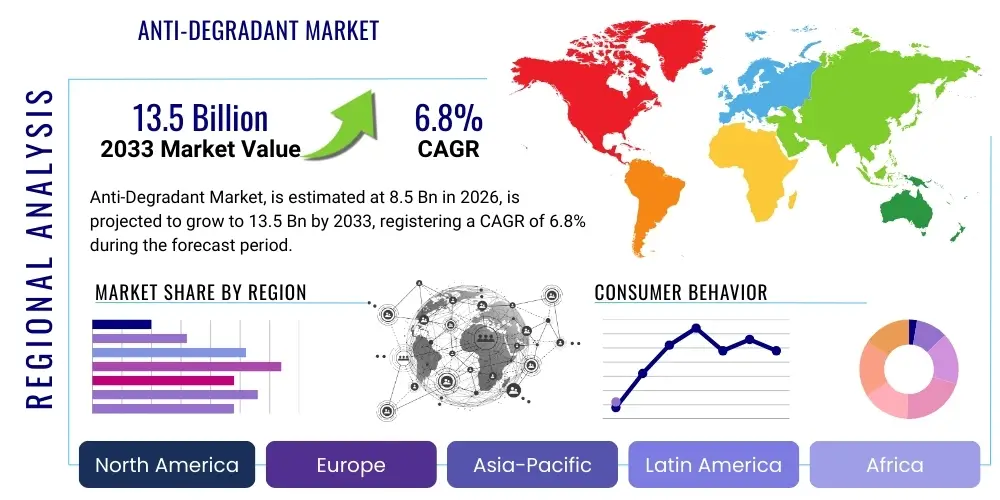

Anti-Degradant Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440490 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Anti-Degradant Market Size

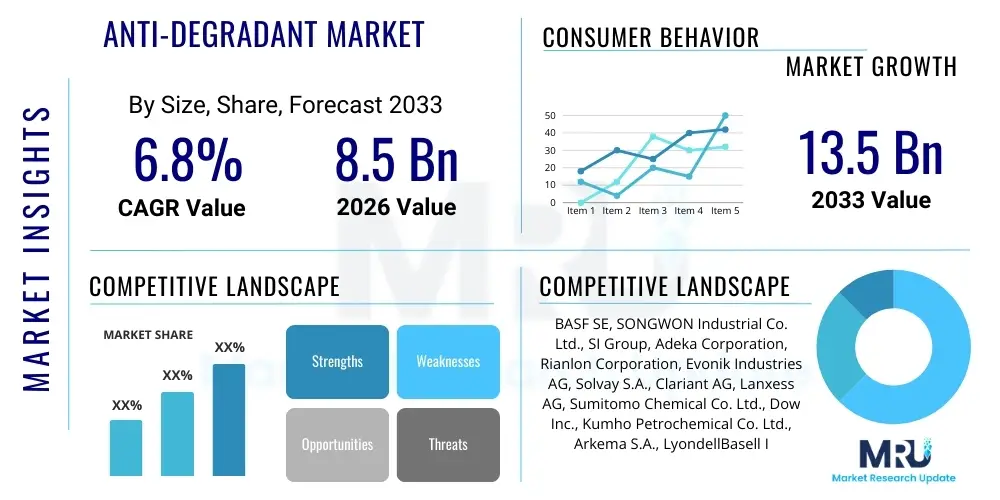

The Anti-Degradant Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 13.5 Billion by the end of the forecast period in 2033. This robust growth is primarily driven by expanding end-use industries such as automotive, packaging, construction, and electronics, all of which increasingly rely on enhanced material durability and lifespan. The demand for anti-degradants, essential additives that protect polymers and other materials from various forms of degradation including oxidation, UV radiation, and heat, is directly correlated with the global production and consumption of plastics, rubber, and synthetic fibers.

The market expansion is further supported by stringent regulatory frameworks promoting product longevity and sustainability, alongside continuous innovation in material science leading to new applications for anti-degradants. Developing economies, particularly in Asia Pacific, are expected to contribute significantly to this growth due to rapid industrialization, urbanization, and increasing disposable incomes driving consumption of durable goods. Strategic investments in research and development by key market players to introduce advanced, environmentally friendly anti-degradant solutions are also playing a pivotal role in shaping the market landscape and unlocking new opportunities.

Anti-Degradant Market introduction

The Anti-Degradant Market encompasses the production and consumption of various chemical additives designed to protect polymeric materials, such as plastics, rubbers, and synthetic fibers, from degradation caused by environmental factors like heat, light (UV radiation), oxygen (oxidation), and mechanical stress. These additives extend the lifespan and enhance the performance of a wide array of products, preventing premature failure, discoloration, loss of mechanical properties, and other forms of material deterioration. Anti-degradants are critical for maintaining the structural integrity, aesthetic appeal, and functional longevity of materials across numerous industrial and consumer applications.

The primary applications of anti-degradants span across diverse sectors including automotive, where they are vital for tires, hoses, and interior components; construction, for roofing membranes, piping, and insulation; packaging, extending the shelf-life of food and other goods; and electronics, protecting wires, cables, and casings. Other significant applications include consumer goods, medical devices, and agricultural films. The benefits of using anti-degradants are substantial, including improved product durability, reduced material waste, enhanced safety, and significant cost savings over the product lifecycle by minimizing the need for frequent replacements. They ensure that materials retain their desired properties even under harsh operating conditions, which is crucial for safety-critical components.

Driving factors for the anti-degradant market include the escalating global demand for high-performance plastics and elastomers, particularly in the automotive and construction industries, which are undergoing rapid technological advancements and expansion. The increasing focus on material sustainability and circular economy principles is prompting manufacturers to seek additives that prolong product life, thereby reducing the environmental footprint. Furthermore, stringent regulatory standards pertaining to product safety and quality across various end-use sectors compel manufacturers to incorporate effective anti-degradants. Rapid industrialization in emerging economies and the continuous development of novel polymer materials that require specialized protection also serve as significant market drivers.

Anti-Degradant Market Executive Summary

The Anti-Degradant Market is experiencing dynamic growth, propelled by robust expansion in key end-use industries and an increasing emphasis on material longevity and performance. Business trends indicate a strong move towards sustainable and multifunctional anti-degradant solutions, driven by evolving regulatory landscapes and consumer preferences for eco-friendly products. Manufacturers are investing heavily in research and development to create novel additive blends that offer superior protection against multiple degradation mechanisms, often integrating properties like flame retardancy or antimicrobial effects. Strategic collaborations, mergers, and acquisitions are common as companies seek to consolidate market share, expand product portfolios, and penetrate new geographic markets. Furthermore, the rise of specialized applications in sectors like renewable energy and medical devices is creating niche opportunities for advanced anti-degradant formulations.

Regionally, Asia Pacific continues to dominate the anti-degradant market, largely due to the rapid industrial growth, particularly in China and India, coupled with increasing production and consumption of plastics and rubbers. North America and Europe represent mature markets characterized by stringent environmental regulations and a strong focus on high-performance and specialty anti-degradants, driving innovation in these regions. Latin America, the Middle East, and Africa are emerging as significant growth hubs, fueled by developing manufacturing bases and expanding infrastructure projects. Each region presents unique challenges and opportunities, with market players tailoring their strategies to meet specific local demands and regulatory requirements, including the transition to halogen-free or low-VOC formulations.

Segmentation trends reveal strong demand for antioxidants, particularly primary antioxidants (phenolics and amines) and secondary antioxidants (phosphites and thioesters), driven by their critical role in protecting polymers from oxidative degradation during processing and end-use. UV stabilizers, including hindered amine light stabilizers (HALS) and UV absorbers, are witnessing significant uptake due to the growing outdoor applications of plastics in construction and automotive sectors. The rubber anti-degradants segment remains robust, primarily propelled by the tire industry’s continuous need for enhanced durability and performance. Furthermore, the increasing adoption of bio-based and non-toxic anti-degradants reflects a broader industry shift towards sustainable and safer chemical solutions, influencing product development and market positioning across all segments.

AI Impact Analysis on Anti-Degradant Market

Users frequently inquire about how artificial intelligence and machine learning could revolutionize the anti-degradant market, seeking insights into enhanced material design, accelerated R&D, and optimized manufacturing processes. Common questions revolve around AI's ability to predict material degradation patterns, personalize anti-degradant formulations for specific applications, and improve the efficiency of quality control. There is significant interest in AI's potential to shorten the discovery cycle for new, more effective, and environmentally friendly anti-degradant molecules, addressing current limitations in traditional experimental approaches. Users also express curiosity about AI’s role in optimizing supply chains, forecasting demand, and enhancing the overall sustainability profile of anti-degradant production and application, aiming for reduced waste and improved resource utilization across the value chain.

- AI-driven predictive modeling can significantly accelerate the discovery and design of novel anti-degradant molecules by simulating molecular interactions and predicting performance characteristics, reducing reliance on extensive physical testing.

- Machine learning algorithms can optimize anti-degradant formulations for specific polymer matrices and end-use conditions, enabling customization that maximizes material lifespan and performance while minimizing additive usage.

- AI-powered analytics can analyze vast datasets from material testing to identify complex degradation pathways, allowing for the development of more targeted and effective protective strategies against various environmental stressors.

- Automated quality control systems integrating AI can monitor anti-degradant production in real-time, detecting anomalies and ensuring batch consistency, leading to higher product reliability and reduced manufacturing defects.

- AI can enhance supply chain efficiency by optimizing inventory management, forecasting demand fluctuations for different anti-degradant types, and identifying potential supply disruptions, thereby ensuring timely delivery and cost savings.

- Digital twins and AI simulations can model the long-term performance and degradation behavior of materials under various conditions, providing crucial insights for product development and informing maintenance schedules for critical applications.

- The use of AI in material informatics can help identify synergistic effects between different anti-degradant types, leading to the creation of multi-functional additive packages with enhanced protective capabilities.

- AI-enabled robotics can automate the blending and compounding processes of anti-degradants with polymers, improving precision, reducing human error, and enhancing workplace safety in manufacturing facilities.

- Data from extensive material databases can be leveraged by AI to identify potential health and environmental impacts of new anti-degradant chemistries, aiding in the development of safer and more sustainable alternatives.

- AI can facilitate personalized marketing and sales strategies by analyzing customer needs and preferences, allowing anti-degradant suppliers to offer tailored solutions and technical support more effectively.

- Integration of AI in material recycling processes can help in identifying and separating plastics containing specific anti-degradants, potentially improving the quality of recycled materials and promoting circular economy initiatives.

DRO & Impact Forces Of Anti-Degradant Market

The Anti-Degradant Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form its Impact Forces. Key drivers include the ever-growing demand for high-performance and durable materials across a multitude of industries such as automotive, packaging, construction, and electronics, all of which rely heavily on extended product lifecycles and enhanced material integrity. The continuous expansion of global polymer production, particularly in emerging economies, directly translates into increased demand for anti-degradants. Furthermore, stringent regulatory frameworks and evolving consumer expectations for safer and longer-lasting products compel manufacturers to incorporate effective anti-degradant solutions to meet quality standards and competitive pressures.

However, the market also faces notable restraints. Fluctuations in raw material prices, particularly for petrochemical-derived inputs, can impact manufacturing costs and overall market profitability. Environmental concerns surrounding the potential toxicity and non-biodegradability of certain synthetic anti-degradants, coupled with increasingly strict regulations regarding chemical usage, pose challenges for product development and market acceptance. The high cost associated with research and development of novel, high-performance, and eco-friendly anti-degradants can also be a barrier for smaller players. Additionally, the complexity of incorporating these additives into various polymer matrices without compromising other material properties requires extensive technical expertise and investment.

Opportunities within the anti-degradant market are substantial and primarily revolve around the development of sustainable and bio-based anti-degradants, which address environmental concerns and cater to a growing demand for green solutions. Innovations in multi-functional anti-degradants that offer combined protection against multiple degradation mechanisms (e.g., UV and oxidation) present significant growth avenues. The increasing adoption of advanced plastics in electric vehicles, renewable energy infrastructure, and smart electronic devices creates new, high-value application areas. Furthermore, digitalization and AI integration in material design and formulation optimization offer unprecedented potential to accelerate R&D and bring more effective solutions to market faster. Strategic collaborations and expansions into untapped markets, particularly in developing regions, also represent lucrative opportunities for market players.

Segmentation Analysis

The Anti-Degradant Market is comprehensively segmented based on various critical parameters including product type, polymer type, and end-use industry, providing a granular view of market dynamics and growth opportunities across different categories. This multi-faceted segmentation helps to understand the diverse demands and applications for anti-degradants, reflecting the intricate needs of different material science and manufacturing sectors. The market's structure is shaped by the specific protective requirements of various polymers and their subsequent use in a broad spectrum of industrial and consumer products, driving specialization in anti-degradant formulations and delivery systems. Analyzing these segments is essential for stakeholders to identify key growth areas, tailor product offerings, and devise effective market entry or expansion strategies.

- By Product Type:

- Antioxidants

- Primary Antioxidants (Phenolics, Amines)

- Secondary Antioxidants (Phosphites, Thioesters)

- UV Stabilizers

- Hindered Amine Light Stabilizers (HALS)

- UV Absorbers (Benzotriazoles, Benzophenones, Triazines)

- Antiozonants

- p-Phenylenediamines (PPDs)

- Waxes

- Flame Retardants

- Halogenated Flame Retardants

- Non-Halogenated Flame Retardants (Phosphorus-based, Metal Hydroxides, Nitrogen-based)

- Thermal Stabilizers

- Lead Stabilizers

- Tin Stabilizers

- Calcium/Zinc Stabilizers

- Organic Stabilizers

- Antimicrobial Agents

- Metal Deactivators

- Other Anti-Degradants (e.g., Anti-Blocking Agents, Slip Agents, Clarifying Agents)

- Antioxidants

- By Polymer Type:

- Plastics

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- Engineering Plastics (e.g., PA, PBT, POM)

- Others (e.g., PLA, PHA)

- Rubbers/Elastomers

- Styrene Butadiene Rubber (SBR)

- Natural Rubber (NR)

- Butadiene Rubber (BR)

- Ethylene Propylene Diene Monomer (EPDM)

- Nitrile Butadiene Rubber (NBR)

- Isoprene Rubber (IR)

- Others (e.g., Silicone Rubber, Fluoroelastomers)

- Synthetic Fibers

- Adhesives & Sealants

- Coatings

- Lubricants

- Fuels

- Others (e.g., Waxes, Fats, Oils)

- Plastics

- By End-Use Industry:

- Automotive

- Tires

- Under-the-hood Components

- Interior & Exterior Parts

- Packaging

- Food & Beverage Packaging

- Industrial Packaging

- Consumer Product Packaging

- Construction

- Pipes & Fittings

- Flooring & Roofing

- Insulation

- Cables & Wiring

- Electrical & Electronics

- Wire & Cable Insulation

- Device Casings

- Printed Circuit Boards

- Agriculture

- Greenhouse Films

- Irrigation Pipes

- Mulch Films

- Textiles

- Apparel

- Technical Textiles

- Home Furnishings

- Healthcare & Medical Devices

- Consumer Goods

- Paints & Coatings

- Adhesives & Sealants

- Industrial Machinery

- Renewable Energy (e.g., Solar Panels, Wind Turbine Components)

- Oil & Gas

- Others (e.g., Sports Equipment, Marine Applications)

- Automotive

- By Form:

- Powder

- Granules

- Liquid

- Pellets

Value Chain Analysis For Anti-Degradant Market

The value chain for the Anti-Degradant Market is a complex network involving multiple stages, from the sourcing of raw materials to the final distribution to end-use industries. It begins with the upstream segment, which includes the extraction and processing of basic chemical feedstocks, primarily petrochemicals like benzene, toluene, phenol, and ammonia, along with other specialized chemicals. These raw materials are then supplied to chemical manufacturers who synthesize the various types of anti-degradant compounds such as antioxidants, UV stabilizers, and antiozonants. The quality and cost-effectiveness of these foundational raw materials significantly influence the final product's performance and market price, making strong supplier relationships crucial for anti-degradant producers. Research and development activities, including the discovery of new chemistries and optimization of existing ones, also form a critical part of the upstream segment, driven by academic institutions and in-house R&D departments of major chemical companies.

Moving downstream, the synthesized anti-degradants are then formulated into specific grades and blends, often customized to meet the unique requirements of different polymer types and end-use applications. This formulation stage involves precise mixing, compounding, and sometimes encapsulation to ensure optimal dispersion and efficacy within the target material. These formulated anti-degradants are then supplied to polymer producers, compounders, and masterbatch manufacturers. Polymer manufacturers incorporate these additives during the polymerization process, while compounders and masterbatch producers create concentrated additive blends that can be easily mixed with virgin polymers by processors. The downstream segment is characterized by strong technical support requirements, as proper selection and dosage of anti-degradants are critical for desired material performance and longevity.

The distribution channel plays a pivotal role in connecting anti-degradant producers with their diverse customer base. This channel can be broadly categorized into direct and indirect methods. Direct distribution involves anti-degradant manufacturers selling their products directly to large-scale end-users or major polymer producers, often facilitated by a dedicated sales force and technical support teams. This approach allows for closer customer relationships, tailored solutions, and better control over product delivery and service. Indirect distribution, on the other hand, involves a network of distributors, agents, and local chemical suppliers who act as intermediaries, particularly serving smaller manufacturers or those in niche markets. These indirect channels provide broader market reach, logistical support, and often local warehousing facilities, which are crucial for maintaining timely supply across diverse geographical locations. Both direct and indirect channels are essential for ensuring efficient market penetration and customer satisfaction within the highly specialized anti-degradant industry.

Anti-Degradant Market Potential Customers

The Anti-Degradant Market serves a vast and diverse array of potential customers, primarily comprising end-users and buyers who seek to enhance the durability, performance, and longevity of their polymeric and other material-based products. These customers are typically manufacturers across various industrial sectors who utilize plastics, rubbers, synthetic fibers, coatings, adhesives, and lubricants as core components of their offerings. The critical need to protect these materials from environmental degradation, such as oxidation, UV radiation, heat, and mechanical stress, makes anti-degradants an indispensable additive in their manufacturing processes. Understanding the specific needs and operational environments of these diverse customer segments is crucial for anti-degradant suppliers to tailor their product offerings and technical support.

One of the largest segments of potential customers is the automotive industry, which relies heavily on anti-degradants for tires, under-the-hood components (hoses, belts, gaskets), interior plastics, and exterior body parts. Manufacturers of vehicles, tire producers, and automotive component suppliers are constantly seeking advanced anti-degradant solutions to meet stringent safety standards, extend vehicle lifespan, and improve performance under harsh operating conditions. Similarly, the construction industry represents a significant customer base, with buyers including manufacturers of pipes, roofing membranes, insulation materials, cables, and various structural and decorative building components. The demand here is driven by the need for materials that can withstand long-term exposure to outdoor elements, high temperatures, and mechanical stress in infrastructure and building applications.

Beyond these major sectors, the packaging industry constitutes another crucial segment, where anti-degradants ensure the integrity and shelf-life of food, beverage, and industrial packaging materials. Electrical and electronics manufacturers are also key customers, utilizing anti-degradants to protect wire and cable insulation, circuit board components, and device casings from thermal and oxidative degradation, ensuring reliability and safety. Other important customer groups include manufacturers in agriculture (greenhouse films, irrigation systems), textiles (technical fabrics, apparel), healthcare (medical devices, disposables), and consumer goods (appliances, toys, sports equipment). The continuous innovation in these industries, coupled with a global push for sustainable and long-lasting products, ensures a consistently high demand for advanced anti-degradant solutions from a broad spectrum of industrial buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 13.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, SONGWON Industrial Co. Ltd., SI Group, Adeka Corporation, Rianlon Corporation, Evonik Industries AG, Solvay S.A., Clariant AG, Lanxess AG, Sumitomo Chemical Co. Ltd., Dow Inc., Kumho Petrochemical Co. Ltd., Arkema S.A., LyondellBasell Industries N.V., Milliken & Company, Chemtura Corporation (now part of Lanxess), Galata Chemicals LLC, Shandong Linyi Sunny Chemical Co. Ltd., Dorf Ketal Chemicals (I) Pvt. Ltd., Penn Color Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Anti-Degradant Market Key Technology Landscape

The Anti-Degradant Market is characterized by a dynamic and continuously evolving technology landscape, driven by the need for more efficient, sustainable, and specialized material protection solutions. A central technological focus revolves around the development of multi-functional anti-degradants that can simultaneously address various degradation mechanisms, such as oxidation, UV radiation, and thermal stress, with a single additive package. This innovation reduces the number of additives required, simplifies formulation processes, and often results in cost savings for end-users while maintaining or improving material performance. Advanced compounding and encapsulation technologies are also crucial, ensuring optimal dispersion of anti-degradants within polymer matrices and preventing leaching or migration, which is essential for long-term effectiveness and compliance with regulatory standards, particularly in food contact applications.

Another significant technological trend is the increasing emphasis on developing green and sustainable anti-degradants. This includes the exploration and commercialization of bio-based anti-degradants derived from natural sources, such as plant extracts or modified natural compounds, offering alternatives to traditional petrochemical-based additives. Research is also focused on creating non-toxic, halogen-free, and low volatile organic compound (VOC) anti-degradant formulations to meet stringent environmental regulations and growing consumer demand for safer products. Innovations in nanotechnology are also impacting the market, with nanoparticles being explored for their potential to act as highly efficient UV blockers or radical scavengers, offering enhanced protection at lower additive concentrations. These advancements not only contribute to product safety but also align with circular economy principles by extending the useful life of materials.

Furthermore, the integration of computational chemistry, machine learning, and artificial intelligence (AI) is rapidly transforming the anti-degradant technology landscape. These advanced computational tools enable in-silico screening of vast chemical libraries, predicting the efficacy and compatibility of novel anti-degradant molecules much faster and more cost-effectively than traditional experimental methods. AI algorithms can optimize existing formulations, identify synergistic additive combinations, and model complex degradation pathways, leading to the rapid development of highly customized and high-performance solutions for specific applications. Techniques like high-throughput experimentation (HTE) are complementing these computational approaches, allowing for rapid synthesis and testing of multiple anti-degradant candidates, thereby significantly accelerating the research and development cycle and fostering a new era of innovation in material protection chemistry.

Regional Highlights

- North America: This region is a mature market characterized by stringent environmental regulations and a strong demand for high-performance anti-degradants in the automotive, construction, and packaging industries. The presence of key market players and significant R&D investments contribute to the development of advanced and sustainable additive solutions. The shift towards electric vehicles and smart infrastructure further drives the need for durable materials.

- Europe: Europe is another developed market with a robust focus on sustainability, circular economy principles, and strict chemical regulations (e.g., REACH). This drives innovation towards bio-based, low-toxicity, and halogen-free anti-degradants. The automotive, building and construction, and electronics sectors are key consumers, with a strong emphasis on product longevity and environmental compliance.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market, propelled by rapid industrialization, urbanization, and a burgeoning manufacturing sector, particularly in China, India, Japan, and South Korea. High production and consumption of plastics and rubbers across automotive, construction, electronics, and packaging industries are the primary growth engines. Increasing disposable incomes and infrastructure development further fuel demand.

- Latin America: This region is an emerging market for anti-degradants, experiencing growth driven by expanding automotive production, increasing construction activities, and a developing packaging industry, especially in Brazil and Mexico. The market is also influenced by global trends towards sustainable materials and rising demand for durable consumer goods, presenting significant opportunities for market penetration.

- Middle East and Africa (MEA): The MEA region shows promising growth potential due to ongoing infrastructure development projects, expansion in the petrochemical sector, and increasing demand from the packaging and automotive industries. Countries like Saudi Arabia, UAE, and South Africa are investing heavily in industrial diversification, which in turn boosts the demand for various anti-degradants to protect materials in harsh climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Anti-Degradant Market.- BASF SE

- SONGWON Industrial Co. Ltd.

- SI Group

- Adeka Corporation

- Rianlon Corporation

- Evonik Industries AG

- Solvay S.A.

- Clariant AG

- Lanxess AG

- Sumitomo Chemical Co. Ltd.

- Dow Inc.

- Kumho Petrochemical Co. Ltd.

- Arkema S.A.

- LyondellBasell Industries N.V.

- Milliken & Company

- Galata Chemicals LLC

- Shandong Linyi Sunny Chemical Co. Ltd.

- Dorf Ketal Chemicals (I) Pvt. Ltd.

- Penn Color Inc.

- Addivant (now part of SI Group)

Frequently Asked Questions

What are anti-degradants and why are they important in industrial applications?

Anti-degradants are chemical additives designed to protect polymeric materials like plastics and rubbers from deterioration caused by environmental factors such as heat, UV light, oxygen, and mechanical stress. They are crucial for extending product lifespan, maintaining performance integrity, and enhancing safety in applications across automotive, construction, packaging, and electronics industries by preventing premature failure and property loss.

Which factors are primarily driving the growth of the anti-degradant market?

The market's growth is primarily driven by the escalating global demand for high-performance and durable materials across major end-use industries like automotive and construction. Additionally, the rapid expansion of global polymer production, stringent regulatory mandates for product quality and safety, increasing focus on material sustainability, and industrialization in emerging economies are significant contributing factors.

What are the key challenges faced by manufacturers in the anti-degradant market?

Manufacturers in the anti-degradant market face several challenges, including the volatility of raw material prices, which impacts production costs. Environmental concerns and stricter regulations regarding the toxicity and environmental impact of certain synthetic additives necessitate continuous R&D for safer alternatives. High investment in research for novel, eco-friendly, and multi-functional anti-degradants also presents a significant hurdle.

How is the anti-degradant market segmented by product type and end-use industry?

By product type, the market is segmented into antioxidants (primary, secondary), UV stabilizers (HALS, UV absorbers), antiozonants, flame retardants, and thermal stabilizers, among others. By end-use industry, key segments include automotive (tires, components), packaging (food, industrial), construction (pipes, roofing), electrical & electronics (wire, casings), agriculture, and textiles, reflecting diverse application needs.

What role does Artificial Intelligence (AI) play in the evolution of anti-degradant technology?

AI is increasingly pivotal in accelerating the discovery and design of new anti-degradant molecules through predictive modeling and simulation, significantly reducing R&D cycles. It optimizes existing formulations, identifies synergistic additive combinations, and helps in understanding complex degradation pathways. AI also enhances quality control, supply chain efficiency, and the development of more sustainable and personalized anti-degradant solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager