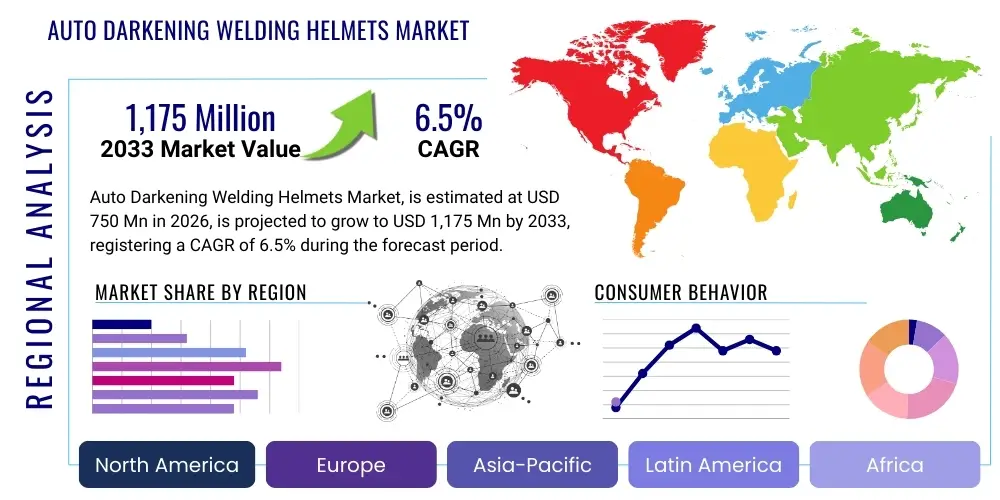

Auto Darkening Welding Helmets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436545 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Auto Darkening Welding Helmets Market Size

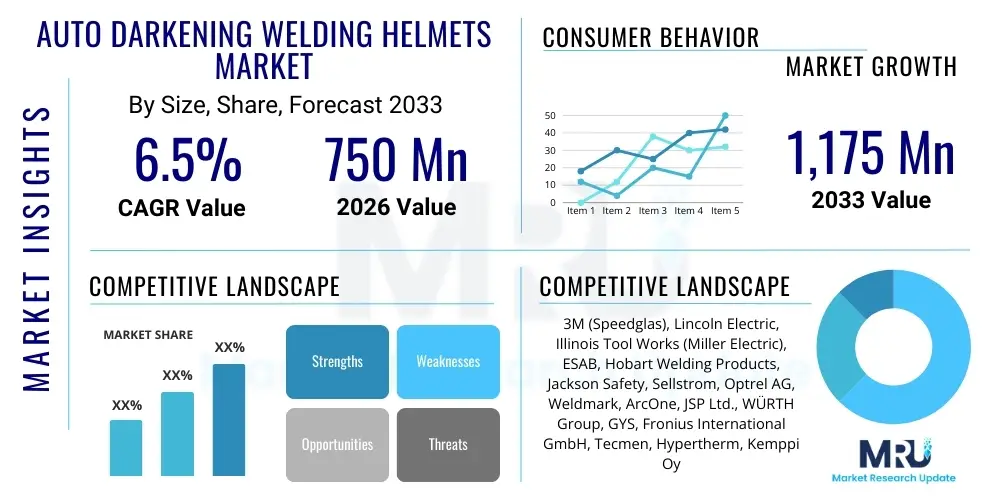

The Auto Darkening Welding Helmets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $750 Million USD in 2026 and is projected to reach $1,175 Million USD by the end of the forecast period in 2033.

Auto Darkening Welding Helmets Market introduction

The Auto Darkening Welding Helmets Market encompasses protective gear utilizing Liquid Crystal Display (LCD) technology and sophisticated optical sensors to automatically detect the electric arc produced during welding. These helmets instantaneously transition from a light resting shade (typically Shade 3 or 4) to a predetermined dark shade (typically Shade 9 to 13) within milliseconds of arc initiation, ensuring optimal protection for the welder’s eyes and face against harmful ultraviolet (UV) and infrared (IR) radiation. This technology represents a significant advancement over traditional passive welding helmets, which require the user to manually flip the visor, thereby reducing operational downtime and significantly enhancing worker safety and weld quality, particularly in demanding industrial environments where precision is paramount.

Key applications of these advanced safety devices span a broad spectrum of heavy and precision industries, including shipbuilding, automotive manufacturing, infrastructure construction, pipeline welding, and aerospace fabrication. The core benefit driving market penetration is the enhanced productivity achieved by allowing welders to maintain the helmet in the down position constantly, facilitating easier setup and positioning of the electrode before striking the arc. Furthermore, modern auto-darkening helmets often incorporate features such as True Color Technology, grind mode, and highly adjustable sensitivity controls, making them versatile tools suitable for various welding processes like Stick (SMAW), TIG (GTAW), MIG (GMAW), and Plasma Arc Welding (PAW), thereby addressing the diverse needs of professional fabricators globally.

The market is primarily driven by increasingly stringent global occupational safety regulations mandated by organizations like OSHA (Occupational Safety and Health Administration) and ISO. Moreover, the accelerating rate of industrialization in emerging economies, coupled with significant investments in infrastructure projects worldwide, elevates the demand for high-quality, reliable personal protective equipment (PPE). The continuous technological evolution in LCD response times, the integration of advanced ergonomics, and improvements in battery efficiency (often incorporating solar assist features) are further contributing factors fostering sustained market expansion, making these helmets indispensable tools in the modern welding profession.

Auto Darkening Welding Helmets Market Executive Summary

The global Auto Darkening Welding Helmets Market exhibits robust growth, primarily propelled by global regulatory pressures emphasizing worker safety and the increasing adoption of automated and specialized welding techniques across industrial sectors. Current business trends indicate a strong consumer preference shift toward premium models offering superior optical clarity (1/1/1/1 optical rating) and advanced features such as X-Mode technology, which prevents false triggering from sunlight or adjacent welding arcs. Manufacturers are focusing on reducing the overall weight of the helmets while enhancing durability and incorporating customizable digital controls, catering to the professional welder who spends extended periods under the hood and requires maximum comfort alongside uncompromising protection.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market, largely due to rapid infrastructure development, robust growth in the automotive sector in countries like China and India, and the consequential high volume of fabrication activities. North America and Europe, while mature, maintain high demand driven by strict adherence to ANSI and CE standards, respectively, and a strong focus on replacing older, passive equipment with technologically superior auto-darkening models. Segmentally, the professional/industrial application segment maintains the largest market share, though the DIY/hobbyist segment is expanding rapidly, fueled by the availability of cost-effective, entry-level auto-darkening solutions and increasing general interest in fabrication and repair projects.

Segmentation trends reveal that filter technology based on reaction speed and optical class remains critical. Furthermore, there is a clear market polarization between high-specification helmets designed for specialized, high-amperage industrial applications (demanding large viewing areas and advanced sensors) and general-purpose helmets used in maintenance and light fabrication. The integration of respiratory protection (Powered Air Purifying Respirators or PAPR systems) with auto-darkening features is also emerging as a significant segment trend, addressing the need for comprehensive protection against welding fumes and particulates in confined or high-risk environments, thereby presenting substantial revenue opportunities for integrated safety solution providers.

AI Impact Analysis on Auto Darkening Welding Helmets Market

User inquiries regarding the impact of Artificial Intelligence (AI) on Auto Darkening Welding Helmets predominantly revolve around enhancing core safety features, improving welding quality, and integrating predictive maintenance into PPE. Common themes include the potential for AI algorithms to analyze and optimize the shading level dynamically based on real-time arc intensity fluctuations, preventing eye strain more effectively than traditional fixed-response sensors. Users are also keen on AI-driven vision systems embedded within the helmet that could monitor electrode travel speed, consistency, and potential weld defects (like porosity or undercut) in real-time, providing immediate haptic or visual feedback to the welder, transforming the helmet from a passive protective device into an active quality assurance tool.

The integration of machine learning could revolutionize safety protocol compliance. By embedding microprocessors capable of running lightweight AI models, helmets could learn specific operational patterns of the welder, identifying fatigue, deviation from standard procedures, or proximity to environmental hazards (e.g., proximity to high heat sources outside the weld zone). Such systems could trigger alerts, log operational data for safety audits, and even temporarily lockout or adjust equipment settings if critical safety thresholds are breached. This shift addresses major user concerns about human error being the primary cause of welding accidents and quality issues, pushing the market toward smart, interconnected PPE solutions that enhance both worker performance and site safety management.

Furthermore, AI-powered predictive maintenance functionalities are gaining traction. By continuously monitoring the performance parameters of the helmet's internal components—such as battery life, sensor efficacy, LCD response time degradation, and shell integrity—AI can forecast component failures before they occur. This is particularly valuable for large industrial users operating hundreds of helmets, allowing for scheduled replacement of critical parts, minimizing unexpected equipment downtime, and ensuring consistent compliance with mandated safety standards throughout the equipment lifecycle. The long-term expectation is that AI will make auto-darkening helmets more intelligent, personalized, and integral to the wider Industrial Internet of Things (IIoT) ecosystem on the manufacturing floor.

- Real-time dynamic shading adjustment based on instantaneous arc energy analysis, enhancing visual comfort and minimizing eye fatigue.

- Embedded vision systems utilizing computer vision algorithms for real-time weld quality monitoring and defect detection.

- Predictive maintenance alerts for LCD filter degradation, sensor malfunction, or battery failure, optimizing equipment upkeep.

- AI-driven monitoring of welder posture and fatigue levels, providing actionable safety alerts to prevent injuries.

- Integration with Augmented Reality (AR) displays for projecting welding parameters, instructional overlays, or quality metrics directly onto the viewing area.

- Automated compliance logging, documenting usage data, and adherence to required shading levels for auditing purposes.

- Enhanced sensor calibration processes utilizing machine learning to distinguish true arc strikes from environmental interference more reliably (improving X-Mode technology performance).

DRO & Impact Forces Of Auto Darkening Welding Helmets Market

The Auto Darkening Welding Helmets Market is fundamentally driven by increasingly stringent global occupational safety standards and a persistent trend toward process automation requiring higher precision. Key drivers include mandatory regulations (like ANSI Z87.1 in the US and EN 379 in Europe) that necessitate the use of advanced eye protection, coupled with significant infrastructural investment, particularly in developing economies, which generates high demand for welding consumables and associated safety gear. The technological advancement offering features such as True Color filtration, superior optical ratings (1/1/1/1), and integration with PAPR systems further accelerates adoption, as industries seek holistic safety solutions that improve productivity while mitigating long-term health risks associated with fumes and UV/IR exposure.

Restraints, however, pose significant challenges to market expansion. High initial investment costs for premium, fully featured auto-darkening helmets, especially those incorporating PAPR units, can be prohibitive for small and medium enterprises (SMEs) or individual contractors in price-sensitive regions. Furthermore, the reliance on complex electronic components, including LCD filters and microprocessors, introduces durability concerns and potential maintenance costs not associated with traditional passive helmets. Counterfeit and low-quality products flooding the market, particularly in Asia, undermine consumer confidence in the technology’s reliability and compliance with established safety standards, forcing manufacturers to invest heavily in brand differentiation and educating end-users about certified compliance.

Opportunities abound, primarily focused on technological integration and penetrating untapped specialized markets. The development of lighter, more comfortable ergonomic designs tailored for niche applications, such as overhead welding or confined space operations, presents lucrative pathways. Furthermore, the opportunity to integrate advanced connectivity features (IoT, Bluetooth) for data logging, remote monitoring, and firmware updates positions these helmets within the smart factory ecosystem. Impact forces are high, characterized by substantial regulatory momentum and rapid technological obsolescence of basic models. The necessity for advanced protection in high-amperage and exotic material welding environments ensures that the market for premium, certified auto-darkening technology will maintain strong upward pressure, offsetting restraints related to price and complexity through demonstrable safety and productivity gains.

Segmentation Analysis

The Auto Darkening Welding Helmets Market is comprehensively segmented based on technology type, power source, viewing area size, and end-user application, allowing manufacturers to target specific operational requirements with tailored products. The primary segmentation centers on the filter type, specifically differentiating between Fixed Shade and Variable Shade filters, with the latter dominating the professional segment due to its versatility across multiple welding processes. The Variable Shade segment is further refined by the optical clarity rating (ranging from 1/1/1/1 to 1/3/3/3), which serves as a critical purchasing criterion for experienced welders focused on reducing distortion and enhancing long-term visual comfort.

Segmentation by end-user application delineates the market into Industrial/Professional use and Do-It-Yourself (DIY)/Hobbyist use. The Industrial segment, encompassing heavy fabrication, construction, and automotive sectors, dictates demand for high-duty cycle performance, superior sensor sensitivity, and compliance with stringent environmental standards (often requiring integrated PAPR systems). Conversely, the DIY segment values affordability, lightweight construction, and ease of use, often settling for lower optical clarity ratings and fixed battery systems, which are sufficient for intermittent, low-amperage tasks typical of home workshops.

Further granularity is achieved through segmentation by the power source, including Battery Powered (primary/replaceable), Solar Powered (with replaceable backup batteries), and purely Solar Assist (which acts as a supplemental charger to an integrated battery). The trend favors integrated solar assist mechanisms, as they significantly extend operational life and reduce the frequency of manual battery replacement, contributing to better sustainability profiles. Understanding these segmented demands enables manufacturers to optimize product portfolios, distribution strategies, and pricing models to effectively capture market share across different proficiency levels and budgetary constraints.

- By Technology Type:

- Fixed Shade Helmets

- Variable Shade Helmets (Shade 9-13, Shade 5-8/9-13)

- By Viewing Area Size:

- Standard Viewing Area (Less than 9 Sq. Inches)

- Large Viewing Area (9 to 12 Sq. Inches)

- Extra-Large Viewing Area (More than 12 Sq. Inches)

- By Power Source:

- Battery Powered (Replaceable)

- Solar Powered/Solar Assist

- By End-User Application:

- Industrial/Professional (Automotive, Construction, Shipbuilding, Aerospace)

- DIY/Hobbyist

- By Integration:

- Standard Helmets

- PAPR Integrated Helmets (Powered Air Purifying Respirator)

- By Optical Class:

- Class 1/1/1/1 (Highest Optical Clarity)

- Class 1/2/1/2 or Lower

Value Chain Analysis For Auto Darkening Welding Helmets Market

The value chain for the Auto Darkening Welding Helmets Market begins with upstream activities focused on securing specialized raw materials, primarily high-impact resistant polymer resins (like nylon or polycarbonate) for the helmet shell, and highly specialized Liquid Crystal Display (LCD) filters and proprietary electronic sensor components. LCD manufacturing is a critical bottleneck, requiring specialized expertise in electro-optics and rapid switching technology to achieve the necessary response times and optical clarity ratings. Relationships with suppliers for precision optics, microprocessors, and sophisticated sensor arrays are crucial, as the performance and certification of the final product hinge entirely on the quality and reliability of these core inputs.

Midstream activities involve the complex assembly and integration of these sensitive components within the helmet shell, including the implementation of ergonomic headgear systems and rigorous quality control testing for response time, UV/IR filtration, and compliance with international standards (e.g., impact resistance tests). Manufacturing processes are characterized by high levels of automation for shell molding and sophisticated cleanroom assembly for the electronic filters. Companies often differentiate themselves at this stage through proprietary filter technologies, such as advanced lens coatings or True Color spectrum enhancement, adding significant value and commanding premium pricing based on certified performance metrics.

Downstream activities involve extensive distribution networks, utilizing both direct sales channels for major industrial clients requiring custom-branded safety gear and indirect channels through large industrial distributors, specialized welding supply stores, and increasingly, e-commerce platforms targeting the DIY and small professional segments. The complexity of the product—requiring education on proper use, maintenance, and compliance—makes robust technical support and aftermarket service vital. Indirect distribution, leveraging the expansive geographical reach of major safety and industrial supply houses (like Grainger or Fastenal), remains the dominant mode for reaching the fragmented end-user base. Marketing efforts heavily rely on demonstration of safety certification, ergonomic benefits, and superior optical performance to justify the higher cost associated with auto-darkening technology over passive alternatives.

Auto Darkening Welding Helmets Market Potential Customers

The primary customer base for Auto Darkening Welding Helmets consists of professional welders and fabricators operating within capital-intensive industries where high standards of safety and productivity are mandated. Key end-users include major players in the automotive sector (both assembly and component manufacturing), which utilizes specialized welding processes for body panels and chassis construction; the oil and gas industry, requiring robust helmets for pipeline welding and infrastructure maintenance in harsh environments; and large-scale construction and infrastructure projects, such as bridge and building erection, where high-duty cycle performance is essential for continuous operation.

Secondary, yet rapidly expanding, customer segments include maintenance, repair, and overhaul (MRO) departments across diverse manufacturing facilities, general fabrication workshops, and specialized precision industries like aerospace and defense. Aerospace customers, for instance, demand the highest optical clarity and extreme sensitivity for welding exotic materials (e.g., titanium, aluminum alloys) using TIG processes. Furthermore, the market encompasses technical education and vocational training institutions globally, which are increasingly adopting auto-darkening technology to ensure students learn best practices using modern, industry-standard equipment, fostering future market growth.

A burgeoning segment involves the residential and small-scale commercial sector, including hobbyists, DIY enthusiasts, and small automotive repair shops. While these users typically opt for entry-level, cost-effective models, their high volume and increasing awareness of welding safety contribute significantly to the overall market volume. Manufacturers are tailoring specific product lines to meet the less stringent duty cycle requirements and lower budget constraints of this segment, often focusing on lightweight design and user-friendly features suitable for intermittent use.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million USD |

| Market Forecast in 2033 | $1,175 Million USD |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M (Speedglas), Lincoln Electric, Illinois Tool Works (Miller Electric), ESAB, Hobart Welding Products, Jackson Safety, Sellstrom, Optrel AG, Weldmark, ArcOne, JSP Ltd., WÜRTH Group, GYS, Fronius International GmbH, Tecmen, Hypertherm, Kemppi Oy, Jasic Technology, Riland Technology, Voestalpine Böhler Welding. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Auto Darkening Welding Helmets Market Key Technology Landscape

The technological evolution of Auto Darkening Welding Helmets is centered on three core areas: enhancing visual quality, improving sensor reliability, and maximizing welder comfort through advanced ergonomics and integrated safety systems. The most significant advancement is the widespread adoption of True Color Technology (TCT), which utilizes specialized LCD filters and coatings to allow a more natural color perception in the light state (and a better defined green/yellow hue in the dark state). Unlike older monochrome filters that presented a dull green view, TCT improves the welder's ability to distinguish colors and read instruments, leading to better puddle control, reduced eye strain over long shifts, and higher overall weld quality. This feature is becoming a standard expectation in premium professional-grade helmets, establishing a new benchmark for optical performance.

Another crucial technological development is the implementation of advanced sensing mechanisms, such as X-Mode or electromagnetic sensing. Traditional helmets rely solely on photo sensors that detect light intensity, making them susceptible to false darkening or flickering when working outdoors in sunlight or when adjacent welders strike an arc. X-Mode technology addresses this by sensing the electromagnetic interference generated by the welding arc itself, ensuring the filter darkens only when a true arc is struck, independent of external light sources. This reliability boost is critical for specialized applications, such as TIG welding at low amperages, where arc starts can be intermittent, demanding highly precise sensor activation.

Furthermore, innovation in power management and integration is driving the landscape. The widespread integration of solar assist panels combined with replaceable lithium batteries ensures extended operational lifespans and reliability. Ergonomics is also leveraged through advanced materials science, resulting in lightweight, impact-resistant thermoplastic shells that reduce neck strain, coupled with highly adjustable, cushioned headgear designed to distribute weight evenly. Finally, the growing market for PAPR integrated systems, which draw air through a filter unit and deliver clean, purified air into the helmet, demonstrates a clear technological path toward comprehensive safety solutions that tackle both optical and respiratory hazards simultaneously, particularly important in environments with chrome, zinc, or cadmium exposure.

Regional Highlights

- North America: North America, particularly the United States and Canada, represents a mature market characterized by extremely rigorous safety standards enforced by bodies like OSHA and ANSI. Market growth is stable and driven by mandatory replacement cycles, significant investment in high-end manufacturing (especially automotive and aerospace), and a strong preference for premium brands offering 1/1/1/1 optical clarity and integrated PAPR systems. The region is a leader in adopting advanced digital welding controls and is willing to absorb the higher costs associated with compliance-driven, technology-rich helmets.

- Europe: The European market is highly regulated under CE standards (EN 379) and exhibits strong demand across Western and Northern European countries. Germany, France, and the UK are key markets due to their advanced manufacturing sectors and focus on high quality, specialized fabrication (e.g., energy, machinery). The emphasis here is often on environmental sustainability and occupational health, leading to high adoption rates of ergonomic and lightweight helmets, as well as PAPR solutions, particularly in confined space welding and shipbuilding applications.

- Asia Pacific (APAC): APAC is the fastest-growing and largest regional market by volume, fueled by unprecedented infrastructure investment, massive growth in the automotive production base in China, India, and Southeast Asia, and rapid industrialization. While price sensitivity remains a factor, driving demand for entry-level and mid-range auto-darkening helmets, the increasing implementation of international safety standards, especially by multinational corporations operating in the region, is steadily boosting the demand for certified, high-quality professional-grade equipment.

- Latin America (LATAM): The LATAM market is developing, with growth tied directly to commodity prices, mining activities, and energy infrastructure projects (particularly in Brazil and Mexico). Adoption rates are increasing due to rising awareness of occupational hazards and moderate industrial expansion. However, market penetration is often hindered by economic volatility and reliance on imported goods, making cost-effectiveness a crucial purchasing factor for regional distributors.

- Middle East and Africa (MEA): The MEA market is largely driven by the oil, gas, and petrochemical sectors, alongside large-scale construction projects in the GCC states. Demand focuses on durable, high-specification helmets capable of performing reliably under extreme heat and harsh environmental conditions. Safety compliance is becoming increasingly formalized in major construction hubs, ensuring a consistent, albeit concentrated, demand for professional auto-darkening solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Auto Darkening Welding Helmets Market.- 3M (Speedglas)

- Lincoln Electric

- Illinois Tool Works (Miller Electric)

- ESAB

- Hobart Welding Products

- Jackson Safety

- Sellstrom

- Optrel AG

- Weldmark

- ArcOne

- JSP Ltd.

- WÜRTH Group

- GYS

- Fronius International GmbH

- Tecmen

- Hypertherm

- Kemppi Oy

- Jasic Technology

- Riland Technology

- Voestalpine Böhler Welding

Frequently Asked Questions

Analyze common user questions about the Auto Darkening Welding Helmets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the current standard for optical clarity in professional auto-darkening welding helmets?

The highest current standard for professional auto-darkening welding helmet optical clarity is designated as 1/1/1/1 according to the EN 379 classification. This rating signifies superior performance across four key metrics: optical class, diffusion of light, variations in luminous transmittance, and angle dependence of luminous transmittance, ensuring minimal visual distortion and superior eye protection for extended periods of use.

How important is True Color Technology (TCT) in modern welding operations?

True Color Technology (TCT) is highly important as it enhances the visible spectrum, allowing the welder to perceive colors more naturally in both the light and dark states. This improves spatial awareness, facilitates easier identification of components, and enhances the ability to monitor the welding puddle and heat input with greater precision, directly contributing to higher quality welds and reduced operational fatigue.

What role do PAPR integrated systems play in the adoption of auto-darkening helmets?

Powered Air Purifying Respirator (PAPR) integrated systems combine auto-darkening functionality with respiratory protection, filtering welding fumes and particulates before delivering clean air to the user. This integration is crucial for compliance in environments involving materials that produce hazardous fumes (e.g., stainless steel, galvanized metals) and significantly drives market growth in sectors focusing on comprehensive occupational health and safety.

Are solar-powered welding helmets fully independent of batteries?

No, most solar-powered auto-darkening welding helmets are better described as solar assist helmets. They utilize the solar panel primarily to charge or supplement a non-replaceable or replaceable lithium backup battery. The battery is necessary to ensure instantaneous and reliable darkening response, especially during initial arc striking or in low-light conditions, maintaining consistent safety performance as mandated by industry standards.

What is the primary difference between fixed shade and variable shade auto-darkening helmets?

Fixed shade auto-darkening helmets are set to a single dark state (e.g., Shade 10) suitable for only one range of amperage/process. Variable shade helmets allow the welder to adjust the darkening level (typically Shade 9–13) based on the amperage and welding process being used, providing crucial versatility, reduced eye strain, and optimizing performance for multiple applications like low-amp TIG and high-amp MIG/Stick welding.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager