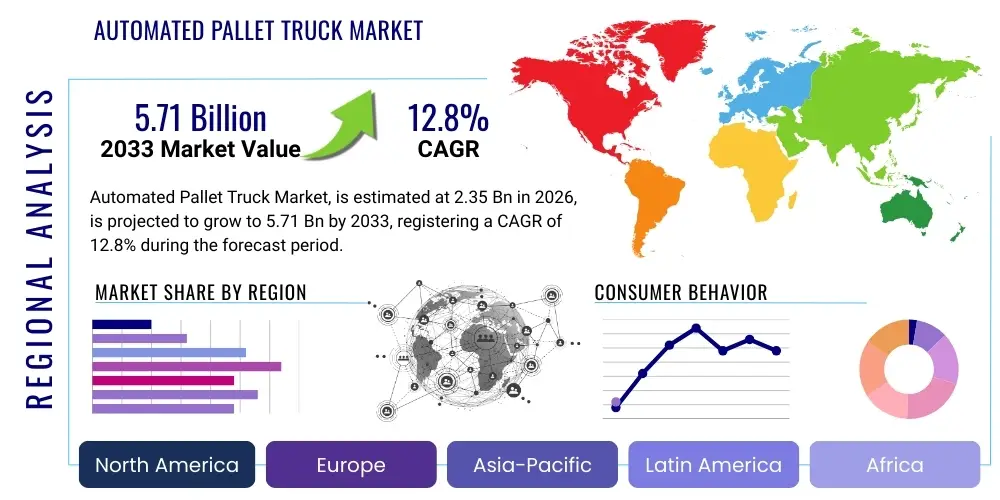

Automated Pallet Truck Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439925 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Automated Pallet Truck Market Size

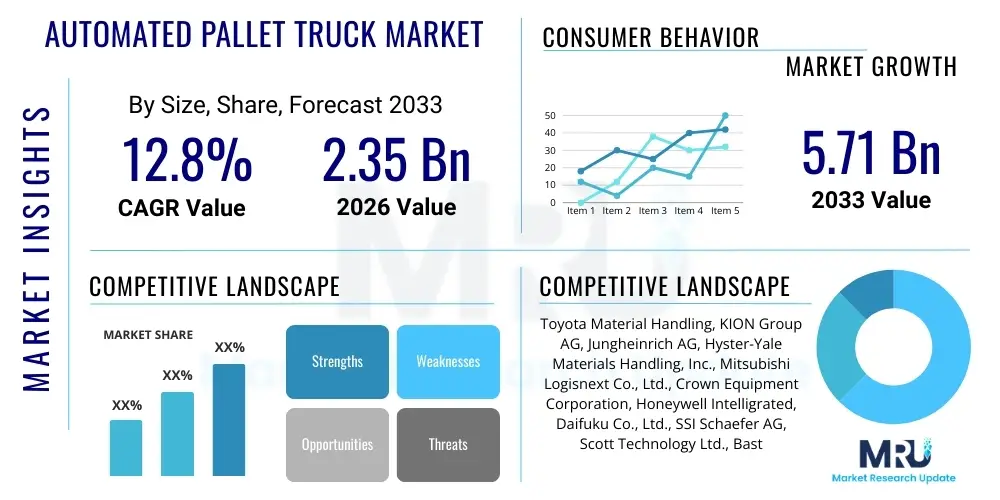

The Automated Pallet Truck Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.8% between 2026 and 2033. The market is estimated at USD 2.35 Billion in 2026 and is projected to reach USD 5.71 Billion by the end of the forecast period in 2033.

Automated Pallet Truck Market introduction

The Automated Pallet Truck Market encompasses the development, manufacturing, and deployment of self-operating vehicles designed to transport pallets within warehouses, distribution centers, and manufacturing facilities without direct human intervention. These sophisticated machines integrate advanced navigation systems, sensors, and software to perform tasks such as loading, unloading, and moving goods, significantly enhancing operational efficiency and safety. Unlike traditional manual or semi-automated pallet trucks, their autonomous capabilities allow them to operate continuously, optimize routes, and reduce labor costs, thereby revolutionizing internal logistics processes across various industries. This market is a critical component of the broader industrial automation landscape, driven by the increasing demand for streamlined supply chains and smart factory initiatives.

Automated pallet trucks, often referred to as AGVs (Automated Guided Vehicles) or AMRs (Autonomous Mobile Robots) in a more advanced context, vary in design and functionality but primarily serve to automate horizontal transport tasks. Their product descriptions typically highlight features like payload capacity, lifting height, battery life, navigation technologies (e.g., LiDAR, vision systems, magnetic tape), and integration capabilities with existing warehouse management systems (WMS) and enterprise resource planning (ERP) software. Major applications span a wide array of sectors, including e-commerce and retail, food and beverage, automotive, pharmaceuticals, and logistics services, where efficient material handling is paramount. They are instrumental in automating repetitive tasks, improving throughput, and ensuring consistent operational quality in dynamic environments.

The benefits derived from adopting automated pallet trucks are multifaceted, ranging from substantial reductions in operational costs due to minimized human labor and decreased product damage, to significant improvements in workplace safety by eliminating human error in material handling. Key driving factors propelling market expansion include the accelerating growth of e-commerce, which necessitates faster and more efficient order fulfillment; persistent labor shortages in logistics and manufacturing sectors; the imperative for enhanced workplace safety standards; and the continuous technological advancements in robotics, artificial intelligence, and sensor technology. Furthermore, the increasing pressure on businesses to optimize supply chain resilience and throughput in a competitive global market is fueling investments in these automated solutions, making them indispensable for modern industrial operations.

Automated Pallet Truck Market Executive Summary

The Automated Pallet Truck Market is witnessing robust growth, propelled by significant business trends that underscore a global shift towards automation and operational efficiency. Enterprises across diverse industries, from retail and e-commerce to automotive and food and beverage, are aggressively adopting these autonomous solutions to mitigate rising labor costs, address persistent workforce shortages, and enhance productivity. The imperative to optimize supply chain resilience and throughput, particularly in the wake of global disruptions, has accelerated investment in automated material handling. This trend is further supported by the increasing complexity of modern logistics and manufacturing operations, demanding smarter, more agile, and error-free material movement, thereby cementing automated pallet trucks as an indispensable asset in contemporary business strategies.

Regionally, the market exhibits varied growth patterns, with developed economies in North America and Europe demonstrating early adoption and a strong foundation for continued expansion, driven by high labor costs and advanced technological infrastructure. Asia Pacific, particularly countries like China, Japan, and India, is emerging as a critical growth engine, characterized by rapid industrialization, burgeoning e-commerce sectors, and substantial government initiatives promoting automation. Latin America, the Middle East, and Africa are also expected to contribute to market growth as awareness of automation benefits increases and infrastructure development progresses. The global nature of supply chains means that regional trends in manufacturing and logistics directly influence the demand for automated pallet trucks, creating a dynamic and interconnected market landscape.

Segmentation trends within the Automated Pallet Truck Market reveal a diverse landscape shaped by technology, application, end-user, and operation mode. The market is increasingly differentiating between Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), with AMRs gaining traction due to their enhanced flexibility and intelligence. Demand is particularly strong for solutions capable of handling heavier loads and operating in complex environments. End-user segments such as third-party logistics (3PL) providers and large-scale manufacturing facilities are driving significant adoption, seeking comprehensive automation solutions. These trends indicate a market moving towards more sophisticated, adaptable, and integrated systems, reflecting a broader evolution in industrial automation paradigms.

AI Impact Analysis on Automated Pallet Truck Market

User inquiries concerning AI's influence on the Automated Pallet Truck Market frequently revolve around enhancements in operational intelligence, predictive maintenance capabilities, and the seamless integration of these systems into complex logistical ecosystems. Users are keen to understand how AI contributes to more efficient route optimization, dynamic obstacle avoidance, and adaptive learning in diverse warehouse environments. There's a strong expectation that AI will unlock greater flexibility and scalability, moving beyond rigid programmed paths to more intelligent, responsive material handling. Concerns often touch upon the initial investment costs, the complexity of integrating AI-driven solutions with legacy systems, and the need for skilled personnel to manage and maintain these advanced technologies. Furthermore, questions arise about AI's role in improving safety protocols and providing real-time data analytics for continuous operational improvement and decision-making, highlighting a desire for transformative impact.

- Enhanced Route Optimization: AI algorithms dynamically analyze real-time traffic, inventory levels, and operational demands to calculate the most efficient paths, significantly reducing travel times and energy consumption for automated pallet trucks.

- Predictive Maintenance: AI-powered analytics monitor truck performance data, identifying potential failures before they occur, thereby minimizing downtime, extending asset lifespan, and reducing maintenance costs.

- Advanced Obstacle Avoidance: AI-driven vision systems and sensors enable automated pallet trucks to intelligently detect and navigate around unexpected obstacles, people, and dynamic changes in the warehouse environment with superior precision and safety.

- Adaptive Learning Capabilities: AI allows trucks to learn from their operating experiences, continuously refining their behaviors, improving task execution, and adapting to new layouts or operational requirements without extensive reprogramming.

- Seamless Integration with WMS/ERP: AI facilitates smarter communication and data exchange between automated pallet trucks and broader warehouse management and enterprise resource planning systems, creating a more cohesive and responsive supply chain.

- Real-time Data Analytics and Insights: AI processes vast amounts of operational data from the trucks, providing actionable insights into productivity, bottlenecks, and areas for further optimization, supporting data-driven decision-making.

- Improved Human-Robot Collaboration: AI algorithms can enable more intuitive and safer interactions between human workers and automated pallet trucks, optimizing workflows where both operate in proximity.

- Dynamic Task Prioritization: AI allows for intelligent prioritization of tasks based on urgency, resource availability, and overall operational goals, ensuring critical material movements are handled promptly.

- Energy Efficiency Optimization: AI can manage battery charging cycles and truck movements to maximize energy efficiency, contributing to lower operational costs and a reduced environmental footprint.

DRO & Impact Forces Of Automated Pallet Truck Market

The Automated Pallet Truck Market is significantly influenced by a confluence of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. Key drivers include the escalating demand for automation in logistics and manufacturing sectors, primarily fueled by the explosive growth of e-commerce, which mandates swift and accurate order fulfillment. Persistent labor shortages across global supply chains compel businesses to invest in automated solutions to maintain operational continuity and efficiency. Furthermore, the increasing emphasis on workplace safety, reducing human error in repetitive material handling tasks, and the desire for substantial operational cost reductions through optimized processes are strong motivators for adoption. Technological advancements in AI, robotics, sensor technology, and battery systems continue to enhance the capabilities and economic viability of these trucks, making them more attractive to a broader range of enterprises.

Despite the strong tailwinds, the market faces several notable restraints. The substantial initial capital investment required for automated pallet truck systems can be a significant barrier, particularly for small and medium-sized enterprises (SMEs) with limited budgets. The complexity of integrating these advanced solutions with existing legacy infrastructure and warehouse management systems often presents technical challenges and demands specialized expertise. Concerns surrounding data security and the need for robust cybersecurity measures for interconnected systems also pose hurdles. Additionally, the availability of skilled personnel required for the deployment, maintenance, and programming of automated systems remains a challenge, impacting the pace of adoption in some regions. These factors necessitate careful planning and resource allocation from potential adopters.

Opportunities within this market are abundant and varied, offering considerable scope for innovation and expansion. The burgeoning trend of industry 4.0 and smart factory initiatives presents a fertile ground for the wider adoption of automated pallet trucks as integral components of fully integrated, intelligent manufacturing environments. The development of more flexible and scalable Autonomous Mobile Robots (AMRs), which offer greater adaptability than traditional AGVs, is opening new application possibilities in dynamic and complex warehouse settings. Moreover, the increasing focus on sustainability is driving demand for energy-efficient electric and hydrogen-powered automated trucks. The emergence of 'robot-as-a-service' (RaaS) models is lowering the barrier to entry for smaller businesses, enabling them to leverage automation without heavy upfront investments, thereby democratizing access to this transformative technology and fostering broader market penetration across various industrial verticals.

Segmentation Analysis

The Automated Pallet Truck Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation facilitates targeted market analysis, strategic planning, and product development by categorizing the market based on various critical attributes such as type, load capacity, navigation technology, end-user industry, and operation mode. Each segment plays a unique role in defining market demand, competitive landscapes, and growth opportunities. Analyzing these segments helps stakeholders identify niche markets, understand customer preferences, and tailor solutions to specific operational requirements across the global material handling ecosystem, ensuring a holistic perspective on market evolution and innovation.

- By Type:

- Automated Guided Vehicles (AGVs) Pallet Trucks

- Autonomous Mobile Robots (AMRs) Pallet Trucks

- By Load Capacity:

- Up to 2,000 kg

- 2,001 kg to 4,000 kg

- Above 4,000 kg

- By Navigation Technology:

- Laser Guidance

- Vision Guidance

- Magnetic Tape Guidance

- Natural Feature Navigation (SLAM)

- Lidar Guidance

- Others (e.g., RFID, GPS)

- By Battery Type:

- Lead-Acid Batteries

- Lithium-Ion Batteries

- Fuel Cells (Hydrogen)

- By End-User Industry:

- E-commerce & Retail

- Food & Beverage

- Automotive

- Pharmaceutical & Healthcare

- Manufacturing

- Logistics & 3PL

- Chemicals & Materials

- Others (e.g., Paper & Printing, Electronics)

- By Application:

- Pallet Transport

- Warehousing & Storage

- Loading & Unloading

- Cross-docking

- Production Line Feeding

Value Chain Analysis For Automated Pallet Truck Market

The value chain for the Automated Pallet Truck Market is a complex network involving multiple stages, from raw material sourcing to end-user deployment and post-sales support. Upstream analysis focuses on the procurement of critical components and raw materials, including advanced sensors (LiDAR, cameras), navigation systems, robotics hardware, motors, batteries (primarily lithium-ion), control units, and specialized software. Key suppliers in this segment range from semiconductor manufacturers and robotics component providers to specialized battery technology companies. Strategic partnerships and reliable sourcing are paramount at this stage to ensure the quality, cost-effectiveness, and availability of high-tech components that form the backbone of these sophisticated machines. Efficiency in this upstream segment directly impacts the manufacturing cost and the overall performance of the automated pallet trucks, making supplier relationships critical for market players.

Midstream activities involve the design, engineering, and manufacturing of automated pallet trucks. This stage is characterized by significant research and development (R&D) investments to integrate hardware with sophisticated software for navigation, safety, and operational intelligence. Manufacturers assemble components, program the intelligent systems, and rigorously test the trucks to meet stringent performance and safety standards. This segment is highly competitive, with established industrial automation companies and specialized robotics firms vying for market share. Manufacturing processes often involve advanced robotics and automation themselves to ensure precision and scalability. The quality of engineering and the robustness of the software are critical differentiators, allowing companies to offer innovative solutions that address evolving customer needs and industry challenges.

Downstream analysis covers the distribution channels, sales, installation, and post-sales services. Automated pallet trucks are typically sold through direct sales teams for large enterprise clients, or through a network of distributors, system integrators, and value-added resellers (VARs) who provide localized expertise and integration services. Direct and indirect distribution channels each cater to different market segments and customer scales, with direct sales often preferred for complex, customized solutions and indirect channels expanding market reach for standardized products. Post-sales support, including maintenance contracts, software updates, technical assistance, and training, is a vital part of the value chain, ensuring optimal performance and customer satisfaction. The effectiveness of these downstream activities directly impacts customer loyalty and the long-term success of automated pallet truck deployments, fostering repeat business and market reputation.

Automated Pallet Truck Market Potential Customers

Potential customers for the Automated Pallet Truck Market span a broad spectrum of industries, all characterized by their need for efficient, safe, and cost-effective material handling operations. These end-users are typically organizations with large-scale warehouses, distribution centers, manufacturing plants, or logistics hubs that process high volumes of goods and require repetitive horizontal transport tasks. The primary goal of these buyers is to optimize their internal logistics, reduce operational expenditures associated with manual labor, mitigate risks of workplace accidents, and improve overall throughput and accuracy within their supply chains. E-commerce giants, brick-and-mortar retail chains, and third-party logistics (3PL) providers represent significant customer bases, driven by the intense demands of rapid order fulfillment and complex inventory management in a fast-paced retail environment.

Beyond the retail and logistics sectors, the automotive industry stands as a major end-user, utilizing automated pallet trucks for transporting components between production lines, managing parts inventory, and supporting assembly operations in often highly automated factories. The food and beverage industry also represents a critical customer segment, seeking robust and hygienic solutions for moving perishable goods, raw materials, and finished products within climate-controlled environments and demanding efficient, continuous operations. Pharmaceutical and healthcare facilities are increasingly adopting these technologies to handle sensitive medical supplies, drugs, and equipment, where precision, sterile conditions, and traceability are paramount, demonstrating a strong emphasis on controlled and error-free material flow.

Manufacturing companies across various sub-sectors, including electronics, heavy machinery, and consumer goods, are also prime candidates for automated pallet trucks. These companies leverage automation to feed production lines, transport work-in-progress materials, and move finished goods to storage or shipping areas, aiming to synchronize operations and enhance lean manufacturing principles. Additionally, emerging segments such as chemical and materials processing industries are exploring automated solutions for handling hazardous or bulky materials safely and efficiently. Ultimately, any organization facing challenges with labor availability, seeking to enhance safety standards, or striving to achieve higher levels of operational efficiency and automation in their material flow processes, represents a potential buyer for automated pallet truck solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.35 Billion |

| Market Forecast in 2033 | USD 5.71 Billion |

| Growth Rate | 12.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Toyota Material Handling, KION Group AG, Jungheinrich AG, Hyster-Yale Materials Handling, Inc., Mitsubishi Logisnext Co., Ltd., Crown Equipment Corporation, Honeywell Intelligrated, Daifuku Co., Ltd., SSI Schaefer AG, Scott Technology Ltd., Bastian Solutions (Toyota Advanced Logistics), JBT Corporation, Kollmorgen (Regal Rexnord), Balyo, Seegrid Corporation, Gideon Brothers, Geek+, Quicktron, MHS Global, Swisslog (KUKA Group) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Pallet Truck Market Key Technology Landscape

The Automated Pallet Truck Market is defined by a rapidly evolving technological landscape, where innovations in robotics, artificial intelligence, and connectivity are continuously enhancing the capabilities and versatility of these autonomous vehicles. Core technologies encompass advanced navigation systems, which allow trucks to operate without human guidance. This includes LiDAR (Light Detection and Ranging) for precise mapping and obstacle detection, vision-based systems utilizing cameras and computer vision algorithms for object recognition and environmental understanding, and Natural Feature Navigation (SLAM - Simultaneous Localization and Mapping) that enables trucks to navigate using existing structural features in the environment. Magnetic tape guidance and wire guidance, while more traditional, still find applications in less dynamic or high-traffic settings, demonstrating a spectrum of technological maturity and application-specific relevance.

Beyond navigation, the power source and communication technologies are equally critical. Lithium-ion batteries are rapidly becoming the standard due to their higher energy density, faster charging capabilities, and longer life cycles compared to traditional lead-acid batteries, facilitating continuous operations with minimal downtime. Emerging fuel cell (hydrogen) technology offers even greater autonomy and faster refueling for specific heavy-duty applications, signaling a shift towards more sustainable and efficient power solutions. Communication protocols, including Wi-Fi, 5G, and proprietary wireless networks, ensure seamless interaction between individual trucks, central control systems, warehouse management systems (WMS), and enterprise resource planning (ERP) platforms, creating a fully integrated and intelligent material flow ecosystem capable of real-time data exchange and dynamic task assignment.

The intelligence embedded within automated pallet trucks is largely driven by Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These technologies empower trucks with capabilities such as dynamic route optimization, predictive maintenance, adaptive learning to new environments, and sophisticated decision-making in complex scenarios. Safety is paramount, relying on a suite of sensor technologies including ultrasonic sensors, safety laser scanners, and emergency stop buttons, all integrated with intelligent safety software to prevent collisions and ensure safe operation alongside human workers. The convergence of these advanced hardware and software components defines the cutting edge of automated pallet truck technology, pushing towards more flexible, intelligent, and scalable solutions that address the escalating demands of modern industrial and logistics operations.

Regional Highlights

- North America: The North American market is a dominant force in the adoption of automated pallet trucks, characterized by high labor costs, a mature industrial automation sector, and significant investments in logistics and e-commerce infrastructure. The presence of major e-commerce players and a strong manufacturing base, particularly in automotive and aerospace, drives consistent demand for advanced material handling solutions. Companies in the U.S. and Canada are aggressively integrating these technologies to enhance supply chain resilience, improve operational efficiency, and address the acute shortage of manual labor in warehousing and distribution centers. Stringent safety regulations and a focus on reducing workplace accidents also accelerate the adoption of autonomous systems, making it a pivotal region for technological advancement and market growth.

- Europe: Europe represents a highly competitive and innovative market for automated pallet trucks, driven by a strong emphasis on Industry 4.0 initiatives, sustainable logistics, and high automation penetration in manufacturing. Countries like Germany, Sweden, and the Netherlands are at the forefront of adopting advanced robotics and automation, supported by robust R&D ecosystems and government funding. The region's diverse industrial landscape, encompassing automotive, food & beverage, pharmaceuticals, and general manufacturing, fuels demand for tailor-made automation solutions. Furthermore, the push for eco-friendly operations is boosting the adoption of electric and hydrogen fuel cell-powered automated trucks, aligning with the EU's green industrial policies and fostering innovation in energy efficiency.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as the fastest-growing market for automated pallet trucks, propelled by rapid industrialization, expanding manufacturing capabilities, and the explosive growth of e-commerce, particularly in China, India, Japan, and South Korea. These economies are witnessing massive investments in new warehouse facilities and smart factories, where automation is seen as crucial for scaling operations, improving productivity, and meeting consumer demand. Government support for technological innovation and automation, coupled with a large and increasingly sophisticated manufacturing base, makes APAC a critical hub for both demand and production of automated material handling solutions. The region's diverse economic landscape also allows for a wide range of adoption patterns, from advanced, fully integrated systems in developed nations to more cost-effective solutions in emerging markets.

- Latin America: The Latin American market for automated pallet trucks is in an nascent yet promising growth phase, driven by increasing foreign direct investment in manufacturing, the expansion of modern logistics infrastructure, and the rising awareness of automation benefits. Countries such as Brazil, Mexico, and Argentina are witnessing growing demand for efficient material handling solutions as local industries strive to improve competitiveness and align with global operational standards. While initial adoption rates might be slower due to economic factors and infrastructure development, the potential for long-term growth is substantial as e-commerce penetration increases and businesses seek to optimize their supply chains to meet regional consumer demands and export requirements, making automation an attractive proposition for future industrial expansion.

- Middle East and Africa (MEA): The Middle East and Africa region presents a developing market with significant future potential for automated pallet trucks. Economic diversification efforts in countries like Saudi Arabia and UAE, coupled with large-scale infrastructure projects including new logistics hubs and smart cities, are creating fertile ground for automation technologies. Investments in oil & gas, retail, and e-commerce sectors are driving the need for sophisticated material handling solutions to enhance operational efficiency and reduce reliance on expatriate labor. While the African market is still in its early stages, increasing industrialization and foreign investment in manufacturing and logistics are expected to accelerate the adoption of automated pallet trucks in key sub-Saharan economies, contributing to a gradual but steady market expansion across the broader MEA region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Pallet Truck Market.- Toyota Material Handling

- KION Group AG

- Jungheinrich AG

- Hyster-Yale Materials Handling, Inc.

- Mitsubishi Logisnext Co., Ltd.

- Crown Equipment Corporation

- Honeywell Intelligrated

- Daifuku Co., Ltd.

- SSI Schaefer AG

- Scott Technology Ltd.

- Bastian Solutions (Toyota Advanced Logistics)

- JBT Corporation

- Kollmorgen (Regal Rexnord)

- Balyo

- Seegrid Corporation

- Gideon Brothers

- Geek+

- Quicktron

- MHS Global

- Swisslog (KUKA Group)

Frequently Asked Questions

What is an Automated Pallet Truck?

An Automated Pallet Truck is a self-operating vehicle designed to autonomously transport pallets within warehouses, manufacturing facilities, and distribution centers without human intervention, utilizing advanced navigation and sensor technologies.

What are the primary benefits of using Automated Pallet Trucks?

Key benefits include reduced labor costs, enhanced operational efficiency, improved workplace safety by minimizing human error, increased throughput, and optimized material flow within complex logistics environments.

How does AI impact the performance of Automated Pallet Trucks?

AI significantly enhances performance through dynamic route optimization, predictive maintenance, advanced obstacle avoidance, adaptive learning capabilities, and seamless integration with warehouse management systems, leading to smarter and more efficient operations.

Which industries are the major end-users of Automated Pallet Trucks?

Major end-users include e-commerce & retail, food & beverage, automotive, pharmaceutical & healthcare, and manufacturing, all requiring efficient and precise material handling for their operations.

What are the main types of Automated Pallet Trucks?

The main types are Automated Guided Vehicles (AGVs) Pallet Trucks, which follow predefined paths, and Autonomous Mobile Robots (AMRs) Pallet Trucks, which can navigate dynamically and adapt to changing environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager