Automated Industrial Nailers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435152 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Automated Industrial Nailers Market Size

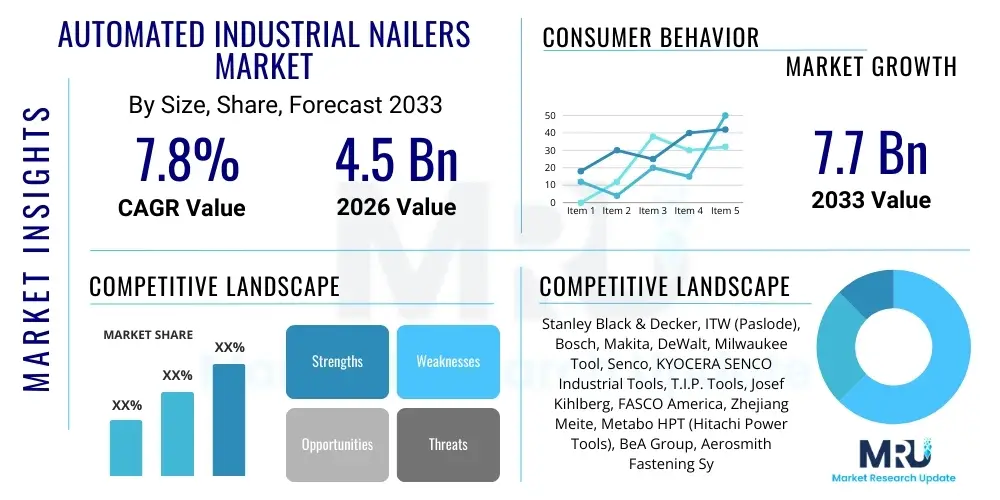

The Automated Industrial Nailers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Automated Industrial Nailers Market introduction

The Automated Industrial Nailers Market encompasses specialized fastening systems designed for high-volume, repetitive industrial applications, significantly improving efficiency, consistency, and worker safety compared to manual nailing processes. These systems range from advanced robotic fastening cells used in automotive assembly and prefabricated construction to semi-automatic tools utilized in packaging and furniture manufacturing. The core product definition involves tools that automatically feed and drive fasteners (nails or staples) using various power sources, predominantly pneumatic, battery, or combustion mechanisms, integrated into automated production lines or robotic arms. The ongoing industrial shift towards Industry 4.0 principles, emphasizing automation and data-driven manufacturing, is a foundational element fueling the sustained expansion of this market globally.

Major applications for automated industrial nailers span critical sectors, most notably residential and commercial construction (framing, sheathing, roofing), high-speed packaging (pallet assembly, crating), and specialized woodworking (cabinetry, furniture). The primary benefits derived from the adoption of these automated solutions include drastically reduced cycle times, highly accurate fastening placement, minimal material waste, and decreased labor intensity, which mitigates the risk of repetitive strain injuries. These advantages directly contribute to lowering the total cost of ownership (TCO) for manufacturing operations that require substantial fastening work.

Driving factors for market growth are intrinsically linked to global macroeconomic trends, including rapid urbanization, particularly in emerging economies, leading to increased construction activity. Furthermore, the stringent quality control requirements in advanced manufacturing sectors, such as automotive and aerospace, necessitate the precision offered by automated nailers. Technological advancements, particularly in lightweight battery technology and the integration of sensors for process monitoring and predictive maintenance, further enhance the appeal and versatility of these industrial tools, positioning them as essential components of modern, streamlined production environments.

Automated Industrial Nailers Market Executive Summary

The Automated Industrial Nailers Market is characterized by robust growth, driven primarily by the global imperative for manufacturing efficiency and labor cost reduction. Business trends indicate a strong movement toward fully robotic fastening solutions, particularly in large-scale prefabricated construction and heavy packaging industries. Key market players are heavily investing in developing smart, connected tools that offer real-time diagnostics and integration with centralized manufacturing execution systems (MES). Furthermore, there is a distinct trend towards environmentally sustainable and ergonomic battery-powered systems, challenging the historical dominance of pneumatic tools, especially in applications demanding high mobility and lower noise levels.

Regionally, North America and Europe maintain leading positions due to established infrastructure, high labor costs necessitating automation, and stringent safety regulations promoting mechanized processes. However, the Asia Pacific (APAC) region is projected to exhibit the highest CAGR during the forecast period, fueled by massive infrastructure investments in China, India, and Southeast Asian nations, alongside the rapid expansion of the regional manufacturing and packaging industries. This growth is also supported by increasing adoption of Western-style timber framing techniques in traditionally concrete-dominated markets, creating new demand niches for specialized automated nailing equipment.

Segmentation trends reveal that the Fully Automatic segment, encompassing CNC-controlled nailing bridges and dedicated robotic cells, is outpacing the Semi-Automatic segment in terms of revenue growth, reflecting the industry's commitment to complete process automation. By application, Construction remains the largest revenue generator, while the Packaging industry is demonstrating accelerated adoption rates due to the constant need for high-speed pallet and crating production. The shift towards lightweight, composite materials in construction and automotive sectors is concurrently influencing fastener and tool design, pushing manufacturers toward developing high-performance, adaptive automated nailers capable of handling diverse material specifications and densities efficiently.

AI Impact Analysis on Automated Industrial Nailers Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Automated Industrial Nailers Market generally center around predictive maintenance capabilities, enhanced quality control (QC) verification, and optimizing robotic nailing path planning. Users are keen to understand how AI algorithms can interpret sensor data from nailers (such as pressure, force applied, and motor current) to predict imminent tool failure, thereby minimizing costly downtime in critical production environments. Furthermore, a major concern is the application of computer vision, powered by AI, to ensure that fasteners are driven to the precise depth and location according to specifications, mitigating defects and improving overall structural integrity, which is vital in industries like prefabricated housing and automotive chassis assembly. Expectations are high that AI integration will shift the market from reactive maintenance models to highly proactive, data-driven operational management, fundamentally changing how these industrial assets are maintained and utilized.

- AI-driven Predictive Maintenance: Analyzing motor vibration, pressure profiles, and cycle counts to predict component failure, significantly reducing unscheduled downtime and optimizing inventory management for spare parts.

- Enhanced Quality Control (QC): Using machine learning algorithms applied to sensor data (force feedback, visual inspection) to verify correct nail depth, angle, and seating in real-time, ensuring adherence to structural standards.

- Robotic Path Optimization: Implementing AI for dynamic route planning in robotic fastening systems, minimizing travel time and optimizing energy consumption for faster overall assembly cycles.

- Self-Correction and Calibration: Automated adjustment of driving pressure and feed rate based on material variability (e.g., density of wood species or composite panel thickness) analyzed via sensor input.

- Data Integration and Analytics: AI platforms aggregating performance data across fleets of nailers, providing actionable insights into process bottlenecks and operator effectiveness.

DRO & Impact Forces Of Automated Industrial Nailers Market

The market trajectory for Automated Industrial Nailers is heavily influenced by a confluence of accelerating drivers, structural restraints, and emerging opportunities, which collectively define the impact forces acting upon the industry. Key drivers include the escalating global labor wages, making automation economically imperative, and the increasing demand for prefabricated construction methods that rely entirely on high-speed, accurate automated fastening. These drivers are amplified by technological advancements, such as the miniaturization of motors and development of high-density battery packs, enhancing the performance and portability of automated tools.

Conversely, significant restraints exist, primarily the substantial initial capital expenditure required for implementing fully robotic fastening systems, which poses a barrier to entry for smaller manufacturers or construction firms. Technical complexity and the need for highly specialized maintenance personnel also limit widespread adoption in certain low-skill markets. Furthermore, standardization challenges persist, particularly concerning fastener specifications and compatibility across different automated platforms, occasionally leading to vendor lock-in and reduced flexibility in sourcing components.

Opportunities abound in developing economies, where infrastructure spending is surging, and in niche high-value sectors, such as composite material fastening for aerospace and electric vehicle battery packaging. The integration of IoT (Internet of Things) capabilities and subscription-based "Fastening-as-a-Service" models represent substantial commercial opportunities, enabling end-users to access advanced technology without large upfront investments. The resulting impact forces are strongly positive, favoring market participants who can successfully navigate the technical complexity to deliver cost-effective, high-precision automated fastening solutions tailored for Industry 4.0 environments.

Segmentation Analysis

The Automated Industrial Nailers Market is highly diversified, segmented based on Product Type, Operation Mode, Application, and End-User. This segmentation allows for precise market analysis and helps stakeholders tailor their offerings to specific industry needs. Product segmentation reflects the power source preferences, ranging from high-torque pneumatic tools used in fixed-line manufacturing to flexible, high-capacity battery-powered systems increasingly favored in mobile construction environments. Operational modes distinguish between human-assisted semi-automatic processes and fully autonomous robotic systems, representing the maturity level of automation adoption across various industries.

- By Product Type:

- Pneumatic Automated Nailers

- Battery-Powered Automated Nailers

- Combustion-Powered Automated Nailers

- Electric Automated Nailers (Corded)

- By Operation Mode:

- Semi-Automatic Systems

- Fully Automatic (Robotic) Systems

- By Application:

- Construction (Framing, Roofing, Sheathing)

- Packaging (Pallet Assembly, Crating)

- Furniture & Woodworking (Cabinetry, Upholstery)

- Automotive (Interior Trim, Specialty Fastening)

- Others (Fencing, Flooring)

- By End-User:

- Residential Construction Firms

- Commercial Construction Firms

- Industrial Manufacturing Facilities

- Logistics and Warehouse Operators

Value Chain Analysis For Automated Industrial Nailers Market

The value chain for the Automated Industrial Nailers Market begins with upstream activities focused on raw material procurement, including high-grade steel, specialized plastics, and electronic components necessary for constructing the tools and their fasteners. Key upstream partners are component suppliers providing motors, specialized valves (for pneumatic systems), sensors, and advanced battery cells. The manufacturing stage involves complex precision engineering, assembly, and rigorous quality control to ensure the reliability and safety standards required for industrial automation equipment. Innovation in this stage is driven by R&D focused on increasing tool longevity, reducing weight, and enhancing speed.

The core midstream activities involve the distribution channel, which is crucial for market penetration. Direct distribution models, where manufacturers supply high-cost robotic systems directly to large industrial clients (e.g., prefabricated home builders or automotive tier 1 suppliers), allow for specialized training and customized integration support. Conversely, indirect distribution relies heavily on authorized dealers, specialized industrial supply houses, and large e-commerce platforms to reach smaller construction firms and general manufacturing end-users. Efficient logistics and warehousing are vital to managing inventory of both the tools and the high-volume consumables (nails/fasteners).

Downstream activities center on post-sale services, including installation, calibration, and long-term maintenance contracts, especially for complex fully automatic systems. Technical support and the continuous supply of proprietary fasteners constitute a significant revenue stream. The ability to offer integrated solutions—combining the nailer, the feeder system, and the digital monitoring platform—is increasingly dictating competitive advantage. End-users (potential customers) are highly focused on reliability, the speed of service, and the total cost of operation (TCO) across the entire lifecycle of the automated fastening equipment.

Automated Industrial Nailers Market Potential Customers

The primary customers for Automated Industrial Nailers are large enterprises and specialized contractors that require high throughput, repeatable accuracy, and reduced manual labor in their fastening processes. These end-users are characterized by their volume demands and the critical nature of fastening in their final products, whether structural integrity in construction or aesthetic quality in furniture. The largest segment remains the industrialized construction sector, including manufacturers of modular homes, prefabricated wall panels, and structural timber components, where automation is essential to meet rapid project timelines and consistent quality standards.

Another major buyer segment includes packaging and logistics operations, specifically those involved in the continuous assembly of heavy-duty wooden crates, shipping containers, and industrial pallets. These customers prioritize robustness, speed, and the ability of the nailer to handle various wood conditions without jamming. The automotive industry represents a high-value, albeit smaller, segment focused on highly precise applications such as securing interior trims, specialized components, and increasingly, battery pack assemblies, where robotic, fully automatic systems are universally deployed to meet zero-defect tolerances and demanding cycle times. These buyers look for seamless integration into existing robotics infrastructure and sophisticated data feedback capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stanley Black & Decker, ITW (Paslode), Bosch, Makita, DeWalt, Milwaukee Tool, Senco, KYOCERA SENCO Industrial Tools, T.I.P. Tools, Josef Kihlberg, FASCO America, Zhejiang Meite, Metabo HPT (Hitachi Power Tools), BeA Group, Aerosmith Fastening Systems, Beck Fastener Group, Max USA Corp., Ingersoll Rand, Ridgid, Porter-Cable. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Industrial Nailers Market Key Technology Landscape

The technology landscape of the Automated Industrial Nailers Market is rapidly evolving, driven by the need for greater mobility, precision, and integration into digital manufacturing ecosystems. One of the most significant technological shifts is the advancement of lithium-ion battery technology. Modern battery-powered nailers now offer runtime and power output levels that rival traditional pneumatic systems, providing end-users with unparalleled flexibility and removing the logistical burden of air compressors and hoses on job sites. This has led to the development of brushless motor technology, which enhances tool efficiency, reduces heat generation, and significantly extends the service life of battery-operated automated systems.

Another crucial technological development is the incorporation of advanced sensing and IoT capabilities. Automated nailers are increasingly equipped with pressure sensors, accelerometers, and microprocessors that monitor every fastening cycle. This data is transmitted wirelessly (via Wi-Fi or Bluetooth) to cloud platforms, allowing manufacturers and end-users to track productivity metrics, monitor tool health (for predictive maintenance), and ensure compliance with fastening specifications. This connectivity is foundational for the rise of sophisticated robotic fastening cells used in large-scale production, enabling closed-loop feedback systems for quality assurance.

Furthermore, innovations in fastener feed mechanisms and magazine design are improving reliability and cycle speed. Advanced material handling systems, often incorporating vision systems and robotics, ensure perfect alignment and high-speed feeding of fasteners, minimizing jams—a historically common issue in high-volume applications. The shift towards lightweight, durable materials (such as reinforced polymers and specialized aluminum alloys) in tool construction also improves ergonomics for semi-automatic handheld models and reduces the load on robotic arms in fully automatic installations, contributing to overall system efficiency and speed.

Regional Highlights

Regional dynamics play a significant role in shaping the demand and technological adoption within the Automated Industrial Nailers Market, driven by varying labor costs, construction standards, and industrial automation levels.

- North America (US and Canada): This region is characterized by high labor costs and the established use of timber frame construction techniques, leading to strong demand for both sophisticated handheld automated tools and fully robotic prefabrication systems. The US is a primary driver, focusing heavily on adopting IoT-enabled and battery-powered professional-grade nailers to enhance on-site productivity and safety standards.

- Europe (Germany, UK, France): Europe shows high market maturity, particularly in Germany and Scandinavia, with a strong focus on high-precision automated systems used in advanced manufacturing and modular housing. Strict environmental regulations favor the adoption of electric and battery-powered systems over combustion-driven alternatives, pushing manufacturers towards sustainable product innovation.

- Asia Pacific (APAC) (China, India, Japan): APAC is the fastest-growing market globally. China's massive industrial base and India's accelerating infrastructure development are fueling explosive demand, particularly in the packaging and manufacturing sectors. While currently price-sensitive, the region is rapidly moving towards adopting advanced robotic solutions to maintain global competitive advantages in large-scale assembly.

- Latin America (LATAM): Market growth in LATAM is gradual, primarily focused on basic pneumatic and semi-automatic systems for packaging and general construction. Economic volatility and lower initial automation budgets pose challenges, but long-term potential remains strong as industrialized construction methods gain traction.

- Middle East and Africa (MEA): Demand is concentrated in the Gulf Cooperation Council (GCC) countries due to large-scale, ongoing construction megaprojects. These projects often source high-end, fully automatic European and North American systems, driven by high quality and speed requirements, particularly for temporary structures and rapid housing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Industrial Nailers Market.- Stanley Black & Decker

- ITW (Illinois Tool Works - Paslode)

- Bosch

- Makita

- DeWalt (Subsidiary of Stanley Black & Decker)

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Senco (KYOCERA SENCO Industrial Tools)

- KYOCERA SENCO Industrial Tools

- T.I.P. Tools

- Josef Kihlberg (Subsidiary of ITW)

- FASCO America

- Zhejiang Meite

- Metabo HPT (Hitachi Power Tools)

- BeA Group

- Aerosmith Fastening Systems

- Beck Fastener Group

- Max USA Corp.

- Ingersoll Rand

- Ridgid (Subsidiary of Emerson Electric)

- Porter-Cable

Frequently Asked Questions

Analyze common user questions about the Automated Industrial Nailers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driving factor for the growth of the Automated Industrial Nailers Market?

The primary driving factor is the escalating cost of manual labor globally, coupled with the increasing need for high-speed, precision fastening in high-volume industries like prefabricated construction, packaging, and automotive manufacturing. Automation significantly improves throughput and ensures consistent quality control, providing a high return on investment (ROI).

How does AI technology benefit automated industrial nailing systems?

AI technology enhances these systems primarily through predictive maintenance, reducing costly downtime by analyzing operational data (vibration, pressure) to anticipate failures. AI also enables superior quality control by using computer vision and force feedback to verify that every nail is driven to the exact specification required for structural integrity.

Which product type currently dominates the Automated Industrial Nailers Market?

Pneumatic automated nailers historically dominate due to their high power output and reliability in fixed industrial settings. However, the battery-powered segment is exhibiting the fastest growth rate, driven by advancements in lithium-ion technology providing comparable power with enhanced mobility and zero emissions, crucial for modern construction sites.

What are the main restraints impacting the adoption of fully automatic nailing systems?

The main restraints are the high initial capital investment required for robotic fastening cells and the complexity associated with integrating these systems into existing production lines. Additionally, the requirement for highly skilled technicians to program and maintain these advanced, proprietary systems limits adoption in markets with low technical expertise.

Which region is expected to show the highest growth rate in this market?

The Asia Pacific (APAC) region, led by China and India, is projected to register the highest Compound Annual Growth Rate (CAGR). This acceleration is fueled by massive infrastructure investments, rapid expansion of industrial manufacturing capabilities, and increasing adoption of automation technologies to meet global production demands efficiently.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager