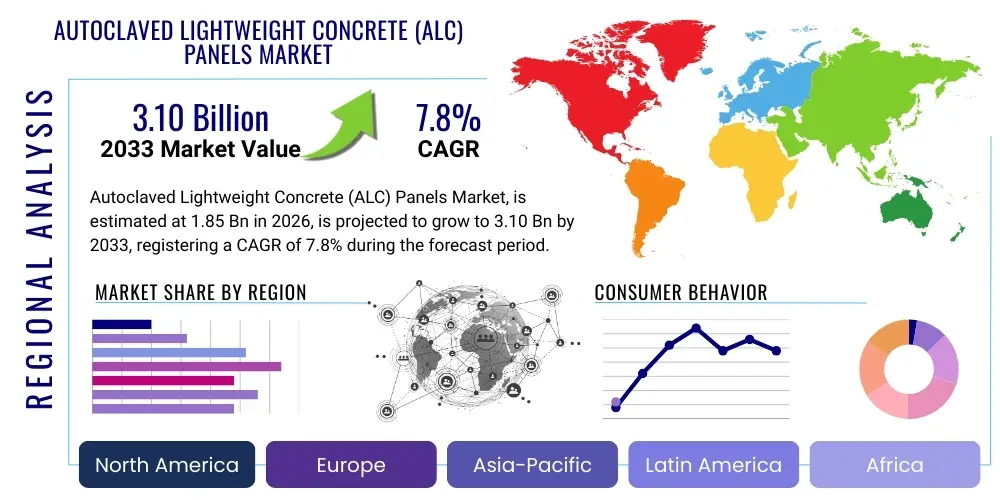

Autoclaved Lightweight Concrete (ALC) Panels Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439537 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Autoclaved Lightweight Concrete (ALC) Panels Market Size

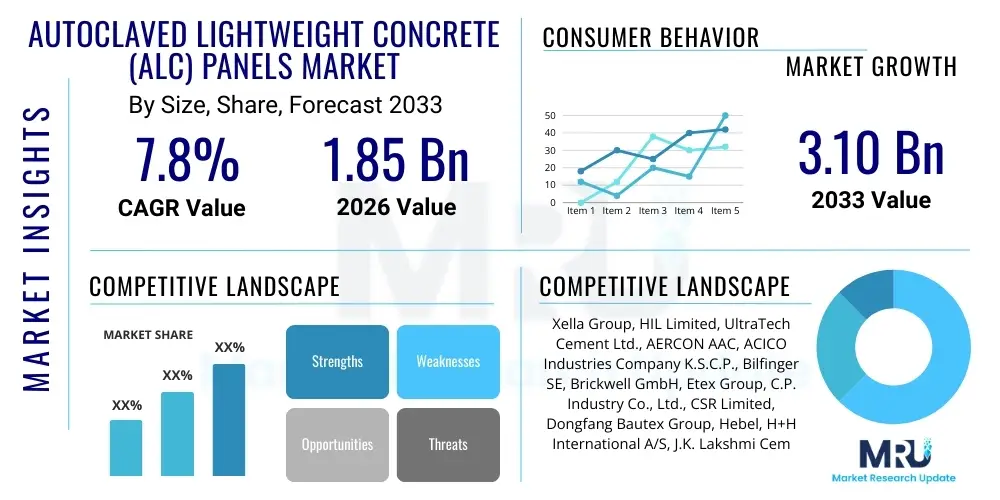

The Autoclaved Lightweight Concrete (ALC) Panels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.10 Billion by the end of the forecast period in 2033.

Autoclaved Lightweight Concrete (ALC) Panels Market introduction

The Autoclaved Lightweight Concrete (ALC) Panels market encompasses the production, distribution, and application of a prefabricated, lightweight, and high-performance building material. ALC panels are manufactured from a mixture of cement, lime, sand, water, and aluminum powder, which creates a cellular structure when cured under high-pressure steam in an autoclave. This unique manufacturing process imparts several desirable properties to the material, making it a preferred choice in modern construction.

These panels are widely recognized for their excellent thermal insulation, fire resistance, acoustic insulation, and structural integrity, despite being significantly lighter than conventional concrete. Major applications span across residential, commercial, and industrial construction, including external walls, partition walls, floor slabs, and roofing systems. The intrinsic benefits of ALC panels, such as reduced construction time, lower labor costs, enhanced energy efficiency, and environmental friendliness due to their sustainable production and recyclable nature, are key factors driving their increasing adoption across the globe. Their versatility allows for diverse architectural applications and contributes to building designs that meet stringent energy performance standards and green building certifications.

Furthermore, the market's growth is significantly fueled by global urbanization trends, robust expansion in the construction sector, and a growing emphasis on green building initiatives. The demand for materials that offer both structural advantages and environmental benefits is accelerating, positioning ALC panels as a pivotal solution. The inherent qualities of ALC panels, such as their precision dimensions which reduce on-site waste and facilitate rapid installation, also make them increasingly attractive in a construction industry striving for greater efficiency and sustainability.

Autoclaved Lightweight Concrete (ALC) Panels Market Executive Summary

The Autoclaved Lightweight Concrete (ALC) Panels market is experiencing dynamic growth, driven by a confluence of evolving business trends, distinct regional developments, and specific segment-wise expansion. A prominent business trend is the escalating global focus on sustainable construction practices and green building certifications, compelling developers and contractors to adopt materials like ALC panels that offer superior energy efficiency and reduced environmental footprint. Additionally, the increasing preference for prefabrication and modular construction methods is significantly boosting the demand for ALC panels, owing to their lightweight nature, ease of installation, and precision manufacturing, which collectively shorten project timelines and reduce on-site labor requirements. Technological advancements in ALC production, leading to enhanced material properties and cost efficiencies, further solidify their market position.

Regionally, the Asia Pacific (APAC) continues to dominate the ALC panels market, primarily propelled by rapid urbanization, massive infrastructure development projects, and a booming residential and commercial construction sector in countries such as China and India. Europe also exhibits substantial growth, underpinned by stringent energy efficiency regulations and a strong emphasis on renovation and refurbishment activities aimed at improving building performance. North America is witnessing a steady uptake, particularly in residential construction, as builders seek cost-effective and time-saving solutions that comply with evolving building codes. Emerging economies in Latin America, the Middle East, and Africa are gradually increasing their adoption of ALC panels for large-scale urban development and housing projects.

Segment-wise, the residential application sector remains a significant driver, with ALC panels increasingly used for internal and external walls in multi-story apartments and independent homes due to their thermal and acoustic benefits. The commercial segment, encompassing offices, retail spaces, and hospitals, is also expanding its reliance on ALC panels for their speed of construction, fire safety, and insulation properties. Furthermore, the industrial and infrastructure sectors are exploring ALC panels for warehouses, factories, and sound barriers, capitalizing on their durability and specific performance characteristics. This broad applicability across diverse construction segments underscores the material's versatility and its critical role in modern building practices.

AI Impact Analysis on Autoclaved Lightweight Concrete (ALC) Panels Market

The integration of Artificial Intelligence (AI) is poised to revolutionize the Autoclaved Lightweight Concrete (ALC) Panels market by enhancing various stages of the value chain, from raw material processing to manufacturing, quality control, and even logistics. Users frequently inquire about how AI can optimize production efficiencies, reduce waste, and improve the overall material characteristics of ALC panels. There is a strong interest in AI's potential to automate complex manufacturing processes, predict material performance under varying conditions, and personalize product offerings to specific project requirements. Concerns often revolve around the initial investment costs of AI implementation and the need for specialized skills, yet the overarching expectation is that AI will unlock new levels of precision, sustainability, and economic viability within the industry.

- AI-driven predictive analytics can optimize raw material blending and mixing ratios, ensuring consistent quality and minimizing material waste during production.

- Machine learning algorithms can monitor and control the autoclaving process in real-time, fine-tuning temperature and pressure to achieve optimal curing and material properties, thereby reducing defects.

- AI-powered visual inspection systems can detect subtle flaws or inconsistencies in ALC panels post-production, significantly improving quality assurance and reducing the need for manual checks.

- Generative design tools, leveraging AI, can assist architects and engineers in optimizing ALC panel designs for structural efficiency, thermal performance, and aesthetic appeal, speeding up the design phase.

- AI applications in supply chain management can predict demand fluctuations, optimize inventory levels, and streamline logistics for ALC panel delivery, leading to reduced transportation costs and improved project scheduling.

- Robotics and automation, often guided by AI, can enhance precision cutting and handling of ALC panels on the manufacturing floor, increasing production speed and worker safety.

- AI-driven data analysis can identify market trends, customer preferences, and competitive landscapes, enabling ALC panel manufacturers to make more informed strategic decisions and tailor product development.

DRO & Impact Forces Of Autoclaved Lightweight Concrete (ALC) Panels Market

The Autoclaved Lightweight Concrete (ALC) Panels market is profoundly shaped by a combination of key drivers, inherent restraints, and emerging opportunities, all interacting with broader impact forces that influence its trajectory. A primary driver is the accelerating global imperative for sustainable and energy-efficient building solutions, as ALC panels inherently offer superior thermal insulation, contributing to reduced energy consumption in buildings. The rapid pace of urbanization and the consequent demand for affordable and quick-to-build housing, particularly in developing economies, further fuel market expansion. Additionally, the growing trend of prefabrication and modular construction, seeking to minimize on-site labor and construction time, strongly favors ALC panels due to their lightweight nature and ease of installation. Government regulations and incentives promoting green building materials also act as significant catalysts for market growth.

However, the market faces several restraints that could impede its progress. The high initial capital investment required for setting up advanced ALC manufacturing facilities can be a barrier for new entrants, limiting market competition and expansion. A lack of widespread awareness and understanding of ALC panels' benefits among traditional builders and contractors in some regions, coupled with established preferences for conventional construction materials like brick and concrete, poses a challenge. Moreover, while ALC panels offer robust performance, their susceptibility to moisture in specific untreated applications and the need for specialized installation techniques can be perceived as drawbacks compared to more universally familiar alternatives. The market also experiences competition from other lightweight and energy-efficient building materials, necessitating continuous innovation and differentiation.

Despite these challenges, significant opportunities exist for the ALC panels market. Emerging economies, with their vast infrastructure and housing deficits, present substantial untapped potential for adoption. Continuous research and development (R&D) focused on enhancing the material properties of ALC, such as improved strength-to-weight ratios or better moisture resistance, can open new application avenues and strengthen market competitiveness. The increasing integration of ALC panels into smart building ecosystems and the expansion of modular construction techniques are also pivotal opportunities. Furthermore, strategic partnerships with construction companies and architects, coupled with targeted marketing and educational campaigns, can overcome awareness barriers and accelerate market penetration. These impact forces—technological advancements, economic development patterns, and evolving regulatory landscapes—collectively dictate the pace and direction of the ALC panels market.

Segmentation Analysis

The Autoclaved Lightweight Concrete (ALC) Panels market is comprehensively segmented to provide a detailed understanding of its diverse applications, product types, end-users, and geographical distribution. This segmentation is crucial for identifying specific market niches, understanding consumer preferences, and formulating targeted business strategies. The market can be broadly categorized by Type, which refers to the specific form and function of the ALC product; by Application, which delineates the primary use cases in different construction settings; by End-Use, distinguishing between new construction and renovation projects; and by Region, highlighting geographical market dynamics.

- By Type

- Wall Panels: These are the most common type, used for both internal partition walls and external facade applications due to their thermal insulation and soundproofing properties.

- Roof Panels: Utilized for roofing systems, offering lightweight solutions with excellent insulation and fire resistance.

- Floor Panels: Employed in flooring systems, providing a lightweight yet sturdy base with good acoustic dampening.

- Cladding Panels: Specifically designed for exterior cladding, offering aesthetic versatility, weather protection, and thermal performance.

- By Application

- Residential: Includes single-family homes, multi-story apartments, and housing complexes, where energy efficiency and speed of construction are paramount.

- Commercial: Covers office buildings, retail establishments, hotels, and hospitals, valuing fire safety, sound insulation, and rapid deployment.

- Industrial: Encompasses warehouses, factories, and manufacturing units, requiring durable, fire-resistant, and insulated building envelopes.

- Infrastructure: Involves applications in public works such as sound barriers along highways, utility buildings, and public facilities.

- By End-Use

- New Construction: Projects involving the erection of entirely new structures, where ALC panels offer significant advantages in terms of speed, cost, and performance.

- Renovation & Maintenance: Projects focused on upgrading existing buildings to improve energy efficiency, structural integrity, or aesthetic appeal.

- By Region

- North America: Comprising the United States, Canada, and Mexico.

- Europe: Including Germany, United Kingdom, France, Italy, Spain, and Rest of Europe.

- Asia Pacific (APAC): Encompassing China, Japan, India, South Korea, Australia, and Rest of APAC.

- Latin America: Consisting of Brazil, Argentina, and Rest of Latin America.

- Middle East & Africa (MEA): Covering UAE, Saudi Arabia, South Africa, and Rest of MEA.

Value Chain Analysis For Autoclaved Lightweight Concrete (ALC) Panels Market

The value chain for the Autoclaved Lightweight Concrete (ALC) Panels market is a complex network involving various stages, from the sourcing of raw materials to the final installation and after-sales support. This chain can be broadly categorized into upstream activities, which involve the procurement and processing of inputs; manufacturing, where raw materials are transformed into finished ALC panels; downstream activities, focusing on distribution and sales; and finally, the end-user application. Understanding each stage is crucial for identifying areas of efficiency, cost optimization, and potential value addition throughout the product lifecycle. The efficiency of this chain directly impacts product quality, market competitiveness, and ultimately, customer satisfaction, making effective management of each link critical for market players.

Upstream analysis begins with the extraction and supply of essential raw materials, including cement, lime, sand (often silica sand), gypsum, water, and aluminum powder. Suppliers of these materials form the foundational layer of the value chain, and their reliability, quality, and pricing significantly influence the production cost and quality of ALC panels. Manufacturers often establish long-term relationships with trusted raw material suppliers to ensure consistent input quality and manage supply chain risks. Logistics for transporting these bulk materials to manufacturing plants also represent a key upstream consideration, requiring efficient planning to minimize costs and environmental impact. Innovations in raw material sourcing, such as using recycled aggregates, can also introduce sustainable value propositions at this stage.

The manufacturing stage involves the precise mixing of raw materials, molding, pre-curing, and the critical autoclaving process where panels are cured under high-pressure steam. This is the core value-adding activity where raw inputs are transformed into high-performance ALC panels. Post-manufacturing, the downstream activities encompass distribution and sales channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large contractors, developers, or government projects, often for customized or large-volume orders. Indirect channels involve a network of distributors, wholesalers, retailers, and specialized construction material suppliers who cater to smaller projects, individual builders, and renovation markets. Effective distribution networks are vital for market penetration and ensuring product availability across diverse geographical regions. Finally, the installation and after-sales support provided by contractors and manufacturers complete the value chain, ensuring proper application and addressing any post-purchase needs, thereby enhancing customer loyalty and brand reputation.

Autoclaved Lightweight Concrete (ALC) Panels Market Potential Customers

The Autoclaved Lightweight Concrete (ALC) Panels market caters to a broad spectrum of potential customers, ranging from large-scale developers and construction companies to individual homeowners undertaking renovation projects. Identifying these diverse end-users is essential for manufacturers and suppliers to tailor their product offerings, marketing strategies, and distribution channels effectively. The appeal of ALC panels lies in their versatility, performance benefits, and cost-effectiveness over the entire lifecycle of a building, attracting various segments looking for modern, sustainable, and efficient construction solutions. Understanding the specific needs and decision-making criteria of each customer group allows for more targeted engagement and market penetration, contributing significantly to overall market growth and product adoption across different construction verticals.

One of the primary customer segments includes residential builders and developers, who are increasingly seeking materials that offer speed of construction, energy efficiency, and fire safety to meet evolving building codes and consumer demand for sustainable homes. For multi-story residential buildings and housing complexes, ALC panels provide lightweight solutions that reduce structural load, thereby cutting foundation costs and speeding up project completion. Similarly, commercial developers, encompassing those involved in office buildings, retail centers, and hospitality projects, are key buyers due to ALC panels' superior thermal and acoustic insulation properties, which contribute to comfortable indoor environments and lower operational costs. The ability to achieve desired design aesthetics coupled with functional benefits makes ALC an attractive choice for commercial ventures aiming for green building certifications and long-term asset value.

Furthermore, industrial contractors engaged in constructing warehouses, factories, and logistics centers represent another significant customer base. These projects often prioritize durability, fire resistance, and rapid enclosure, all of which are strong attributes of ALC panels. Government entities and infrastructure developers are also emerging as important potential customers, particularly for public housing initiatives, educational institutions, and sound barrier projects, where the panels offer a balance of performance, sustainability, and economic viability. Architects and consulting engineers play a crucial role as influencers, recommending ALC panels for their technical advantages and design flexibility. Lastly, individual homeowners and small-scale renovators, though often served through indirect channels, are increasingly interested in ALC panels for extensions, internal partitions, or energy-efficient upgrades, driven by a growing awareness of their benefits. These diverse customer profiles highlight the wide applicability and market potential of ALC panels across the entire built environment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.10 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Xella Group, HIL Limited, UltraTech Cement Ltd., AERCON AAC, ACICO Industries Company K.S.C.P., Bilfinger SE, Brickwell GmbH, Etex Group, C.P. Industry Co., Ltd., CSR Limited, Dongfang Bautex Group, Hebel, H+H International A/S, J.K. Lakshmi Cement Ltd., LightStone Building Materials, SCG Group, Sumitomo Mitsui Construction Co., Ltd., U.S. SILICA COMPANY, WAPCO, Saint-Gobain. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Autoclaved Lightweight Concrete (ALC) Panels Market Key Technology Landscape

The Autoclaved Lightweight Concrete (ALC) Panels market is continuously evolving, driven by advancements in manufacturing processes, material science, and digital technologies. At the heart of ALC production is the highly specialized autoclaving process, which involves curing the mixed raw materials under specific conditions of high temperature and pressure. This core technology is subject to ongoing refinement, with manufacturers investing in advanced control systems to optimize energy consumption, reduce cycle times, and ensure consistent product quality. Innovations in mixing technologies are also crucial, aiming to achieve a more homogenous blend of raw materials, which directly impacts the cellular structure and performance characteristics of the final panel. Precision cutting technologies, often involving wire cutting or CNC machines, ensure accurate panel dimensions, minimizing on-site waste and facilitating rapid, seamless installation.

Beyond the manufacturing floor, the ALC panels market is increasingly leveraging digital tools and automation to enhance efficiency and product development. Building Information Modeling (BIM) software is becoming indispensable, allowing architects and engineers to integrate ALC panel specifications directly into their digital designs, facilitating better collaboration, clash detection, and quantity take-offs. This digital integration reduces design errors and improves project planning efficiency. Automation throughout the production line, from raw material handling to packaging, is becoming more sophisticated, incorporating robotics and sensor technologies to monitor quality, reduce manual labor, and improve overall operational safety. These automated systems contribute to higher production volumes and a more uniform product output, addressing the growing demand for ALC panels.

Furthermore, the key technology landscape includes advancements in material composition and sustainable manufacturing practices. Research and development efforts are focused on incorporating recycled content, such as fly ash or slag, into ALC formulations to enhance their environmental profile and improve specific performance attributes like compressive strength or insulation value. Technologies for waste heat recovery in autoclaving processes and water recycling within plants are also gaining traction, aligning with global sustainability goals. The development of specialized surface treatments and coatings for ALC panels is also an area of innovation, aimed at improving moisture resistance, aesthetic finishes, and compatibility with various external rendering systems. Collectively, these technological advancements are propelling the ALC panels market forward, making the material more versatile, cost-effective, and environmentally responsible.

Regional Highlights

- Asia Pacific (APAC): Dominates the global ALC panels market, driven by unprecedented urbanization, rapid industrialization, and massive government investments in infrastructure and housing projects in countries like China, India, and Southeast Asian nations. The region benefits from abundant raw materials and a large labor force, making it a cost-effective production hub.

- Europe: Exhibits significant growth, fueled by stringent energy efficiency regulations, a strong focus on green building initiatives, and a robust renovation market aimed at upgrading existing building stock. Countries such as Germany, the UK, and France are leading adopters, valuing ALC panels for their thermal insulation properties and contribution to sustainable construction.

- North America: Experiences steady market expansion, particularly in the residential construction sector, due to increasing demand for lightweight, energy-efficient, and quick-to-install building materials. Growing awareness of the long-term cost savings associated with ALC panels, coupled with evolving building codes, supports market growth in the U.S. and Canada.

- Latin America: An emerging market for ALC panels, characterized by ongoing infrastructure development and rising demand for affordable housing solutions. Countries like Brazil and Mexico are witnessing increased adoption as construction companies seek efficient and sustainable alternatives to traditional building methods.

- Middle East & Africa (MEA): Shows promising growth potential, driven by ambitious urban development plans, diversification away from oil economies, and a focus on constructing modern, energy-efficient buildings in response to extreme climatic conditions. The UAE and Saudi Arabia are at the forefront of this regional expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Autoclaved Lightweight Concrete (ALC) Panels Market.- Xella Group

- HIL Limited

- UltraTech Cement Ltd.

- AERCON AAC

- ACICO Industries Company K.S.C.P.

- Bilfinger SE

- Brickwell GmbH

- Etex Group

- C.P. Industry Co., Ltd.

- CSR Limited

- Dongfang Bautex Group

- Hebel

- H+H International A/S

- J.K. Lakshmi Cement Ltd.

- LightStone Building Materials

- SCG Group

- Sumitomo Mitsui Construction Co., Ltd.

- U.S. SILICA COMPANY

- WAPCO

- Saint-Gobain

Frequently Asked Questions

What are Autoclaved Lightweight Concrete (ALC) Panels?

Autoclaved Lightweight Concrete (ALC) Panels are prefabricated building materials made from cement, lime, sand, water, and aluminum powder, which expands and cures under high pressure and steam in an autoclave. This process creates a lightweight, cellular structure known for excellent thermal and acoustic insulation, fire resistance, and structural integrity.

What are the primary benefits of using ALC Panels in construction?

The primary benefits of ALC panels include superior thermal insulation for energy efficiency, exceptional fire resistance, good acoustic dampening, lightweight properties that reduce structural loads and construction time, ease of installation, and environmental friendliness due to sustainable production and recyclable content. They also offer high dimensional stability and pest resistance.

How do ALC Panels compare to traditional concrete or brick in terms of performance?

ALC panels are significantly lighter than traditional concrete or brick, reducing foundation costs and construction time. They offer much better thermal insulation (up to 4-8 times higher than traditional concrete) and acoustic performance, contributing to energy savings and quiet interiors. While strength is lower than dense concrete, it is sufficient for many structural and non-structural applications, and their fire resistance is typically superior.

Are ALC Panels considered an environmentally friendly or sustainable building material?

Yes, ALC panels are considered environmentally friendly. Their production often utilizes recycled industrial by-products like fly ash, and the manufacturing process is energy-efficient. Their excellent thermal insulation properties significantly reduce the energy consumption for heating and cooling buildings, leading to a lower carbon footprint over the building's lifecycle. ALC is also non-toxic and recyclable.

What are the main applications for Autoclaved Lightweight Concrete (ALC) Panels?

ALC panels are widely used for both structural and non-structural applications across various construction sectors. Main applications include external walls, internal partition walls, floor slabs, roofing systems, and cladding in residential, commercial, and industrial buildings. They are also suitable for specialized uses like firewalls, sound barriers, and thermal insulation layers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager