Aseptic Magnetic Mixer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439162 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Aseptic Magnetic Mixer Market Size

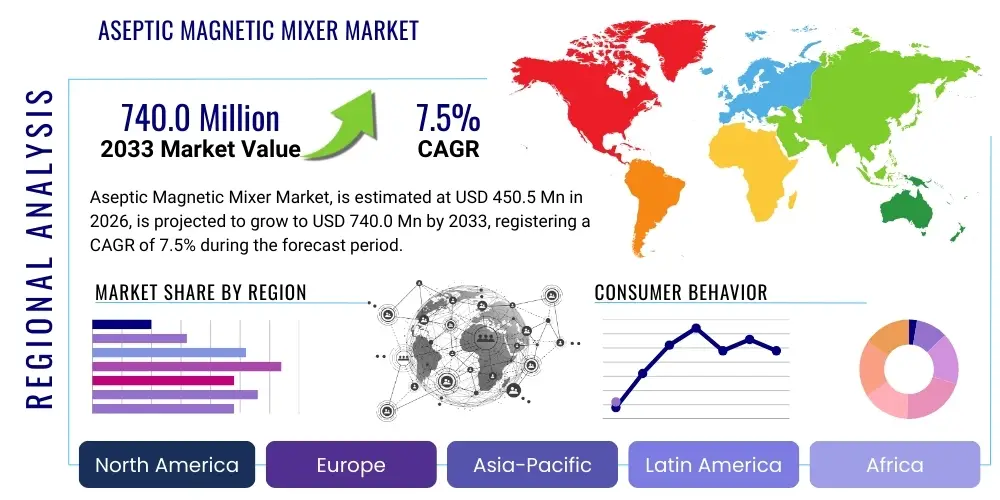

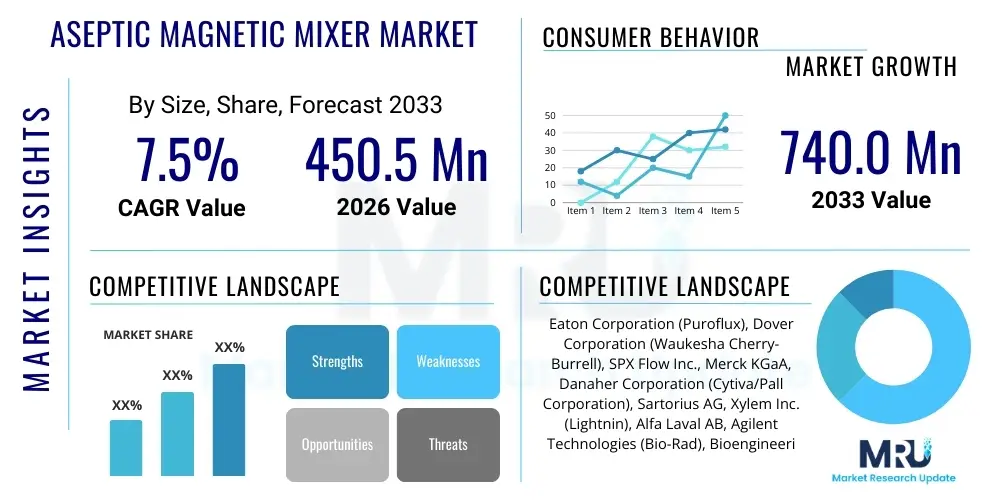

The Aseptic Magnetic Mixer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 740.0 Million by the end of the forecast period in 2033.

The substantial growth trajectory is underpinned by the increasing global demand for biopharmaceuticals, including monoclonal antibodies, cell therapies, and vaccines, which necessitate extremely sterile and contained processing environments. Aseptic magnetic mixers are instrumental in these operations, offering a critical solution for fluid handling and homogenization without the risk associated with conventional mechanical seals. The inherent design of these mixers, utilizing magnetic coupling, eliminates the shaft penetration through the vessel wall, thereby eradicating a primary pathway for contamination and ensuring compliance with Good Manufacturing Practices (GMP) and stringent regulatory guidelines.

Furthermore, market expansion is significantly driven by continuous technological advancements, particularly the integration of single-use (disposable) components compatible with aseptic magnetic mixing technologies. These disposable systems reduce cleaning validation time, minimize cross-contamination risks, and offer operational flexibility, making them highly attractive to contract manufacturing organizations (CMOs) and major pharmaceutical producers alike. The shift toward smaller batch production and personalized medicine also favors the adoption of highly scalable and contamination-proof mixing solutions like aseptic magnetic mixers.

Aseptic Magnetic Mixer Market introduction

The Aseptic Magnetic Mixer Market encompasses sophisticated equipment designed for critical mixing applications in sterile environments, primarily within the biotechnology, pharmaceutical, and high-purity food and beverage industries. These mixers utilize magnetic coupling to transmit torque from a drive unit positioned outside the sealed vessel to an impeller inside, ensuring that the integrity of the containment vessel remains unbroken. This design is paramount for maintaining aseptic conditions, preventing the ingress of microbial contaminants or external particles into sensitive product batches.

The primary applications of these mixers span critical processes such as buffer preparation, media formulation, fermentation, cell culture suspension, high-viscosity product blending, and final API formulation. Key benefits include zero leakage risk, enhanced product purity, reduced maintenance requirements compared to mechanically sealed mixers, and superior cleanability due to the absence of complex internal mechanisms. These advantages directly address the stringent quality requirements mandated by regulatory bodies like the FDA and EMA for injectable and high-ppurity drug products.

The market growth is fundamentally driven by the accelerated pipeline of biological drugs, the robust investments in large-scale vaccine manufacturing capabilities globally, and the consistent industry transition toward validated and automated processing equipment that minimizes human intervention and ensures batch reproducibility. The superior containment capabilities and the increasing adoption of large-volume single-use mixing bags compatible with magnetic impellers are major forces propelling market volume and value expansion.

Aseptic Magnetic Mixer Market Executive Summary

The Aseptic Magnetic Mixer Market is characterized by robust expansion driven by stringent global regulatory landscapes and the flourishing biopharmaceutical sector, particularly in specialized areas like gene therapy and personalized medicine. Business trends indicate a strong preference for hybrid systems that combine fixed stainless steel vessels with disposable magnetic mixing elements, balancing capital efficiency with operational flexibility. Key industry players are focusing on miniaturization and scalability, offering modular systems that cater to research and development scales through to commercial high-volume manufacturing, alongside integrating advanced sensors for real-time process monitoring and control.

Regionally, North America maintains market dominance due to high concentration of major biopharma companies, early technology adoption, and significant R&D spending. However, Asia Pacific (APAC) is emerging as the fastest-growing region, fueled by expanding domestic drug manufacturing capabilities in countries like China and India, increased foreign investment in biotechnology infrastructure, and improving regulatory harmonization. European market growth is stable, driven by established pharmaceutical hubs and high adherence to GMP standards.

Segment trends reveal that the Bottom Mount Aseptic Magnetic Mixer segment holds the largest share due to its efficiency in draining and mixing high-viscosity liquids, while the Single-Use segment is exhibiting the highest CAGR, reflective of the industry's widespread adoption of disposable solutions for speed and reduced validation overhead. The application segment remains heavily dominated by Biopharmaceuticals, underscoring the critical dependency of sterile drug manufacturing on this technology.

AI Impact Analysis on Aseptic Magnetic Mixer Market

User queries regarding AI integration in the Aseptic Magnetic Mixer Market typically revolve around process optimization, predictive maintenance, and quality assurance. Common concerns focus on whether AI can enhance mixing efficiency, predict impeller failure or bearing wear before catastrophic events occur, and automatically adjust parameters (like speed or shear rate) based on real-time analytical data (e.g., pH, dissolved oxygen, cell density). Users are keen to understand how AI-driven predictive analytics can reduce costly downtime, improve batch consistency, and streamline regulatory compliance by generating highly accurate, auditable process records. The key theme is leveraging advanced algorithms to transition from reactive maintenance and standardized processing to highly optimized, adaptive, and autonomous mixing operations within sterile production environments.

AI's primary impact will be transforming Aseptic Magnetic Mixers from purely mechanical components into smart, interconnected devices. By analyzing vast datasets generated during mixing cycles—including torque measurements, temperature profiles, and vibration analysis—AI algorithms can detect subtle anomalies indicative of impending equipment failure, thereby shifting maintenance schedules from time-based to condition-based. Furthermore, machine learning models can be utilized to fine-tune mixing protocols for complex biological media, ensuring optimal homogeneity and minimizing cell damage (shear stress) or aggregation, which is critical for sensitive products like viral vectors or stem cells.

- AI enhances predictive maintenance by analyzing vibration and torque signatures, minimizing unplanned downtime.

- Machine learning algorithms optimize mixing parameters based on real-time critical quality attributes (CQAs) of the bioprocess.

- Integration with digital twins allows for simulation and testing of complex mixing processes before physical implementation.

- AI supports enhanced inventory management of single-use magnetic impellers and drive units.

- Automated anomaly detection improves audit trails and supports regulatory compliance in sterile operations.

DRO & Impact Forces Of Aseptic Magnetic Mixer Market

The dynamics of the Aseptic Magnetic Mixer Market are shaped by powerful Drivers (D) such as the exponential growth in the biopharmaceutical industry, particularly in vaccine and monoclonal antibody manufacturing, necessitating high-purity fluid handling. Restraints (R) include the significantly high initial capital investment required for magnetic mixing systems compared to conventional mixers, alongside the technical complexity and specific expertise needed for maintenance and validation. Opportunities (O) lie in the increasing adoption of single-use technology compatible with magnetic mixing, expansion into developing markets in Asia Pacific, and integration of IoT and smart sensors for enhanced process control and automation.

The overall Impact Forces driving market progression are strongly positive. The critical need for zero-contamination risk in sterile manufacturing environments overrides the high cost restraint, especially in the context of high-value biological products where batch failure is financially catastrophic. Furthermore, the regulatory environment is constantly tightening, making solutions that inherently reduce contamination risk, like aseptic magnetic mixers, essential infrastructure rather than optional upgrades. These forces compel sustained investment in advanced mixing technology across global pharmaceutical manufacturing supply chains.

- Drivers:

- Stringent regulatory requirements for sterile processing (FDA, EMA).

- Rapid expansion of the biopharmaceutical sector, notably biologics and cell therapies.

- Increasing adoption of single-use manufacturing systems demanding aseptic fluid transfer.

- Restraints:

- High initial capital expenditure and cost of proprietary magnetic drive systems.

- Limitations in handling extremely high-viscosity fluids or large-scale legacy stainless steel tanks (in some models).

- Complex maintenance and specialized technical expertise required for magnetic bearing systems.

- Opportunities:

- Development of miniaturized and highly integrated mixers for bench-scale and continuous processing.

- Market penetration in emerging economies focusing on local drug production.

- Technological advancements in bearing materials (e.g., ceramics) enhancing durability and cleanability.

- Impact Forces:

- High Product Purity Requirements (Strong Positive Impact).

- Technological Innovation and Automation (Moderate Positive Impact).

- Capital Costs (Moderate Negative Impact).

Segmentation Analysis

The Aseptic Magnetic Mixer Market is comprehensively segmented based on technology type, material, application, and operating scale, allowing for precise market tracking and strategic planning. The core differentiation lies between stainless steel reusable systems and single-use disposable systems, reflecting the industry's hybrid approach to manufacturing efficiency. Segmentation by application highlights the dependence of the biopharmaceutical industry on these mixers for various stages of drug development and production, while segmentation by mounting type (Top Mount vs. Bottom Mount) addresses specific engineering requirements related to agitation intensity, vessel geometry, and drainage efficiency.

Understanding these segments is crucial as technological adoption rates vary significantly; for instance, smaller biotech startups often prefer single-use systems for speed and low validation costs, whereas large, established pharmaceutical companies may rely on validated stainless steel systems for high-volume legacy production. The continuing innovation in impeller design, bearing technology (such as ceramic or PEEK bearings), and drive unit power efficiency further refine these segments, offering specialized solutions for high-shear mixing, low-shear gentle blending, and continuous mixing processes essential for modern pharmaceutical manufacturing practices.

- By Type:

- Bottom Mount Mixers (BMM)

- Top Mount Mixers (TMM)

- By Technology:

- Reusable (Stainless Steel/Fixed) Systems

- Single-Use (Disposable) Systems

- By End-User Application:

- Biopharmaceutical Manufacturing

- Vaccine Production

- Monoclonal Antibodies (mAbs)

- Cell and Gene Therapy Production

- Buffer and Media Preparation

- Food and Beverage Processing (High Purity)

- Cosmetics and Personal Care

- Chemical and Specialty API Synthesis

- By Operating Scale:

- Laboratory Scale (1L to 50L)

- Pilot Scale (50L to 500L)

- Commercial Scale (500L to 20,000L+)

Value Chain Analysis For Aseptic Magnetic Mixer Market

The value chain for the Aseptic Magnetic Mixer Market begins with upstream activities involving the sourcing of highly specialized materials, including high-grade stainless steel (316L), advanced plastics (such as PTFE and PEEK for impellers and bearings), and high-strength permanent magnets (e.g., Neodymium). Critical upstream processing involves precision engineering and machining to ensure tight tolerances, especially for the impeller-bearing interface and magnetic drive coupling, which directly impacts aseptic integrity and mixing performance. Suppliers of high-purity, validated components constitute a crucial element of the upstream segment, ensuring adherence to USP Class VI standards.

Midstream activities focus on core manufacturing, assembly, and rigorous testing, including sterilization validation and Factory Acceptance Testing (FAT). Distribution channels are predominantly direct sales to major pharmaceutical manufacturers and CMOs due to the highly technical nature of the product, requiring specialized installation and validation support. Indirect channels include authorized distributors or specialized laboratory equipment suppliers who manage regional sales, often targeting smaller biotech firms or academic research institutions. The downstream segment involves installation, operational qualification (OQ), performance qualification (PQ), and long-term service and maintenance contracts, particularly important for reusable stainless steel systems.

The high complexity and necessity of validation documentation mean that direct distribution channels are often preferred, allowing manufacturers to maintain tight control over product quality and providing necessary expert support throughout the equipment lifecycle. For single-use systems, the distribution chain also involves logistical management of disposable bags and impellers, often bundled with broader bioprocess consumables contracts. Success in the downstream market is heavily reliant on providing robust technical support, rapid spare parts availability, and comprehensive validation packages that accelerate the customer's time to market.

Aseptic Magnetic Mixer Market Potential Customers

The primary end-users and buyers of Aseptic Magnetic Mixers are entities operating under strict regulatory oversight where contamination prevention is non-negotiable, specifically organizations involved in manufacturing products intended for human administration or consumption. The largest customer segment comprises global pharmaceutical and biotechnology companies specializing in the production of complex biological medicines, including vaccines, insulin, human growth hormones, and cutting-edge therapeutics like CAR T-cells.

Contract Development and Manufacturing Organizations (CDMOs) and Contract Manufacturing Organizations (CMOs) represent a rapidly expanding customer base. These organizations require flexible, validated, and often disposable mixing solutions to serve multiple clients and diverse product pipelines efficiently, driving demand for single-use aseptic magnetic mixing technology. Furthermore, specialized entities in the food and beverage industry focused on high-purity ingredients, dairy alternatives, and nutraceuticals, along with high-end cosmetic manufacturers, also constitute significant potential customers, seeking solutions to minimize spoilage and extend shelf life through superior sterile processing.

Academic and governmental research institutions, while smaller in volume, are important customers for laboratory and pilot-scale units used in early-stage formulation studies and process development. The driving factor for all these buyers remains compliance, product integrity, and the minimization of batch loss due to microbial contamination, justifying the higher investment associated with aseptic magnetic technology compared to standard industrial mixers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 740.0 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation (Puroflux), Dover Corporation (Waukesha Cherry-Burrell), SPX Flow Inc., Merck KGaA, Danaher Corporation (Cytiva/Pall Corporation), Sartorius AG, Xylem Inc. (Lightnin), Alfa Laval AB, Agilent Technologies (Bio-Rad), Bioengineering AG, Steridose (a SPX FLOW Brand), ChargePoint Technology, Bionet Engineering, LevTech (A Thermo Fisher Brand), T-T Pumps, Saint-Gobain, Mixer Direct, Milton Roy. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Aseptic Magnetic Mixer Market Key Technology Landscape

The technological landscape of the Aseptic Magnetic Mixer Market is defined by innovation aimed at improving efficiency, scalability, and integration with disposable systems while minimizing shear stress on delicate biological products. A key technology is the development of robust, high-performance ceramic and engineered polymer (e.g., PEEK) bearing materials, which offer superior resistance to corrosion, wear, and cleaning agents compared to traditional materials, thereby extending the service life and maintaining particle-free operation required for aseptic processes. Furthermore, advanced impeller designs, such as hydrofoil and proprietary axial flow designs, are engineered to provide efficient mixing at low shear rates, critical for preserving cell viability in bioprocessing applications.

Another major technological driver is the maturation of single-use magnetic mixing technology. This involves designing specialized disposable polyethylene bags (bioreactor bags) integrated with pre-sterilized magnetic impellers and bearing assemblies. The single-use format drastically reduces capital investment in cleaning-in-place (CIP) and sterilization-in-place (SIP) infrastructure, accelerating batch turnaround times. Manufacturers are also focusing on designing drive units capable of handling a wider range of volumes and viscosities, often incorporating advanced controls and variable speed drives (VSDs) for precise power delivery and optimal process flexibility across different applications.

Integration of Smart Manufacturing principles, including IoT connectivity and sensor technology, represents the forward-looking technological trend. Modern aseptic magnetic mixers often incorporate embedded torque sensors, vibration monitoring systems, and connectivity modules that feed real-time performance data into central process control systems. This enables sophisticated control algorithms, enhances predictive maintenance capabilities, and ensures continuous validation of the mixing process, aligning with industry 4.0 standards and further solidifying the equipment's role as a critical component of validated bioprocess lines.

Regional Highlights

The global Aseptic Magnetic Mixer Market exhibits varied growth patterns influenced by regional pharmaceutical investment, regulatory stringency, and biotechnology adoption rates. North America, encompassing the United States and Canada, holds the dominant market share. This is attributed to the presence of world-leading pharmaceutical and biotechnology companies, substantial R&D expenditure on novel biologics, strong government support for drug innovation, and the early and extensive adoption of single-use technologies in biomanufacturing. High demand for cell and gene therapy manufacturing infrastructure further cements North America's leadership position.

Europe represents the second-largest market, characterized by mature pharmaceutical manufacturing bases in Germany, Switzerland, Ireland, and the UK. The market growth here is driven by strict adherence to EMA guidelines, continuous facility modernization efforts, and a strong focus on high-quality, high-purity drug production. The push toward sustainable manufacturing also encourages the replacement of older, less efficient mechanical mixers with modern, aseptic magnetic systems that reduce downtime and environmental impact.

Asia Pacific (APAC) is projected to experience the highest growth rate during the forecast period. This rapid expansion is fueled by massive investments in local biomanufacturing capacity in China, India, and South Korea, aiming to satisfy local demand and become global contract manufacturing hubs. Government initiatives promoting biotechnology, increasing healthcare spending, and rising foreign direct investment in local pharmaceutical infrastructure are key catalysts for the robust demand for aseptic processing equipment across the region. Latin America and the Middle East & Africa (MEA) markets are gradually expanding, supported by regional public health initiatives and increasing localized vaccine production efforts.

- North America: Dominant market share due to high biopharmaceutical R&D expenditure and widespread adoption of single-use mixing technology.

- Europe: Stable growth driven by stringent regulatory compliance (EMA) and modernization of established pharmaceutical facilities.

- Asia Pacific (APAC): Fastest-growing region, fueled by capacity expansion in China, India, and South Korea for biologics and vaccines manufacturing.

- Latin America: Emerging market driven by local generic drug production and increasing investments in localized vaccine development.

- Middle East and Africa (MEA): Growth stimulated by regional efforts to improve healthcare infrastructure and reduce reliance on imported pharmaceuticals.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Aseptic Magnetic Mixer Market.- Eaton Corporation (Puroflux)

- Dover Corporation (Waukesha Cherry-Burrell)

- SPX Flow Inc.

- Merck KGaA

- Danaher Corporation (Cytiva/Pall Corporation)

- Sartorius AG

- Xylem Inc. (Lightnin)

- Alfa Laval AB

- Bioengineering AG

- Steridose (a SPX FLOW Brand)

- ChargePoint Technology

- Bionet Engineering

- LevTech (A Thermo Fisher Brand)

- Saint-Gobain

- Mixer Direct

- Milton Roy

- Bredel (Watson-Marlow Fluid Technology Solutions)

- GEA Group Aktiengesellschaft

- Andritz Group

- IDEX Corporation

Frequently Asked Questions

Analyze common user questions about the Aseptic Magnetic Mixer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of an aseptic magnetic mixer over a conventional mechanical mixer?

The primary advantage is the elimination of the mechanical seal by utilizing magnetic coupling, ensuring hermetic sealing of the vessel. This prevents shaft penetration, eradicating the main entry point for microbial contamination and safeguarding product sterility crucial for biopharmaceutical processing.

How do single-use aseptic magnetic mixers impact pharmaceutical manufacturing costs and efficiency?

Single-use systems significantly reduce operational costs and increase efficiency by eliminating the time, resources, and validation required for Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP) protocols. They also minimize the risk of cross-contamination between batches, leading to faster turnaround and higher batch success rates.

Which application segment drives the highest demand for aseptic magnetic mixers?

The Biopharmaceutical Manufacturing segment, particularly for the production of vaccines, monoclonal antibodies, and cell culture media preparation, drives the highest demand due to the absolute requirement for sterile processing environments and compliance with stringent GMP standards enforced globally.

What are the typical maintenance considerations for aseptic magnetic mixers, especially regarding bearings?

Maintenance primarily focuses on monitoring bearing wear, often using advanced materials like ceramics or PEEK for extended life. Predictive maintenance driven by vibration analysis is increasingly utilized to anticipate bearing or impeller failure, ensuring optimal performance and minimizing unscheduled downtime, which is significantly less frequent than the maintenance required for complex mechanical seals.

Is the Aseptic Magnetic Mixer Market seeing adoption in non-pharmaceutical industries?

Yes, while biopharma is the largest user, the technology is increasingly adopted in high-purity sectors such as specialized food and beverage (e.g., aseptic dairy alternatives) and high-end cosmetics, where preventing microbial ingress is crucial for product quality, safety, and regulatory compliance.

The Aseptic Magnetic Mixer Market continues to evolve rapidly, responding to increasing global demand for sterile processed products, particularly within the advanced therapy medicinal products (ATMPs) sector. Innovation focusing on higher torque capacity, compatibility with large-volume single-use systems, and integration with real-time process monitoring tools defines the competitive landscape. Suppliers are strategically expanding their global service and validation support networks to cater to the growing demand in emerging APAC markets, further solidifying the technology's irreplaceable role in modern biomanufacturing infrastructure. Future growth is strongly linked to successful scale-up of novel biologics and the transition towards modular, flexible manufacturing footprints.

The development of ultra-low shear magnetic mixing solutions is particularly relevant for sensitive cell culture applications, ensuring high cell viability during suspension and transfer operations. Furthermore, standardization efforts across the industry for magnetic impeller interfaces are critical to facilitate seamless integration of components from different suppliers within a single-use assembly. This push for interoperability aids in reducing supply chain risks and encourages broader adoption of the technology across both large-scale commercial facilities and small, agile biotech labs. Regulatory acceptance of these single-use assemblies has significantly accelerated market penetration, establishing aseptic magnetic mixing as the gold standard for contained, sterile fluid dynamics.

Technological advancement is not limited to mechanical components; the magnetic drive units themselves are becoming more energy-efficient and powerful. Utilizing advanced motor controls and rare-earth magnets, modern drive systems provide greater mixing control precision, critical for achieving batch consistency in highly regulated environments. The long-term trajectory suggests a complete transition away from conventional mechanical sealing systems in critical sterile applications, cementing the magnetic mixer's essential status throughout the entire biomanufacturing lifecycle, from upstream media preparation to downstream final formulation steps.

Market analysts project significant consolidation among key players as companies seek to offer comprehensive, integrated bioprocessing solutions that include not only the mixer but also bioreactors, filtration units, and associated single-use consumables. Strategic mergers and acquisitions targeting niche technology providers focused on advanced materials science or specialized sensor integration are anticipated to enhance competitive advantage. This vertical integration strategy aims to simplify the procurement and validation process for end-users, especially large CDMOs managing complex and varied client projects.

The necessity for robust supply chain management, particularly regarding the proprietary components of the magnetic coupling and the sterile single-use impeller assemblies, is a critical operational consideration for market participants. Geopolitical stability and reliable sourcing of raw materials, such as high-purity stainless steel and specialized polymers, are constantly being monitored to ensure uninterrupted production capacity to meet the accelerating global pharmaceutical demand. Investment in regional manufacturing hubs outside of established areas like North America and Europe is a clear trend to mitigate logistical risks and capitalize on local market growth opportunities.

Finally, environmental sustainability concerns are beginning to influence product design. While single-use systems offer aseptic advantages, the resultant plastic waste generation is a growing concern. Manufacturers are actively exploring bio-based or recyclable polymer materials for single-use magnetic mixing components and packaging to align with broader corporate social responsibility goals and impending environmental regulations in key markets, balancing the non-negotiable sterility requirements with sustainable practices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager