Anaerobic Digester Covers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437116 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Anaerobic Digester Covers Market Size

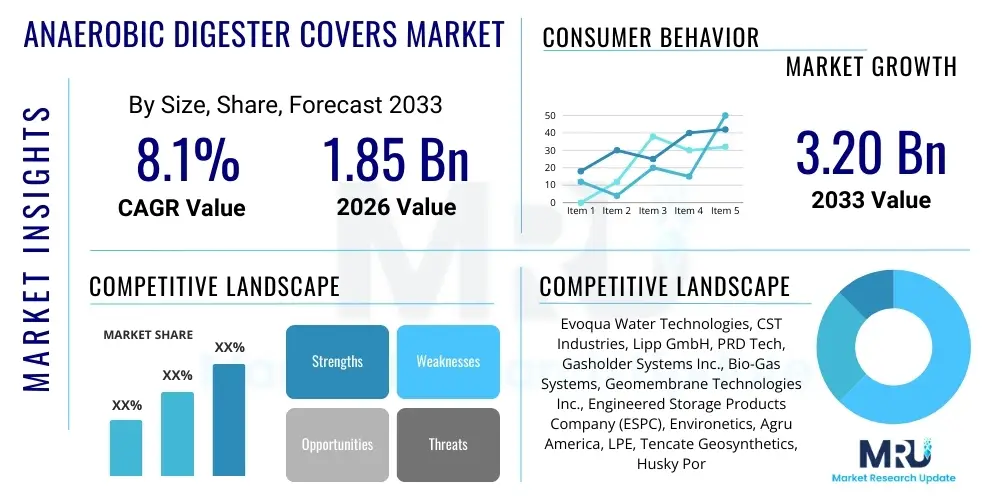

The Anaerobic Digester Covers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.1% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.20 Billion by the end of the forecast period in 2033.

Anaerobic Digester Covers Market introduction

The Anaerobic Digester Covers Market encompasses specialized containment systems designed to seal anaerobic digestion tanks, optimizing the process of biogas production and minimizing fugitive emissions. These covers are critical components in waste-to-energy facilities, ranging from municipal wastewater treatment plants to agricultural manure management systems. The primary function of these covers is twofold: first, to create an airtight environment necessary for anaerobic bacteria to break down organic matter efficiently, and second, to capture the methane-rich biogas generated during the process, which is subsequently used for heat or electricity generation.

Products available in this market include various technological configurations, notably single membrane, double membrane, and fixed or rigid covers constructed from materials like PVC, HDPE, or reinforced fabrics. Double membrane covers, often preferred in large-scale installations, offer superior insulation and stability, maintaining optimal temperature and pressure within the digester system. The increasing global focus on renewable energy sources, coupled with stringent environmental regulations mandating efficient waste processing and emission control, are the primary forces driving the adoption of sophisticated digester cover systems across developed and rapidly industrializing economies.

Major applications for anaerobic digester covers span diverse sectors, including municipal sludge treatment, industrial effluent processing (such as food and beverage manufacturing waste), and dedicated agricultural biomass digestion. Benefits derived from implementation include significant reductions in greenhouse gas emissions (by capturing methane), the generation of sustainable renewable energy (biogas), and the production of valuable digestate, a nutrient-rich soil amendment. These interconnected advantages solidify the market’s integral role in circular economy initiatives and sustainable infrastructure development globally.

- Product Description: Specialized airtight systems (e.g., membranes, domes) used to seal anaerobic digestion tanks for efficient biogas capture and temperature maintenance.

- Major Applications: Municipal wastewater treatment, agricultural waste management, industrial effluent processing, and dedicated waste-to-energy facilities.

- Key Benefits: Methane capture for biogas energy generation, reduction of greenhouse gas emissions, containment of odors, and optimization of digestion efficiency.

- Driving Factors: Global push for renewable energy targets, favorable government incentives for biogas production, and increasing volumes of municipal and industrial organic waste.

Anaerobic Digester Covers Market Executive Summary

The Anaerobic Digester Covers Market is experiencing robust expansion, fundamentally fueled by the imperative for sustainable waste management solutions and the strategic shift toward decentralized renewable energy generation. Key business trends indicate a strong move toward highly engineered, durable materials, such as specialized fluoropolymers and reinforced HDPE, which offer extended lifecycles and enhanced resistance to corrosive biogas environments. Furthermore, integration with advanced monitoring systems—leveraging sensors and IoT capabilities—is becoming a standard feature, enabling predictive maintenance and optimizing pressure regulation within the cover systems. Market players are strategically focusing on geographical expansion into high-growth regions like Asia Pacific and Latin America, where rapid urbanization is accelerating the need for scalable wastewater infrastructure.

Regionally, Europe and North America currently dominate the market, largely due to established regulatory frameworks supporting biogas utilization and existing widespread infrastructure for anaerobic digestion. However, the Asia Pacific region is poised for the highest growth rate, driven by significant governmental investments in clean water programs, the expansion of livestock farming, and the massive scale of food waste generation, particularly in countries like China and India. This regional growth is characterized by a high demand for cost-effective, durable membrane covers suitable for both centralized and small-scale agricultural digester projects. The maturity of the European market, conversely, focuses on replacement cycles and technology upgrades, favoring sophisticated double membrane and concrete fixed covers for maximum efficiency.

Segment trends reveal that the double membrane cover type holds the largest market share due to its superior gas storage capacity and inherent safety features, making it the preferred choice for large municipal and industrial installations where biogas yield maximization is paramount. Application-wise, municipal wastewater treatment plants remain the dominant end-user category, representing consistent demand driven by population growth and mandatory infrastructure upgrades. The Material segment is shifting towards high-performance composites, reflecting the need for covers that can withstand extreme weather conditions, UV exposure, and chemical degradation while maintaining structural integrity over decades.

AI Impact Analysis on Anaerobic Digester Covers Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Anaerobic Digester Covers Market frequently center on predictive maintenance, operational efficiency improvements, and smart gas yield optimization. Users are keen to understand how AI algorithms can leverage real-time data from cover-mounted sensors—monitoring parameters like gas pressure, temperature profiles, and membrane stress—to preemptively identify potential failures or leaks. The primary concerns revolve around the cost justification of integrating AI systems into existing infrastructure and ensuring data security for sensitive operational metrics. Expectations are high regarding AI’s potential to optimize biogas storage management under dynamic weather conditions and varying feedstock inputs, thereby maximizing energy output and extending the operational lifespan of the cover systems.

AI is fundamentally transforming the operational paradigm of anaerobic digestion facilities, shifting them from reactive management to predictive operational excellence. By analyzing vast datasets collected from integrated IoT sensors embedded within the digester covers—which monitor gas volume, ambient pressure, and material strain—AI models can detect subtle deviations indicating early signs of structural compromise or material fatigue long before manual inspection or traditional alarms trigger. This capability significantly reduces the risk of catastrophic cover failure, minimizes expensive unscheduled downtime, and ensures continuous biogas capture efficiency, directly impacting the return on investment for plant operators.

Furthermore, AI models are increasingly utilized in sophisticated pressure management systems. In double membrane covers, where precise internal pressure balance is critical for structural stability and gas withdrawal, machine learning algorithms can dynamically adjust blower speeds and gas flow valves in real time. This optimization capability allows facilities to maintain optimal operating conditions regardless of fluctuating environmental variables or variations in biogas production rates, enhancing safety, energy storage capacity, and overall process stability. The integration of AI extends the serviceable life of the membrane materials by minimizing excessive stress cycles, moving the industry toward truly resilient and intelligent infrastructure.

- AI-driven Predictive Maintenance: Utilizing sensor data (pressure, strain, temperature) to forecast material failure or leakage in membrane covers.

- Optimized Biogas Yield Forecasting: Machine learning algorithms analyze feedstock data and environmental conditions to predict biogas production and optimize cover gas storage.

- Automated Pressure Regulation: AI systems dynamically adjust cover pressure in double membrane systems to maintain structural integrity and maximize storage capacity.

- Enhanced Process Control: Integrating AI with SCADA systems for real-time adjustments to heating and mixing, maximizing the efficiency of the biological process under the cover.

- Digital Twin Simulation: Creating virtual replicas of digester systems to test cover performance under various stress scenarios before physical installation or modification.

- Supply Chain Optimization: Using AI to predict demand for replacement materials (e.g., specific membrane types) based on historical failure rates and regional climatic data.

DRO & Impact Forces Of Anaerobic Digester Covers Market

The Anaerobic Digester Covers Market is governed by a complex interplay of Drivers, Restraints, and Opportunities, which collectively determine its growth trajectory and competitive landscape. The primary drivers are rooted in global environmental mandates and energy policy, while restraints often involve initial capital expenditure and logistical complexities. Opportunities are largely centered on technological advancements, such as material science innovations and digitization. The combined impact of these forces dictates market dynamism, particularly favoring solutions that offer high durability, low maintenance, and maximum efficiency in biogas recovery, ensuring long-term profitability for both manufacturers and end-users.

Key drivers significantly propelling market expansion include the increasing volume of organic waste globally, necessitating robust processing solutions; strong regulatory support across North America and Europe mandating biogas capture and utilization; and substantial subsidies and incentives encouraging investment in waste-to-energy infrastructure. The growing recognition of anaerobic digestion as a critical climate mitigation technology, capable of offsetting fossil fuel consumption while managing complex waste streams, further solidifies its market position. The demand for covers that can efficiently withstand corrosive hydrogen sulfide environments and extreme climatic variability is accelerating material science innovation and product differentiation.

Conversely, the market faces several restraining factors, including the high initial investment required for sophisticated cover systems, particularly double membrane technologies, which can deter smaller agricultural operators. Furthermore, technical challenges associated with gas leakage detection and repair, coupled with the need for specialized installation expertise, sometimes impede rapid deployment in developing regions. Market opportunities primarily lie in retrofitting aging municipal infrastructure with modern, high-performance covers, developing modular and portable cover solutions for decentralized applications, and integrating IoT and AI for intelligent operational management, addressing the efficiency gap prevalent in older installations.

Segmentation Analysis

The Anaerobic Digester Covers Market is broadly segmented based on Type, Application, and Material, reflecting the diverse requirements across various end-user industries and operational scales. This granular segmentation allows for tailored product development, addressing specific needs ranging from the large gas storage demands of municipal utility systems to the cost-efficiency required for small-scale agricultural manure management. The segmentation profile is crucial for understanding competitive positioning, identifying high-growth niches, and allocating R&D resources toward materials and designs optimized for particular corrosive or climatic environments.

Segmentation by Type distinguishes between flexible membrane structures (single and double) and rigid covers (fixed, floating, or concrete). Flexible membrane covers dominate due to their ease of installation, lower weight, and superior gas storage elasticity, with double membranes leading the revenue charts due to enhanced thermal insulation and superior safety standards required for high-volume gas handling. Rigid covers, though higher in upfront cost, offer exceptional durability and longevity, often preferred in permanent, high-load industrial or municipal setups where structural permanence is paramount and space is less constrained. This differentiation highlights the trade-offs between flexibility, capital cost, and expected operational lifespan.

Application-based segmentation emphasizes the major end-user verticals, with Municipal Wastewater Treatment Plants being the foundational market segment, driven by governmental mandates and population density. The Industrial Wastewater Treatment segment, particularly within the Food & Beverage and Chemical sectors, demands highly customized, chemical-resistant covers due to the aggressive nature of their effluents. The Agricultural Digesters segment is characterized by rapid adoption of simpler, cost-effective single membrane solutions suitable for farm-scale biogas production. Material segmentation dictates performance characteristics, favoring specialized PVC, durable HDPE, and high-strength fabric composites capable of resisting UV degradation, microbial attack, and mechanical stresses inherent in long-term outdoor operation.

- By Type:

- Single Membrane Covers

- Double Membrane Covers

- Fixed/Rigid Covers (Concrete, Steel)

- Floating Covers

- By Application:

- Municipal Wastewater Treatment Plants

- Industrial Wastewater Treatment Plants (F&B, Chemical)

- Agricultural Digesters (Manure Management)

- Food & Beverage Waste Processing

- By Material:

- High-Density Polyethylene (HDPE)

- Polyvinyl Chloride (PVC)

- Fabric Reinforced Composites (e.g., PTFE coated fiberglass)

- Ethylene Propylene Diene Monomer (EPDM)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Anaerobic Digester Covers Market

The value chain for the Anaerobic Digester Covers Market begins with the sourcing and manufacturing of high-performance polymer and composite raw materials, followed by the highly specialized design, fabrication, and integration of the cover system. Upstream activities involve material suppliers providing UV-resistant polymers (HDPE, PVC) and technical textiles, where cost and quality control of these base materials critically influence the final product’s lifespan and performance, especially its resistance to corrosive biogas components like hydrogen sulfide. Key upstream players maintain strict quality checks to ensure material integrity, which is essential for compliance with safety standards governing methane containment and pressure regulation.

The midstream stage focuses on engineering and fabrication, transforming raw materials into custom-fit digester covers, often involving complex welding, sealing, and integration of mechanical components like pressure relief valves, access ports, and gas transfer piping. Direct sales and installation channels are prevalent for large, bespoke municipal projects, where manufacturers often provide end-to-end design, installation, and commissioning services, leveraging in-house engineering expertise. Indirect distribution, involving specialized contractors, environmental engineering firms, and regional distributors, plays a crucial role in serving the fragmented agricultural and smaller industrial segments, offering localized support and faster deployment times.

Downstream analysis focuses on the end-users—primarily municipal, agricultural, and industrial operators—who require long-term maintenance and operational support. The service component of the value chain, encompassing scheduled inspections, gas monitoring, leak detection, and eventual replacement of membrane covers, represents a significant recurring revenue stream. The successful deployment and long-term performance of the covers rely heavily on the integrity of the distribution channel and the expertise of the installation partners, underscoring the importance of training and certifications in this specialized infrastructure sector.

Anaerobic Digester Covers Market Potential Customers

The primary customers for Anaerobic Digester Covers are entities involved in large-scale organic waste processing and centralized renewable energy generation. Municipalities, through their public utility departments, represent the largest and most stable customer base, continuously investing in upgrades and expansions of wastewater treatment infrastructure to comply with environmental mandates and manage growing urban waste loads. These buyers typically prioritize longevity, regulatory compliance, structural stability (often favoring concrete or double membrane systems), and integration capabilities with existing SCADA and odor control technologies, signifying a high-value, quality-driven purchasing criteria.

Industrial customers form a high-growth segment, particularly those in the Food and Beverage, Pulp and Paper, and Pharmaceutical manufacturing sectors, which generate high volumes of organic effluent suitable for anaerobic digestion. These commercial buyers seek customized solutions that can efficiently handle highly variable and often chemically aggressive waste streams, demanding specialized material resistance (e.g., PTFE-coated fabrics) and guaranteed high rates of biogas recovery to offset their significant energy costs, positioning them as sophisticated, ROI-focused purchasers who prioritize efficiency and resilience.

The agricultural sector, comprising large-scale livestock farms and cooperative manure management facilities, constitutes another vital customer group. These users are often driven by regulatory pressures concerning manure runoff and the economic incentive of generating on-site energy. Agricultural buyers typically favor more economical, easy-to-install, and scalable single-membrane or flexible cover systems designed for efficient, farm-scale operation. Overall, potential customers are unified by the need to efficiently convert biological waste into a valuable resource (biogas/digestate) while adhering to strict environmental and safety regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.20 Billion |

| Growth Rate | 8.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Evoqua Water Technologies, CST Industries, Lipp GmbH, PRD Tech, Gasholder Systems Inc., Bio-Gas Systems, Geomembrane Technologies Inc., Engineered Storage Products Company (ESPC), Environetics, Agru America, LPE, Tencate Geosynthetics, Husky Portable Containment, Schauer Agrotronic, Netafim, BÖRGER GmbH, UTS Biogas, Pure Air Solutions, ZELTWANGER Dichtungen, Hydro International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Anaerobic Digester Covers Market Key Technology Landscape

The technological landscape of the Anaerobic Digester Covers Market is characterized by continuous material science evolution and rapid integration of digital monitoring and control systems. Contemporary cover technology focuses intensely on enhancing durability, gas tightness, and thermal efficiency. Innovations in polymer compounding have led to the introduction of advanced reinforced composite materials that exhibit superior resistance to UV radiation, chemical corrosion from hydrogen sulfide (a common biogas contaminant), and extreme temperature fluctuations, thereby significantly extending the useful service life of flexible membrane systems and reducing frequency of costly replacement cycles.

The shift towards intelligent cover systems, or 'Smart Covers,' represents a major technological advancement. These systems incorporate embedded sensors (IoT devices) that monitor crucial parameters such as internal pressure, gas composition, temperature, and membrane stress in real-time. This sensor network transmits data to cloud-based analytical platforms, often utilizing AI/ML algorithms to perform predictive maintenance diagnostics. This capability moves maintenance from a calendar-based schedule to a condition-based approach, ensuring optimal operational stability and proactively mitigating potential gas leakage or structural failures, which is paramount for safety and regulatory compliance.

Furthermore, technology is advancing in the structural design and installation techniques for large-scale fixed and floating covers. New construction methodologies utilize specialized geodesic dome structures and highly optimized bolted steel or concrete components that provide robust containment for massive digester tanks, particularly in municipal settings. These modern designs prioritize modularity, allowing for faster on-site assembly and reduced construction downtime. The application of advanced welding techniques, specifically high-frequency welding for PVC and HDPE membranes, guarantees superior seam strength and gas impermeability, which is a critical technological differentiator in achieving high-efficiency biogas capture.

Regional Highlights

Regional dynamics within the Anaerobic Digester Covers Market are highly correlated with governmental commitment to renewable energy, waste management infrastructure maturity, and agricultural density. Europe currently stands as a mature market leader, driven by ambitious EU directives targeting significant reductions in methane emissions and promoting biogas as a primary renewable energy source. Countries such as Germany, the UK, and Italy possess established infrastructure and a high concentration of operational anaerobic digestion plants, leading to consistent demand focused primarily on replacement, modernization, and optimization of existing cover systems, favoring high-efficiency, durable double membrane designs.

North America, led predominantly by the United States and Canada, presents a highly dynamic market driven by favorable federal policies, particularly the Renewable Fuel Standard (RFS) in the US, which incentivizes the production of renewable natural gas (RNG) from biogas. This has spurred significant investment in converting municipal and agricultural digesters into RNG production facilities, necessitating the adoption of advanced, high-integrity cover systems for efficient gas capture and conditioning. The region’s technological adoption rate is high, with strong demand for integrated monitoring and smart cover solutions to ensure high uptime and compliance with stringent environmental regulations.

The Asia Pacific (APAC) region is projected to register the highest growth rate during the forecast period. This rapid expansion is driven by population growth, accelerated urbanization, and subsequent immense generation of municipal solid waste and agricultural residue, especially in economies like China, India, and Southeast Asia. Government initiatives focused on improving sanitation, managing manure waste from large livestock operations, and mitigating air and water pollution are creating massive greenfield opportunities for digester cover manufacturers. While cost sensitivity is higher in APAC, the increasing scale of projects favors the adoption of durable, localized manufacturing solutions and robust, simple-to-install membrane covers.

- Europe: Market maturity, strong regulatory framework favoring biogas utilization, high demand for modernization and high-efficiency double membrane covers, led by Germany and Italy.

- North America: Driven by Renewable Natural Gas (RNG) policy incentives, strong investment in large-scale municipal and agricultural facilities, high adoption rate of smart, integrated cover technologies.

- Asia Pacific (APAC): Highest growth potential fueled by urbanization, massive organic waste volumes, and government initiatives in China and India promoting decentralized waste treatment infrastructure.

- Latin America: Emerging market with increasing focus on energy security, driven by industrial and agricultural waste management initiatives in Brazil and Mexico.

- Middle East & Africa (MEA): Growth focused primarily on urban wastewater treatment projects and industrial effluent management, often leveraging foreign technology expertise.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Anaerobic Digester Covers Market.- Evoqua Water Technologies

- CST Industries

- Lipp GmbH

- PRD Tech

- Gasholder Systems Inc.

- Bio-Gas Systems

- Geomembrane Technologies Inc.

- Engineered Storage Products Company (ESPC)

- Environetics

- Agru America

- LPE

- Tencate Geosynthetics

- Husky Portable Containment

- Schauer Agrotronic

- Netafim

- BÖRGER GmbH

- UTS Biogas

- Pure Air Solutions

- ZELTWANGER Dichtungen

- Hydro International

- Cover-All Building Systems

- Flexxaire Manufacturing

- Layfield Group

- MTS Systems

Frequently Asked Questions

Analyze common user questions about the Anaerobic Digester Covers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Anaerobic Digester Covers Market?

The primary driver is the accelerating global shift towards renewable energy sources, specifically biogas capture and utilization, supported by stringent governmental mandates for methane emission reduction and sustainable organic waste management practices in municipal and agricultural sectors.

How do double membrane covers differ significantly from single membrane covers?

Double membrane covers offer superior thermal insulation and safety by utilizing an outer protective membrane and an inner gas storage membrane, separated by an air layer. This configuration allows for pressurized gas storage and greater structural stability, making them ideal for high-volume biogas facilities.

Which material is most commonly used for flexible anaerobic digester covers?

High-Density Polyethylene (HDPE) and specialized PVC-coated polyester fabrics are the most common materials due to their excellent chemical resistance against corrosive biogas components, strong UV stability, and flexibility, ensuring long service life in demanding environments.

What role does AI and IoT integration play in modern digester cover operations?

AI and IoT enable real-time monitoring of critical parameters like pressure and temperature, facilitating predictive maintenance to detect leaks or material stress early. This technology optimizes gas storage management, enhances operational efficiency, and significantly reduces the risk of unscheduled downtime.

Which geographical region is expected to exhibit the highest market growth rate?

The Asia Pacific (APAC) region is forecasted to achieve the highest Compound Annual Growth Rate (CAGR), driven by massive infrastructure investments in wastewater treatment and waste-to-energy projects necessary to cope with rapid urbanization and vast agricultural waste generation across key nations like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager