Angle Valves Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436922 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Angle Valves Market Size

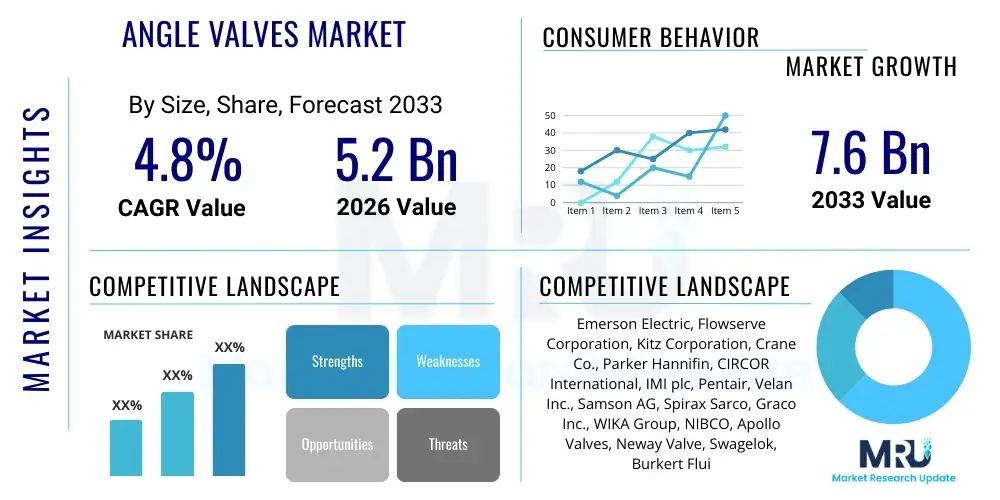

The Angle Valves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2033.

Angle Valves Market introduction

Angle valves are specialized flow control devices designed with an inlet and outlet positioned at a 90-degree angle to each other, optimizing flow path changes and reducing pipeline complexity in installations where space or directional changes are critical. These valves are widely recognized for their robust design, which minimizes turbulence, reduces pressure drop, and allows for effective throttling and shut-off capabilities in high-pressure and high-temperature environments. Their unique configuration is particularly beneficial in applications requiring self-draining capabilities or where the valve needs to serve as both a flow regulator and an elbow fitting, simplifying piping layouts and lowering installation costs.

The primary applications of angle valves span across critical industrial sectors including oil and gas refining, chemical processing, power generation, and sophisticated heating, ventilation, and air conditioning (HVAC) systems. Key benefits driving their adoption include superior sealing capabilities, ease of maintenance due to their design allowing in-line access to internal components, and their inherent ability to handle fluids containing suspended solids or slurries without excessive erosion or clogging. Furthermore, they are extensively utilized in utility systems such as boiler feedwater, steam lines, and cooling circuits where reliable, precise fluid control is paramount for operational safety and efficiency.

Major factors driving the growth of the Angle Valves Market include the relentless expansion of global infrastructure projects, particularly in water treatment and power generation sectors in Asia Pacific and the Middle East, necessitating robust and reliable control components. The increasing global focus on industrial safety standards and regulatory compliance mandates the use of high-integrity valves capable of preventing leakage and catastrophic failures, thereby fueling demand. Additionally, technological advancements leading to smart angle valves equipped with enhanced diagnostics and remote monitoring capabilities are significantly contributing to market expansion by improving predictive maintenance strategies and overall operational uptime.

Angle Valves Market Executive Summary

The global Angle Valves market is experiencing stable growth, primarily driven by sustained investment in the energy and chemical processing industries, where these valves are critical for managing high-stress fluids. Business trends indicate a strong move toward digitalization and the integration of Industrial Internet of Things (IIoT) capabilities into valve infrastructure, offering manufacturers opportunities to differentiate their products through enhanced data analytics and remote operational features. Furthermore, the market is characterized by intense competition focused on material science innovation, particularly the development of alloys that can withstand extreme corrosive and abrasive conditions, ensuring longer lifecycle performance and reduced total cost of ownership for end-users.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, burgeoning demand for electricity, and large-scale expansion of chemical and petrochemical complexes, especially in China and India. North America and Europe, while mature, are focusing on replacement cycles and the adoption of high-performance, specialized angle valves compliant with stringent environmental regulations governing fugitive emissions. The Middle East and Africa (MEA) continue to be vital due to massive oil and gas exploration and production activities, demanding durable angle valves for upstream and downstream operations, often prioritizing high-pressure capabilities.

In terms of segmentation, the Stainless Steel segment maintains dominance owing to its versatility and corrosion resistance, essential in process industries. However, the pneumatic and electric operated valve segments are rapidly gaining traction, reflecting the broader industrial shift towards automation and precision control, moving away from purely manual operations in critical applications. End-user demand is heavily concentrated in the Oil & Gas and Power Generation sectors, though pharmaceuticals and high-purity water systems are showing accelerated growth due to the non-contaminating and efficient sealing properties offered by advanced angle valve designs, particularly the diaphragm and bellows sealed variants.

AI Impact Analysis on Angle Valves Market

Common user questions regarding AI's impact on the Angle Valves Market often revolve around predictive maintenance schedules, optimization of valve performance under varying load conditions, and the automation of supply chain management for replacement parts. Users are keen to understand how AI-driven algorithms can move maintenance from reactive to predictive modes, reducing downtime and operational expenditure (OPEX). Key concerns include the integration complexity of AI systems with legacy industrial control systems (ICS), data security implications related to operational data exchange, and the accuracy of AI models in detecting subtle valve degradation signs such as minor seat wear or stem packing failure. Expectations center on AI enhancing the lifespan of critical valves, reducing human error during calibration and operation, and dynamically adjusting flow characteristics in complex piping networks for optimal energy efficiency and process consistency, thereby directly improving asset integrity management.

- AI enables predictive maintenance scheduling by analyzing sensor data (pressure, temperature, vibration) to forecast potential angle valve failure, minimizing unplanned downtime.

- Generative AI assists in optimizing valve design parameters, suggesting material improvements or structural modifications to enhance flow dynamics and durability.

- Machine Learning (ML) algorithms optimize inventory and supply chain management for spare angle valve parts based on predicted failure rates across large industrial fleets.

- AI systems facilitate advanced diagnostics and remote monitoring, allowing operators to dynamically adjust valve settings to maintain optimal efficiency and reduce energy consumption.

- Natural Language Processing (NLP) speeds up the analysis of maintenance logs and operational manuals, providing technicians with rapid access to troubleshooting guides specific to angle valve types.

DRO & Impact Forces Of Angle Valves Market

The Angle Valves Market is shaped by a confluence of influential factors, categorized as Drivers (D), Restraints (R), and Opportunities (O), which collectively define the Impact Forces on market evolution. Primary drivers include escalating demand from the rapidly expanding oil and gas infrastructure, coupled with stringent environmental regulations mandating efficient fluid control to mitigate leaks and emissions, particularly in hydrocarbon processing. Restraints often encompass the high initial capital expenditure required for specialized, high-alloy angle valves, especially those designed for ultra-high-pressure or corrosive applications, along with market susceptibility to volatility in key raw material costs such as nickel and chromium. Opportunities primarily stem from the technological paradigm shift toward Industrial Internet of Things (IIoT) integration, allowing for the development of smart, digitally-enabled angle valves that offer real-time diagnostics and superior control capabilities.

The Impact Forces analysis reveals that the regulatory landscape, particularly concerning industrial safety (e.g., ASME, API standards), exerts a powerful influence, compelling end-users to upgrade to premium, certified angle valve technologies, overriding simple cost concerns. Economically, the cycle of capital expenditure in the energy sector dictates short-term demand fluctuations, while the long-term trend remains positive due to necessary infrastructure maintenance and expansion globally. Furthermore, the persistent challenge of counterfeiting and ensuring the authenticity of mission-critical valve components remains a significant market concern, pushing reputable manufacturers to invest in advanced traceability and authentication systems to protect their market share and consumer trust.

The interplay between the accelerating need for operational efficiency (Driver) and the challenge of high maintenance complexity (Restraint) is driving significant innovation (Opportunity) in seal materials and actuator design. Manufacturers are focusing on developing modular angle valve systems that simplify replacement procedures and reduce overall lifecycle costs. These market dynamics ensure that while the sector is mature, continuous technological refinement remains essential for competitive advantage, particularly in specialized segments like cryogenics, where ultra-low temperature performance demands precise and flawless sealing mechanisms achievable only with cutting-edge materials and precision engineering.

Segmentation Analysis

The Angle Valves Market is extensively segmented based on criteria such as the valve design type, the material of construction, the method of operation, and the final end-use application. This segmentation provides a granular view of demand patterns, highlighting areas of high growth and technological specialization. Understanding these segments is crucial for manufacturers to tailor their product offerings, focusing on specialized requirements such as corrosion resistance for chemical processing (Material) or high-speed actuation for emergency shutoff systems (Operation). The market structure reflects the complexity and diversity of industrial fluid handling needs globally.

By Type, angle valves are classified into various mechanical configurations, including globe, piston, needle, and ball designs, each optimized for specific flow control characteristics, ranging from precise throttling (needle) to high-flow, low-pressure drop capabilities (globe angle). The Material segmentation, covering stainless steel, cast iron, and exotic alloys, directly correlates with the fluid compatibility and operational environment constraints, driving material selection toward maximum resilience and safety. Operationally, the shift from manual to pneumatic and electric actuation underscores the broader industrial trend toward automation, minimizing manual intervention and enabling integration with automated process control systems (PCS) for enhanced precision and responsiveness.

The End-Use industry analysis confirms that heavy process industries like Oil & Gas and Power Generation remain the cornerstone of demand, requiring high volumes of robust, certified valves. However, sectors such as pharmaceuticals and food & beverage are increasingly important, driving demand for specialized sanitary and high-purity angle valves constructed from FDA-approved materials. This comprehensive segmentation allows market participants to identify niche opportunities, such as the growing demand for bellow-sealed angle valves in nuclear facilities where preventing environmental leakage is an absolute operational mandate.

- By Type: Globe Angle Valves, Piston Angle Valves, Needle Angle Valves, Ball Angle Valves, Diaphragm Angle Valves

- By Material: Stainless Steel (304, 316, Duplex), Cast Iron, Bronze, Brass, Engineered Plastics, Exotic Alloys (Hastelloy, Monel)

- By Operation: Manual, Pneumatic Actuated, Electric Actuated, Hydraulic Actuated

- By End-Use Industry: Oil & Gas (Upstream, Midstream, Downstream), Chemical & Petrochemical, Power Generation (Thermal, Nuclear), Water & Wastewater Treatment, HVAC, Pharmaceuticals & Biotechnology, Food & Beverage

Value Chain Analysis For Angle Valves Market

The value chain for the Angle Valves Market begins with upstream activities centered on raw material procurement, encompassing the sourcing of metals such as specialized steel alloys, cast iron, and non-ferrous metals like brass and bronze, along with critical sealing materials like PTFE and various elastomers. Key upstream decisions involve managing commodity price volatility and ensuring the quality and traceability of materials, which directly impact the final valve performance and certification status. Manufacturers then engage in core processes including casting, forging, machining, assembly, testing, and surface treatments, emphasizing precision engineering to meet strict dimensional tolerances and pressure ratings. The efficiency of the manufacturing process, particularly the reduction of scrap rates and optimization of machining time, is critical for competitive pricing.

Downstream analysis focuses on the distribution and end-use phases. Angle valves typically reach end-users through a complex network comprising direct sales channels for large, custom projects (especially in Oil & Gas and Power sectors) and indirect distribution channels involving specialized industrial distributors, stockists, and third-party value-added resellers (VARs). The selection of the distribution channel often depends on the complexity of the valve and the required level of technical support; high-specification valves often mandate direct manufacturer involvement. Post-sales services, including installation guidance, maintenance contracts, and rapid supply of spare parts, constitute a critical component of the downstream value proposition, ensuring customer loyalty and maximizing asset lifespan.

Direct distribution is favored for Original Equipment Manufacturers (OEMs) and major engineering, procurement, and construction (EPC) contractors involved in building new industrial plants, as it ensures technical consultation and tailored solutions. Conversely, indirect channels are vital for the maintenance, repair, and overhaul (MRO) market, providing rapid local access to standard valve sizes and common replacement items. The overall profitability within the value chain is increasingly influenced by logistics efficiency and the manufacturer's ability to maintain certification standards across different global regulatory bodies, positioning quality assurance as a major value differentiator from low-cost competitors.

Angle Valves Market Potential Customers

The primary consumers and end-users of angle valves are large-scale industrial operators whose core processes rely on precise, reliable, and safe management of high-pressure or critical fluids. The Oil & Gas industry, spanning crude extraction (upstream), pipeline transport (midstream), and refining operations (downstream), represents the largest customer base, utilizing angle valves for choke service, blowdown systems, and emergency isolation points where quick shut-off at a 90-degree turn is advantageous. Similarly, major utility companies, particularly those operating thermal, combined cycle, and nuclear power plants, constitute significant buyers, using these valves extensively in feedwater regulation, steam distribution, and cooling water circuits where continuous, high-integrity operation is essential to avoid thermal runaway or process disruption.

Beyond the energy sector, the chemical and petrochemical industries are essential customers, demanding angle valves constructed from highly corrosion-resistant materials (e.g., specialized alloys) to handle aggressive acids, solvents, and intermediate products used in manufacturing fertilizers, plastics, and various base chemicals. The Water and Wastewater Treatment sector is also rapidly expanding its consumption, focusing on angle valves suitable for slurry handling and large volume flow control in filtration and distribution networks. These customers prioritize durability, low maintenance requirements, and the ability of the valve design to minimize clogging from particulate matter commonly found in municipal water processes.

Emerging but high-value customers include pharmaceutical manufacturers and biotechnology firms, which require angle valves designed to sanitary standards (often diaphragm-type angle valves) that minimize dead space and facilitate clean-in-place (CIP) and sterilize-in-place (SIP) procedures, ensuring product purity. Furthermore, large industrial HVAC systems and complex machinery manufacturers, such as those producing large compressors or hydraulic presses, utilize angle valves for precision fluid routing and pressure relief functions, solidifying a diverse customer profile that spans regulatory-heavy process industries and general infrastructure installations, all prioritizing safety and performance longevity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 7.6 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Emerson Electric, Flowserve Corporation, Kitz Corporation, Crane Co., Parker Hannifin, CIRCOR International, IMI plc, Pentair, Velan Inc., Samson AG, Spirax Sarco, Graco Inc., WIKA Group, NIBCO, Apollo Valves, Neway Valve, Swagelok, Burkert Fluid Control Systems, Richards Industrials, TLV Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Angle Valves Market Key Technology Landscape

The technological evolution within the Angle Valves Market is driven by the imperative for enhanced sealing integrity, faster response times, and smarter operational capabilities, particularly in critical process control applications. Modern angle valve technology is heavily focused on optimizing stem sealing mechanisms, leading to the increased adoption of bellows-sealed designs. These hermetically sealed valves are crucial in mitigating fugitive emissions, especially in chemical and petrochemical facilities handling volatile organic compounds (VOCs), thus ensuring compliance with stringent environmental standards like ISO 15848. Furthermore, materials science innovation is leading to the use of advanced ceramics and specialized metallic coatings for trim components, dramatically improving resistance to erosion, cavitation, and high-temperature abrasion, thereby extending the valve’s operational life in highly demanding environments such as supercritical steam lines.

A significant technological advancement is the integration of smart actuation and sensor technology, transforming traditional mechanical angle valves into digitally-enabled assets. Electric and pneumatic actuators are increasingly equipped with embedded microprocessors, allowing for sophisticated proportional control, precise position feedback, and real-time diagnostic monitoring. These smart valves communicate their health and performance data back to centralized control systems (DCS/SCADA) via industrial communication protocols such as HART or Fieldbus. This integration facilitates advanced features like partial stroke testing (PST), ensuring that emergency shutdown (ESD) angle valves remain fully functional, a non-negotiable requirement for safety instrumented systems (SIS) in high-risk applications.

Furthermore, additive manufacturing (3D printing) is beginning to influence the production landscape, particularly for rapid prototyping of complex internal geometries and for producing specialized, low-volume valve components made from exotic alloys that are difficult or costly to machine conventionally. This technology promises to reduce lead times for custom-engineered angle valves and optimize flow paths based on computational fluid dynamics (CFD) analysis, leading to lower pressure drops and improved energy efficiency. The convergence of IoT connectivity, predictive diagnostics, and advanced material engineering defines the current cutting edge, positioning the industry for safer, more efficient, and maintenance-optimized operation.

Regional Highlights

The Angle Valves Market demonstrates varied growth dynamics across major global regions, reflective of industrial maturity, regulatory environment, and investment in infrastructure:

- North America (USA, Canada): This mature market emphasizes replacement and upgrading existing valve infrastructure to comply with strict environmental mandates concerning fugitive emissions. Demand is high for advanced smart angle valves featuring IoT integration and superior sealing technologies (e.g., bellows seal) within the downstream refining and chemical sectors.

- Europe (Germany, UK, France): Driven by robust manufacturing and adherence to the EU's comprehensive climate and energy policy, Europe focuses on high-efficiency, precision-engineered angle valves for HVAC, power generation modernization, and specialized industrial processes. Germany and the UK remain centers for valve manufacturing excellence and technological innovation.

- Asia Pacific (China, India, Japan): Representing the fastest-growing region, APAC’s demand is fueled by massive urbanization, new power plant construction (especially coal and nuclear in China and India), and the rapid expansion of petrochemical complexes. This region provides significant opportunities for both standard and high-specification angle valves due to large volume consumption in new installations.

- Latin America (Brazil, Mexico): Market growth is closely tied to investment cycles in oil and gas exploration (e.g., Brazil’s pre-salt fields) and mineral processing. Demand is steady but sensitive to global commodity prices, requiring robust, cost-effective valve solutions for harsh environments.

- Middle East and Africa (Saudi Arabia, UAE, South Africa): This region is dominated by the upstream and midstream oil and gas sector, necessitating extremely durable, high-pressure, and high-temperature angle valves for crucial infrastructure projects, including pipeline networks and LNG facilities. Significant capital expenditure in petrochemicals ensures sustained, high-value demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Angle Valves Market.- Emerson Electric Co.

- Flowserve Corporation

- Kitz Corporation

- Crane Co.

- Parker Hannifin Corporation

- CIRCOR International, Inc.

- IMI plc

- Pentair plc

- Velan Inc.

- Samson AG

- Spirax Sarco Engineering plc

- Graco Inc.

- WIKA Group

- NIBCO Inc.

- Apollo Valves (Conbraco Industries, Inc.)

- Neway Valve Co., Ltd.

- Swagelok Company

- Burkert Fluid Control Systems

- Richards Industrials

- TLV Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Angle Valves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of using an angle valve over a standard globe valve?

The primary advantage of the angle valve configuration is that it facilitates a 90-degree turn in the piping system while simultaneously performing flow control, effectively serving as both a valve and an elbow. This design minimizes pressure drop, reduces piping components, and allows for superior self-draining capabilities, making it ideal for slurry and steam applications.

Which end-use industry contributes most significantly to the demand for angle valves?

The Oil & Gas industry, encompassing upstream, midstream, and downstream activities, is the most significant contributor to demand. Angle valves are essential in this sector for critical flow isolation, throttling, and emergency blowdown services due to their robust design and ability to handle high-pressure, high-temperature hydrocarbon fluids reliably.

How is industrial automation influencing the design and adoption of angle valves?

Industrial automation is driving demand for angle valves equipped with electric or pneumatic actuation and integrated sensors (smart valves). These actuated valves enable remote operation, proportional control, real-time diagnostics, and integration into Safety Instrumented Systems (SIS), improving process precision and operational safety while reducing manual intervention.

What materials are most commonly used in the construction of angle valves and why?

Stainless steel (specifically 316 and 304 grades) is the most common material due to its excellent corrosion resistance, high tensile strength, and suitability for a wide range of media, including chemicals and high-purity fluids. Cast iron and bronze are also utilized for utility and general service applications where cost-effectiveness and moderate pressure handling are key requirements.

What is the expected CAGR for the Angle Valves Market between 2026 and 2033?

The Angle Valves Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 4.8% during the forecast period of 2026 to 2033, driven largely by infrastructure expansion in the APAC region and increasing regulatory compliance requirements across process industries globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager