Atomizing Copper Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439934 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Atomizing Copper Powder Market Size

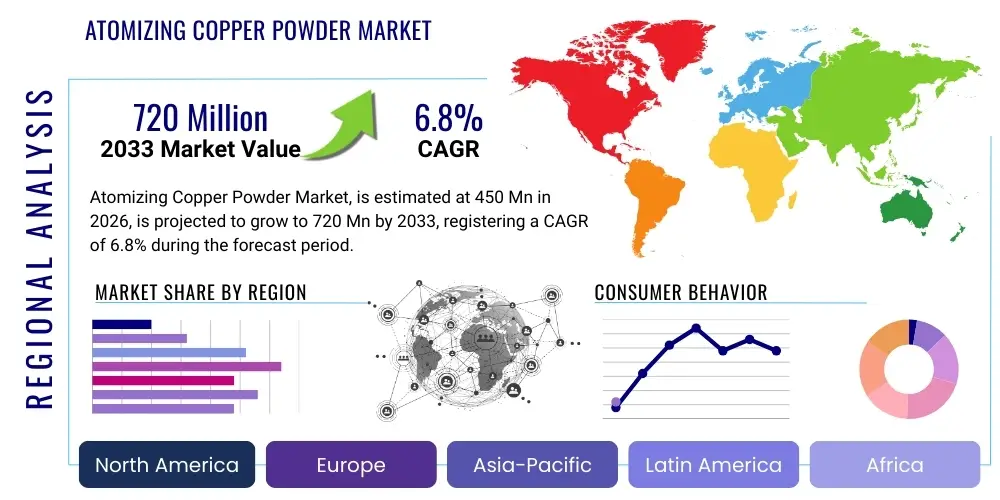

The Atomizing Copper Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 720 Million by the end of the forecast period in 2033.

Atomizing Copper Powder Market introduction

The atomizing copper powder market encompasses the production and distribution of finely divided copper particles manufactured through atomization processes. Atomization involves melting copper or copper alloys and then rapidly breaking the molten stream into fine droplets using high-pressure gas or water, which then solidify into spherical or irregular powder particles. This method is preferred for producing high-purity powders with controlled particle size distribution and morphology, crucial for a wide array of high-performance applications across various industrial sectors. The precise control over particle characteristics allows for tailored material properties, making atomized copper powders indispensable in modern manufacturing. The market's growth is inherently linked to advancements in technologies that demand superior material performance and reliability.

Atomizing copper powder finds its primary applications in industries such as additive manufacturing (3D printing), where its spherical shape and high purity are ideal for laser and electron beam melting processes to create complex geometries. It is also extensively used in electrical and electronics for conductive pastes, thermal management solutions, and electromagnetic shielding due to its excellent electrical and thermal conductivity. Furthermore, the automotive sector utilizes these powders for components requiring high strength, wear resistance, and efficient heat dissipation, while powder metallurgy processes leverage them for fabricating intricate parts with minimal waste. The versatility of atomized copper powder, coupled with its superior metallurgical properties compared to other copper powder production methods, positions it as a critical material for advanced engineering applications.

The benefits of atomized copper powder include enhanced material density, superior mechanical properties, improved thermal and electrical conductivity, and greater flowability, particularly important for processes like additive manufacturing. These characteristics contribute to the production of high-quality, durable, and efficient end-products. Key driving factors for market expansion include the surging demand from the rapidly expanding additive manufacturing industry, the continuous innovation and miniaturization in the electronics sector, and the increasing focus on lightweighting and performance enhancement in the automotive industry. Additionally, the growing adoption of renewable energy technologies and electric vehicles, which require advanced conductive and thermal management materials, further propels the demand for atomized copper powder, establishing its foundational role in future industrial advancements.

Atomizing Copper Powder Market Executive Summary

The Atomizing Copper Powder Market is experiencing robust growth driven by significant advancements in manufacturing technologies and an escalating demand for high-performance materials across diverse sectors. Current business trends indicate a strong push towards customization and specialized powder formulations to meet the specific requirements of sophisticated applications, particularly in areas like 3D printing and advanced electronics. Manufacturers are investing heavily in research and development to improve powder purity, optimize particle size distribution, and enhance flowability, aiming to provide superior materials that enable more efficient and reliable end-products. Strategic collaborations between powder producers and end-use industries are becoming more prevalent, fostering innovation and accelerating market adoption. Furthermore, the emphasis on sustainability and circular economy principles is prompting producers to explore more energy-efficient atomization processes and investigate recycling initiatives for copper, influencing overall market dynamics and driving operational efficiencies.

Regionally, the Asia Pacific continues to dominate the market, propelled by its robust manufacturing base, significant investments in electronics and automotive industries, and rapid adoption of additive manufacturing technologies, especially in countries like China, Japan, and South Korea. North America and Europe are also experiencing substantial growth, primarily driven by strong R&D activities, the increasing penetration of advanced manufacturing techniques, and a burgeoning demand for high-end industrial components. These regions benefit from established industrial infrastructures and a strong focus on high-value applications in aerospace, medical, and specialized industrial machinery. Emerging economies in Latin America and the Middle East & Africa are showing promising growth potential, albeit from a smaller base, as industrialization efforts and technological advancements begin to take hold, creating new demand avenues for sophisticated metallic powders.

In terms of segmentation, the market for atomizing copper powder is predominantly influenced by its end-use applications. The additive manufacturing segment is projected to exhibit the highest growth rate, fueled by the expanding use of 3D printing for prototyping, tooling, and functional parts in various industries. The electrical and electronics sector remains a cornerstone of demand, with copper powders critical for manufacturing conductive inks, printed circuit boards, and thermal interfaces in next-generation devices. The powder metallurgy segment also maintains a substantial share, providing cost-effective solutions for complex component production in automotive and industrial machinery. Within types, pure copper powder commands a larger share due to its excellent intrinsic properties, while copper alloy powders are gaining traction for applications requiring specific mechanical or corrosion resistance characteristics. These segment trends underscore the market's dynamic nature and its responsiveness to technological shifts and evolving industrial requirements.

AI Impact Analysis on Atomizing Copper Powder Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Atomizing Copper Powder Market frequently revolve around themes of process optimization, material innovation, and predictive analytics. Users are keen to understand how AI can enhance the efficiency and precision of the atomization process itself, from controlling melt parameters to predicting particle size distribution with greater accuracy. There is significant interest in AI's role in accelerating the discovery and development of novel copper alloy compositions suitable for specific high-performance applications, effectively reducing research cycles and costs. Furthermore, concerns often surface about the potential for AI to revolutionize quality control, enable proactive maintenance of production equipment, and provide deeper insights into market trends and supply chain dynamics, ultimately leading to more agile and responsive manufacturing operations within the industry. These questions highlight a clear expectation that AI will act as a transformative force, driving efficiencies and innovation.

The integration of AI technologies is expected to bring about a paradigm shift in the manufacturing of atomizing copper powder, particularly through advanced data analysis. AI algorithms can process vast amounts of sensor data collected during the atomization process, including melt temperature, gas pressure, nozzle design, and cooling rates, to identify optimal parameters for producing powders with desired characteristics. This level of granular control, previously unattainable through traditional methods, allows for precise tailoring of particle morphology, size distribution, and chemical purity, directly addressing the stringent requirements of high-value applications like aerospace and medical implants. Predictive modeling powered by AI can forecast equipment failures, optimize maintenance schedules, and reduce downtime, significantly improving overall operational efficiency and reducing production costs. Moreover, AI-driven process simulation can accelerate the development of new powder formulations, reducing the need for extensive physical prototyping.

Beyond the manufacturing floor, AI's influence extends to market strategy and product development. By analyzing global market data, demand forecasts, and technological trends, AI can provide manufacturers with actionable insights into emerging application areas and customer needs, guiding strategic investments in R&D and production capacity. AI can also facilitate intelligent supply chain management by predicting raw material price fluctuations, optimizing inventory levels, and identifying potential supply chain disruptions, thereby enhancing resilience and cost-effectiveness. The capability of AI to correlate material properties with end-product performance will enable a more sophisticated approach to material design, fostering a new generation of atomized copper powders specifically engineered for advanced functionality. The long-term impact points towards a more automated, intelligent, and responsive atomizing copper powder industry, capable of meeting evolving demands with unprecedented precision and efficiency.

- Process Optimization: AI-driven control systems can optimize atomization parameters like melt temperature, gas flow, and nozzle geometry in real-time to achieve precise particle size distribution, morphology, and purity, reducing material waste and energy consumption.

- Predictive Quality Control: Machine learning models analyze in-process data to predict and prevent quality deviations, ensuring consistent product quality without extensive post-production testing and significantly improving yield rates.

- Accelerated Material Development: AI algorithms can screen vast material databases and simulate new alloy compositions, drastically shortening the R&D cycle for developing specialized atomized copper powders with enhanced properties for specific applications.

- Equipment Predictive Maintenance: AI monitors sensor data from atomization equipment to predict potential failures, enabling proactive maintenance, reducing costly downtime, and extending the operational lifespan of machinery.

- Market & Supply Chain Intelligence: AI analyzes market trends, customer demands, and global supply chain data to provide insights for strategic decision-making, optimizing production schedules, inventory management, and raw material procurement.

DRO & Impact Forces Of Atomizing Copper Powder Market

The Atomizing Copper Powder Market is shaped by a complex interplay of driving forces, inherent restraints, and emerging opportunities, all of which are subject to various impact forces that can significantly alter market trajectories. A primary driver is the burgeoning demand from additive manufacturing (3D printing) across industries like aerospace, automotive, and healthcare, which relies heavily on spherical, high-purity metal powders for intricate part fabrication. The electronics industry's relentless pursuit of miniaturization and enhanced performance also fuels demand, as atomized copper powders are critical for conductive inks, thermal interfaces, and electromagnetic shielding. Furthermore, the global shift towards electric vehicles (EVs) and renewable energy solutions necessitates advanced thermal and electrical management materials, directly boosting the consumption of these specialized powders. These drivers collectively create a robust growth environment, pushing manufacturers to innovate and expand production capacities to meet the evolving technological landscape.

Despite strong growth drivers, the market faces several significant restraints. The high capital investment required for atomization equipment and associated infrastructure poses a barrier to entry for new players, limiting market competitiveness. The production process itself is energy-intensive, leading to relatively high manufacturing costs compared to other powder production methods, which can impact pricing and end-user adoption in cost-sensitive applications. Furthermore, the volatility of copper raw material prices on global commodity markets introduces uncertainty in production costs and profitability, necessitating effective risk management strategies. Stringent quality control requirements for high-performance applications, particularly in aerospace and medical sectors, add to the complexity and cost of production, as any deviation in powder characteristics can compromise the integrity of the final product. These restraints mandate continuous innovation in process efficiency and cost reduction to sustain market momentum.

Opportunities for growth are abundant within the Atomizing Copper Powder Market, primarily stemming from continuous technological advancements and the exploration of new application areas. The development of advanced atomization techniques promising higher yields, finer powders, and reduced energy consumption presents significant opportunities for market leaders. Furthermore, the expansion into niche applications such as medical implants, where biocompatibility and high strength are paramount, and the development of next-generation 5G communication technologies, which require superior thermal and electrical performance, offer substantial growth avenues. Regional market expansion into developing economies, coupled with increased investment in localized manufacturing capabilities, provides additional avenues for market penetration. The increasing focus on circular economy principles and sustainable manufacturing also opens doors for innovations in recycling atomized copper powder and developing more environmentally friendly production methods, promising long-term market resilience and growth. These opportunities, when strategically pursued, can significantly mitigate the impact of existing restraints and propel the market forward.

Segmentation Analysis

The Atomizing Copper Powder market is meticulously segmented to provide a granular understanding of its diverse landscape, reflecting variations in product type, application areas, and the intricate manufacturing processes involved. This segmentation allows for targeted market analysis, identifying high-growth segments and specific industry demands. The product types differentiate between pure copper powders and various copper alloy powders, each with unique properties tailored for distinct functional requirements. Application segments delineate the primary end-use industries, highlighting sectors that are driving the most significant demand and exhibiting the highest growth potential. Understanding these segments is crucial for stakeholders to tailor their product offerings, develop strategic marketing initiatives, and allocate resources effectively, ensuring alignment with market needs and optimizing their competitive positioning within this dynamic industry.

- By Type: This segment categorizes atomizing copper powder based on its composition, distinguishing between pure copper and various copper alloys.

- Pure Copper Powder: Characterized by its high electrical and thermal conductivity, corrosion resistance, and ductility, making it ideal for electrical components, heat sinks, and conductive pastes. Its unalloyed nature ensures maximum intrinsic properties for demanding applications.

- Copper Alloy Powder: These powders combine copper with other elements like tin, zinc, nickel, or aluminum to enhance specific properties such as strength, wear resistance, or machinability.

- Brass Powder: An alloy of copper and zinc, valued for its strength, corrosion resistance, and good machinability, used in decorative items, bearings, and porous filters.

- Bronze Powder: Typically an alloy of copper and tin, offering excellent wear resistance, lubricity, and strength, widely used in bearings, bushings, and structural parts in powder metallurgy.

- Others: Includes specialized alloys like Cu-Ni (for high temperature and corrosion resistance), Cu-Fe (for strength and hardness), and Cu-Cr-Zr (for high conductivity and strength at elevated temperatures), catering to highly specific industrial needs.

- By Application: This segment focuses on the diverse industries and uses where atomizing copper powder is predominantly employed.

- Additive Manufacturing (3D Printing): The fastest-growing segment, utilizing atomized copper powder for producing complex, high-density components with intricate geometries in aerospace, medical, and automotive sectors, driven by demand for rapid prototyping and functional parts.

- Electrical & Electronics: A cornerstone application, where atomized copper powder is crucial for conductive inks, pastes for printed circuit boards (PCBs), electromagnetic interference (EMI) shielding, and thermal management solutions in various electronic devices.

- Metallurgy (Powder Metallurgy & Brazing): Used extensively in powder metallurgy for manufacturing intricate parts with high precision and minimal waste, such as gears, bearings, and structural components. In brazing, it serves as a filler material for joining metal parts.

- Automotive: Applied in the production of lightweight, high-performance components like engine parts, brake pads, and electrical contacts, contributing to fuel efficiency and enhanced vehicle performance.

- Chemical: Utilized as a catalyst in various chemical reactions, as well as in the production of pigments, anti-fouling paints, and other specialized chemical formulations due to its reactive properties.

- Others: Includes diverse applications such as medical implants (biocompatible alloys), defense, general industrial machinery, and decorative coatings, each leveraging the specific properties of atomized copper powder.

- By Production Method: While the report specifically focuses on "Atomizing" copper powder, within atomization there are different methods, primarily differentiated by the medium used to break the molten metal.

- Water Atomization: Involves using high-pressure water jets to disintegrate molten metal, typically producing irregular-shaped powders suitable for conventional powder metallurgy.

- Gas Atomization: Employs high-pressure inert gas (e.g., nitrogen, argon) to atomize molten metal, resulting in highly spherical and finer powders, preferred for additive manufacturing and advanced electronics.

- Others: Includes specialized or less common atomization methods like centrifugal atomization or plasma atomization, used for specific powder characteristics or niche applications.

Value Chain Analysis For Atomizing Copper Powder Market

The value chain for the Atomizing Copper Powder market is an intricate network that begins with the extraction and refining of raw materials and extends through various processing stages to the final application by end-users. The upstream segment primarily involves the mining of copper ore, followed by refining processes to produce high-purity copper cathodes or ingots. This initial stage is critical as the quality and purity of the primary copper directly impact the characteristics of the final powder. Key players in this segment are global mining giants and large-scale copper refineries. Given the capital-intensive nature of mining and refining, this segment significantly influences the cost structure and supply stability of raw copper, which in turn affects the pricing and availability of atomizing copper powder. Therefore, robust supplier relationships and long-term contracts are essential for powder manufacturers to ensure consistent and high-quality raw material supply.

The midstream of the value chain is dominated by the powder manufacturing process itself, where refined copper is melted and then atomized using gas or water to produce fine metallic powders. This stage requires specialized equipment, advanced technical expertise, and stringent quality control to achieve the desired particle size distribution, morphology, and chemical purity. Powder manufacturers often invest heavily in research and development to optimize atomization processes, develop proprietary alloy compositions, and enhance powder characteristics for specific applications. After atomization, the powders undergo further processing steps such as sieving, blending, and sometimes surface treatment to meet application-specific requirements. These manufacturers then distribute their products through various channels to downstream industries, acting as the critical link between raw material suppliers and end-users, adding significant value through their specialized processing capabilities and technical know-how.

The downstream segment encompasses the distribution channels and the end-user industries where atomizing copper powder is consumed. Distribution can be both direct, where large powder manufacturers supply directly to major industrial clients like additive manufacturing service bureaus or large electronics companies, and indirect, involving distributors and agents who cater to smaller businesses or specialized niche markets. Direct sales channels allow for closer collaboration and customized solutions, while indirect channels provide broader market reach and logistical support. The end-users of atomizing copper powder are diverse, including additive manufacturing, electrical and electronics, automotive, powder metallurgy, and chemical sectors. Each industry leverages the unique properties of these powders to create high-performance components and products. Strong relationships with these end-users, understanding their evolving needs, and providing technical support are paramount for sustained market success and product innovation within the atomizing copper powder value chain.

Atomizing Copper Powder Market Potential Customers

Potential customers for atomizing copper powder span a broad spectrum of advanced manufacturing and technological industries, each seeking specific material properties to enhance their product performance and production efficiency. The primary end-users are those involved in additive manufacturing (3D printing), including aerospace and defense contractors, medical device manufacturers, and automotive prototyping firms, who leverage the powder's spherical morphology and high purity to produce complex, high-strength, and lightweight components. These customers often require highly customized powder specifications, demanding precise particle size distributions and alloy compositions to achieve optimal print quality and mechanical properties in their final products. The growing trend of digital manufacturing and on-demand production within these sectors ensures a continuous and increasing demand for specialized atomized copper powders, driving innovation in material science and processing techniques to meet evolving application requirements.

Another significant customer base resides within the electrical and electronics sector, encompassing manufacturers of printed circuit boards (PCBs), semiconductor devices, thermal management solutions, and electromagnetic shielding components. These industries value atomized copper powder for its exceptional electrical and thermal conductivity, which is critical for creating efficient and reliable electronic devices. Companies producing conductive inks and pastes for flexible electronics, sensors, and solar cells also represent key customers, relying on the fine and uniform particle size of atomized powder for consistent electrical performance and printability. As electronic devices become more compact and powerful, the demand for advanced thermal dissipation materials and miniaturized conductive elements intensifies, making atomized copper powder an indispensable material for future electronic innovations and advancements.

Furthermore, the automotive industry, particularly manufacturers focused on electric vehicles (EVs) and lightweighting initiatives, constitutes a rapidly expanding customer segment. These customers utilize atomized copper powder for high-performance electrical contacts, efficient motor components, and thermal management systems in battery packs and power electronics, contributing to improved vehicle efficiency and range. Traditional powder metallurgy companies, producing intricate and durable components for industrial machinery, bearings, and braking systems, also remain vital customers, valuing the cost-effectiveness and design flexibility offered by copper powder metallurgy. The chemical industry, using copper powder as a catalyst or for pigments, and the medical sector, requiring biocompatible copper alloys for implants and instruments, further diversify the customer landscape, demonstrating the widespread utility and strategic importance of atomizing copper powder across high-value industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 720 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GKN Sinter Metals, Höganäs AB, Sandvik AB, Sumitomo Electric Industries, JX Nippon Mining & Metals Corporation, Fukuda Metal Foil & Powder Co., Ltd., Umicore, SCAM S.A., ECKA Granules GmbH, Makin Metal Powders (UK) Ltd., Pometon S.p.A., AMETEK Inc., Nanjing Zhongbo New Material Technology Co., Ltd., CNPC Powder Co., Ltd., Beijing Xing Rong Wuxi New Materials Co., Ltd., H.C. Starck Solutions, Metalor Technologies SA, Gripmaterial Co.,Ltd., Mitsubishi Materials Corporation, Reade International Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Atomizing Copper Powder Market Key Technology Landscape

The key technology landscape for the Atomizing Copper Powder Market is characterized by continuous innovation aimed at enhancing powder quality, optimizing production efficiency, and developing specialized materials for advanced applications. At the core are the atomization techniques themselves, primarily gas atomization and water atomization, which have undergone significant refinement. Gas atomization, using high-pressure inert gases like argon or nitrogen, is predominantly favored for producing highly spherical, fine powders with low oxygen content, crucial for demanding applications such as additive manufacturing and advanced electronics. Recent technological advancements in gas atomization focus on optimizing nozzle designs, controlling gas flow dynamics, and improving cooling rates to achieve even finer particle sizes and tighter size distributions, thereby expanding its applicability in micro-electronics and precision engineering. This method's ability to produce highly consistent and flowable powders underpins its strategic importance in the market.

Water atomization, while typically yielding more irregular-shaped powders, continues to be a vital technology, particularly for conventional powder metallurgy applications where inter-particle interlocking is beneficial. Innovations in water atomization are centered on developing hybrid systems that combine elements of both gas and water atomization to achieve a wider range of particle morphologies and characteristics. Furthermore, advancements in process control and automation, often leveraging artificial intelligence and machine learning, are becoming increasingly prevalent across all atomization methods. These smart systems monitor critical parameters in real-time, predict potential deviations, and adjust operating conditions to maintain consistent product quality and optimize energy consumption. The integration of sensors, data analytics, and predictive modeling is transforming atomization facilities into highly efficient and responsive manufacturing environments, significantly reducing waste and improving overall yield.

Beyond the core atomization processes, advancements in post-processing technologies are also pivotal. Techniques such as spheroidization, surface modification, and advanced sieving and classification systems are crucial for tailoring powder properties to specific end-use requirements. Spheroidization, for instance, can enhance the flowability of irregularly shaped powders, making them suitable for some additive manufacturing processes. Surface treatments improve properties like corrosion resistance or adherence to polymer matrices. Moreover, the development of advanced characterization techniques, including laser diffraction for particle size analysis, scanning electron microscopy (SEM) for morphology, and inductively coupled plasma (ICP) for elemental composition, is essential for ensuring the high quality and performance demanded by sophisticated applications. These technological advancements collectively contribute to the market's ability to supply high-quality, customized atomizing copper powders that meet the stringent requirements of rapidly evolving industrial sectors.

Regional Highlights

- Asia Pacific (APAC): Dominates the Atomizing Copper Powder Market, driven by the presence of a robust manufacturing sector, particularly in electronics, automotive, and a rapidly expanding additive manufacturing industry. Countries like China, Japan, South Korea, and India are key contributors due to significant investments in industrialization and technological advancements, coupled with high demand for advanced materials in consumer electronics and electric vehicles.

- North America: A significant market characterized by strong R&D capabilities, high adoption of additive manufacturing in aerospace and defense, and a robust medical device industry. The United States is a leading consumer, driven by innovation in advanced materials and a growing emphasis on high-performance components for critical applications.

- Europe: Exhibits substantial growth, fueled by stringent environmental regulations promoting sustainable manufacturing and a strong focus on advanced engineering and automotive industries in countries such as Germany, France, and the UK. The region is a hub for innovation in powder metallurgy and high-performance alloys, contributing to sustained demand.

- Germany: A powerhouse in European manufacturing, with a strong automotive industry and a growing presence in additive manufacturing, driving demand for high-quality atomized copper powders for both conventional and advanced applications.

- United Kingdom: A key market in Europe, with significant research and development in additive manufacturing and aerospace, fostering innovation and adoption of advanced metallic powders.

- China: The largest market in APAC and globally, benefiting from its extensive electronics manufacturing base, rapid expansion of electric vehicle production, and substantial government support for additive manufacturing technologies.

- Japan: A technological leader in electronics, automotive, and robotics, demonstrating consistent demand for atomized copper powder for high-precision and high-performance components.

- South Korea: A major player in the global electronics and automotive industries, driving the adoption of advanced materials including atomized copper powders for next-generation products.

- India: An emerging market with growing industrialization, increasing investments in infrastructure, electronics, and automotive sectors, signaling potential for future growth in atomized copper powder consumption.

- Latin America: Showing nascent but growing demand, particularly in countries like Brazil and Mexico, due to expanding manufacturing capabilities and increasing foreign investments in automotive and electronics production.

- Middle East & Africa (MEA): Represents an emerging market with potential, driven by diversification efforts from oil-dependent economies into manufacturing, infrastructure development, and defense sectors, though starting from a lower base compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Atomizing Copper Powder Market.- GKN Sinter Metals

- Höganäs AB

- Sandvik AB

- Sumitomo Electric Industries

- JX Nippon Mining & Metals Corporation

- Fukuda Metal Foil & Powder Co., Ltd.

- Umicore

- SCAM S.A.

- ECKA Granules GmbH

- Makin Metal Powders (UK) Ltd.

- Pometon S.p.A.

- AMETEK Inc.

- Nanjing Zhongbo New Material Technology Co., Ltd.

- CNPC Powder Co., Ltd.

- Beijing Xing Rong Wuxi New Materials Co., Ltd.

- H.C. Starck Solutions

- Metalor Technologies SA

- Gripmaterial Co.,Ltd.

- Mitsubishi Materials Corporation

- Reade International Corp.

Frequently Asked Questions

Analyze common user questions about the Atomizing Copper Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is atomizing copper powder and its primary production methods?

Atomizing copper powder consists of fine copper particles produced by disintegrating molten copper or copper alloys using high-pressure gas (gas atomization) or water (water atomization). Gas atomization typically yields spherical powders ideal for additive manufacturing, while water atomization often produces irregular-shaped powders used in conventional powder metallurgy. These methods ensure controlled particle size and morphology, crucial for high-performance applications across various industries.

Which industries are the largest consumers of atomizing copper powder?

The largest consumers are the additive manufacturing (3D printing) sector, due to its demand for high-purity, spherical powders for complex geometries; the electrical and electronics industry, for conductive pastes, thermal management, and EMI shielding; and the automotive sector, for lightweight components and electrical systems. Powder metallurgy and chemical industries also represent significant end-users, leveraging the unique properties of these powders for diverse applications.

What are the key drivers for the growth of the atomizing copper powder market?

Key drivers include the rapid expansion of additive manufacturing, increasing demand from the electronics sector for miniaturized and high-performance components, and the growing adoption of electric vehicles and renewable energy technologies which require advanced conductive and thermal materials. Additionally, advancements in powder metallurgy and the need for lightweight, durable materials across industrial applications further propel market growth.

What challenges does the atomizing copper powder market face?

Challenges include high production costs associated with advanced atomization equipment and energy-intensive processes, significant capital investment barriers for new entrants, and the volatility of raw material (copper) prices. Meeting stringent quality control standards for high-performance applications also adds complexity and cost, requiring continuous technological improvements and efficient operational management to overcome these hurdles.

How is AI impacting the atomizing copper powder manufacturing process?

AI is transforming the manufacturing process by enabling real-time optimization of atomization parameters, leading to more precise control over particle characteristics and reduced waste. It facilitates predictive quality control to ensure consistent product quality, accelerates the development of new alloy formulations, and powers predictive maintenance for equipment, significantly enhancing efficiency, innovation, and cost-effectiveness across the entire production lifecycle.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager