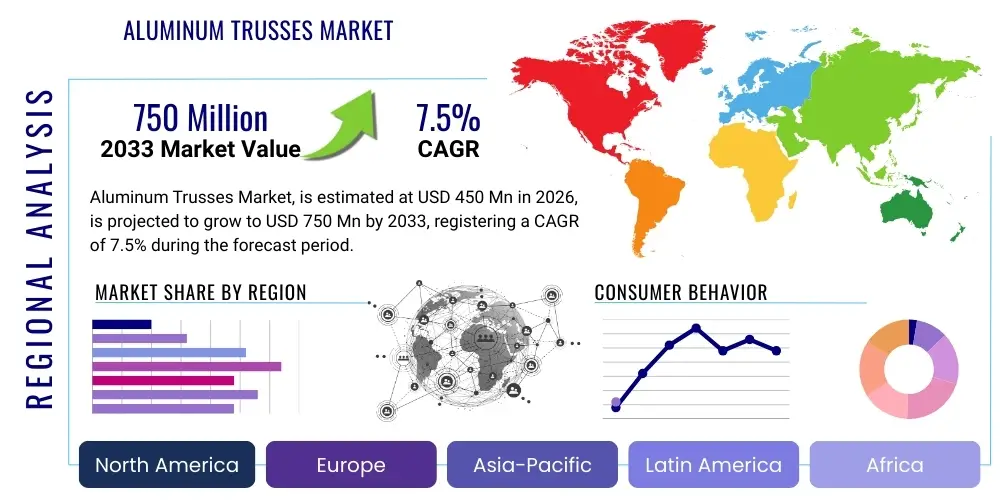

Aluminum Trusses Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438713 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Aluminum Trusses Market Size

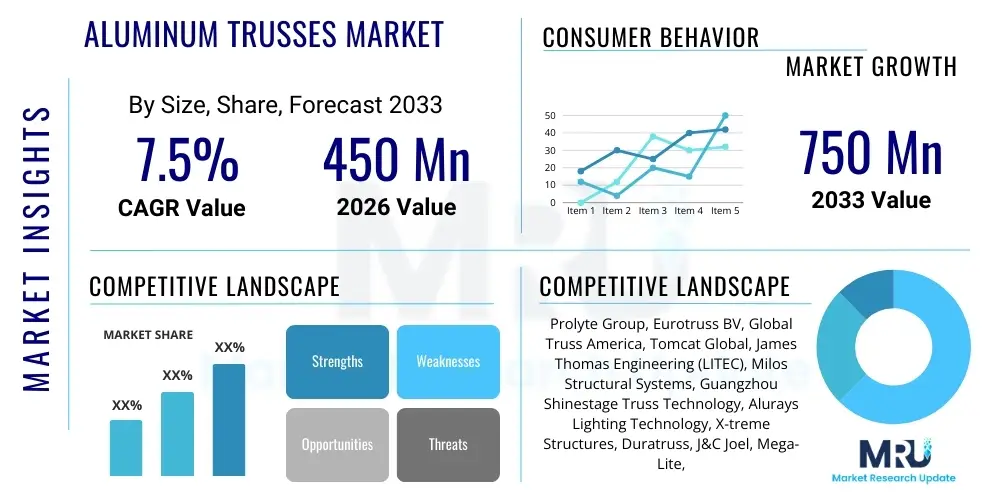

The Aluminum Trusses Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 750 Million by the end of the forecast period in 2033.

Aluminum Trusses Market introduction

The Aluminum Trusses Market encompasses the design, manufacture, and distribution of modular structural components made primarily from high-strength aluminum alloys, such as 6061-T6 and 6082-T6. These lightweight yet robust structures are essential for creating temporary or permanent support frameworks in various environments. Aluminum trusses are favored over traditional steel alternatives due to their superior strength-to-weight ratio, resistance to corrosion, ease of transport, and rapid assembly/disassembly capabilities. They are highly adaptable and form the backbone for suspending lighting, sound equipment, stage scenery, and structural roofing elements across diverse industries, facilitating complex structural designs that require both reliability and flexibility.

The primary applications driving the demand for aluminum trusses include the entertainment and events sector, covering large-scale concerts, festivals, theatrical productions, and corporate expos. Furthermore, the construction and infrastructure sectors utilize aluminum trusses extensively for temporary scaffolding, roof support systems, and specialized architectural installations where minimal weight load is critical. The intrinsic benefits of aluminum trusses—including longevity, aesthetic appeal, and modular standardization—significantly contribute to their widespread adoption. These features allow event organizers and construction firms to meet stringent safety standards while achieving efficient project timelines and cost management, thereby ensuring continued market expansion globally.

Key driving factors propelling the market include the global increase in live entertainment events and music festivals, demanding sophisticated staging and structural setups. Rapid urbanization, particularly in developing economies, also fuels the construction sector's need for temporary and specialized structural supports. Moreover, technological advancements in material science and welding techniques have led to the creation of higher load-bearing and safer truss designs, increasing confidence among end-users. Regulatory emphasis on safety in temporary structures further mandates the use of certified, high-quality aluminum products, reinforcing market growth trajectories across professional sectors.

Aluminum Trusses Market Executive Summary

The Aluminum Trusses Market is characterized by robust growth, primarily propelled by the burgeoning global entertainment industry and significant infrastructure investments. Business trends indicate a strong focus on modularity, quick-connect systems, and the integration of smart technologies for load monitoring and structural integrity checks. Manufacturers are increasingly prioritizing sustainability by employing recycled aluminum and optimizing production processes to reduce carbon footprints, responding to rising corporate social responsibility (CSR) demands from major event promoters and construction companies. Furthermore, competitive differentiation is achieved through specialized product lines catering to extreme load requirements or aesthetic needs, such as curved and custom-shaped trusses for architectural showcases, indicating a move towards specialized, high-value offerings.

Regionally, the market exhibits high activity in North America and Europe, which possess mature entertainment markets and established safety regulations necessitating premium truss systems. However, the Asia Pacific region, led by China and India, is emerging as the fastest-growing market due to massive government spending on public infrastructure, rapid development of convention centers, and the proliferation of international music and sporting events. Latin America and the Middle East also show promising growth potential, driven by tourism infrastructure projects and large-scale cultural events. This geographical dynamism requires global players to establish localized distribution networks and manufacturing facilities to reduce logistics costs and better serve regional demands efficiently.

Segment-wise, the Box Truss segment dominates the market due to its high load-bearing capacity and versatility across both staging and construction applications. However, the Circular/Curved Truss segment is experiencing accelerated growth, driven by architectural demand for unique, visually compelling structures in retail, exhibitions, and themed environments. The Entertainment & Events application remains the primary revenue generator, though the Industrial and Manufacturing segment is steadily increasing its market share, utilizing aluminum trusses for temporary cleanroom structures, equipment rigging, and specialized lifting operations. The market landscape suggests a continuous evolution toward lightweight, high-performance alloys (like 7000 series prototypes) for ultra-heavy-duty applications, ensuring future market expansion through innovation.

AI Impact Analysis on Aluminum Trusses Market

User inquiries regarding AI's influence in the Aluminum Trusses Market predominantly center on how artificial intelligence can enhance structural safety, optimize logistics, and automate manufacturing processes. Users frequently question the role of machine learning in predicting material fatigue and determining optimal truss designs under variable loading conditions, seeking assurances on enhanced reliability. Key concerns revolve around the integration costs of AI-powered monitoring systems (IoT sensors paired with ML algorithms) and the potential for streamlining complex inventory management for large rental fleets used in touring productions. The common expectation is that AI will minimize human error in assembly planning, accelerate design cycles through generative design tools, and ultimately reduce operational risks and insurance liabilities associated with temporary structures.

- AI-driven Generative Design: Utilizes machine learning to simulate thousands of load scenarios, optimizing truss geometry for maximum strength-to-weight ratio, resulting in material savings and superior structural integrity.

- Predictive Maintenance: AI algorithms analyze real-time sensor data (IoT integration) from deployed trusses to predict potential structural failures or material fatigue before they occur, scheduling proactive maintenance and ensuring operational safety.

- Automated Inventory Management: Machine learning optimizes the allocation, tracking, and logistics of truss components for complex, multi-venue tours or large construction sites, minimizing transit time and reducing component mismatch errors.

- Robotic Welding and Fabrication: AI-powered vision systems guide precision robotic welding, ensuring standardized quality and strength of joints, which is critical for safety-critical components like aluminum trusses.

- Optimized Load Planning: AI assists staging professionals in determining the ideal configuration and placement of lighting and sound equipment on trusses, calculating precise load distribution to stay within safe working limits.

DRO & Impact Forces Of Aluminum Trusses Market

The dynamics of the Aluminum Trusses Market are dictated by a balanced interplay of propelling forces and restrictive constraints, underpinned by significant market opportunities and external factors. The core drivers stem from the continuous global expansion of the live events sector, requiring standardized, high-quality rigging solutions, coupled with increased infrastructure spending across emerging economies where rapid, temporary structural solutions are paramount. However, the market faces restraints such as significant fluctuations in primary aluminum prices, which directly impact manufacturing costs and product pricing, alongside stringent regulatory hurdles related to safety certifications and load capacity standards across different jurisdictions. Opportunities are abundant in developing specialized, lightweight alloys and integrating smart monitoring technologies (IoT/AI) for enhanced structural performance and asset tracking, creating new value propositions for rental companies and structural engineers.

The impact forces influencing this market include two main dimensions: macroeconomic volatility and technological displacement. Macroeconomic downturns or global crises, such as pandemics, severely impact the events industry, leading to immediate contraction in demand for trusses. Conversely, stable economic growth stimulates tourism, construction, and corporate events, boosting demand. Technologically, the shift towards more sustainable manufacturing practices and the development of composite materials pose an indirect threat, potentially leading to alternatives that offer better weight characteristics, although aluminum currently maintains a strong competitive edge due to its established supply chain and recycling efficiency. These forces necessitate continuous innovation in design and supply chain resilience for sustained competitive advantage.

The market faces five distinct forces of competition. First, the intensity of rivalry among existing competitors is high, driven by differentiation based on proprietary connection systems and safety certifications. Second, the threat of new entrants is moderate, balanced by high capital requirements for precision manufacturing but eased by globally accessible aluminum sourcing. Third, the bargaining power of buyers (large rental houses or event production companies) is substantial, given their volume procurement capabilities. Fourth, the bargaining power of suppliers is moderate to high, particularly concerning high-grade aluminum alloys (6061-T6), which are commodities influenced by global trade policies. Finally, the threat of substitutes is low to moderate; while steel remains an option for permanent, extremely heavy structures, no material currently matches aluminum’s combination of lightweight characteristics, durability, and corrosion resistance for temporary structural applications.

Segmentation Analysis

The Aluminum Trusses Market is systematically segmented based on product type, material grade, and end-use application, providing clarity on varying demand patterns across industries. Product segmentation helps differentiate the market based on structural configurations essential for specific load requirements and architectural aesthetics, while material grade segmentation highlights the importance of alloy strength and longevity for heavy-duty versus standard applications. The application segment reveals the primary revenue streams, emphasizing the dependence of the market on the entertainment sector alongside increasing contributions from construction and industrial sectors globally, facilitating targeted marketing and product development efforts by manufacturers.

- Product Type:

- Box Truss (Square Truss)

- Triangular Truss

- Flat Truss (Ladder Truss)

- Circular Truss (Curved Truss)

- Custom Truss Systems

- Material Grade:

- 6061-T6 Aluminum Alloy

- 6082-T6 Aluminum Alloy

- Other High-Strength Alloys (e.g., 7000 Series)

- Application:

- Entertainment and Events (Concerts, Festivals, Theater)

- Construction and Infrastructure (Temporary Roofing, Scaffolding)

- Exhibition and Trade Shows (Display Booths, Signage)

- Industrial and Manufacturing (Rigging, Lifting, Temporary Structures)

- Connection Type:

- Spigot (Conical) Connection

- Bolt Connection

- Sleeve Connection

Value Chain Analysis For Aluminum Trusses Market

The value chain for the Aluminum Trusses Market begins with upstream activities, primarily encompassing the sourcing and production of high-grade aluminum billets and specialized alloys, such as the widely used 6061-T6 and 6082-T6. This initial stage is highly capital-intensive and governed by global commodity pricing. Following material sourcing, midstream activities involve the specialized extrusion of aluminum profiles, precision cutting, and highly skilled welding processes to form the finished truss segments. Quality control and rigorous testing for load-bearing capacity and safety certification (e.g., TÜV, CE) are critical value-addition steps at this stage, ensuring the final product meets stringent industry standards required for public safety.

Downstream activities focus on logistics, distribution, and end-user engagement. Distribution channels are bifurcated into direct sales to large, integrated event production companies or major construction firms, and indirect sales through a global network of specialized truss rental companies, distributors, and dealers. Rental companies form a vital part of the ecosystem, managing large inventories, offering consultation services, and providing setup/teardown services for temporary installations. The proximity of distributors to major metropolitan areas and entertainment hubs is crucial for prompt service delivery and minimized shipping costs, significantly impacting the final market price and accessibility.

Direct sales offer manufacturers higher margins and closer relationships with key end-users, enabling better feedback loops for product refinement. However, the indirect channel, dominated by rental companies, offers market penetration and scale, particularly for smaller events and regional construction projects that cannot afford outright purchase. The long-term durability and high residual value of aluminum trusses mean that rental services remain the most dominant distribution method in the entertainment sector. Maximizing value throughout the chain relies heavily on maintaining low production waste, optimizing logistics for bulky items, and ensuring compliance with evolving international safety regulations, which requires continuous investment in training and certified materials.

Aluminum Trusses Market Potential Customers

The primary end-users and buyers of aluminum truss systems are centered within the global live events ecosystem, encompassing major music promoters (e.g., Live Nation, AEG), specialized staging and rigging contractors, and large equipment rental houses that serve regional markets. These customers require durable, certified, and modular systems capable of supporting complex loads (audio, lighting, video screens) safely across numerous venues and often demanding rapid setup and teardown capabilities. Their purchasing decisions are heavily influenced by product certification, connector reliability (spigot versus bolt), and manufacturer reputation for safety and customer service.

Beyond the entertainment sector, significant potential customers reside in the construction, infrastructure, and exhibition industries. Construction companies utilize trusses for temporary support structures, specialized scaffolding for unique architectural designs (e.g., curved facades), and temporary event roofing systems. Exhibition organizers and trade show managers are consistent buyers and renters, relying on lightweight trusses to build complex, multi-story booths and display structures quickly and affordably. In the industrial sector, manufacturing facilities use trusses for temporary clean rooms, overhead rigging for equipment maintenance, and material handling systems that require high flexibility.

In addition to commercial entities, governmental and public sector bodies represent a niche yet consistent customer base. This includes municipal departments responsible for public festivals, sporting events, and disaster relief efforts where temporary, quickly deployable shelters or lighting structures are required. Military and defense sectors also utilize lightweight, modular truss systems for temporary camp infrastructure and communications towers. The diversity of applications mandates that manufacturers offer a broad portfolio, ranging from micro-trusses for display use to heavy-duty 500mm box trusses designed for stadium-sized touring productions, ensuring they meet the specific load requirements and regulatory standards of each distinct customer vertical.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 750 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Prolyte Group, Eurotruss BV, Global Truss America, Tomcat Global, James Thomas Engineering (LITEC), Milos Structural Systems, Guangzhou Shinestage Truss Technology, Alurays Lighting Technology, X-treme Structures, Duratruss, J&C Joel, Mega-Lite, TAF, Total Structures, Stage Tech Inc., Area Four Industries, Sixfab, ADJ Products, Beijing Beida Jade Bird Group, Suzhou Goldwell Stage Equipment. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aluminum Trusses Market Key Technology Landscape

The technology landscape of the Aluminum Trusses Market is defined by continuous evolution in material science, precision manufacturing, and connectivity. Central to this landscape is the advancement in aluminum extrusion and welding techniques, specifically robotic welding, which ensures unparalleled consistency in weld penetration and geometry, directly enhancing the load capacity and safety profile of the trusses. Furthermore, non-destructive testing (NDT) technologies, such as ultrasonic and eddy current testing, are routinely employed to certify the integrity of high-stress joints, a critical requirement for maintaining global safety standards. The shift from basic structural design to computer-aided engineering (CAE) modeling allows manufacturers to simulate extreme wind, vibration, and static loads with high accuracy before physical prototyping, significantly reducing design cycles and risk.

A burgeoning technological trend is the integration of Internet of Things (IoT) sensors into truss segments, creating "smart trusses." These embedded sensors monitor critical parameters such as strain, temperature, and overall load distribution in real time. This data is transmitted to cloud platforms, enabling structural engineers and event managers to receive instant alerts if load limits are approached or exceeded. This provides an unprecedented level of real-time safety monitoring for complex stage setups and temporary roofing structures, drastically minimizing the risk of catastrophic failure and streamlining inspection processes, moving the industry towards predictive rather than reactive safety management.

Furthermore, connection technology remains a key area of innovation. While spigot (conical) and bolt connections are standard, manufacturers are developing proprietary quick-connect systems that minimize reliance on tools, reducing assembly time and labor costs on site. These proprietary systems are designed to be intuitive while maintaining certified strength ratings, providing a competitive edge in the fast-paced events sector. Advances in specialized powder coating and anodizing techniques also contribute to the technological landscape by improving the corrosion resistance and aesthetic durability of the trusses, catering to high-end architectural and coastal construction applications where material longevity is paramount.

Regional Highlights

- North America: This region dominates the global market in terms of revenue and technological adoption, driven by a highly mature and extensive live entertainment industry, encompassing major music tours, film productions, and sporting events. The United States, in particular, has stringent safety regulations (OSHA standards) that mandate the use of high-quality, certified aluminum truss systems. The presence of major global truss manufacturers and large-scale rental companies solidifies North America’s leading position.

- Europe: Europe represents a robust market, characterized by a strong historical tradition of theater, exhibitions (like the Frankfurt and Hannover trade fairs), and major music festivals (Glastonbury, Tomorrowland). Countries like Germany, the UK, and the Netherlands exhibit high demand, emphasizing design innovation, TUV certification compliance, and sustainability in manufacturing processes, often leading the world in adopting quick-connect modular systems and recycled aluminum alloys.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region during the forecast period. This growth is fueled by massive urbanization, infrastructure projects (development of convention centers, stadiums), and the rapidly expanding domestic entertainment markets in countries such as China, India, and Southeast Asian nations. Increased disposable income and Western cultural adoption are driving the demand for large-scale concerts and international events, though pricing sensitivity remains a key factor.

- Latin America: This region shows steady growth, primarily concentrated around major economic hubs like Brazil and Mexico. Market growth is closely tied to investment in tourism infrastructure and the hosting of major international events and expos. The market faces challenges related to logistics and the penetration of uncertified or lower-quality products, pushing reputable manufacturers to emphasize quality and certification compliance.

- Middle East and Africa (MEA): The MEA region is witnessing significant infrastructural investment, particularly in the Gulf Cooperation Council (GCC) countries (UAE, Saudi Arabia) related to vision-based economic diversification (e.g., Saudi Vision 2030). These mega-projects, including EXPOs, cultural centers, and world-class tourist attractions, necessitate state-of-the-art aluminum truss structures for both temporary and permanent architectural installations, driving high-value demand, especially for custom and heavy-duty systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aluminum Trusses Market.- Prolyte Group

- Eurotruss BV

- Global Truss America

- Tomcat Global

- James Thomas Engineering (LITEC)

- Milos Structural Systems

- Guangzhou Shinestage Truss Technology

- Alurays Lighting Technology

- X-treme Structures

- Duratruss

- J&C Joel

- Mega-Lite

- TAF

- Total Structures

- Stage Tech Inc.

- Area Four Industries

- Sixfab

- ADJ Products

- Beijing Beida Jade Bird Group

- Suzhou Goldwell Stage Equipment

Frequently Asked Questions

Analyze common user questions about the Aluminum Trusses market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between aluminum trusses made from 6061-T6 and 6082-T6 alloys?

The primary distinction lies in chemical composition and strength properties. 6082-T6 alloy, containing more manganese and silicon, generally offers slightly higher strength and improved corrosion resistance, making it the preferred choice in Europe and for extremely high-load applications. 6061-T6 is widely used globally and provides excellent weldability and good general strength, often used for standard and medium-duty truss systems. Both are high-performance structural materials.

How does the shift towards sustainable event production impact the Aluminum Trusses Market?

The sustainability trend strongly favors aluminum trusses due to aluminum's high recyclability. Manufacturers are increasingly using recycled aluminum content, reducing the environmental footprint of production. Furthermore, the lightweight nature of aluminum trusses reduces transportation fuel consumption and logistical costs, aligning directly with industry efforts to minimize the carbon emissions associated with large-scale touring and event setups, thereby driving market demand for eco-conscious products.

Which connection type is most reliable for heavy-duty aluminum truss applications?

For ultra-heavy-duty or highly permanent structures requiring maximal structural rigidity and load bearing, bolt connection systems are typically preferred as they offer a highly secure, non-wobbling connection. However, the conical (spigot) connection system is dominant in the entertainment industry due to its superior speed of assembly and disassembly, offering reliability suitable for most high-load touring applications when properly pinned and maintained according to manufacturer specifications.

What are the key safety standards and certifications manufacturers must adhere to?

Key safety standards vary by region but commonly include European standards (TÜV, CE marking, DIN standards), North American standards (ANSI, OSHA, and codes like ESTA), and global engineering standards (such as Eurocode 9 for aluminum structures). Compliance involves rigorous testing of load capacity, connection integrity, and welding quality. These certifications are essential for market access and liability management, especially in public-facing events and critical infrastructure projects.

How is technological innovation improving the lifespan and performance of aluminum trusses?

Technological advancements, including precision robotic welding, non-destructive testing (NDT), and advanced corrosion-resistant coatings, significantly extend the lifespan of trusses by ensuring material integrity and joint strength. The introduction of smart truss systems, incorporating IoT sensors for real-time load monitoring and predictive maintenance alerts, optimizes performance by preventing overloading and facilitating proactive asset management, maximizing return on investment for rental companies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Aluminum Trusses Market Statistics 2025 Analysis By Application (Entertainment Industry, Exhibition Industry, Others), By Type (Ladder Truss, Triangular Truss, Square Truss, Circular & Oval Truss, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Aluminum Trusses Market Statistics 2025 Analysis By Application (Entertainment Industry, Exhibition Industry), By Type (Ladder Truss, Triangular Truss, Square Truss, Circular & Oval Truss, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager