Automatic Biomass Briquetting Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433186 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Automatic Biomass Briquetting Machine Market Size

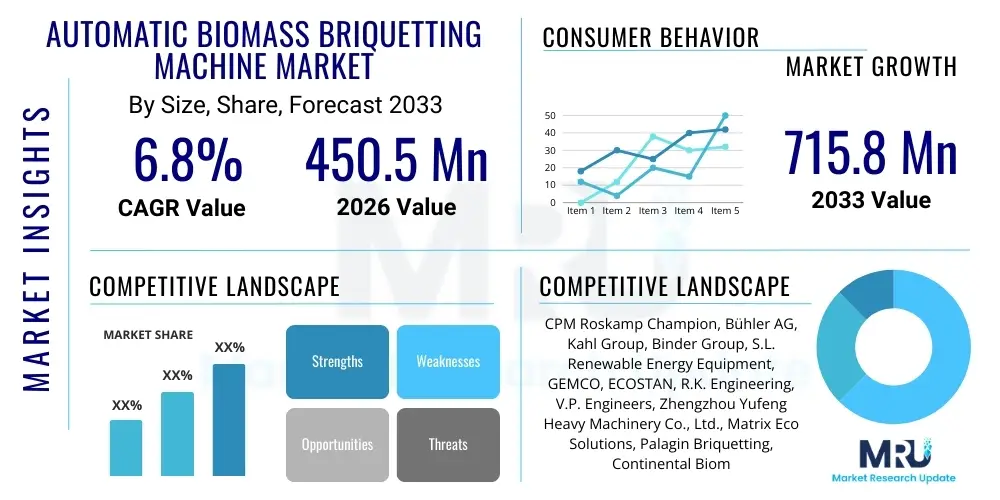

The Automatic Biomass Briquetting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 million in 2026 and is projected to reach USD 715.8 million by the end of the forecast period in 2033.

Automatic Biomass Briquetting Machine Market introduction

The Automatic Biomass Briquetting Machine Market encompasses equipment designed for compressing various agricultural and forest waste materials—such as sawdust, crop residue, and groundnut shells—into high-density, uniform solid fuel blocks known as briquettes. This machinery operates autonomously, reducing the need for continuous manual intervention, thereby increasing production efficiency and lowering operational costs. These briquettes serve as an environmentally friendly, high-calorific alternative to traditional fossil fuels like coal, finding extensive application in industrial boilers, thermal power generation, heating systems, and domestic cooking, especially across developing economies focused on sustainable energy transitions. The primary objective of these machines is waste volume reduction and value addition to biomass waste streams, contributing significantly to circular economy initiatives and rural energy security.

Key technological advancements driving this market include the integration of hydraulic pressing systems, screw press mechanisms, and automated material handling units, ensuring consistent product quality and throughput capacity. The high pressure exerted by these automatic systems eliminates the need for binding agents, producing clean fuel that burns more efficiently with lower emissions compared to raw biomass. The growing global impetus toward renewable energy sources, coupled with strict regulations concerning agricultural waste burning, positions the Automatic Biomass Briquetting Machine as a critical component in the modern bioenergy infrastructure.

Major applications span diverse sectors, including cement production, textile processing, brick kilns, and large-scale commercial heating. The inherent benefits, such as reduced transportation costs for compressed fuel, stable energy supply, and utilization of otherwise discarded waste, significantly drive market penetration. Furthermore, governmental subsidies and incentive programs aimed at promoting bioenergy generation, particularly in Asia Pacific and Europe, act as substantial accelerants for the adoption of these automated solutions.

Automatic Biomass Briquetting Machine Market Executive Summary

The Automatic Biomass Briquetting Machine Market is characterized by robust growth, primarily fueled by the accelerating global transition towards sustainable energy and improved waste management practices. Key business trends include the increasing integration of Internet of Things (IoT) sensors and remote monitoring capabilities into briquetting systems, enhancing predictive maintenance and operational efficiency for large-scale users. Furthermore, market participants are focusing on developing high-capacity, multi-feedstock processing machines capable of handling heterogeneous biomass inputs, addressing the varied agricultural landscapes globally. Strategic collaborations between machinery manufacturers and biomass logistics providers are becoming common to create integrated supply chain solutions, thereby reducing the entry barriers for new briquette producers.

Regionally, Asia Pacific dominates the market, driven by massive agricultural residue availability in countries like India and China, coupled with strong governmental support for converting waste to energy to tackle pollution and meet ambitious renewable energy targets. Europe is witnessing significant growth due to stringent environmental policies, high fossil fuel costs, and established bioenergy markets seeking constant supply optimization. North America focuses more on developing high-throughput systems for forestry residue utilization, emphasizing quality control and pelletization processes, which are often integrated with briquetting technologies.

Segment trends reveal a strong preference for hydraulic press technology due to its ability to produce highly dense briquettes without binders, ensuring superior energy output, although screw press machines remain popular for medium-scale operations requiring flexibility. The end-user segment is heavily weighted towards industrial heating applications, such as large boiler operations and power plants, which require bulk, consistent, and cost-effective fuel sources. The increasing automation level across all segments reflects the market's maturity and the industry’s need for minimal labor and maximal throughput, driving investment in fully automatic models over semi-automatic alternatives.

AI Impact Analysis on Automatic Biomass Briquetting Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Automatic Biomass Briquetting Machine Market predominantly center on achieving operational predictability, optimizing feedstock quality management, and automating complex maintenance schedules. Users are keen to understand how AI-driven vision systems can analyze the moisture content and heterogeneity of incoming biomass streams in real-time to adjust machine parameters (pressure, temperature, dwell time) instantaneously, thereby maximizing briquette quality and minimizing energy consumption. Concerns also revolve around the cost-effectiveness of integrating sophisticated AI models into traditional mechanical systems and the requirement for specialized technical staff capable of maintaining and interpreting AI-generated insights. Overall, the expectation is that AI will transform briquetting from a mechanical conversion process into a smart, self-optimizing manufacturing operation, significantly enhancing efficiency and reducing unplanned downtime.

- AI-Powered Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and pressure data from critical components (screws, dies, hydraulic pumps) to forecast potential failures, minimizing downtime and maximizing equipment lifespan.

- Feedstock Quality Optimization: Employing computer vision and sensor fusion combined with AI to assess and classify diverse biomass inputs (particle size, moisture level, composition) in real-time, automatically adjusting briquetting parameters for optimal density and combustion characteristics.

- Automated Process Control: Implementing reinforcement learning to continuously fine-tune operational settings (e.g., feeder speed, hydraulic pressure cycle) based on output quality metrics, achieving higher energy efficiency and consistent briquette standards.

- Supply Chain and Logistics Forecasting: Using AI to predict the availability and pricing of specific biomass types across different regions, optimizing procurement strategies and raw material inventory management for briquetting facilities.

- Energy Consumption Reduction: Applying AI algorithms to monitor and modulate power usage during peak and off-peak times, optimizing the machine's energy footprint based on grid prices and production targets.

DRO & Impact Forces Of Automatic Biomass Briquetting Machine Market

The Automatic Biomass Briquetting Machine Market is primarily driven by escalating global energy demands, coupled with the urgent need for sustainable waste management solutions, positioning biomass briquettes as a critical component in the renewable energy mix. Restraints include the high initial capital investment required for fully automatic, large-capacity machines and the logistical challenges associated with consistent biomass collection, transportation, and storage, which can be highly seasonal and geographically dispersed. Opportunities abound in emerging economies where large quantities of agricultural waste are currently underutilized or openly burned, offering vast untapped resources for briquetting conversion. The impact forces are significantly modulated by regulatory frameworks promoting biomass utilization and the volatility of fossil fuel prices, which make biomass briquettes a competitively priced alternative.

Key drivers include substantial government incentives and subsidies worldwide, particularly in fast-growing industrial economies, aimed at promoting biomass energy use and reducing greenhouse gas emissions. The rising awareness regarding the negative environmental impacts of conventional waste disposal methods, such as landfilling and open-field burning of crop residue, further pushes the adoption of briquetting technology as a responsible disposal and value-addition technique. Moreover, technological advancements leading to machines with higher throughput, increased energy efficiency, and lower maintenance requirements are lowering the total cost of ownership, making them more accessible to small and medium-scale enterprises.

However, the market faces constraints related to the heterogeneity of biomass feedstock, which requires specialized pre-processing steps (like drying and grinding) before briquetting, adding complexity and cost to the process. Furthermore, the lack of standardized testing and quality certification for biomass briquettes across all regions sometimes hampers their acceptance in highly regulated industrial applications. Nonetheless, the inherent market opportunity lies in developing robust, mobile briquetting solutions that can process decentralized agricultural residues at the source, streamlining the supply chain and dramatically reducing logistical costs, especially in rural areas with plentiful feedstock.

Segmentation Analysis

The Automatic Biomass Briquetting Machine Market is comprehensively segmented based on technology type, material type, application, and capacity, providing granular insights into varying demand patterns across end-user industries. Technology segmentation differentiates between high-pressure hydraulic presses, which are favored for producing high-density industrial fuel, and screw presses, which offer flexibility in feedstock handling and are often preferred for smaller operations. Capacity segmentation, ranging from low (under 1 ton/hour) to high (over 4 tons/hour), dictates the market's response to different scales of industrial and commercial biomass usage, directly correlating with the level of automation required.

Material type classification focuses on the biomass source, including agricultural waste (like rice husk, cotton stalk, groundnut shells) and forestry residue (such as sawdust, wood chips, and logging waste). The preference for specific machines often depends on the inherent characteristics of these materials, such as density and lignin content. Application segmentation identifies the primary users, with industrial boilers, heating systems, and power generation facilities being the most significant consumers of the resulting briquettes, driving demand for robust, continuous operation machinery.

Geographically, the segmentation highlights regions with high agricultural activity and established bioenergy policies, confirming the localized nature of biomass feedstock supply and consumption. This detailed segmentation aids stakeholders in tailoring their product offerings and marketing strategies to specific regional and operational needs, focusing on customized solutions that maximize feedstock utilization and optimize fuel properties for different applications.

- By Technology:

- Hydraulic Press Briquetting Machine

- Screw Press Briquetting Machine

- Ram/Piston Press Briquetting Machine

- By Material Type:

- Agricultural Residue (Rice Husk, Bagasse, Cotton Stalk, etc.)

- Forestry Residue (Sawdust, Wood Chips, Bark, etc.)

- Industrial Waste (Paper Pulp, Coir Pith, etc.)

- By Capacity:

- Low Capacity (Under 1 Ton/Hour)

- Medium Capacity (1 to 4 Tons/Hour)

- High Capacity (Above 4 Tons/Hour)

- By Application:

- Industrial Heating & Boiler Fuel

- Power Generation

- Commercial & Residential Heating

- Brick Kilns and Furnaces

Value Chain Analysis For Automatic Biomass Briquetting Machine Market

The value chain for the Automatic Biomass Briquetting Machine Market begins with the upstream suppliers of raw materials, primarily steel, specialized components (hydraulic cylinders, motors, gearbox systems, heating elements), and electronic controls. Manufacturers focus on procurement efficiencies and quality control of these specialized components, as machine reliability and operational lifespan are highly dependent on the quality of inputs. Upstream analysis also involves specialized engineering firms that design and provide blueprints for the high-pressure molding mechanisms and automated feeding systems, which constitute the core intellectual property of briquetting technology.

The midstream involves the core activity of machine manufacturing, assembly, rigorous testing, and quality assurance. Direct distribution channels involve manufacturers selling high-capacity machines directly to large industrial end-users (e.g., power plants or large biomass processing facilities), often requiring extensive post-sales support, installation, and operator training. Indirect channels, typically involving regional distributors and authorized dealers, handle sales of medium and low-capacity machines to SMEs and agricultural cooperatives, utilizing established local networks for quicker market penetration and localized maintenance support.

Downstream activities center on machine installation, commissioning, maintenance, and the crucial consumption of the resulting biomass briquettes. Downstream analysis emphasizes the symbiotic relationship between machine providers and biomass fuel purchasers, such as large boiler operators or industrial heating units. Efficient logistics and reliable after-sales service are critical in maintaining long-term customer relationships and ensuring optimal machine performance, especially given the continuous and demanding operational environments typical in bioenergy production.

Automatic Biomass Briquetting Machine Market Potential Customers

The primary potential customers for automatic biomass briquetting machines are industries that rely heavily on thermal energy or seek efficient solutions for managing large volumes of organic waste. These customers typically prioritize operational continuity, fuel cost reduction, and compliance with increasingly strict environmental regulations. The largest segment of buyers includes manufacturers operating large industrial boilers in sectors such as cement, textiles, sugar mills, and food processing, all of whom require high-quality, consistent, and cost-effective solid fuel for their heating processes.

Another significant customer segment comprises dedicated bioenergy generation companies and thermal power plants actively shifting away from coal toward renewable fuels to meet sustainability quotas and carbon reduction targets. These large-scale facilities specifically demand high-capacity, fully automated briquetting systems that can operate continuously, handling vast quantities of diverse biomass feedstock while maintaining stringent fuel quality specifications necessary for grid-connected power generation.

Furthermore, agricultural cooperatives, large farm holdings, and wood processing facilities (sawmills and furniture manufacturers) represent a growing customer base. For these entities, the briquetting machine acts primarily as a waste management solution that converts otherwise discarded residue into a valuable, marketable fuel source or a cost-saving heat source for their internal operations. Their purchasing decisions are often influenced by the machine’s capacity to handle specific regional biomass types and its ease of operation and maintenance in non-industrial settings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 million |

| Market Forecast in 2033 | USD 715.8 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CPM Roskamp Champion, Bühler AG, Kahl Group, Binder Group, S.L. Renewable Energy Equipment, GEMCO, ECOSTAN, R.K. Engineering, V.P. Engineers, Zhengzhou Yufeng Heavy Machinery Co., Ltd., Matrix Eco Solutions, Palagin Briquetting, Continental Biomass Industries (CBI), General Energy Biomass (GEB), Promecon, Shanghai Dongmeng Road & Bridge Machinery Co., Ltd., Teknovas, Makel Machinery, JK Bioenergy, Amandus Kahl GmbH & Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automatic Biomass Briquetting Machine Market Key Technology Landscape

The technology landscape of the Automatic Biomass Briquetting Machine Market is dominated by two primary methodologies: high-pressure hydraulic presses and high-torque screw extruders. Hydraulic press machines utilize immense pressure, often exceeding 1,500 kg/cm², to compress pre-processed biomass into dense, cylindrical briquettes without the addition of any chemical binders. This method is highly effective for producing fuel logs characterized by high mechanical stability and superior calorific value, making them ideal for large-scale industrial consumers demanding premium fuel quality and consistency. Continuous innovation in this space focuses on developing more robust hydraulic systems with quicker cycle times and reduced energy consumption per unit of output.

Screw press technology, conversely, utilizes a specialized screw mechanism to simultaneously compress and heat the biomass. The frictional heat generated during this extrusion process causes the lignin naturally present in the biomass to soften and act as a natural binding agent. This technology is often favored for processing materials with high lignin content, like wood sawdust, and is known for producing hole-in-the-center briquettes (pini-kay style), which offer better combustion properties. Current technological refinements in screw presses include optimizing screw geometry and materials to reduce wear and tear, which historically has been a major maintenance concern, thereby enhancing operational longevity and efficiency.

A significant trend in modern automatic briquetting machines is the integration of peripheral technologies crucial for fully automated operation. This includes automated feeding systems (conveyors and agitators) ensuring a consistent flow of feedstock, sophisticated moisture sensors for real-time quality control, and advanced Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) for remote monitoring and centralized control. The future trajectory involves incorporating digital twin technology for simulated testing and maintenance, further elevating the operational efficiency and predictive capabilities of these biomass conversion systems.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, primarily due to the vast availability of agricultural waste (e.g., rice husk, wheat straw) in countries like India, China, and Southeast Asian nations. Governments in these regions are aggressively promoting biomass briquetting to curb air pollution caused by crop residue burning and secure decentralized energy supplies. Industrialization and rapid urbanization necessitate reliable energy sources, positioning automatic briquetting machines as essential equipment for waste-to-energy projects.

- Europe: Europe is a mature market driven by stringent renewable energy directives and high fossil fuel costs. The focus here is on utilizing forestry residue and specialized energy crops. European users demand high-efficiency, highly automated, and quality-certified machines, often integrating briquetting operations with existing pelletization facilities to diversify bioenergy product output. Germany, the UK, and Scandinavia are key markets prioritizing sustainability and low-emission technology.

- North America: The North American market is characterized by large-scale commercial operations, particularly utilizing timber industry waste and logging residue. Demand is skewed towards high-capacity hydraulic press systems that can handle large volumes of woody biomass. The market growth is stable, underpinned by supportive federal tax credits and regional incentives for biomass fuel production and consumption, particularly in states with significant forestry activity.

- Latin America (LATAM): Growth in LATAM is driven by the sugar and coffee industries, which produce substantial bagasse and husk waste. Countries like Brazil and Mexico are witnessing increased adoption as they seek localized, reliable fuel sources for their vast industrial base. The market is developing, focusing on robust, easy-to-maintain machines suitable for tropical conditions and heterogeneous agricultural residue mixtures.

- Middle East & Africa (MEA): This region is emerging, with growth concentrated in countries pursuing energy diversification strategies. The adoption is spurred by managing waste from date palms, olive processing, and specific agricultural schemes. Challenges related to water scarcity (impacting biomass growth) and infrastructure limitations require specialized, often modular, briquetting solutions. South Africa and specific Gulf Cooperation Council (GCC) nations are leading initial market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automatic Biomass Briquetting Machine Market.- CPM Roskamp Champion

- Bühler AG

- Kahl Group

- Binder Group

- S.L. Renewable Energy Equipment

- GEMCO (Zhengzhou Genyond Machinery Manufacturing Co., Ltd.)

- ECOSTAN

- R.K. Engineering

- V.P. Engineers

- Zhengzhou Yufeng Heavy Machinery Co., Ltd.

- Matrix Eco Solutions

- Palagin Briquetting

- Continental Biomass Industries (CBI)

- General Energy Biomass (GEB)

- Promecon

- Shanghai Dongmeng Road & Bridge Machinery Co., Ltd.

- Teknovas

- Makel Machinery

- JK Bioenergy

- Amandus Kahl GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Automatic Biomass Briquetting Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for fully automatic biomass briquetting machines?

The primary demand drivers are the global imperative for utilizing agricultural and forestry waste effectively, the escalating cost volatility of conventional fossil fuels, and widespread governmental initiatives and subsidies promoting renewable bioenergy adoption for industrial heating and power generation across developing and developed nations.

How does an automatic briquetting machine handle varied moisture content in biomass feedstock?

Automatic briquetting systems, particularly high-density hydraulic and screw presses, typically require pre-processed biomass with moisture content below 12% to ensure briquette structural integrity. Modern machines integrate sensors and automated drying systems in the production line, allowing for real-time adjustment of pre-processing steps, optimizing consistency and preventing machine damage or inefficient briquette formation.

What is the typical return on investment (ROI) period for installing a high-capacity automatic briquetting plant?

The ROI period typically ranges between two to four years, depending significantly on local biomass feedstock costs, the selling price of the resulting briquettes, the initial capital expenditure, and the plant’s operational capacity utilization. Areas with high fossil fuel prices and readily available, cheap biomass feedstock often achieve the quickest payback due to high energy cost savings.

What are the key technical differences between hydraulic press and screw press briquetting technologies?

Hydraulic press technology uses sheer, high pressure (without external heating) to create extremely dense briquettes, relying on mechanical force alone. Screw press technology uses a screw extruder that generates frictional heat to melt the natural lignin binder within the biomass, resulting in slightly less dense briquettes with a central hole, which often facilitates better combustion characteristics in certain applications.

Which regional market shows the highest growth potential for biomass briquetting equipment?

The Asia Pacific (APAC) region exhibits the highest growth potential, largely driven by massive agricultural economies (China and India) struggling with pollution from crop residue burning. Strong governmental policy support for large-scale waste-to-energy conversion projects and the huge, underutilized biomass resource base make APAC the leading region for market expansion and investment in automated briquetting technology.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager