Analytical Nebulizer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435738 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Analytical Nebulizer Market Size

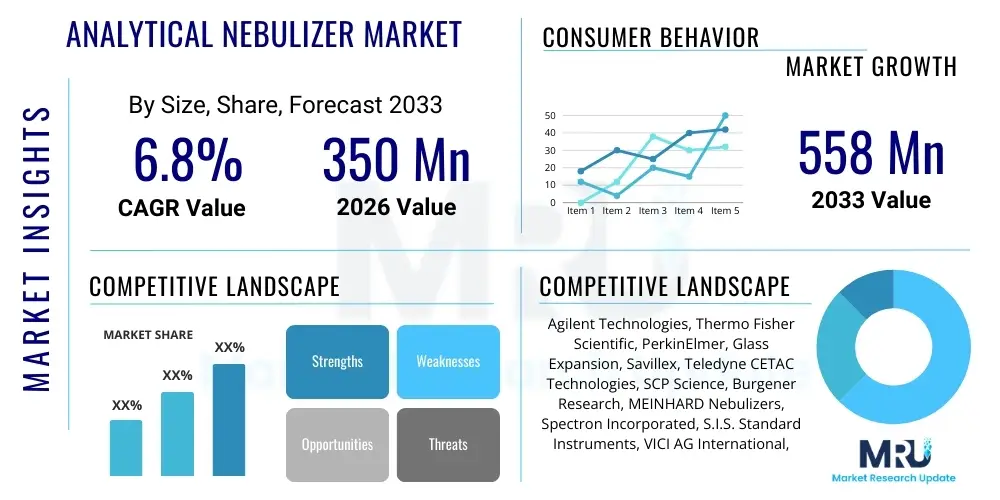

The Analytical Nebulizer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 558 Million by the end of the forecast period in 2033.

Analytical Nebulizer Market introduction

The Analytical Nebulizer Market encompasses devices critical for introducing liquid samples into various analytical instruments, primarily Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). These instruments require the liquid sample to be converted into a fine aerosol spray for efficient atomization and ionization in the plasma torch. The market is driven by the increasing need for high-precision elemental analysis across regulated industries.

Analytical nebulizers are sophisticated components designed to maximize sample uptake efficiency while maintaining low memory effects and high chemical inertness. Key product types include concentric, cross-flow, and specialized high-ppurity fluoropolymer (PFA) nebulizers tailored for specific sample matrices, such as those with high dissolved solids or highly corrosive properties. Major applications span environmental monitoring, quality control in the food and beverage industry, pharmaceutical analysis, and complex material testing, where trace elemental concentrations must be accurately quantified.

The primary benefits of advanced analytical nebulizers include improved detection limits, enhanced long-term signal stability, and reduced sample consumption. Driving factors for market expansion include stringent global regulations regarding heavy metal contamination, continuous technological advancements in ICP instrumentation that demand better sample introduction systems, and the expanding adoption of high-throughput analysis techniques in clinical and research laboratories worldwide.

Analytical Nebulizer Market Executive Summary

The Analytical Nebulizer Market is poised for stable growth, fueled primarily by escalating regulatory scrutiny across major economies concerning elemental contaminants in consumer products and the environment. Business trends indicate a shift toward specialized, chemically inert nebulizers, particularly PFA types, driven by the expanding complexity of sample matrices and the push for ultra-trace detection capabilities in advanced materials research and semiconductor manufacturing. Key market participants are focusing on developing nebulizers integrated with micro-sampling techniques and automated sample handling systems to meet the demands of high-volume laboratories, thereby improving workflow efficiency and reducing manual error potential.

Regionally, North America and Europe maintain dominance due to established infrastructure in analytical testing and significant investment in pharmaceutical and environmental monitoring sectors. However, the Asia Pacific (APAC) region is demonstrating the highest growth trajectory, propelled by rapid industrialization, increasing awareness of food safety standards, and substantial governmental investment in scientific research facilities, particularly in China and India. This regional expansion is leading to increased adoption of ICP-based instrumentation, subsequently driving demand for compatible nebulizer units and consumables.

Segmentation trends reveal that the Inductively Coupled Plasma Mass Spectrometry (ICP-MS) application segment accounts for a substantial market share, reflecting its superior sensitivity and multi-element detection capabilities required for complex applications like isotope analysis and ultra-trace level testing. Furthermore, among product types, the demand for concentric nebulizers remains robust due to their high efficiency and versatility, while the high-purity PFA nebulizers segment is expected to exhibit the fastest growth owing to their indispensable role in analyses requiring minimal contamination, such as those related to semiconductor grade chemicals and high-purity water testing.

AI Impact Analysis on Analytical Nebulizer Market

Common user inquiries regarding AI in this domain frequently center on how machine learning can optimize nebulizer performance, predict maintenance needs, and enhance data quality within ICP workflows. Users are keen on understanding if AI algorithms can automatically adjust nebulization parameters (like carrier gas flow or pump speed) in real-time to compensate for matrix effects or plasma loading variations, thereby improving analytical stability and robustness. Furthermore, there is significant interest in using AI for predictive maintenance—forecasting when a nebulizer will clog or degrade—to minimize instrument downtime and ensure maximum uptime in high-throughput environments.

AI's primary influence on the Analytical Nebulizer Market is indirect but transformative, focusing on optimizing the entire sample introduction and measurement pipeline. While the nebulizer itself is a mechanical component, the surrounding analytical ecosystem benefits immensely from artificial intelligence. Specifically, AI-driven data processing tools can drastically improve the interpretation of complex spectra resulting from nebulization, allowing for better background correction and interference removal. This enhancement in data quality reduces the operational burden on technicians and allows for more confident quantification at lower detection limits, indirectly validating the performance metrics of high-precision nebulizers.

In the future, integrated smart nebulizer systems equipped with micro-sensors and machine learning capabilities may become standard. These systems could monitor flow dynamics, aerosol droplet size distribution, and internal component wear in real-time, providing feedback loops to the ICP software. This integration moves the nebulizer from a simple consumable accessory to an intelligent, self-optimizing analytical subsystem. Manufacturers are investing in AI to develop sophisticated algorithms that enable automated matrix matching and dynamic operational adjustments, ensuring optimal performance across a diverse range of samples without constant manual calibration.

- AI-driven optimization of gas flow and pump parameters for enhanced aerosol stability.

- Predictive maintenance schedules for nebulizers, reducing unexpected instrument failure and downtime.

- Machine learning algorithms improving spectral interference correction resulting from plasma instability caused by nebulization issues.

- Automated quality control (QC) checks detecting subtle shifts in nebulizer performance and alerting users.

- Integration of intelligent software to manage complex sample matrices and reduce matrix effect variability.

DRO & Impact Forces Of Analytical Nebulizer Market

The market dynamics are governed by a complex interplay of high demand for trace analysis sensitivity (Driver), the high cost of specialized consumables and potential for clogging (Restraint), and the emergence of micro-sampling techniques (Opportunity). Impact forces, including increasing regulatory standards and technological advancements in spectrometry, significantly shape investment and innovation trajectories within this sector. The push for ultra-low detection limits in fields such as semiconductor manufacturing requires highly inert and efficient nebulizers, generating consistent demand for premium, specialized products.

Drivers: The market is substantially propelled by the global tightening of environmental, food safety, and pharmaceutical regulations. Authorities worldwide are continuously lowering the permissible limits for heavy metals and toxic elements, demanding instruments that can achieve ultra-trace analysis, which directly relies on highly efficient nebulization systems. Furthermore, the rapid expansion of the pharmaceutical and biotechnology sectors, necessitating strict quality control and impurity profiling (USP <232>/<233> compliance), contributes robustly to the adoption of advanced ICP-based instruments and compatible nebulizers. The ongoing miniaturization of analytical systems also drives demand for nebulizers optimized for low sample volumes.

Restraints: Significant restraints include the high initial and ongoing maintenance costs associated with specialized nebulizer units, particularly those made from inert materials like PFA, which are essential for corrosive matrices. Furthermore, nebulizers are highly susceptible to clogging when analyzing samples with high concentrations of dissolved solids (TDS), requiring frequent cleaning or replacement, thereby increasing operational expenses and instrument downtime. This maintenance requirement acts as a bottleneck, particularly in high-throughput or budget-constrained laboratories.

Opportunities: A major growth opportunity lies in the development of robust, clog-resistant nebulizer designs and systems tailored for micro-volume sample analysis, catering to emerging needs in clinical diagnostics and metabolomics. The integration of advanced manufacturing techniques, such as 3D printing, may lead to novel, cost-effective designs with improved aerosol characteristics. Moreover, increasing penetration into emerging economies that are currently bolstering their analytical infrastructure presents substantial market potential for both standard and high-performance nebulizers.

Impact Forces: The overarching impact force is the relentless pursuit of lower detection limits, pushing manufacturers to continuously innovate material science and fluid dynamics within nebulizer design. Economic forces related to laboratory budget allocations and operational expenditure influence purchasing decisions, often favoring consumables that offer superior longevity and reduced total cost of ownership. Regulatory shifts, particularly concerning required sensitivity levels, are the primary external pressure dictating product specifications and market growth direction.

Segmentation Analysis

The Analytical Nebulizer Market is intricately segmented based on Type, Application, and End-User, reflecting the diverse requirements of modern elemental analysis techniques. Understanding these segments is crucial as different nebulizer technologies are optimized for specific sample characteristics and instrumentation platforms. For instance, the choice between a concentric glass nebulizer and a PFA cross-flow nebulizer is dictated entirely by whether the priority is high sensitivity with aqueous samples or chemical inertness with harsh, high-acid matrices, respectively. This specialization ensures that laboratories can maximize the performance of their expensive ICP systems across varied testing environments.

The segmentation by Application clearly distinguishes between the requirements of ICP-MS and ICP-OES. While both techniques utilize nebulizers for aerosol generation, ICP-MS demands exceptionally stable aerosol streams to ensure minimal signal noise and superior sensitivity, driving demand for premium nebulizers that offer tighter control over droplet size distribution. Conversely, segmentation by End-User highlights sectors like Environmental Testing and Pharmaceutical R&D, which often require high throughput and excellent chemical resistance, fueling the market for automated and inert nebulizer solutions that minimize matrix effects and cross-contamination risk.

The ongoing trend towards high-purity analysis, particularly in the semiconductor industry, is significantly impacting the Type segmentation, increasing the relative market share of specialized PFA nebulizers over traditional glass components. This comprehensive segmentation reflects a market moving toward greater specialization, where manufacturers must offer a broad portfolio of products tailored to optimize performance for specific analytical challenges and industry standards.

- By Type:

- Concentric Nebulizers (Glass and Quartz)

- Cross-flow Nebulizers (Glass and PFA)

- Babington/V-Groove Nebulizers

- High-Purity PFA/Polymer Nebulizers

- Micro-nebulizers (for micro-sampling)

- By Application:

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

- Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

- Atomic Absorption Spectrometry (AAS)

- By End-User:

- Pharmaceutical and Biotechnology Companies

- Environmental Testing Laboratories

- Food and Beverage Industry

- Clinical Diagnostics and Research

- Academia and Government Research Institutes

- Semiconductor and Materials Science Industries

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Analytical Nebulizer Market

The value chain for the Analytical Nebulizer Market begins with upstream material suppliers, primarily focused on high-quality specialized materials such as high-purity quartz, inert glass, and advanced fluoropolymers (like PFA). The selection and quality of these raw materials are paramount as they directly influence the chemical inertness, precision, and longevity of the final product. Manufacturers rely heavily on consistent supply chains for these materials to ensure minimal batch-to-batch variation in performance. Upstream activities involve rigorous material testing and certification to meet the ultra-high purity demands of trace elemental analysis.

The midstream stage involves the highly specialized manufacturing and assembly processes. Nebulizer fabrication, especially for concentric and micro-nebulizers, requires high-precision machining, glassblowing, or polymer molding to achieve the micron-level tolerances necessary for consistent aerosol generation. Major ICP instrument manufacturers often produce their own proprietary nebulizers, while specialized third-party consumable companies focus on compatible or specialized high-performance designs. Quality control at this stage is intensive, involving spray pattern analysis and droplet size distribution measurements.

Downstream activities focus on distribution, sales, and end-user support. Distribution channels are predominantly indirect, leveraging specialized scientific equipment distributors who maintain deep relationships with analytical laboratories and research institutions. Direct sales are common for high-value contracts involving large instrumentation packages. Crucially, post-sales support, including technical service for troubleshooting clogging issues and material compatibility advice, forms a vital part of the value proposition. The indirect channel relies on distributors providing localized inventory and rapid replacement of consumables, which is essential for maintaining laboratory uptime.

Analytical Nebulizer Market Potential Customers

Potential customers for analytical nebulizers are laboratories and industrial entities heavily reliant on elemental analysis using techniques such as ICP-MS and ICP-OES. These sophisticated instruments are the standard tools for quantifying trace elements, meaning the primary buyers are high-specification testing facilities. The largest customer segment encompasses highly regulated industries that must adhere to stringent domestic and international quality and safety standards, driving consistent demand for new and replacement nebulizer units.

The pharmaceutical and biotechnology sector represents a critically important customer base, driven by regulatory mandates (e.g., ICH Q3D, USP <232>/<233>) that require comprehensive elemental impurity testing in drug substances and products. These organizations demand highly inert (PFA) nebulizers to handle strong acid digestions and complex matrices while preventing elemental contamination that could compromise results. Environmental testing laboratories, which perform routine water, soil, and air quality analyses, form another pillar of the customer base, requiring robust, versatile nebulizers capable of handling high volumes of varied environmental samples.

Beyond highly regulated industries, academic and government research institutes are continuous buyers, driven by fundamental research in geochemistry, materials science, and health. The food and beverage sector utilizes these components for quality assurance, checking for heavy metals in raw ingredients and finished products. Emerging customer segments include semiconductor manufacturing, which demands ultra-pure nebulizers for analyzing high-purity chemicals and validating cleanliness standards crucial for microchip fabrication.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 558 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Agilent Technologies, Thermo Fisher Scientific, PerkinElmer, Glass Expansion, Savillex, Teledyne CETAC Technologies, SCP Science, Burgener Research, MEINHARD Nebulizers, Spectron Incorporated, S.I.S. Standard Instruments, VICI AG International, Nippon Instruments Corporation, Analytik Jena, GBC Scientific Equipment |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Analytical Nebulizer Market Key Technology Landscape

The technological landscape of the Analytical Nebulizer Market is characterized by continuous refinement in material science and engineering precision, aimed at achieving superior aerosol consistency, chemical resistance, and minimized sample waste. Core technologies revolve around the mechanism of aerosol generation. Concentric nebulizers, often made of glass or quartz, rely on the Bernoulli effect where a high-velocity gas jet draws the liquid sample and shears it into fine droplets. Innovations here focus on tightening manufacturing tolerances to ensure highly consistent droplet size distribution, which is crucial for reducing plasma noise and improving detection limits, particularly in ICP-MS applications.

A major technological advancement involves the increasing adoption of High-Purity Fluoropolymer (PFA) technology. PFA nebulizers, including specialized cross-flow and high-efficiency designs, are chemically inert, making them mandatory for handling highly acidic, high-salt, or organic matrices common in geochemistry and semiconductor analysis. Their non-metallic construction virtually eliminates elemental contamination from the nebulizer itself, a critical factor for ultra-trace analysis. Furthermore, manufacturers are incorporating robust PFA components designed to minimize sample uptake memory effects, thereby increasing throughput and reducing washout times between samples.

The future technology landscape is moving towards specialized micro-nebulizers and micro-flow technologies. Micro-nebulizers are essential for coupling with micro-sampling techniques, such as flow injection analysis or laser ablation, where sample volumes are severely restricted. These devices are optimized to function efficiently at extremely low sample uptake rates (typically less than 100 microliters per minute), significantly conserving valuable or scarce samples. Innovations in ultrasound and piezoelectric nebulization techniques are also emerging, offering alternative, precise methods for generating fine aerosols with greater control over droplet size than traditional pneumatic nebulizers, though pneumatic systems still dominate the conventional market due to their simplicity and robustness.

Regional Highlights

- North America: North America holds the largest share in the Analytical Nebulizer Market, driven by the presence of a mature analytical instrumentation sector and significant regulatory oversight in environmental protection (EPA) and pharmaceuticals (FDA). The U.S. and Canada are early adopters of advanced spectroscopic techniques, leading to consistent high demand for premium, specialized nebulizer consumables. High expenditure on R&D, especially in materials science and nanotechnology, fuels the need for ultra-trace analysis capabilities, favoring the demand for high-purity PFA nebulizers and micro-flow systems. The robust biotechnology sector in regions like California and Massachusetts ensures continuous investment in quality control infrastructure.

- Europe: Europe represents a highly established market segment, characterized by stringent chemical regulations (REACH) and strong emphasis on food safety standards. Germany, the UK, and France are key contributors, boasting a dense network of accredited testing laboratories and significant academic research activity. The region shows high penetration of ICP-MS technology, necessitating high-performance nebulizers to meet low detection limit requirements. The focus on green chemistry and sustainable practices also drives the demand for analytical tools that minimize reagent use and maximize efficiency, favoring micro-sampling techniques and associated nebulizers.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, increasing disposable income, and governmental initiatives focused on modernizing laboratory infrastructure. China and India are the primary growth engines, driven by their burgeoning pharmaceutical manufacturing sectors, increased environmental monitoring efforts due to urbanization, and vast expansion of food testing capabilities. While the initial demand often centers on cost-effective standard nebulizers, the push toward semiconductor manufacturing and high-purity chemical production is rapidly accelerating the uptake of specialized, inert PFA nebulizers, representing a substantial long-term growth opportunity.

- Latin America (LATAM): The LATAM market is growing steadily, primarily driven by mining and natural resource sectors (especially in Brazil and Chile), which require routine high-precision analysis of complex geological samples. Additionally, tightening quality standards for agricultural exports and food processing are increasing the reliance on ICP-based testing. Market growth is often dependent on foreign investment and technology transfer, leading to strong sales of replacement consumables rather than new instrument installations, making the replacement cycle a vital sales driver for nebulizer manufacturers.

- Middle East and Africa (MEA): The MEA market is currently smaller but exhibits niche growth potential, largely centered around oil and gas analysis, water desalination projects, and governmental investment in improving health infrastructure. Countries like Saudi Arabia and UAE are investing in research universities and specialized environmental laboratories. Demand is concentrated on robust, high-tolerance nebulizers capable of handling samples with high dissolved solids, necessary for water and petrochemical testing, though growth can be volatile depending on regional geopolitical and economic stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Analytical Nebulizer Market.- Agilent Technologies

- Thermo Fisher Scientific

- PerkinElmer

- Glass Expansion

- Savillex

- Teledyne CETAC Technologies

- SCP Science

- Burgener Research

- MEINHARD Nebulizers

- Spectron Incorporated

- S.I.S. Standard Instruments

- VICI AG International

- Nippon Instruments Corporation

- Analytik Jena

- GBC Scientific Equipment

- Büchi Labortechnik

- Pneumac

- Lennox Instruments

- Spectro Analytical Instruments

Frequently Asked Questions

Analyze common user questions about the Analytical Nebulizer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an analytical nebulizer in elemental analysis?

The primary function of an analytical nebulizer is to convert a liquid sample stream into a fine, homogeneous aerosol spray. This aerosol is then transported into the plasma source (e.g., in ICP-MS or ICP-OES) for subsequent desolvation, atomization, and ionization or excitation, which is essential for accurate trace elemental quantification.

Why are PFA nebulizers increasingly preferred over glass or quartz nebulizers?

PFA (Perfluoroalkoxy) nebulizers are preferred for ultra-trace analysis and handling corrosive matrices because they are chemically inert and non-metallic. This inertness eliminates the risk of elemental contamination leaching from the nebulizer material and allows for the stable introduction of highly acidic or organic samples, ensuring better accuracy at parts-per-trillion levels.

What factors determine the choice between concentric and cross-flow nebulizer types?

Concentric nebulizers are generally chosen for high sensitivity and low sample uptake, ideal for clean aqueous samples. Cross-flow nebulizers are more robust, less prone to clogging, and better suited for samples with high total dissolved solids (TDS) or complex matrices, though they may offer slightly lower sensitivity than their concentric counterparts.

How does nebulizer clogging affect ICP instrument performance?

Clogging significantly disrupts the laminar flow dynamics, leading to inconsistent aerosol delivery, fluctuating plasma stability, and substantial signal depression (drift). This results in poor precision, increased detection limits, and necessitates costly instrument downtime for cleaning or replacement, critically impacting laboratory throughput and data reliability.

Which End-User segment drives the highest demand for high-purity analytical nebulizers?

The Semiconductor and Materials Science industries, followed closely by the Pharmaceutical sector, drive the highest demand for high-purity (PFA) nebulizers. These industries require the absolute lowest levels of contamination for quality control of high-purity chemicals and detection of elemental impurities in sensitive drug compounds, respectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager