Ambient Vaporizer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434918 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Ambient Vaporizer Market Size

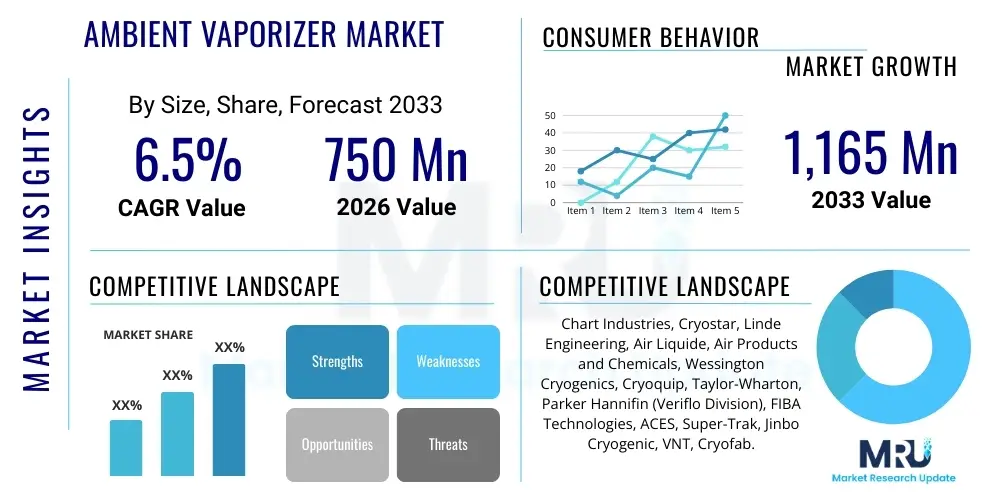

The Ambient Vaporizer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,165 Million by the end of the forecast period in 2033.

This steady growth is primarily fueled by the escalating global demand for industrial gases such as Liquid Nitrogen (LIN), Liquid Oxygen (LOX), and Liquid Argon (LAr), particularly in emerging economies undergoing rapid industrialization and expansion of manufacturing bases. Ambient vaporizers, valued for their operational simplicity, low maintenance requirements, and zero energy consumption (relying solely on atmospheric heat exchange), represent a cost-effective alternative to powered vaporizers, making them the preferred choice for bulk gas handling facilities, especially in remote or energy-sensitive locations.

Furthermore, the significant proliferation of Liquefied Natural Gas (LNG) as a cleaner transition fuel in the transportation and power generation sectors is critically boosting the market. Ambient vaporizers are essential components in small-scale LNG terminals, satellite stations, and vehicle fueling infrastructure, converting the cryogenic LNG back into natural gas for distribution and consumption. Regulatory pressures favoring cleaner energy sources and the continuous expansion of the medical sector, requiring reliable oxygen and nitrogen supply systems, solidify the market's robust trajectory through 2033.

Ambient Vaporizer Market introduction

Ambient vaporizers are highly efficient heat exchange units designed to convert cryogenic liquids stored at extremely low temperatures (such as LOX, LIN, LAr, and LNG) back into their gaseous state using the thermal energy naturally available in the surrounding air. These devices operate without external power or heating elements, offering a fundamentally reliable and environmentally benign method for gas delivery in high-volume applications. Their construction typically involves specialized finned aluminum extrusions that maximize the surface area for efficient heat absorption, ensuring consistent gas flow rates commensurate with industrial consumption demands. The absence of moving parts significantly reduces maintenance costs and improves system longevity, cementing their position as critical infrastructure in the industrial gas supply chain.

The product portfolio encompasses various designs, including natural draft vaporizers, which rely on convection, and forced draft units, which use fans to enhance heat transfer in regions with lower ambient temperatures or high humidity. Major applications span metallurgy, where oxygen and nitrogen are crucial for production; the chemical industry, utilizing inert gases for safety and processing; and the rapidly expanding medical sector, where reliable oxygen delivery is paramount. The fundamental benefits—including zero energy consumption, reduced operational expenditure, intrinsic safety, and scalability—make them indispensable for bulk cryogenic storage facilities globally, supporting continuous gas supply to end-user processes.

Key market driving factors include the substantial increase in global steel production, which demands large quantities of oxygen; the burgeoning demand for cryogenic storage for vaccine and biological material preservation; and accelerated investment in small-scale LNG infrastructure, particularly in Asia Pacific and North America. The shift toward decentralized gas supply systems and the emphasis on energy efficiency across industrial processes further act as significant accelerators for market penetration, compelling industrial gas suppliers and end-users alike to prioritize passive vaporization technologies.

Ambient Vaporizer Market Executive Summary

The Ambient Vaporizer Market is characterized by stable technology, focused primarily on material efficiency and design optimization to handle extreme temperature differentials and fluctuating flow rates reliably. Current business trends indicate a strong move toward modular and skid-mounted solutions that integrate vaporization units with pressure regulation and safety systems, simplifying installation and compliance for end-users, especially those developing satellite LNG plants. Regional trends highlight the Asia Pacific as the dominant growth engine, driven by massive infrastructure investments, burgeoning medical gas demand in densely populated areas, and the establishment of new industrial corridors. Europe and North America, while mature, show sustained demand fueled by replacement cycles and the increasing adoption of specialized high-pressure and high-flow ambient units for specific chemical and energy applications.

Segment-wise, the Application segment sees the Industrial Manufacturing and Energy sectors holding the largest market share due to consistent high-volume consumption of oxygen, nitrogen, and argon in primary production processes like welding, refining, and metal cutting. The LNG fueling sub-segment is registering the fastest growth, propelled by maritime and heavy-duty transport utilizing LNG as bunkering fuel. Technological segmentation emphasizes aluminum-finned natural draft vaporizers as the workhorse of the industry due to their optimal cost-to-efficiency ratio, although stainless steel variants are gaining traction in highly corrosive or specialized clean-room environments.

Competitive dynamics remain centered around specialized engineering expertise and supply chain reliability. Key players are investing in enhanced heat transfer algorithms and specialized coatings to improve performance in challenging climatic conditions, such as high moisture or extreme cold, without resorting to electrical heating. Overall, the market outlook is overwhelmingly positive, underpinned by non-cyclical industrial gas consumption patterns and the critical role these passive devices play in ensuring energy transition goals and industrial output stability worldwide.

AI Impact Analysis on Ambient Vaporizer Market

User inquiries regarding AI's impact on the Ambient Vaporizer Market typically center on how artificial intelligence can optimize the performance and maintenance of these fundamentally passive systems, and whether AI-driven predictive analytics can enhance the efficiency of cryogenic supply chains. Key concerns often revolve around the practical application of AI in a component that consumes no energy and has no moving parts, focusing instead on data generated by upstream storage tanks and downstream gas pipelines. Users expect AI to mitigate risks associated with fluctuating ambient conditions, predict icing events, and schedule proactive maintenance for peripheral control systems (like pressure regulators and valves) connected to the vaporizer assembly. The core expectation is moving from reactive maintenance to highly precise, predictive operational adjustments across distributed gas networks where vaporizers are deployed.

- AI-enhanced Predictive Maintenance: Utilizing machine learning algorithms on sensor data (temperature, pressure, flow rate) to predict component failure in ancillary equipment (valves, controls) associated with vaporizer skids.

- Optimal Flow Rate Management: AI models analyze weather data and real-time gas consumption trends to suggest optimal vaporization unit deployment and sequencing, preventing resource waste or supply interruptions.

- Icing Prediction and Mitigation: Leveraging historical and real-time environmental data (humidity, ambient temperature) to predict the onset of dangerous icing conditions on vaporizer fins, allowing operators to preemptively switch units or activate backup systems.

- Supply Chain and Logistics Optimization: Integrating vaporizer operational status into larger cryogenic logistics platforms, enabling AI to optimize tank truck delivery routes and inventory levels based on localized consumption and vaporizer performance data.

- Design Optimization: Using generative design and simulation driven by AI to model complex fin geometries that maximize heat transfer efficiency under specific regional climatic profiles, leading to smaller, more efficient units.

DRO & Impact Forces Of Ambient Vaporizer Market

The Ambient Vaporizer Market is significantly influenced by a blend of persistent industrial demand, stringent safety regulations, and the inherent limitations related to thermal performance. Drivers predominantly include the robust and non-cyclical demand for industrial gases in sectors like healthcare, electronics, and food processing, coupled with the global push for cleaner fuels like LNG, necessitating widespread vaporization infrastructure. Restraints primarily stem from the physical limitations inherent in passive heat transfer, notably performance degradation due to atmospheric icing in humid or cold climates, which necessitates the installation of costly standby units or switch-over systems. Opportunities emerge through expanding into niche high-pressure applications (e.g., hydrogen refueling infrastructure) and developing materials or coatings that resist frost accumulation without external energy input, enhancing operational uptime and reliability.

Impact forces are heavily skewed by operational cost-efficiency, as ambient vaporizers inherently offer the lowest total cost of ownership compared to steam or electric-powered alternatives, providing a strong incentive for adoption in new facilities. Regulatory standards, particularly those governing pressure vessel design (ASME, PED), ensure quality and reliability but also impose high barriers to entry for new manufacturers, stabilizing the competitive landscape. The long-term impact of environmental regulations favoring cleaner energy sources continues to propel the LNG application segment, ensuring sustained capital investment in the required vaporization infrastructure globally.

The interdependence of this market with the capital expenditure cycles of major industrial gas producers (like Air Liquide, Linde, and Air Products) means that large-scale global projects heavily dictate procurement volumes. While the technology itself is mature, the constant drive for increased flow capacity within smaller footprints, especially in urban environments, remains a key technological lever. The balance between maximizing heat exchange surface area and minimizing unit size, while adhering to structural integrity standards, defines the ongoing evolution and market stability of ambient vaporization technology.

Segmentation Analysis

The Ambient Vaporizer Market is strategically segmented based on factors crucial to their deployment, including the cryogenic liquid being handled, the required flow capacity, and the specific application sector. This granular segmentation allows manufacturers to tailor design specifications—such as material composition, fin density, and pressure rating—to meet the precise operational demands of diverse end-users, ranging from small clinical facilities requiring minimal oxygen flow to massive LNG import terminals demanding throughput measured in metric tons per hour. Understanding these segments is vital for accurate market forecasting and targeted product development, ensuring alignment with global industrial and energy transition requirements.

The segmentation by capacity—small (less than 1,000 Nm3/h), medium, and large (over 10,000 Nm3/h)—reflects the scale of the facility, with large units typically serving pipeline filling stations and industrial complexes, while smaller units are common in laboratories and mobile applications. Application segmentation demonstrates the critical reliance of key industries on continuous gas supply. The material segment highlights the trade-off between the high thermal conductivity of aluminum alloys (most common) and the enhanced corrosion resistance and higher pressure capability offered by specialized stainless steel constructions used in high-purity or harsh chemical settings.

- By Application:

- Industrial Manufacturing (Steel, Chemicals, Electronics)

- Medical and Healthcare (Hospitals, Clinical Labs)

- Energy and Fueling (LNG/LPG Satellite Stations, Power Generation)

- Food and Beverage Processing (Cryogenic Freezing, Inerting)

- By Flow Rate Capacity:

- Low Flow (100–500 Nm3/h)

- Medium Flow (500–5,000 Nm3/h)

- High Flow (Above 5,000 Nm3/h)

- By Cryogenic Liquid:

- Nitrogen (LIN)

- Oxygen (LOX)

- Argon (LAr)

- Natural Gas (LNG)

- Carbon Dioxide (LCO2)

- By Material:

- Aluminum (Standard Industrial Use)

- Stainless Steel (High Purity/Corrosive Applications)

Value Chain Analysis For Ambient Vaporizer Market

The Ambient Vaporizer market value chain begins with the upstream sourcing of specialized raw materials, primarily high-grade aluminum alloys and, to a lesser extent, stainless steel tubes and plates. Manufacturing involves precision extrusion of the finned heat exchange elements, a highly specialized process crucial for maximizing thermal efficiency. Companies invest heavily in advanced welding techniques to ensure leak-proof assembly capable of withstanding extreme thermal cycling and high internal pressures. The upstream complexity lies in managing volatile metal prices and maintaining consistent quality standards for materials that must operate reliably near absolute zero temperatures while enduring external climatic variables.

Midstream activities involve the core manufacturing, assembly, and integration of safety devices (pressure relief valves, regulators) into skid-mounted systems, often customized to specific client specifications regarding flow rate and local pressure codes. The distribution channel is bifurcated: direct sales channels are common for large industrial gas companies (who purchase bulk customized units for their infrastructure), while indirect channels, utilizing specialized distributors and engineering procurement and construction (EPC) firms, service smaller end-users and complex project installations. EPC firms play a crucial intermediary role, integrating the vaporizers into broader cryogenic storage and piping networks, requiring deep technical knowledge of gas handling standards.

Downstream activities include installation, commissioning, and long-term maintenance and servicing. Since ambient vaporizers are robust and low-maintenance, the downstream value is often captured through service contracts for associated pressure regulation equipment and scheduled inspections for fin integrity and pressure safety compliance. The final consumption stage is driven by the consistent operational demands of end-users across industrial, medical, and energy sectors, emphasizing reliable performance over outright purchasing cost, as failure leads to immediate and costly production halts.

Ambient Vaporizer Market Potential Customers

Potential customers for ambient vaporizers span the entire spectrum of industries reliant on bulk cryogenic gases for their operations, making the customer base highly diversified yet concentrated within specific high-consumption sectors. The primary buyers are large industrial gas producers and distributors who own and operate extensive cryogenic infrastructure, including storage tanks and distribution networks. These companies require ambient vaporizers as standard equipment at every customer site or satellite filling station to convert their stored liquid product into usable gas, making them the largest volume purchasers globally.

Beyond the industrial gas giants, significant demand originates directly from end-user industries that manage their own gas supply or maintain onsite generation capabilities. This includes major steel mills and metallurgical foundries that require vast amounts of oxygen for smelting; large chemical processing plants needing inert gases (nitrogen, argon) for safety purging; and hospitals and healthcare networks investing in centralized bulk liquid oxygen systems. The shift towards small-scale and micro-LNG installations also creates a growing customer segment among regional utilities, maritime operators, and heavy-duty fleet managers adopting cleaner fuels.

Furthermore, specialized end-users in high-technology fields, such as semiconductor manufacturing (requiring high-purity nitrogen) and aerospace engineering (requiring LOX/LIN for testing), represent highly lucrative niche markets demanding custom-designed, high-specification ambient units. The common denominator among all potential customers is the critical need for a continuous, safe, and highly cost-efficient method of converting cryogenic storage into a regulated, usable gas stream, positioning ambient vaporizers as essential capital equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,165 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Chart Industries, Cryostar, Linde Engineering, Air Liquide, Air Products and Chemicals, Wessington Cryogenics, Cryoquip, Taylor-Wharton, Parker Hannifin (Veriflo Division), FIBA Technologies, ACES, Super-Trak, Jinbo Cryogenic, VNT, Cryofab. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ambient Vaporizer Market Key Technology Landscape

The technology landscape for ambient vaporizers is characterized by continuous refinement of heat exchange mechanics and materials science rather than fundamental paradigm shifts. The core technology centers on specialized aluminum extrusions, often in star or multi-finned patterns, designed to maximize heat transfer area relative to the physical volume. Recent advancements focus on optimizing the internal geometry of the fluid paths to reduce pressure drop while maintaining turbulent flow, thereby enhancing vaporization efficiency and reducing the size and weight of units required for a given flow rate. A critical area of technological focus involves proprietary aluminum alloys and surface treatments aimed at improving thermal conductivity and mitigating internal corrosion risks associated with trace impurities in cryogenic fluids.

Another significant technological theme is the development of intelligent management systems for vaporizer banks. While the vaporizer itself is passive, the surrounding controls, including automatic switch-over manifolds and pressure regulating stations, are increasingly sophisticated. Modern systems utilize advanced Programmable Logic Controllers (PLCs) and integrated telemetry to monitor real-time gas flow, pressure, and, crucially, external environmental parameters (temperature, humidity). This data-driven approach allows for precise management of multiple units in parallel, ensuring smooth switch-over between duty and standby banks, particularly important in maintaining critical supply continuity during predicted icing events.

The emerging technological frontier involves anti-icing and defrosting solutions that minimize reliance on external energy sources. This includes specialized hydrophobic coatings applied to the aluminum fins to reduce moisture adhesion and passive heat recovery systems that strategically reroute warmer gas streams back to the unit base to prevent localized freezing. While electric and steam assist vaporizers exist for harsh environments, the market trend is toward enhancing the efficiency and robustness of purely ambient units, driven by stringent energy efficiency targets and the desire for autonomous, remote-operable infrastructure across the expansive industrial gas network.

Regional Highlights

The global Ambient Vaporizer Market exhibits diverse growth patterns influenced by industrial density, energy infrastructure priorities, and regional climate conditions. Asia Pacific (APAC) commands the largest market share and is projected to be the fastest-growing region. This dominance is driven by massive infrastructure expansion, particularly in China and India, involving large-scale steel production, chemical manufacturing, and the rapid deployment of LNG import and distribution terminals to meet growing energy needs. The high population density also drives substantial investment in medical gas systems, requiring widespread deployment of ambient oxygen vaporizers at hospital and regional distribution centers.

North America and Europe represent mature markets characterized by stringent safety and environmental regulations, leading to a focus on replacing aging infrastructure and adopting high-efficiency, standardized units. In North America, the robust domestic energy sector, particularly the expansion of natural gas liquefaction and distribution networks, sustains consistent demand for large ambient LNG vaporization units. European demand is stable, driven by the specialized chemical industry and the ongoing transition to hydrogen, which utilizes similar high-pressure cryogenic infrastructure, offering future growth pathways.

The Middle East and Africa (MEA) and Latin America are emerging markets where demand is intrinsically linked to major resource extraction projects (oil and gas) and nascent industrialization efforts. In MEA, investments in petrochemical complexes necessitate large volumes of nitrogen and oxygen, stimulating demand for corresponding vaporizers. Latin America’s market growth is more localized, centered around major metropolitan areas and the development of regional LNG distribution hubs, with regional climate often favoring ambient solutions due to stable high temperatures and lower risk of pervasive icing.

- APAC (Asia Pacific): Dominant market share fueled by industrial expansion (China, India), large-scale LNG adoption, and significant government investment in public healthcare infrastructure demanding cryogenic oxygen supply.

- North America: Stable demand driven by replacement cycles, sophisticated high-pressure industrial gas applications, and extensive LNG satellite fueling station deployment.

- Europe: Focus on high-specification units supporting specialized chemical manufacturing, adherence to strict Pressure Equipment Directive (PED) standards, and early adoption in the burgeoning cryogenic hydrogen supply chain.

- MEA & Latin America: Growth tied to petrochemical expansion projects, natural resource processing, and the development of regional gas distribution networks in urban centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ambient Vaporizer Market.- Chart Industries

- Cryostar

- Linde Engineering

- Air Liquide

- Air Products and Chemicals

- Wessington Cryogenics

- Cryoquip

- Taylor-Wharton

- Parker Hannifin (Veriflo Division)

- FIBA Technologies

- ACES

- Super-Trak

- Jinbo Cryogenic

- VNT

- Cryofab

- Koxka

- Inoxcva

- Gas Equipment Company (GEC)

- CIMC Enric

- VRV S.r.l.

Frequently Asked Questions

Analyze common user questions about the Ambient Vaporizer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an ambient vaporizer in the industrial gas supply chain?

An ambient vaporizer converts cryogenic liquids (such as LIN, LOX, or LNG) stored at extremely low temperatures into their usable gaseous form by utilizing the thermal energy naturally present in the surrounding air. This process is essential for delivering continuous gas supply to industrial processes, hospitals, and fueling stations.

Why are ambient vaporizers preferred over electric or steam-heated vaporizers?

Ambient vaporizers are preferred primarily due to their superior cost-efficiency and reliability. They require no external power source or fuel consumption, resulting in zero operational energy costs and minimal maintenance, making them highly cost-effective for large-volume, continuous applications.

What are the main drawbacks or limitations of ambient vaporizer technology?

The primary limitation is performance degradation caused by icing. In high-humidity or extremely cold climates, atmospheric moisture freezes on the external fins, insulating them and significantly reducing the heat transfer efficiency, which can necessitate the use of standby units or forced draft assists to maintain required flow rates.

Which industry segment drives the highest demand for Ambient Vaporizers globally?

The Industrial Manufacturing sector, encompassing metallurgy, chemicals, and electronics, historically drives the highest sustained demand for ambient vaporizers due to the critical and continuous need for bulk volumes of gases like nitrogen and oxygen in their primary production and safety processes.

How does the type of cryogenic liquid affect the vaporizer design and material selection?

The type of liquid dictates the required pressure rating and material compatibility. For example, high-purity applications or corrosive gases may require stainless steel construction, while standard industrial gases like LIN and LOX typically use high-efficiency aluminum alloys designed specifically to handle the extreme temperature differentials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Ambient Vaporizer Market Size Report By Type (Low Pressure Ambient Vaporizer, High Pressure Ambient Vaporizer), By Application (Industrial Gas, LNG, Petrochemical Industries), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Ambient Vaporizer Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Low Pressure Ambient Vaporizer, High Pressure Ambient Vaporizer), By Application (Industrial Gas, LNG, Petrochemical Industries), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager