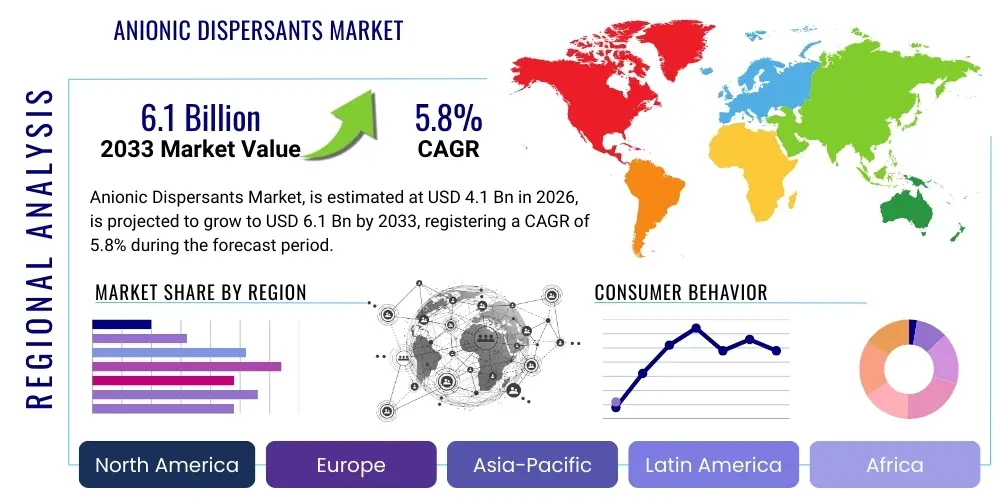

Anionic Dispersants Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438304 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Anionic Dispersants Market Size

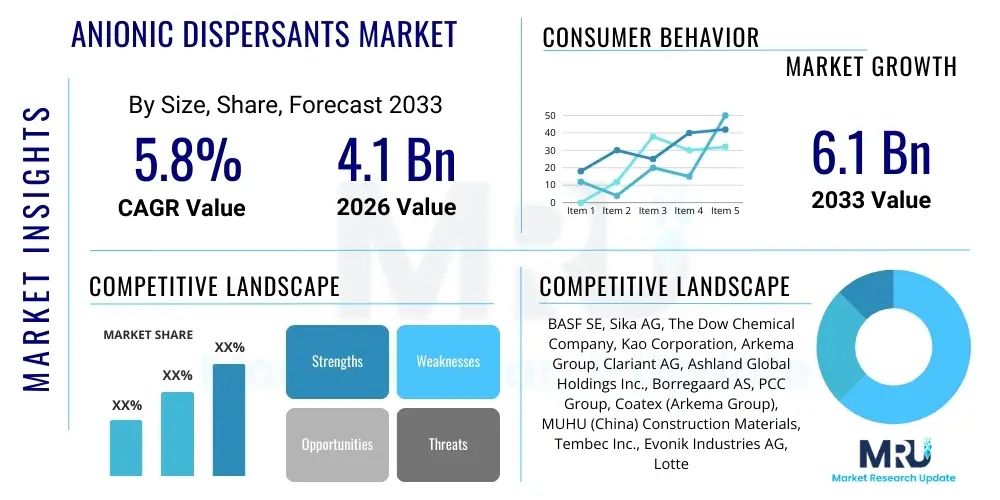

The Anionic Dispersants Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Anionic Dispersants Market introduction

Anionic dispersants are surface-active agents characterized by a negatively charged (anionic) hydrophilic group, which plays a crucial role in stabilizing colloidal systems. These chemical additives function primarily by ensuring the uniform distribution and non-reaggregation of solid particles within a liquid medium, typically through electrostatic repulsion mechanisms. Common examples include polycarboxylates, lignosulfonates, naphthalene sulfonates, and fatty acid derivatives. Their effectiveness stems from their ability to adsorb onto the particle surface, imparting a stabilizing charge that prevents flocculation and sedimentation, thereby maintaining the desired viscosity and rheological properties of the formulation.

The product finds extensive utility across a multitude of industrial sectors, serving as essential components in formulations where particle management is paramount. Major applications include high-performance concrete additives, where they are used as superplasticizers to reduce water content while maintaining workability; in paints and coatings, where they ensure pigment stability and color uniformity; and in agricultural chemicals (agrochemicals) for stabilizing active ingredients in suspension concentrates. Furthermore, they are vital in the production of ceramics, textiles, and enhanced oil recovery operations. The versatility and efficiency of anionic dispersants in handling complex suspensions drive their consistent demand across industrial value chains.

Key benefits driving market adoption include improved product stability, enhanced performance characteristics (such as flowability and shelf life), and the ability to formulate highly concentrated systems. The driving factors for market expansion are primarily centered around rapid urbanization and infrastructure development globally, necessitating high-quality construction chemicals, particularly in the Asia Pacific region. Additionally, stringent environmental regulations pushing for waterborne and low-VOC (Volatile Organic Compound) coating systems further amplify the need for advanced, efficient anionic dispersants capable of stabilizing complex aqueous formulations.

Anionic Dispersants Market Executive Summary

The global Anionic Dispersants Market exhibits robust growth, propelled by sustained demand from the construction and paints and coatings sectors. Business trends indicate a shift towards specialized, high-performance dispersants, such as modified polycarboxylates and bio-based alternatives, responding to increasing functional requirements and sustainability mandates. Key players are focusing on backward integration and strategic acquisitions to secure raw material supply chains and expand regional manufacturing capabilities, particularly in high-growth economies. Furthermore, technological innovation is concentrated on developing highly efficient products that require lower dosage rates, thus reducing overall formulation costs for end-users and improving the environmental profile of the final products. The competitive landscape is moderately fragmented, with large multinational chemical companies competing alongside specialized regional manufacturers offering niche solutions.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market due to massive infrastructural investment, rapid growth in residential and commercial construction, and expanding manufacturing bases for paints, textiles, and agrochemicals, notably in China and India. North America and Europe demonstrate mature markets characterized by stringent regulatory environments favoring high-solids, low-VOC coatings, driving demand for premium, customized dispersant solutions compliant with REACH and EPA standards. The markets in Latin America and the Middle East & Africa (MEA) are emerging, driven by increasing industrialization and diversification efforts, particularly in the oil and gas sector (for drilling fluids) and construction.

Segment trends reveal that the Polycarboxylates (PCEs) segment holds the largest market share, attributable to their superior performance as superplasticizers in concrete, offering high water reduction capabilities and extended slump retention. However, Lignosulfonates remain highly relevant due to their cost-effectiveness and utilization in niche applications like gypsum board manufacturing and lower-grade concrete formulations. Application-wise, the construction sector is the leading consumer, though the fastest growth is anticipated in the agrochemicals segment, driven by the necessity for advanced formulation stability to maximize the efficacy of modern pesticide and fertilizer products under various environmental conditions.

AI Impact Analysis on Anionic Dispersants Market

User queries regarding AI's influence in the anionic dispersants domain frequently center on optimizing molecular design, enhancing quality control, and streamlining complex synthesis processes. Users are keenly interested in how Artificial Intelligence can accelerate the discovery of novel dispersant chemistries with improved dispersion efficiency and better environmental profiles, particularly substitutes for legacy chemistries like naphthalene sulfonates. Concerns often revolve around the upfront investment required for integrating AI tools into existing R&D infrastructure and the need for specialized data scientists capable of handling large datasets related to polymer structure-property relationships. Key expectations focus on AI's capability to predict optimal dosages for specific applications (e.g., concrete mixes or pigment dispersions) under varying environmental conditions, leading to significant material savings and performance guarantees. The central theme emerging is the utilization of AI for precision chemistry—moving from traditional trial-and-error R&D to data-driven predictive modeling for tailored dispersant solutions.

- AI-driven optimization of polymer structure: Machine learning models predict the most effective molecular weight, charge density, and functional group placement for specific dispersion tasks, accelerating R&D cycles.

- Enhanced process efficiency: AI algorithms monitor reaction kinetics in synthesis, optimizing temperature and pressure parameters to maximize yield and purity of anionic dispersants, reducing batch-to-batch variability.

- Predictive quality control: Computer vision and machine learning enable real-time analysis of dispersion quality in end-use applications (e.g., paint viscosity or concrete slump), ensuring immediate adjustment and minimizing waste.

- Raw material sourcing optimization: AI analyzes global commodity prices and supply chain logistics for feedstocks (e.g., naphthalene, formaldehyde, acrylic acid), leading to more resilient and cost-effective procurement strategies.

- Personalized formulation guidance: Predictive analytics tools recommend optimal anionic dispersant types and loading levels based on specific client application requirements (particle size distribution, solid content, required stability time).

DRO & Impact Forces Of Anionic Dispersants Market

The Anionic Dispersants Market is fundamentally shaped by robust demand dynamics originating from global construction and infrastructure expansion (Drivers), offset by significant regulatory pressures and cost sensitivities (Restraints), while emerging technologies and sustainability mandates create new avenues for growth (Opportunities). The primary impact forces include the increasing global shift towards sustainable building materials, which elevates the need for high-performance dispersants in low-cement, high-strength concrete mixes. Furthermore, volatile raw material pricing, particularly for petrochemical derivatives, exerts considerable influence on manufacturer margins and product competitiveness, necessitating continuous process optimization and supply chain diversification strategies to mitigate risk.

A key driver is the accelerated technological transition in the coatings industry toward waterborne and high-solids systems, moving away from solvent-based formulations. Anionic dispersants, particularly specialized polymeric variants, are indispensable in these environmentally preferred systems, ensuring adequate pigment wetting and long-term storage stability in aqueous media. Conversely, a major restraint is the market's dependence on petroleum-derived feedstocks, which subjects pricing to crude oil volatility and heightens scrutiny regarding lifecycle environmental impact. Furthermore, the commercialization of novel, non-traditional dispersant technologies, such as certain non-ionic or amphoteric systems, could pose a competitive threat in specific application niches where extreme shear stability or multi-functional properties are required.

The primary opportunities lie in the development and commercialization of bio-based and biodegradable anionic dispersants, responding directly to consumer and regulatory pressure for sustainable chemistry, particularly in Europe and North America. The optimization of dispersants for complex high-concentration suspensions, such as those used in advanced battery slurries for electric vehicles (EVs), presents a high-value niche market. Impact forces, therefore, revolve around the delicate balance between achieving superior performance characteristics—such as enhanced durability in concrete or improved pigment loading in coatings—and meeting increasingly rigorous global environmental, safety, and health (EHS) standards, which necessitates continuous investment in green chemistry innovation.

Segmentation Analysis

The Anionic Dispersants Market segmentation provides a crucial framework for understanding market dynamics based on chemical composition (type), application area, and end-use industry. The market is broadly categorized into major chemical families, reflecting distinct performance profiles, cost structures, and compatibility with specific end-user systems. Polycarboxylates dominate the value segment due to their superior performance in construction applications, offering unparalleled efficacy in cement dispersion. However, application versatility dictates revenue distribution, with construction and paints & coatings consistently consuming the largest volumes, driven by global urbanization and infrastructure spending.

Segmentation by type differentiates between established, cost-effective chemistries like lignosulfonates and naphthalene sulfonates, and high-performance, higher-cost alternatives like polycarboxylates and sulfonated polymers. End-use industries such as agrochemicals and oil & gas require highly specialized, often customized, dispersant solutions to meet stringent stability requirements, demanding unique molecular designs tailored to specific active ingredients or extreme downhole conditions. This nuanced demand profile drives R&D investment towards targeted specialty dispersant products rather than commodity chemicals.

Geographically, market segmentation highlights regional variances in technology adoption and regulatory compliance. North America and Europe prioritize performance and environmental compliance, driving demand for innovative, low-emission products, while Asia Pacific focuses heavily on volume and cost-effectiveness for mass construction projects. Understanding these segment dynamics is essential for market participants seeking to optimize production portfolios and tailor commercial strategies to specific industrial needs and regional regulatory mandates across the global value chain.

- By Type:

- Polycarboxylates (PCE)

- Lignosulfonates

- Naphthalene Sulfonates

- Sulfonated Polymers (e.g., Acrylic Copolymers)

- Others (e.g., Phosphate esters, Fatty acid derivatives)

- By Application:

- Construction Chemicals (Superplasticizers, Mortars)

- Paints and Coatings (Pigment Dispersion)

- Agrochemicals (Suspension Concentrates, Wettable Powders)

- Textiles and Leather

- Oil & Gas (Drilling Fluids, Cementing)

- Pulp and Paper

- Ceramics

- Others (Detergents, Water Treatment)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Anionic Dispersants Market

The value chain for anionic dispersants commences with upstream analysis, focusing on the procurement of primary chemical feedstocks. For polycarboxylates, this involves sourcing acrylic acid, maleic anhydride, and specialized ether monomers. Lignosulfonates rely on the wood pulping industry byproducts (lignin), while naphthalene sulfonates utilize crude naphthalene derived from petroleum or coal tar. Volatility in the pricing and supply stability of these petrochemical and forestry inputs significantly impacts the production cost structure of dispersant manufacturers. Efficient upstream management requires strong supplier relationships and hedging strategies against commodity price fluctuations, ensuring the consistent availability of quality raw materials necessary for polymerization and functionalization.

The core of the value chain is the manufacturing process, involving polymerization, sulfonation, or chemical modification of the feedstocks to yield the final anionic dispersant polymer. Manufacturers invest heavily in R&D to optimize molecular architecture, targeting specific charge densities, molecular weights, and side-chain compositions to enhance dispersion efficiency and stability for diverse applications. Quality control, particularly concerning purity and effective charge density, is crucial at this stage. Following manufacturing, the distribution channel plays a vital role. Direct channels are often utilized for large-volume customers like major construction chemical formulators or global paint manufacturers, allowing for customized product delivery and technical support. Indirect distribution, leveraging regional distributors and specialized chemical traders, services smaller clients and niche markets, providing wider geographical reach and logistical efficiency.

Downstream analysis involves the integration of anionic dispersants into final products across numerous industries. In construction, dispersants are formulated into superplasticizers and mortar additives; in coatings, they are mixed directly with pigments and resins. The effectiveness of the dispersant directly influences the performance, stability, and longevity of the end product. Therefore, close collaboration between dispersant producers and end-users is essential for fine-tuning formulations and ensuring optimal dosage rates. The final stage involves consumption by end-users—ranging from large-scale infrastructure projects to individual consumers purchasing paint—completing the flow from raw material extraction to functional application.

Anionic Dispersants Market Potential Customers

The primary customers for anionic dispersants are large industrial organizations that rely on stabilizing solid particles within liquid systems to manufacture their final products. The largest segment comprises construction chemical formulators, including companies specializing in concrete admixtures (superplasticizers), cement additives, and gypsum board manufacturers. These customers require high volumes of polycarboxylates and lignosulfonates to achieve high-strength, durable, and highly workable concrete mixes essential for modern infrastructure, bridges, and high-rise construction projects. The performance requirement is centered on maintaining slump retention and water reduction efficiency.

Another significant customer base resides within the paints and coatings industry, specifically manufacturers of architectural, industrial, and automotive coatings. These buyers utilize specialized anionic dispersants (often sulfonated polymers or polycarboxylates) to effectively wet and stabilize inorganic pigments (like titanium dioxide) and organic pigments within waterborne or high-solids formulations. Their purchasing decisions are driven by the dispersant's ability to maximize pigment loading, ensure color consistency, and extend the shelf life of the paint product while complying with stringent VOC regulations.

Further potential customers include agrochemical companies, which use dispersants to create stable suspension concentrates (SCs) and wettable powders (WPs) for herbicides, fungicides, and insecticides, ensuring optimal delivery and efficacy of the active ingredients. The ceramics and advanced materials sectors, particularly those involved in producing technical ceramics or battery slurries, represent high-growth, specialty customer niches demanding ultra-pure and highly efficient dispersant systems to control rheology and particle packing density, ensuring defect-free manufacturing of critical components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Sika AG, The Dow Chemical Company, Kao Corporation, Arkema Group, Clariant AG, Ashland Global Holdings Inc., Borregaard AS, PCC Group, Coatex (Arkema Group), MUHU (China) Construction Materials, Tembec Inc., Evonik Industries AG, Lotte Fine Chemical, Chemipol, W. R. Grace & Co., Setre Chemical, King Industries, Inc., Croda International Plc, CHT Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Anionic Dispersants Market Key Technology Landscape

The technology landscape in the Anionic Dispersants Market is focused heavily on sophisticated polymer chemistry, particularly the synthesis of comb-polymer structures. The prevailing technology centers around advanced polycarboxylate ether (PCE) superplasticizers, which utilize controlled free radical polymerization (CFRP) or similar techniques to achieve highly specific molecular architectures. This allows manufacturers to precisely control the ratio of anionic backbone groups (for adsorption) and non-ionic polyethylene oxide side chains (for steric hindrance). This control over structure leads to superior performance characteristics, such as extended slump life in concrete and enhanced compatibility across varied cement chemistries, driving their dominance in high-performance construction applications.

In addition to PCE advancements, significant technological effort is directed towards improving lignosulfonate modification. Historically a lower-cost, less-efficient alternative, modern lignosulfonate technology involves chemical grafting and fractionation techniques to remove inactive components and introduce functional groups that enhance dispersion capacity and thermal stability. This refinement enables lignosulfonates to compete in certain specialty applications that require high purity or sustainable sourcing. Furthermore, the development of specialized dispersants for micro- and nano-particle systems—crucial for modern battery slurries and advanced ceramic manufacturing—requires expertise in surface chemistry to effectively manage extremely high surface areas and complex inter-particle forces, moving beyond simple electrostatic stabilization to incorporate powerful steric stabilization mechanisms.

Digitalization and high-throughput experimentation (HTE) are rapidly becoming integral to the technology landscape. HTE platforms allow chemical companies to screen hundreds of potential monomer combinations and polymerization conditions quickly, accelerating the discovery of novel dispersant formulations optimized for specific industrial pigments or mineral fillers. Sustainability-focused technology includes developing bio-based monomers derived from agricultural waste or renewable resources to replace petroleum-based acrylic components. These technological advancements collectively aim to reduce dosage rates, improve cost-efficiency, and provide highly tailored solutions that meet the increasing regulatory and performance demands of the global end-user industries.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and most dynamic market for anionic dispersants, driven primarily by massive investments in infrastructure and real estate in China, India, and Southeast Asian nations. The region’s dominance stems from rapid urbanization, necessitating huge volumes of construction chemicals, particularly superplasticizers based on Polycarboxylates and high-volume, cost-effective Lignosulfonates. Furthermore, APAC is a global manufacturing hub for textiles, paints, and agrochemicals, ensuring continuous high demand across diverse applications. Regulatory harmonization, particularly concerning environmental standards in major markets, is beginning to shift demand towards higher-quality, low-VOC dispersant systems.

- North America: This region is characterized by high adoption of specialty, high-performance dispersants, favoring PCEs and advanced sulfonated polymers due to stringent quality standards in construction and strict environmental regulations governing coatings (e.g., maximizing solids content and minimizing VOCs). The market is mature, emphasizing innovation in bio-based and sustainable chemistry, driven by consumer demand and corporate sustainability initiatives. Growth is steady, focusing on renovation projects and specialized construction (e.g., high-durability infrastructure).

- Europe: Europe maintains a strong focus on sustainability, driven by REACH regulations, which prioritize the development and use of safe, low-toxicity chemicals. This legislative environment fuels demand for advanced, environmentally benign anionic dispersants, particularly customized polymer solutions for waterborne coatings and concrete applications. The construction sector remains a core consumer, while the textile and industrial coatings segments are key growth areas, demanding specialized, high-efficiency products compliant with EU environmental directives.

- Latin America (LATAM): The LATAM market is experiencing moderate growth, linked to fluctuating economic conditions but underpinned by consistent demand from the construction sectors in Brazil, Mexico, and Argentina. The market primarily utilizes cost-competitive lignosulfonates and naphthalene sulfonates, though adoption of advanced PCE technology is increasing for high-profile infrastructure projects requiring superior performance and longevity. Regional manufacturers are increasing capacity to serve local market needs and reduce reliance on imports.

- Middle East & Africa (MEA): Growth in MEA is highly concentrated in the Gulf Cooperation Council (GCC) countries due to mega-project development in infrastructure and urban planning. Demand is robust for dispersants optimized for challenging climate conditions (high temperatures), requiring specialized formulations that maintain concrete workability and performance reliability. The oil and gas sector remains a critical end-user, demanding high-performance dispersants for drilling fluid stabilization and cementing operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Anionic Dispersants Market.- BASF SE

- Sika AG

- The Dow Chemical Company

- Kao Corporation

- Arkema Group

- Clariant AG

- Ashland Global Holdings Inc.

- Borregaard AS

- PCC Group

- Coatex (Arkema Group)

- MUHU (China) Construction Materials

- Tembec Inc.

- Evonik Industries AG

- Lotte Fine Chemical

- Chemipol

- W. R. Grace & Co.

- Setre Chemical

- King Industries, Inc.

- Croda International Plc

- CHT Group

Frequently Asked Questions

Analyze common user questions about the Anionic Dispersants market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary chemical types driving the Anionic Dispersants Market?

The market is primarily driven by Polycarboxylates (PCEs) due to their superior performance as superplasticizers in high-performance concrete. Other key types include cost-effective Lignosulfonates, specialized Naphthalene Sulfonates, and various Sulfonated Polymers crucial for paints and coatings formulations.

Which end-use industry holds the largest market share for anionic dispersants?

The Construction Chemicals industry is the largest consumer of anionic dispersants globally. This dominance is attributed to the widespread use of PCEs and lignosulfonates as concrete superplasticizers, essential for reducing water content and improving the flow and durability of modern concrete mixes in infrastructure projects.

How are environmental regulations influencing the future development of anionic dispersants?

Environmental regulations, particularly regarding VOC limits and sustainability mandates, are strongly influencing the market. This drives manufacturers to innovate bio-based dispersants and high-performance products optimized for waterborne coatings, seeking alternatives to petrochemical-derived chemistries to enhance eco-friendliness and compliance.

What is the Compound Annual Growth Rate (CAGR) projected for the Anionic Dispersants Market?

The Anionic Dispersants Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% between the forecast period of 2026 and 2033, driven by infrastructure growth in the Asia Pacific region and technological advancements in superplasticizer chemistry.

What role does molecular architecture play in the performance of modern anionic dispersants?

Molecular architecture, specifically in Polycarboxylate Ethers (PCEs), is critical. Controlled polymerization techniques allow precise tailoring of anionic backbone groups for adsorption and non-ionic side chains for steric stabilization, enabling superior control over particle dispersion, rheology, and long-term stability across various industrial applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager