Aquaculture ROV Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438084 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Aquaculture ROV Market Size

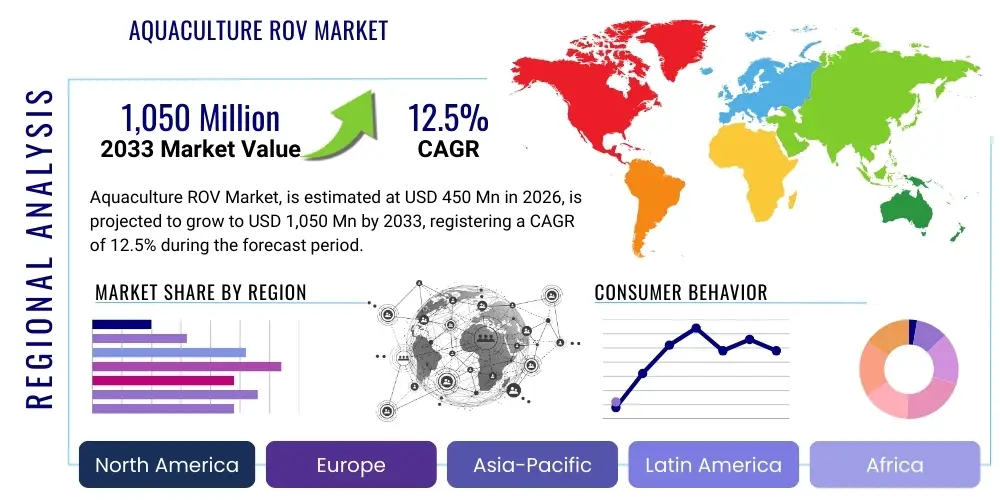

The Aquaculture ROV Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $1,050 Million by the end of the forecast period in 2033.

Aquaculture ROV Market introduction

The Aquaculture ROV (Remotely Operated Vehicle) Market involves the manufacturing and deployment of specialized underwater robots designed specifically for the rigorous demands of aquatic farming environments. These sophisticated systems are pivotal tools utilized across various facets of modern aquaculture, including the inspection of submerged infrastructure such as nets, cages, moorings, and pipelines, ensuring structural integrity and preventing environmental breaches. Furthermore, ROVs are increasingly integrated into daily operational tasks suchiding automated feeding management, precise cage cleaning to optimize water flow and fish health, and real-time biometric monitoring of fish stocks, minimizing the need for manual, diver-based interventions which can be costly and hazardous.

Major applications of Aquaculture ROVs span both open-sea and land-based recirculating aquaculture systems (RAS). In marine environments, ROVs enhance site management efficiency by providing high-definition visual and sensor-based data essential for preemptive maintenance and regulatory compliance. Key benefits include improved stock health surveillance through non-invasive inspection, substantial reduction in operational costs, and elevated safety standards for personnel. The continuous advancements in battery technology, sensor payload capacity, and navigational precision are solidifying the ROV's role as a cornerstone technology for sustainable and intensive aquaculture practices globally.

Driving factors fueling this market expansion include the escalating global demand for sustainable seafood, pressuring aquaculture operators to enhance production efficiency and minimize environmental footprint. Regulatory bodies are increasingly mandating stricter monitoring protocols, which ROVs are ideally suited to meet. Moreover, the shortage of skilled commercial divers, coupled with the inherent risks associated with underwater manual labor in challenging conditions, accelerates the adoption of automated robotic solutions, establishing the Aquaculture ROV as an indispensable asset in the transition towards highly automated, data-driven 'AquaFarming 4.0'.

Aquaculture ROV Market Executive Summary

The Aquaculture ROV market is experiencing robust growth driven by the convergence of sustainable seafood demand and technological advancements, positioning automation as essential for modern farm management. Business trends indicate a strong move toward hybrid and autonomous underwater vehicles (AUVs) integrated with advanced data analytics platforms, shifting the competitive focus from hardware sales to comprehensive data service provision. Key market players are concentrating on developing modular payloads, allowing the same ROV platform to handle diverse tasks from net inspection and fouling removal to precise environmental sensing, thereby increasing the return on investment for aquaculture producers. Consolidation in the vendor landscape, marked by strategic partnerships between traditional marine technology firms and specialized aquaculture software providers, is optimizing the development cycle and accelerating market penetration of advanced, integrated robotic solutions.

Regionally, the market is heavily influenced by the presence of large-scale salmon farming operations in Norway, Chile, and Canada, establishing these areas as early adopters and innovation hubs, particularly for deep-water and harsh-environment systems. Asia Pacific, driven by intensive coastal farming in China, Vietnam, and Southeast Asia, presents the fastest-growing segment, though adoption here is centered on smaller, more cost-effective inspection-class ROVs for near-shore applications. European regulations emphasizing fish welfare and environmental monitoring continue to propel technology adoption, whereas North America focuses on automating large, geographically dispersed offshore farms. These regional disparities dictate product specifications, with ruggedized, long-duration systems favored in high-latitude environments and compact, versatile units popular in the dense farming regions of APAC.

Segment trends highlight the dominance of the inspection and monitoring application segment, which utilizes small to medium-sized ROVs equipped with sophisticated cameras and sensors to ensure cage integrity and fish health. However, the largest growth trajectory is observed in the net cleaning and maintenance segment, where heavy-duty, specialized ROVs equipped with powerful jetting systems or rotating brushes drastically reduce reliance on manual cleaning. Propulsion system segmentation shows brushless DC motor technology gaining traction due to superior efficiency and reduced maintenance requirements. Furthermore, the increasing integration of machine vision and telemetry within ROV software packages is transforming raw inspection data into actionable operational insights, driving value beyond simple visual assessment.

AI Impact Analysis on Aquaculture ROV Market

User queries regarding the impact of Artificial Intelligence (AI) on the Aquaculture ROV Market frequently center on automation levels, data efficacy, and disease detection accuracy. Users are keen to understand how AI-driven image recognition models can autonomously assess fish biomass and detect early signs of stress or disease, minimizing manual oversight and maximizing early intervention. A major concern revolves around the robustness of AI algorithms in dynamic, low-visibility underwater environments and the subsequent requirement for massive, labeled training datasets specific to diverse aquatic species. Expectations are high that AI will transform ROVs from simple inspection tools into intelligent, decision-making platforms, capable of optimizing feeding schedules, navigating complex net structures autonomously, and generating predictive maintenance alerts for both the farm infrastructure and the ROV itself. This shift towards smart automation is viewed as the key driver for enhancing profitability and environmental sustainability in aquaculture.

- Autonomous Navigation and Task Execution: AI algorithms enable ROVs to plan optimal inspection routes, avoid obstacles such as mooring lines and fish schools, and execute complex tasks like net repair or component retrieval without continuous human joystick control.

- Biomass Estimation and Counting: Deep learning models analyze video feeds in real-time to accurately count fish and estimate average biomass, replacing less precise manual or acoustic methods, crucial for inventory management and harvesting planning.

- Early Disease and Stress Detection: Machine vision systems identify subtle behavioral anomalies, physical signs of lesions, or parasitic presence (e.g., sea lice), allowing farm managers to implement proactive health management strategies rapidly.

- Automated Net Health Assessment: AI processes sensor data from acoustic and visual inspections to automatically identify, classify, and quantify net damage, tear size, and biofouling levels, prioritizing maintenance needs efficiently.

- Optimized Feeding Regimes: AI analyzes fish behavior (appetite, aggregation patterns) captured by ROV cameras, correlating it with environmental factors (temperature, oxygen levels) to adjust feed disbursement rates in real-time, minimizing waste and maximizing feed conversion ratio (FCR).

- Predictive Maintenance for ROVs: AI analyzes operational data (motor strain, battery discharge, thruster efficiency) to predict potential component failures in the ROV itself, scheduling maintenance proactively and maximizing operational uptime.

- Environmental Monitoring and Compliance: AI integrates data from multiple ROV-mounted sensors (pH, dissolved oxygen, temperature) to create dynamic 3D models of the water column, ensuring compliance with environmental discharge regulations and optimizing cage placement.

DRO & Impact Forces Of Aquaculture ROV Market

The Aquaculture ROV Market is powerfully shaped by a dynamic interplay of Drivers (D), Restraints (R), Opportunities (O), and critical Impact Forces. The primary drivers revolve around the global imperative for food security and the need for higher yields from controlled environments, making automation an economic necessity. Restraints largely center on the significant initial capital expenditure required for sophisticated ROV fleets and the existing technological challenge of ensuring seamless data transmission in highly turbid or electromagnetically noisy deep-sea environments. Opportunities abound in integrating these robotics with Big Data platforms and AI for advanced predictive analytics, alongside expanding their use into emerging high-growth aquaculture sectors like seaweed and shellfish farming. The predominant impact forces compelling market transformation include stringent governmental regulations on fish welfare and environmental sustainability, which mandate the transparency and precision monitoring capabilities offered exclusively by ROV technology.

Key drivers sustaining market momentum include the escalating focus on minimizing operational risks associated with diving, such as decompression sickness and adverse weather conditions, alongside the consistent rise in labor costs within established aquaculture regions. The capabilities of modern ROVs to remain submerged for extended periods, operating autonomously or semi-autonomously, provide a clear competitive advantage over traditional methods, particularly in harsh or remote marine locations. Furthermore, the rising incidence of infectious diseases in densely populated fish farms necessitates continuous, non-invasive health monitoring, which ROV-mounted multispectral cameras and sensors are uniquely suited to perform, thus preventing catastrophic stock losses and ensuring food safety standards are upheld for consumer trust and international trade.

Conversely, significant restraints limit the pace of adoption, notably the requirement for specialized technical expertise to operate, maintain, and repair complex ROV systems, creating a skills gap among traditional farm personnel. High acquisition costs and the associated depreciation curve pose a barrier for smaller, independent farm operators who may struggle to justify the upfront investment without clear financing models or governmental subsidies. Technological hurdles also persist, including the limited endurance of battery systems for very long missions, the susceptibility of underwater sensors to biofouling, and the bandwidth limitations of acoustic or tethered communication links, which restrict the real-time processing of high-definition video and sensor data critical for AI applications. Addressing these constraints through standardization, leasing models, and user-friendly software interfaces is crucial for broad market expansion and saturation across diverse aquaculture geographies.

Segmentation Analysis

The Aquaculture ROV Market is strategically segmented based on several critical parameters including the type of vehicle, the application area, the propulsion system utilized, and the weight classification. This multi-dimensional segmentation provides a nuanced view of market dynamics, revealing where investment is currently concentrated and identifying niche areas poised for rapid technological adoption. The dominant segmentation by application reflects the essential role ROVs play across the entire aquaculture lifecycle, from initial site survey and cage installation to daily monitoring, feeding, and harvest preparation. Understanding these segments is vital for vendors to tailor their product offerings, focusing on payload capacity, depth rating, and maneuverability optimized for specific tasks like high-pressure cleaning or delicate sample collection.

- By Type:

- Small and Micro ROVs (Inspection Class)

- Medium ROVs (Observation and Light Work Class)

- Heavy Duty ROVs (Work Class for heavy maintenance and cleaning)

- By Application:

- Net and Cage Inspection and Monitoring

- Net Cleaning and Maintenance

- Automated Feeding Management

- Biomass Estimation and Inventory Management

- Environmental Monitoring (Water Quality, Seabed Surveys)

- Recovery and Retrieval Operations

- By Propulsion System:

- Electric Thrusters (Dominant due to efficiency)

- Hydraulic Thrusters (For heavy-duty work class systems)

- By Region:

- North America (U.S., Canada)

- Europe (Norway, U.K., Scotland, Mediterranean)

- Asia Pacific (China, Japan, South Korea, Vietnam, Australia)

- Latin America (Chile, Brazil)

- Middle East & Africa (MEA)

Value Chain Analysis For Aquaculture ROV Market

The value chain for the Aquaculture ROV market commences with the upstream analysis, dominated by component and material suppliers. This includes manufacturers of high-performance microprocessors, specialized deep-sea sensors (sonar, depth, temperature, HD cameras), advanced composite materials for hull construction, and efficient brushless DC electric motors and thruster components. Critical technological inputs, such as battery management systems and specialized underwater communication modems, form the foundation of ROV reliability. Key upstream activities involve stringent quality control and securing resilient supply chains for specialized electronics, where vendor relationships and geopolitical stability significantly influence production costs and timeframes for system integration.

The core midstream phase involves the ROV manufacturing and system integration. This phase is characterized by intense R&D focusing on software development (AI-driven control, image processing) and hydrodynamics to ensure stability and maneuverability. System integrators assemble the components, rigorously test performance in controlled environments, and develop proprietary software interfaces tailored for aquaculture operations. Distribution channels are varied, including direct sales from large manufacturers to major aquaculture conglomerates (Direct), specialized distributors or marine technology service providers who offer leasing and maintenance packages (Indirect), and sometimes third-party consulting firms that bundle ROVs with broader farm management solutions. The choice of channel depends heavily on the geographic location and the technical maturity of the end-user.

The downstream analysis focuses on the application and maintenance services delivered to the end-users. This involves the deployment, operation training, data processing, and ongoing system maintenance. Specialized service companies often emerge to provide "ROV-as-a-Service," reducing the capital expenditure burden on farmers. Data collected by the ROV—such as net integrity reports, fish health metrics, and environmental data—is processed into actionable insights, providing the ultimate value proposition. The effectiveness of the downstream segment relies heavily on robust after-sales support and the ability to rapidly diagnose and repair systems, minimizing costly downtime during critical farming cycles, ensuring high operational availability.

Aquaculture ROV Market Potential Customers

The primary End-Users/Buyers of Aquaculture ROV technology span the entire spectrum of global aquatic food production, ranging from multinational corporate entities managing extensive offshore salmon farms to smaller, localized businesses focusing on near-shore finfish or shellfish cultivation. Large-scale industrial aquaculture companies represent the highest volume buyers, often requiring fleets of heavy-duty work-class ROVs for continuous, high-intensity operations like deep-sea net cleaning and mooring inspection. These conglomerates prioritize reliability, data integration capabilities, and robust service contracts that ensure minimal operational disruption across their dispersed global sites, viewing the ROV investment as critical for scaling production and ensuring regulatory compliance across multiple jurisdictions.

Mid-sized and independent fish farms, particularly those focusing on high-value species like sea bass, sea bream, or specialized trout, are increasingly adopting inspection-class and light work-class ROVs. For this segment, the primary attraction is the ability to conduct cost-effective, daily visual inspections and health monitoring without relying on external diving contractors, significantly improving response times to issues like minor net tears or early signs of disease outbreaks. The affordability and ease of use associated with micro-ROVs, often controlled via intuitive tablet interfaces, make them highly appealing, focusing on maximizing fish welfare through frequent, non-stressful surveillance, thereby improving product quality and market competitiveness.

Furthermore, auxiliary users include marine research institutes, governmental regulatory bodies, and specialized marine engineering firms. Research institutes utilize ROVs for detailed biological surveys and environmental impact assessments around farming sites, contributing to sustainable practice guidelines. Regulatory bodies deploy them for independent compliance verification, ensuring that farms adhere to environmental protection standards and animal welfare mandates. Specialized engineering and salvage firms represent another niche customer base, utilizing ROVs for complex recovery operations or specialized subsea construction related to new cage installation or infrastructure decommissioning, requiring high-precision positioning and tool-manipulation capabilities beyond standard farm tasks.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $1,050 Million |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Saab Seaeye Ltd., Kongsberg Maritime, Deep Ocean Engineering, Inc., Ocean Robotics Group, VideoRay LLC, Subsea Tech, Innova AS, Outland Technology, Inc., N-O-V-A Group, Tritech International Ltd., Blueye Robotics, Aqua-Robotix, Remotely Operated Vehicle Solutions, S.L., Marine Advanced Research, Hydrovision International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aquaculture ROV Market Key Technology Landscape

The technological landscape of the Aquaculture ROV market is rapidly evolving, driven by the necessity for greater operational endurance, enhanced data acquisition quality, and increased autonomy. Current advancements are heavily focused on optimizing propulsion and energy storage. The widespread adoption of high-efficiency, oil-filled brushless DC electric thrusters has significantly improved maneuverability and reduced acoustic noise, which is critical for minimizing stress on fish stocks during close-proximity inspections. Concurrently, the transition to high-density lithium-ion battery packs and sophisticated battery management systems (BMS) is enabling longer mission durations, pushing the boundary toward true autonomous underwater vehicle (AUV) capabilities, particularly for large, spread-out offshore installations where constant tether management is impractical.

The market's competitive edge is increasingly determined by sensor payload technology and the intelligence embedded within the control software. Modern aquaculture ROVs routinely integrate advanced multi-frequency imaging sonar for navigation in low-visibility environments and high-resolution, low-light cameras specifically optimized for underwater videography. Furthermore, specialized sensors, including dissolved oxygen probes, pH meters, CTDs (Conductivity, Temperature, Depth), and fluorometers, are being miniaturized and integrated into compact platforms, providing real-time environmental data mapping crucial for compliance and optimizing fish health. The utilization of Fused Deposition Modeling (FDM) and other additive manufacturing techniques for prototyping and creating custom ROV components allows for rapid, cost-effective customization tailored to unique regional aquaculture requirements.

Crucially, the fusion of robotics with advanced computational technologies—specifically AI and Machine Learning—is defining the next generation of Aquaculture ROV operations. Machine vision algorithms are now standard for automated tasks such as fish counting, precise biomass estimation, and the immediate identification of net damage, often surpassing human accuracy and speed. This intelligence extends to advanced communication protocols, including high-speed acoustic modems and advanced fiber-optic tethers, ensuring the massive streams of sensor and video data can be reliably transmitted and processed in centralized cloud-based platforms. These integrated technologies facilitate predictive maintenance scheduling and provide farm managers with dashboard-style, actionable insights, transforming the role of the ROV from a simple tool to a core component of the farm’s comprehensive digital management ecosystem.

Regional Highlights

- Europe (Norway, Scotland, Mediterranean): Europe remains the leading market for high-value Aquaculture ROV systems, primarily driven by the massive offshore salmon farming industry in Norway and Scotland. Norwegian producers are pioneers in deep-water and exposed-site aquaculture, requiring the most technologically advanced, robust work-class ROVs for challenging net cleaning, lice treatment, and subsea infrastructure maintenance. Strict environmental and fish welfare regulations enforced by the European Union and national agencies necessitate continuous, high-fidelity monitoring, thereby guaranteeing a sustained demand for premium inspection-class vehicles and integrated data services. The region also acts as a primary innovation hub, hosting key market vendors and leading research institutions focused on developing AI-powered autonomous aquaculture solutions.

- Asia Pacific (China, Vietnam, Japan, Australia): APAC is projected to exhibit the highest growth rate, fueled by the vast scale of coastal aquaculture, particularly in China and Southeast Asia, which dominates global aquaculture production volume. Initial adoption is concentrated among small and micro-ROVs, due to lower operational depths and a greater emphasis on cost-efficiency. However, modernization efforts, especially in Australia and Japan's high-tech marine farming sectors, are rapidly increasing the demand for larger, feature-rich ROVs capable of biomass assessment and complex cage maintenance. Government initiatives promoting sustainable seafood practices and modernization of traditional farming methods are key accelerators for ROV uptake in emerging economies across the region.

- North America (U.S., Canada): The North American market is characterized by a strong focus on regulatory compliance and the burgeoning growth of offshore aquaculture ventures. In Canada, particularly British Columbia and the Atlantic provinces, ROVs are integral to managing fish health, preventing environmental escape, and adhering to rigorous governmental reporting standards for salmon farms. In the U.S., while marine aquaculture is nascent compared to Europe, expanding investment in sustainable offshore fish farming projects, especially in the Gulf of Mexico and coastal Pacific regions, is creating significant demand for heavy-duty, reliable ROV platforms for construction support, infrastructure inspection, and sophisticated real-time monitoring of large-scale, high-risk assets.

- Latin America (Chile): Chile represents a critical market segment due to its position as one of the world's largest salmon producers. The market here focuses heavily on efficiency and rapid response capabilities, particularly concerning net integrity and disease control, given the high density of farming operations. ROV deployment is essential for deep-sea operations and managing challenging weather conditions. Adoption is accelerating as farms seek to minimize reliance on costly and often unreliable external service providers, opting instead for in-house ROV teams to conduct routine inspections and net maintenance.

- Middle East and Africa (MEA): This region is an emerging market, driven primarily by government investment in diversifying food sources and establishing high-tech aquaculture projects in countries like Saudi Arabia and the UAE. While the current market size is smaller, the high capital expenditure budgets for these new, state-of-the-art facilities favor the immediate adoption of advanced, integrated ROV solutions for precision monitoring and automated farm management, bypassing older, traditional farming methodologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aquaculture ROV Market.- Saab Seaeye Ltd.

- Kongsberg Maritime

- Deep Ocean Engineering, Inc.

- Ocean Robotics Group

- VideoRay LLC

- Subsea Tech

- Innova AS

- Outland Technology, Inc.

- N-O-V-A Group

- Tritech International Ltd.

- Blueye Robotics

- Aqua-Robotix

- Remotely Operated Vehicle Solutions, S.L. (ROV Solutions)

- Marine Advanced Research

- Hydrovision International

- EvoLogics GmbH

- Seamor Marine Ltd.

- AC-CESS GmbH

- Underwater Vehicles Inc.

- I-Tech AB (Focusing on fouling control integration)

Frequently Asked Questions

Analyze common user questions about the Aquaculture ROV market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of Aquaculture ROVs in modern fish farming?

Aquaculture ROVs are primarily utilized for submerged infrastructure inspection, including nets, moorings, and pipelines; automated net cleaning and maintenance; real-time biomass estimation and fish counting; and environmental monitoring to ensure optimal water quality and regulatory compliance.

How does AI integration enhance the efficiency of Aquaculture ROVs?

AI integration enables autonomous navigation and task execution, reduces reliance on constant human control, and drives data intelligence through automated visual analysis for early disease detection, precise biomass measurement, and optimization of critical operational variables like feeding rates.

Which regional market holds the dominant share for high-value Aquaculture ROV systems?

Europe, specifically driven by the large-scale salmon farming industries in Norway and Scotland, holds the dominant market share for high-value and advanced work-class Aquaculture ROV systems due to stringent regulations and the operational demands of exposed, deep-water sites.

What are the main technical challenges currently facing ROV deployment in aquaculture?

The main technical challenges include overcoming limitations in battery endurance for long-duration autonomous missions, ensuring reliable high-bandwidth underwater communication for real-time data transfer, and mitigating sensor fouling in biologically dense marine environments.

Are micro-ROVs suitable for commercial aquaculture operations?

Yes, micro-ROVs (inspection class) are highly suitable for routine daily visual inspections, immediate damage assessment, and smaller near-shore farm operations due to their portability, ease of deployment, and significantly lower initial capital cost compared to large work-class vehicles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager