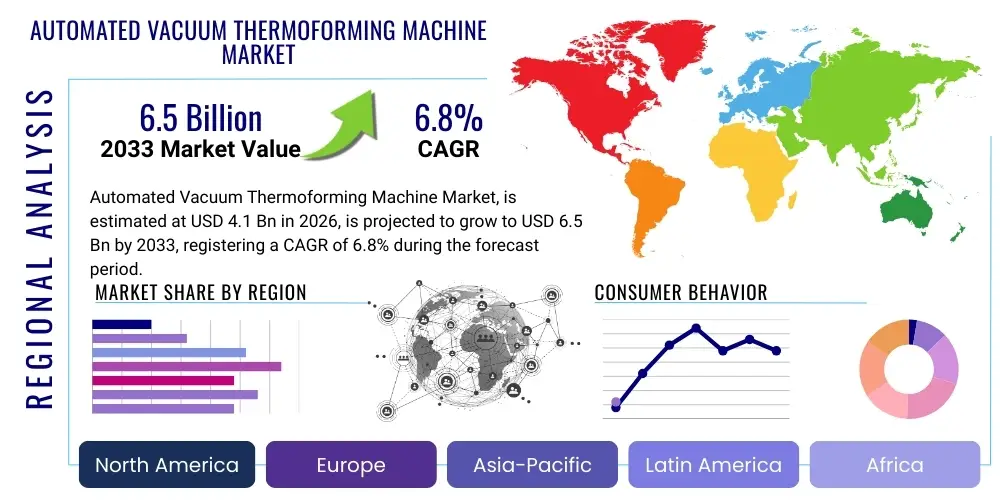

Automated Vacuum Thermoforming Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436608 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Automated Vacuum Thermoforming Machine Market Size

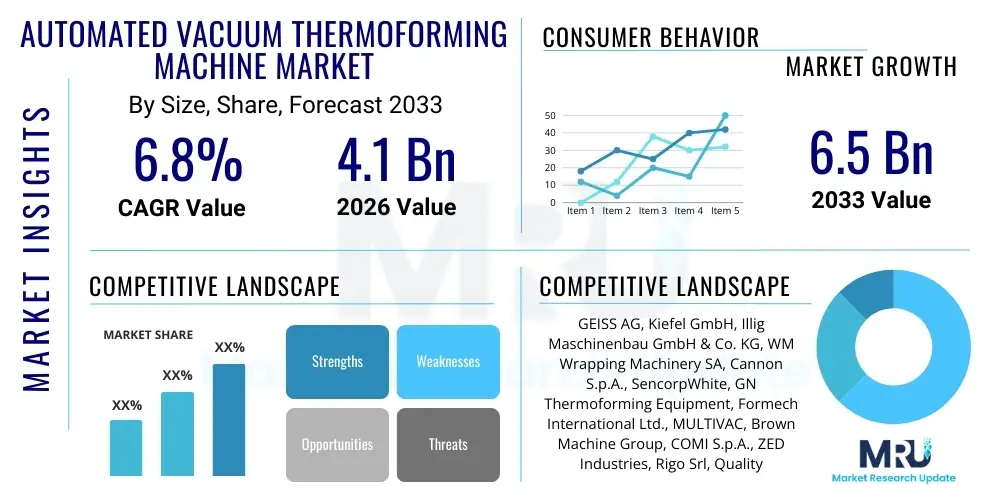

The Automated Vacuum Thermoforming Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.5 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for high-speed, precision packaging solutions across diverse industries, particularly food & beverage, pharmaceuticals, and consumer electronics, necessitating advanced automation to optimize production yield and reduce labor costs.

The market expansion is further underpinned by technological advancements, specifically the integration of sophisticated sensors, Industrial Internet of Things (IIoT) capabilities, and enhanced material compatibility, allowing machines to handle complex polymer structures efficiently. Developed regions, such as North America and Europe, are prioritizing sustainability, pushing manufacturers towards machines capable of processing recycled and bio-based plastics, thereby creating a robust replacement cycle for older, less efficient equipment. The shift toward smaller batch production runs and rapid prototyping, driven by customization trends, necessitates the flexibility and quick changeover capabilities inherent in modern automated thermoforming systems.

Automated Vacuum Thermoforming Machine Market introduction

The Automated Vacuum Thermoforming Machine Market encompasses advanced industrial equipment designed for high-volume plastic forming processes, utilizing heat and vacuum pressure to shape thermoplastic sheets into desired product geometries. These systems are characterized by continuous, automated operation, integrating functions such as sheet feeding, heating, forming, trimming, and stacking into a seamless, high-speed production line. Key applications span rigid packaging (trays, clamshells, blister packs), automotive components (interior parts, dashboards), medical devices (sterile packaging), and consumer goods, offering superior speed and precision compared to traditional manual or semi-automated methods. The primary driving factors include the stringent regulatory requirements for sterile pharmaceutical packaging, the rapid growth of the e-commerce sector demanding protective and aesthetically pleasing consumer packaging, and the global push towards optimizing manufacturing efficiency and reducing operational waste.

Automated Vacuum Thermoforming Machine Market Executive Summary

The Automated Vacuum Thermoforming Machine Market is currently experiencing robust growth, primarily propelled by global business trends emphasizing operational efficiency, supply chain resilience, and sustainable manufacturing practices. Key business trends include the consolidation among major machinery manufacturers focused on integrating advanced Industry 4.0 features, such as predictive maintenance and remote diagnostics, into their product offerings. Furthermore, the rising adoption of high-barrier films and multilayer materials for extended shelf life in the food industry is driving demand for sophisticated forming technologies capable of handling diverse material specifications and thicknesses with high precision, ensuring consistent quality across mass production cycles and significantly reducing material scrap rates.

Regionally, the Asia Pacific (APAC) market is exhibiting the fastest growth trajectory, fueled by rapid industrialization, burgeoning middle-class consumption, and massive expansion in the domestic food processing and electronics manufacturing sectors in countries like China, India, and Southeast Asia. Conversely, North America and Europe maintain dominance in terms of technological maturity and high adoption rates of advanced, energy-efficient machinery, driven by stringent environmental regulations and high labor costs, necessitating maximum automation penetration. Latin America and MEA are emerging as key opportunity zones, supported by investments in new manufacturing infrastructure and improving supply chain logistics, shifting consumption patterns towards packaged goods.

Segmentation trends indicate that continuous forming machines, particularly those utilizing roll-fed processes, dominate the market due to their suitability for high-volume packaging applications. Material-wise, Polystyrene (PS) and Polyethylene Terephthalate (PET) remain the most utilized resins, though there is a discernible shift towards machines optimized for bio-plastics and recycled PET (rPET) in alignment with corporate sustainability goals. The Food and Beverage industry segment consistently commands the largest market share, driven by the indispensable need for standardized, sterile, and attractive packaging solutions, closely followed by the Medical and Pharmaceutical sectors where regulatory compliance and product integrity are paramount considerations for equipment selection and procurement.

AI Impact Analysis on Automated Vacuum Thermoforming Machine Market

User queries regarding the impact of Artificial Intelligence (AI) on automated thermoforming systems predominantly center around operational optimization, quality control enhancement, and predictive maintenance capabilities. Users are keen to understand how AI algorithms can minimize material waste, autonomously adjust machine parameters based on real-time sensory data (e.g., material temperature variance, vacuum pressure fluctuations), and predict equipment failures before they cause costly downtime. The central themes reveal high expectations for AI to transition thermoforming from a reactive, operator-dependent process to a highly proactive, self-optimizing manufacturing cell, leading to higher throughputs and significantly improved product uniformity, especially in complex, high-precision molding applications required by the medical and aerospace industries.

- AI algorithms enable real-time defect detection using machine vision systems, minimizing human error and ensuring immediate process adjustments.

- Predictive maintenance schedules are optimized through AI analysis of vibrational data and operational history, significantly reducing unplanned downtime and maintenance costs.

- Autonomous parameter tuning utilizes reinforcement learning to optimize heating cycles, cooling times, and vacuum levels based on material characteristics, maximizing energy efficiency.

- Supply chain integration is enhanced, using AI to forecast material requirements and schedule production runs efficiently, aligning machine throughput with dynamic market demand.

- AI supports the rapid programming of complex mold designs and facilitates virtual commissioning, accelerating new product introduction (NPI) cycles.

DRO & Impact Forces Of Automated Vacuum Thermoforming Machine Market

The Automated Vacuum Thermoforming Machine Market is propelled by powerful growth drivers, tempered by significant restraints, and presents numerous untapped opportunities, all interacting to form a complex set of impact forces shaping its trajectory. A primary driver is the pervasive demand for improved packaging quality and aesthetics across consumer-facing industries, coupled with the necessity for highly sterile packaging in the burgeoning medical device sector. However, the high initial capital expenditure associated with purchasing and implementing fully automated, high-precision thermoforming machinery acts as a major restraint, particularly for Small and Medium-sized Enterprises (SMEs) in developing economies. Opportunities are abundant in the adoption of sustainable packaging materials and the customization of specialized machinery for emerging niche applications, such as large-format architectural components or complex drone casings.

Impact forces are centered around technological disruption and regulatory shifts. The increasing integration of smart factory technologies, including IIoT, machine learning, and advanced robotics for automated loading and unloading, represents a powerful accelerating force, pushing the boundaries of machine speed and precision. Conversely, stringent global regulations concerning plastic waste and recyclability, particularly in the European Union, necessitate costly R&D efforts for machinery compatible with diverse bio-plastics and post-consumer recycled content, posing a restrictive force while simultaneously creating market opportunities for compliant solutions. The volatile nature of raw material (plastic resin) prices also exerts significant pressure on machinery operating costs, forcing end-users to seek out equipment that offers superior material yield and waste reduction capabilities to maintain profitability margins.

Furthermore, the competitive landscape is intensely focused on patent protection and intellectual property related to heating efficiency and rapid mold changeover mechanisms, enhancing the differentiation between market leaders. The need for specialized technical expertise to operate and maintain these complex automated systems presents a unique restraint, driving demand for simplified Human-Machine Interfaces (HMIs) and remote diagnostic support offered by manufacturers. The overarching force remains the global population increase and subsequent rising consumer spending on packaged goods, which inherently guarantees sustained long-term demand for high-speed, reliable automated thermoforming solutions capable of scaling production quickly and cost-effectively to meet the exponentially increasing global consumption rates.

Segmentation Analysis

The Automated Vacuum Thermoforming Machine Market is segmented based on product type, operation type, automation level, end-use application, and material processed, reflecting the diverse industrial requirements and technological complexity inherent in the manufacturing process. This deep segmentation allows stakeholders to accurately gauge market penetration and demand concentration across various niches, from high-speed, continuous packaging lines to lower-volume, specialized custom part fabrication. Understanding these segments is crucial as market dynamics are heavily influenced by the varying capital investment cycles and regulatory pressures within each end-user sector, such as the strict validation requirements in the pharmaceutical industry versus the high throughput demands of the consumer electronics sector.

By Product Type, the market is broadly classified into Thin Gauge and Thick Gauge thermoforming machines. Thin-gauge systems dominate in terms of volume, catering primarily to disposable and rigid packaging solutions where material thickness is less than 1.5mm. Thick-gauge machines (above 1.5mm) are crucial for durable goods, functional parts, and specialized applications like automotive interiors, recreational vehicle components, and large protective enclosures, commanding higher unit prices due to their robustness and specialized heating capabilities. The convergence of automation and precision across all segments is a key trend, pushing manufacturers to offer modular solutions that allow rapid reconfiguration for handling different gauges and material types, thus maximizing machine utilization and versatility in a dynamic manufacturing environment.

The End-Use Application segment remains the most influential factor driving technology investment, with the Food and Beverage sector requiring superior hygiene standards and speed, while the Medical and Pharmaceutical segment demands absolute process validation and traceability. The rising prominence of the electronics and automotive sectors, particularly concerning customized interiors and sophisticated component protection, is catalyzing demand for machines with integrated trimming and robotic handling systems to achieve complex geometries and tight tolerances. This targeted demand necessitates machine designs that prioritize specific features, such as deep-draw capabilities for food containers or high-temperature forming for engineering plastics used in industrial components, further stratifying the competitive landscape based on specialized expertise.

- By Product Type:

- Thin Gauge Automated Thermoforming Machines (Typically 0.2 mm to 1.5 mm thickness)

- Thick Gauge Automated Thermoforming Machines (Typically 1.5 mm to 10 mm thickness)

- By Operation Type:

- Roll-fed Systems (Continuous Production)

- Sheet-fed Systems (Batch Production)

- By Automation Level:

- Fully Automated Systems (Integrated trimming, stacking, and robotic handling)

- Semi-Automated Systems (Manual Loading or Unloading)

- By End-Use Application:

- Food and Beverage Packaging (Containers, Trays, Cups)

- Medical and Pharmaceutical Packaging (Blister Packs, Sterile Trays)

- Consumer Goods and Electronics Packaging

- Automotive Components (Interior Trim, Body Parts)

- Industrial and Construction Applications

- By Material Processed:

- Polystyrene (PS)

- Polyethylene Terephthalate (PET and rPET)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- ABS and other engineering plastics

- Bio-plastics and Compostable Polymers

Value Chain Analysis For Automated Vacuum Thermoforming Machine Market

The value chain for the Automated Vacuum Thermoforming Machine Market commences with upstream activities involving raw material suppliers, primarily high-precision steel and alloy manufacturers for machine frames and molds, and specialized component providers supplying advanced heating elements, vacuum pumps, pneumatic systems, and sophisticated programmable logic controllers (PLCs). The competitive advantage at this stage often lies in securing high-quality, durable components that contribute directly to the machine's overall operational lifespan and reliability, which are crucial selling points for automated industrial equipment. The middle stage involves the machine manufacturers themselves, who focus heavily on R&D, system integration, software development (HMI and control systems), and precision engineering to meet specific forming parameters, transforming raw components into complex, high-speed automated production units ready for deployment.

Downstream analysis focuses on the distribution channels and the end-user deployment and service stages. Distribution is typically handled through a combination of direct sales forces for large, bespoke systems requiring extensive customization and highly specialized, regional distributors or agents who provide local sales support, installation, training, and critical after-sales service. The effectiveness of the after-market service, including spare parts availability and rapid technical support, significantly impacts customer satisfaction and long-term revenue streams for manufacturers. Furthermore, key strategic alliances between machine builders and mold makers are becoming increasingly common to offer integrated, turnkey solutions to end-users, streamlining the procurement and validation process, especially within regulated industries like medical device manufacturing.

Direct sales are prevalent when dealing with major global corporations procuring multiple high-cost, customized machines, ensuring detailed technical consultation and direct contractual relationships. Indirect distribution, leveraging local agents, is essential for penetrating geographically dispersed or emerging markets where localized knowledge of regulatory compliance and installation environments is paramount. The increasing trend towards subscription-based maintenance services (Service-as-a-Service, S-a-a-S) and remote monitoring, enabled by IIoT connectivity, is fundamentally altering the service component of the downstream value chain, shifting revenue generation from one-time sales to continuous operational partnerships focused on maximizing customer uptime and performance efficiency.

Automated Vacuum Thermoforming Machine Market Potential Customers

The primary potential customers and end-users of Automated Vacuum Thermoforming Machines are large-scale manufacturers and specialized packaging converters operating across highly regulated and volume-intensive industries. The largest customer segment encompasses rigid packaging providers who supply trays, clamshells, and containers to the vast Food and Beverage industry, including fresh produce, frozen meals, dairy products, and baked goods, where speed, hygiene, and low per-unit cost are critical procurement drivers. These buyers require continuous, roll-fed systems capable of running 24/7 operations with minimal labor intervention, demanding exceptional reliability and integrated quality control mechanisms to prevent costly mass recalls.

Another significant customer base lies within the Medical Device and Pharmaceutical manufacturing sectors. These customers purchase machines specifically designed for cleanroom environments (ISO certification), requiring high precision for sterile barrier systems, blister packs, and validated trays for surgical instruments and medical implants. For these buyers, regulatory compliance, documented process validation (IQ/OQ/PQ), material traceability, and minimizing particulate contamination are the highest priorities, often justifying the investment in the most technologically advanced and expensive equipment available, often featuring integrated automated handling solutions to maintain sterility.

Furthermore, specialized industrial manufacturers, including those in the automotive, aerospace, and consumer electronics fields, constitute a growing segment. These customers utilize thick-gauge thermoforming for custom components such as vehicle interior panels, protective coverings for fragile electronic assemblies, and specialized equipment housings. Their purchasing decisions are driven by the machine's ability to handle complex geometries, high-performance engineering plastics, and the capability for in-line trimming and robotic routing to achieve tight dimensional tolerances, differentiating them from high-volume packaging converters primarily concerned with speed and throughput metrics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEISS AG, Kiefel GmbH, Illig Maschinenbau GmbH & Co. KG, WM Wrapping Machinery SA, Cannon S.p.A., SencorpWhite, GN Thermoforming Equipment, Formech International Ltd., MULTIVAC, Brown Machine Group, COMI S.p.A., ZED Industries, Rigo Srl, Quality Vacuum Formers, Toolless Plastic Solutions, Pishon Automation, MAAC Machinery, V.F.P., Gabler Thermoform GmbH, Thermoforming Systems LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automated Vacuum Thermoforming Machine Market Key Technology Landscape

The technological landscape of the Automated Vacuum Thermoforming Machine Market is characterized by continuous advancements aimed at improving energy efficiency, material flexibility, speed, and precision control. A primary focus is the development of sophisticated heating technologies, moving beyond traditional resistive elements to integrated ceramic heaters and advanced infrared systems that offer precise, zonal temperature control and dramatically reduce warm-up times. These innovations are critical for efficiently processing multilayer and composite films, ensuring uniform material heating across large sheets, thereby preventing weak spots and improving the quality of the formed product, especially for deep-draw applications where material distribution is a key challenge.

Furthermore, the integration of Industry 4.0 principles, including high-speed communication protocols and advanced sensor arrays, is transforming modern thermoforming machines into smart, connected assets. Machines are now routinely equipped with IIoT capabilities, allowing for cloud-based data acquisition, remote monitoring, and comprehensive machine-to-machine (M2M) communication within a production line environment. This connectivity facilitates predictive maintenance regimes, enables rapid diagnostic troubleshooting by remote technicians, and allows manufacturers to optimize complex processing variables using proprietary software algorithms, shifting the operational paradigm towards data-driven manufacturing excellence and minimizing reliance on manual operator expertise for fine-tuning production runs.

Another major technological trend involves the evolution of mold technology and handling automation. Quick-change mold systems, utilizing automated clamping and cooling connections, drastically reduce downtime during product changeovers, a crucial factor for companies running diverse product portfolios. Coupled with sophisticated five-axis trimming robots and vision-guided pick-and-place systems, modern automated thermoforming lines now offer unparalleled speed and flexibility in handling finished parts, especially fragile or complex shapes. Additionally, technology development is heavily invested in vacuum pump efficiency and rapid pressure cycling capabilities, allowing for faster forming times while maintaining consistent, high-fidelity reproduction of mold details, which is essential for detailed consumer product packaging and intricate medical components.

Regional Highlights

The global Automated Vacuum Thermoforming Machine Market exhibits distinct characteristics across its primary geographical regions—North America, Europe, Asia Pacific (APAC), Latin America, and Middle East & Africa (MEA)—each driven by unique economic, regulatory, and industrial factors. North America remains a significant market, characterized by high adoption rates of the most advanced, high-speed automated systems. The region’s growth is fueled by robust demand from the medical device manufacturing sector, which requires validated, high-precision packaging machinery to comply with FDA regulations, and the fast-moving consumer goods (FMCG) sector, which prioritizes energy efficiency and integration with sophisticated robotic packaging lines to offset high labor costs. Investments are primarily directed towards upgrading legacy equipment with IIoT functionality and systems compatible with sustainable materials like RPET and bio-based polymers to align with increasing consumer environmental awareness and corporate social responsibility goals.

Europe holds a commanding position in terms of technological innovation and market maturity, largely driven by strict environmental mandates, particularly the EU Plastics Strategy, which necessitates significant investment in machinery capable of processing high percentages of recycled content and monomaterials for easier recycling. European manufacturers, particularly in Germany and Italy, are global leaders in producing high-precision, robust thermoforming equipment, often integrating proprietary heating and cooling technologies that deliver superior energy performance. The demand is heavily concentrated in sophisticated food packaging, emphasizing extended shelf life (Modified Atmosphere Packaging or MAP) and traceability, pushing regional adoption towards highly customized, fully automated roll-fed systems designed for seamless integration into complex, high-hygiene factory environments, maintaining a competitive edge through engineering quality and adherence to rigorous standards.

The Asia Pacific region, led by China, India, and Southeast Asian nations, is the fastest-growing market globally, primarily driven by explosive growth in manufacturing output, rapid urbanization, and rising per capita income leading to increased consumption of packaged foods and electronics. The demand here is dual-pronged: a need for cost-effective, high-volume machines for standard food packaging and an emerging requirement for advanced, high-precision systems to support growing domestic automotive and electronics assembly hubs. Government policies supporting 'Make in India' or 'Made in China 2025' initiatives encourage local and foreign investment in modern factory infrastructure, accelerating the shift from semi-automated processes to fully automated thermoforming lines, focusing heavily on acquiring machinery that offers competitive throughput metrics and scalability to meet rapidly expanding local and export market demands simultaneously.

Latin America and the Middle East & Africa (MEA) represent emerging opportunity areas, characterized by ongoing economic diversification and significant investments in local packaging manufacturing capabilities to reduce reliance on imported finished goods. In Latin America, countries like Brazil and Mexico are seeing increased demand driven by the packaged food industry and automotive component manufacturing, requiring reliable, medium-to-high capacity automated machines. The MEA region, particularly the GCC countries, is investing heavily in food security initiatives and pharmaceutical production infrastructure, necessitating specialized thermoforming equipment that meets international standards for quality and hygiene. While price sensitivity remains a factor in procurement decisions in these regions, the long-term trend favors automated systems due to the clear operational benefits in terms of waste reduction and consistent product quality, promoting greater market penetration for international machinery suppliers offering robust service and local support infrastructure.

- North America: Focus on medical device packaging (FDA compliance), automation for labor cost mitigation, and high demand for rPET and sustainable material processing capabilities.

- Europe: Driven by stringent environmental regulations (EU Plastics Strategy), leading innovation in energy efficiency and material science; strong demand in high-end food and pharmaceutical sectors.

- Asia Pacific (APAC): Highest growth region fueled by rapid industrialization, massive packaging consumption growth, and expanding domestic manufacturing in electronics and automotive sectors; emphasis on scalable, high-volume systems.

- Latin America: Emerging market with increasing industrial investment, demand focused on food and beverage packaging expansion, and automotive component production in large economies like Brazil.

- Middle East & Africa (MEA): Growth stimulated by new infrastructure projects in food processing and pharmaceuticals, aiming for self-sufficiency and compliance with international hygiene standards, increasing the uptake of automated systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automated Vacuum Thermoforming Machine Market.- GEISS AG

- Kiefel GmbH

- Illig Maschinenbau GmbH & Co. KG

- WM Wrapping Machinery SA

- Cannon S.p.A.

- SencorpWhite

- GN Thermoforming Equipment

- Formech International Ltd.

- MULTIVAC

- Brown Machine Group

- COMI S.p.A.

- ZED Industries

- Rigo Srl

- Quality Vacuum Formers

- Toolless Plastic Solutions

- Pishon Automation

- MAAC Machinery

- V.F.P.

- Gabler Thermoform GmbH

- Thermoforming Systems LLC

Frequently Asked Questions

Analyze common user questions about the Automated Vacuum Thermoforming Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of fully automated thermoforming machines?

The primary factor driving adoption is the necessity for increased operational efficiency and reduced production costs through high throughput, coupled with the stringent quality and hygiene standards required in the food, beverage, and medical packaging sectors, where consistent, automated processes minimize contamination risk and waste.

How are environmental regulations impacting the design of new thermoforming equipment?

Environmental regulations, particularly in Europe, are forcing manufacturers to design machines compatible with high percentages of post-consumer recycled (PCR) materials and bio-plastics, requiring advanced heating controls and sophisticated forming processes to handle the variable characteristics of these sustainable resins efficiently.

Which end-use application segment holds the largest market share for automated thermoforming?

The Food and Beverage packaging segment consistently holds the largest market share due to the immense global volume of trays, cups, and containers required for standardized and sterilized consumer products, necessitating continuous, high-speed roll-fed automated systems.

What role does Industry 4.0 play in the competitive landscape of this market?

Industry 4.0 plays a crucial role by enabling features such as IIoT connectivity, predictive maintenance, and AI-driven quality control. These features offer end-users higher uptime, remote diagnostics, and optimized energy usage, becoming major differentiators and key competitive advantages for leading machine manufacturers.

What is the expected CAGR for the Automated Vacuum Thermoforming Machine Market through 2033?

The Automated Vacuum Thermoforming Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by industrial automation trends and increasing global demand for sophisticated packaging solutions across emerging economies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager