensive construction projects, and robust automotive production, particularly in countries such as China, India, and Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager