Automatic Bottle Blowing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432275 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Automatic Bottle Blowing Machine Market Size

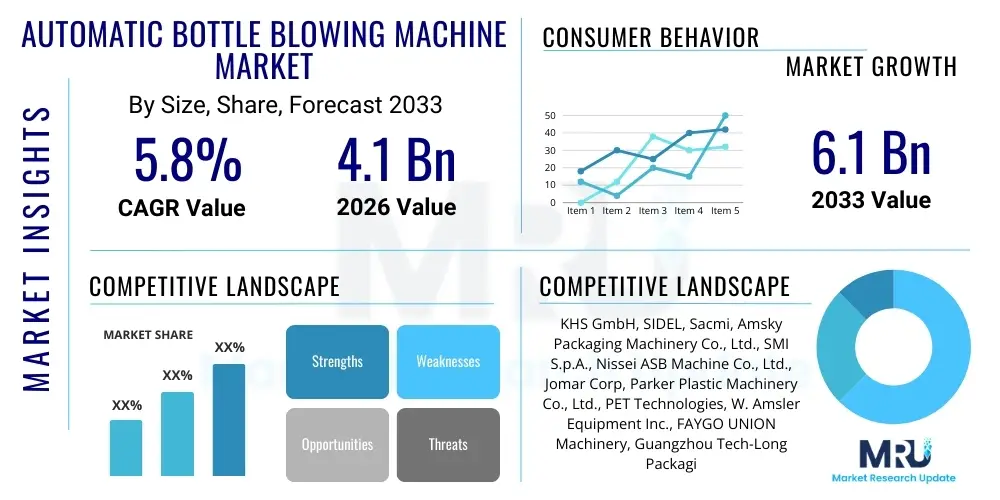

The Automatic Bottle Blowing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Automatic Bottle Blowing Machine Market introduction

The Automatic Bottle Blowing Machine Market encompasses equipment utilized for manufacturing plastic bottles, primarily employing processes like stretch blow molding (SBM), injection blow molding (IBM), and extrusion blow molding (EBM). These machines convert preforms or parisons, usually made from PET, HDPE, or PP, into finished bottles used across various industrial applications. The key product characteristic is high efficiency, repeatability, and minimal human intervention, making them essential for high-volume production lines. Major applications span the beverage industry (carbonated soft drinks, water), pharmaceuticals, cosmetics, and chemicals. The primary benefits include superior production speeds, energy efficiency improvements through servo technology integration, and enhanced bottle quality consistency. Driving factors accelerating market growth include the rising global consumption of packaged beverages, stringent hygiene standards requiring automated systems, and the continuous innovation toward lightweight and sustainable plastic packaging designs.

Automatic Bottle Blowing Machine Market Executive Summary

The Automatic Bottle Blowing Machine Market is characterized by robust business trends focusing on increased automation, digitalization, and integration of smart factory concepts, aiming for higher throughput and reduced operational costs. Regionally, the Asia Pacific (APAC) continues its dominance due to massive population growth, expanding industrialization, and high demand from emerging economies for packaged goods, although North America and Europe lead in adopting advanced, highly efficient rotary systems and specialized PET molding technologies. Segment trends highlight the prominent position of the Stretch Blow Molding (SBM) segment, particularly for PET applications, driven by its versatility and lower material consumption. Furthermore, electric and servo-driven machines are rapidly displacing hydraulic systems across all segments, reflecting a strong industry commitment to energy efficiency and environmental sustainability, influencing purchasing decisions across the food and beverage sectors globally.

AI Impact Analysis on Automatic Bottle Blowing Machine Market

User inquiries regarding AI's influence in the automatic bottle blowing sector frequently revolve around predictive maintenance capabilities, quality control automation, and optimizing machine parameters in real-time. Stakeholders are concerned with how AI can minimize downtime, predict component failure before it occurs, and ensure zero-defect production through enhanced vision systems and deep learning algorithms. Expectations center on achieving unprecedented levels of operational efficiency (OEE) and energy savings by dynamically adjusting heating, pressure, and cooling cycles based on material input variations and environmental conditions. The consensus theme is that AI will transform bottle blowing from a reactive, empirical process into a highly proactive, data-driven manufacturing system, significantly reducing material waste and streamlining complex changeover operations, which is crucial for high-mix, low-volume production environments.

- Predictive Maintenance: AI algorithms analyze machine sensor data (vibration, temperature, pressure) to forecast potential failures, maximizing uptime and reducing unplanned maintenance.

- Automated Quality Control: High-speed vision systems powered by deep learning identify microscopic defects in preforms and final bottles, ensuring consistent product integrity far beyond human capacity.

- Real-Time Process Optimization: AI dynamically adjusts blow molding parameters (e.g., thermal profiling, blowing pressure) based on polymer batch variations and external factors, optimizing material distribution and reducing energy consumption.

- Supply Chain Integration: AI enhances logistics and raw material management by predicting demand fluctuations and automatically ordering preforms or resin, minimizing stockouts and excess inventory.

- Enhanced Energy Management: Machine learning models optimize the utilization of compressed air systems, the largest energy consumer in bottle blowing, achieving significant power reduction per cycle.

- Autonomous Setup and Changeover: AI-driven systems learn optimal settings for different bottle shapes and materials, automatically configuring the machine for new production runs, drastically shortening changeover times.

DRO & Impact Forces Of Automatic Bottle Blowing Machine Market

The market growth is primarily Driven by the relentless expansion of the packaged water and beverage industry, coupled with the increasing shift towards lightweight PET bottles that require sophisticated blowing technology. However, the market faces significant Restraints, notably the high initial capital expenditure associated with high-speed rotary machines and the increasing regulatory scrutiny and consumer backlash against single-use plastics, forcing manufacturers to invest in new material compatibility. Significant Opportunities emerge from the untapped potential in developing regions for pharmaceutical packaging automation and the growing adoption of bio-based and recycled PET (rPET), driving demand for adaptable machine designs. The central Impact Force is technological advancement, where continuous innovations in servo technology and smart manufacturing (Industry 4.0 integration) dictate competitive advantage, forcing slower, less efficient legacy systems into obsolescence and accelerating adoption cycles across major global manufacturers.

Segmentation Analysis

The Automatic Bottle Blowing Machine Market is segmented based on the type of technology employed, the degree of automation, the end-user application, and the resin type utilized. The technological segmentation, specifically distinguishing between Stretch Blow Molding (SBM), Extrusion Blow Molding (EBM), and Injection Blow Molding (IBM), is critical, as it determines the speed, complexity, and end-product compatibility of the machinery. SBM machines dominate due to their efficiency in producing biaxially oriented PET bottles for beverages, while EBM remains crucial for complex shapes requiring handles, such as containers for detergents and industrial chemicals. The market also sees differentiation between rotary and linear systems, with rotary machines favored for ultra-high-speed beverage lines, while linear machines offer greater flexibility and lower tooling costs suitable for shorter runs and specialized products, offering diverse solutions to cater to the varied needs of global packaging manufacturers.

- By Technology:

- Stretch Blow Molding (SBM)

- Injection Blow Molding (IBM)

- Extrusion Blow Molding (EBM)

- By Orientation/Mechanism:

- Linear Machines

- Rotary Machines

- By End-User Industry:

- Beverages (Water, CSD, Juice, Dairy)

- Food (Edible Oil, Sauces)

- Pharmaceuticals and Medical

- Cosmetics and Personal Care

- Chemicals and Fertilizers

- By Material:

- PET (Polyethylene Terephthalate)

- HDPE (High-Density Polyethylene)

- PP (Polypropylene)

- PVC (Polyvinyl Chloride)

- By Function:

- Fully Automatic Machines

- Semi-Automatic Machines

Value Chain Analysis For Automatic Bottle Blowing Machine Market

The value chain begins with Upstream Analysis, encompassing the procurement of specialized raw materials, including high-grade steel, complex electronic components (PLCs, servo motors, control systems), and precision molds required for machine construction. Key suppliers include specialized mold makers and industrial automation companies. The manufacturing phase involves intricate assembly, rigorous testing, and quality assurance of the blowing equipment. The Distribution Channel is predominantly indirect, relying on specialized industrial distributors, agents, and system integrators who provide installation, training, and aftermarket services, particularly for complex rotary systems. Direct sales are often reserved for large, multinational beverage corporations purchasing custom-engineered, integrated production lines. The Downstream Analysis centers on the end-user industries—primarily beverage and food packaging companies—which utilize the equipment for mass production. Aftermarket services, including spare parts supply, maintenance contracts, and technological upgrades, form a crucial revenue stream, ensuring the longevity and continued efficiency of installed machines throughout their operational life cycle.

Automatic Bottle Blowing Machine Market Potential Customers

The primary purchasers of automatic bottle blowing machines are large-scale industrial processors and contract packaging service providers requiring high-volume output and exceptional precision. Within the End-User/Buyers spectrum, the beverage sector stands as the most dominant customer group, encompassing major global manufacturers of bottled water, carbonated soft drinks, and juices, who demand ultra-high-speed, dedicated production lines, often utilizing linear or rotary stretch blow molding technology. Other significant buyers include pharmaceutical companies, which require specialized cleanroom-compatible machines for sterile packaging, and manufacturers in the household chemicals and cosmetics industries, who frequently purchase Extrusion Blow Molding machines to produce containers with specific design features, such as integrated handles or complex shapes. Furthermore, emerging market players in regions like Southeast Asia and Latin America, expanding their local packaging capabilities, represent a rapidly growing customer base, often preferring mid-speed, reliable linear models.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | KHS GmbH, SIDEL, Sacmi, Amsky Packaging Machinery Co., Ltd., SMI S.p.A., Nissei ASB Machine Co., Ltd., Jomar Corp, Parker Plastic Machinery Co., Ltd., PET Technologies, W. Amsler Equipment Inc., FAYGO UNION Machinery, Guangzhou Tech-Long Packaging Machinery Co., Ltd., E-PAK Machinery Inc., Krones AG, SIPA S.p.A., ZQ Machinery, ASG Plastic, Techne S.r.l., CHUMPOWER Machinery Corp., LTD., Heuft Systemtechnik GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automatic Bottle Blowing Machine Market Key Technology Landscape

The technological evolution of the Automatic Bottle Blowing Machine Market is heavily dictated by the shift towards precision, speed, and sustainability. A key advancement is the widespread adoption of Servo-Electric Technology, replacing traditional hydraulic systems. Servo motors offer superior control over movement, leading to higher repeatability, faster cycle times, and substantial energy savings—sometimes up to 40% compared to hydraulic counterparts. This technology is vital in modern rotary SBM machines, enabling production rates exceeding 80,000 bottles per hour. Furthermore, the integration of Industry 4.0 components, including Industrial Internet of Things (IIoT) sensors, enables comprehensive machine monitoring, remote diagnostics, and data analytics. This data allows operators to optimize maintenance schedules and fine-tune machine performance in real-time, moving closer to autonomous manufacturing environments.

Another pivotal area of innovation lies in Mold Technology and Heating Systems. Advanced preform heating using specialized infrared (IR) lamps and precise temperature control zoning ensures optimal material distribution during the blowing phase, which is crucial for lightweighting initiatives. Lightweighting reduces overall material consumption while maintaining bottle structural integrity, directly addressing sustainability goals. Simultaneously, sophisticated mold technologies, including variable pitch molds and specialized coating materials, increase mold lifespan and reduce changeover times. The market is also seeing increased research into machines specifically designed to handle Recycled PET (rPET) and bio-plastics, materials that present unique thermal processing challenges, requiring flexible heating and blowing profiles to achieve acceptable bottle clarity and strength, ensuring future market compatibility.

The continuous improvement in Compressor and Air Recovery Systems is also foundational to the technology landscape. Since compressed air accounts for a substantial portion of the operational cost, newer machines are incorporating highly efficient, oil-free compressors and sophisticated air recovery mechanisms that recapture and reuse high-pressure air, significantly lowering the Total Cost of Ownership (TCO). This focus on ancillary equipment optimization, combined with intelligent control systems (PLCs) capable of managing complex timing sequences and integrated robotic handling for preform loading and bottle discharge, solidifies the automatic bottle blowing machine as a highly complex, capital-intensive, and technologically advanced piece of modern factory equipment, indispensable for mass production environments globally.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, driven by rapid urbanization, massive population size, and burgeoning demand for packaged goods in China, India, and Southeast Asian countries. This region is characterized by high volume installations of both linear (flexibility) and rotary (speed) machines, often focused on bottled water and affordable beverages.

- North America: A mature market characterized by stringent quality standards and a strong focus on high-speed, fully automatic rotary SBM systems. Growth here is primarily driven by technological upgrades, replacement of older hydraulic machines with energy-efficient servo-electric models, and expansion into specialty beverages and sustainable rPET usage.

- Europe: Exhibits leadership in sustainability and technological sophistication. The European market prioritizes machines compatible with bio-based plastics and high percentages of rPET. Regulatory pressures promoting circular economy initiatives mandate innovation in machine design that minimizes material use and maximizes energy efficiency, driving high adoption of premium, intelligent blowing machines.

- Latin America: Experiences steady growth, particularly in countries like Brazil and Mexico, fueled by robust local beverage consumption and increased foreign direct investment into manufacturing facilities. The market balances between cost-effective linear machines for localized production and high-speed rotary systems for major national brands.

- Middle East and Africa (MEA): Emerging market with strong growth potential, particularly in the Gulf Cooperation Council (GCC) countries and South Africa, driven by climate conditions necessitating high consumption of bottled water and expanding pharmaceutical manufacturing sectors. Investments are concentrated in stable, reliable, and durable machinery suitable for challenging operating environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automatic Bottle Blowing Machine Market.- KHS GmbH

- SIDEL

- Sacmi

- Amsky Packaging Machinery Co., Ltd.

- SMI S.p.A.

- Nissei ASB Machine Co., Ltd.

- Jomar Corp

- Parker Plastic Machinery Co., Ltd.

- PET Technologies

- W. Amsler Equipment Inc.

- FAYGO UNION Machinery

- Guangzhou Tech-Long Packaging Machinery Co., Ltd.

- E-PAK Machinery Inc.

- Krones AG

- SIPA S.p.A.

- ZQ Machinery

- ASG Plastic

- Techne S.r.l.

- CHUMPOWER Machinery Corp., LTD.

- Heuft Systemtechnik GmbH

- Automa S.p.A.

- Bekum Maschinenfabriken GmbH

- Chen Hsong Holdings Limited

- Haitian International Holdings Limited

- Demag Plastics Group

Frequently Asked Questions

Analyze common user questions about the Automatic Bottle Blowing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology driving efficiency in modern automatic bottle blowing machines?

The primary technology driving efficiency is the shift from hydraulic systems to Servo-Electric Technology. Servo-driven machines offer precise control over movements, resulting in faster cycle times, lower energy consumption (up to 40% reduction), and higher product repeatability compared to older hydraulic counterparts, thus enhancing overall equipment effectiveness (OEE).

How is sustainability influencing the demand and design of bottle blowing machines?

Sustainability significantly influences machine design by driving demand for equipment optimized for processing Recycled PET (rPET) and bio-plastics. Manufacturers require flexible heating systems to handle these materials while simultaneously integrating lightweighting features to reduce overall plastic consumption, meeting stringent global environmental and regulatory standards.

What are the key differences between linear and rotary automatic bottle blowing machines?

Linear machines offer greater flexibility, lower initial investment, and are ideal for short runs or specialized products. Rotary machines are designed for ultra-high-speed, continuous production (up to 80,000 bottles per hour) and are preferred by major beverage companies for mass-market applications where throughput maximization is the critical metric.

Which end-user segment accounts for the highest adoption rate of automatic bottle blowing equipment?

The Beverage Industry accounts for the highest adoption rate. This sector, including bottled water, carbonated soft drinks (CSD), and juices, demands continuous, high-volume production of standardized PET packaging, making high-speed Stretch Blow Molding (SBM) machines indispensable for their operational scale.

What role does Industry 4.0 play in the maintenance and operation of these machines?

Industry 4.0, facilitated by IIoT sensors and AI, enables Predictive Maintenance by analyzing operational data in real-time to forecast potential component failure, minimizing costly unplanned downtime. It also allows for remote monitoring, diagnostic checks, and dynamic process optimization, maximizing operational continuity and lowering labor costs.

What are the typical initial investment costs associated with acquiring a fully automatic rotary blowing system?

The initial investment for a high-speed, fully automatic rotary stretch blow molding system is substantial, often ranging from USD 1.5 million to over USD 5 million, depending on capacity, configuration, integration level, and the inclusion of auxiliary equipment like compressors and chillers. This capital expenditure is justified by the extremely high throughput and low operating cost per bottle over the machine's lifespan.

How do automatic bottle blowing machines handle material variations, such as different grades of PET?

Modern machines utilize sophisticated Closed-Loop Control Systems and Advanced Infrared Heating Zones. These systems precisely monitor the temperature profile of the preforms and dynamically adjust heating elements and blow pressures to compensate for minor variations in intrinsic viscosity (IV) or moisture content of different PET grades or rPET percentages, ensuring consistent wall thickness and strength.

What is the difference between single-stage and two-stage bottle blowing processes?

The Single-Stage Process (often IBM) manufactures the preform and the final container on the same integrated machine, ideal for high-precision, smaller runs, and specialized pharmaceutical containers. The Two-Stage Process (often SBM) involves two separate machines: one for injection molding the preform and another for reheating and blowing the final container. Two-stage is preferred for high-volume PET production due to its high speed and efficiency.

Are automatic bottle blowing machines capable of producing containers larger than two liters?

Yes, while SBM is common for standard sizes, specialized Extrusion Blow Molding (EBM) machines are specifically designed to produce large containers, such as 5-gallon water coolers, large chemical drums, and jerrycans, by utilizing continuous extrusion of a parison, catering to industrial and bulk consumer demands.

What is 'lightweighting' in the context of bottle blowing, and why is it important?

Lightweighting is the process of reducing the weight of the plastic bottle while maintaining its structural integrity and performance requirements. It is critical for sustainability efforts, as it directly reduces raw material costs, decreases transportation weight (lowering fuel consumption), and minimizes the overall environmental footprint of the packaging.

How do pharmaceutical companies leverage automated blowing machines?

Pharmaceutical companies rely on highly automated, often single-stage, Injection Blow Molding (IBM) machines operating in cleanroom environments. This ensures sterile production, high dimensional accuracy essential for closures, and reduces contamination risk, crucial for medical vials, eye drops, and small dosage containers.

What safety features are mandatory in the latest automatic bottle blowing equipment?

Mandatory safety features include comprehensive machine guarding, interlocking safety gates, emergency stop (E-stop) mechanisms, pressure relief valves, and advanced sensory feedback systems compliant with international standards like CE or OSHA. Modern systems often incorporate light curtains and safe torque off (STO) features in servo drives for enhanced operator protection during high-speed operations.

Which geographical region is showing the fastest adoption rate for new bottle blowing technologies?

While APAC leads in total volume, Europe often demonstrates the fastest adoption rate for the newest, most energy-efficient, and sustainable technologies, driven by proactive regulations regarding energy consumption, CO2 reduction, and the mandatory incorporation of recycled content (rPET) in packaging materials.

What impact does the pressure system have on the operational cost of the machines?

The pressure system, specifically the high-pressure air compressor, is the largest consumer of electrical energy in a bottle blowing operation. Optimizing this system, often through integrating air recovery features and utilizing efficient, oil-free compressors, directly and significantly lowers the operational cost per bottle and improves the machine's overall profitability.

How is Artificial Intelligence (AI) improving quality control in bottle production?

AI is employed through High-Speed Vision Systems combined with machine learning. These systems rapidly scan every preform and final bottle, detecting subtle defects like uneven wall thickness, contamination, or micro-cracks that are undetectable at human processing speeds, ensuring only consistently high-quality products proceed downstream and drastically reducing scrap rates.

What role do molds play in the total lifecycle cost of a blowing machine?

Molds are critical components, often representing a significant portion of the initial tooling investment. Their quality, material (e.g., aluminum, stainless steel), and precision directly affect bottle quality and production speed. Durable molds with specialized coatings reduce maintenance needs and extend operational lifespan, lowering the overall lifecycle cost of the machine.

What are the challenges associated with blowing containers made from materials like HDPE or PP?

HDPE and PP, typically processed using Extrusion Blow Molding (EBM), are more challenging than PET due to their lower melt strength and difficulty in maintaining consistent parison thickness. EBM machines require sophisticated parison programming systems to control wall distribution, especially for containers with handles or complex geometries, ensuring adequate structural integrity.

How do manufacturers ensure hygienic production, especially for sensitive products like baby food or dairy?

Hygienic production is ensured through "Blow-Fill-Seal" (BFS) integration or dedicated sterile areas. Machines use specialized air filtration (HEPA filters), enclosed processing chambers, and non-contact transfer systems. This is particularly crucial for the dairy and pharmaceutical sectors, adhering to strict cleanroom protocols and minimizing external contamination risks.

What is the typical lifespan of a modern, high-quality automatic bottle blowing machine?

A well-maintained, high-quality automatic bottle blowing machine, especially a servo-electric model from a leading manufacturer, can typically have an operational lifespan ranging from 15 to 25 years. The lifespan depends heavily on regular maintenance, quality of components, and adherence to manufacturer-recommended upgrade cycles for software and critical parts.

How does the type of machine orientation (linear vs. rotary) affect factory layout and space requirements?

Linear machines typically require less floor space but need a longer, straight production line footprint, making them suitable for facilities with limited width. Rotary machines, while faster, require a significant circular area and extensive surrounding access for maintenance, but their compact design maximizes production capacity per square meter, favored in high-density factory environments.

What technological advancements are helping reduce noise levels during machine operation?

Noise reduction is primarily achieved through the implementation of Servo-Electric Drives, which operate much quieter than older hydraulic systems. Additionally, the use of sound-dampening materials in machine enclosures, optimized pneumatic circuits, and specialized muffler technologies helps minimize operational noise, meeting increasingly stringent workplace noise regulations.

What is the current market trend regarding multi-layer bottle production?

The market trend for multi-layer bottles is increasing, particularly in the food (e.g., long shelf-life juices) and chemical sectors, where barrier properties are essential. Machines, often using EBM or co-injection processes, are engineered to precisely layer different resins (like EVOH) to provide oxygen barriers, crucial for extending the product shelf life and ensuring flavor preservation.

How does the machine's control system (PLC) contribute to overall efficiency?

The advanced Programmable Logic Controller (PLC) is the central brain, precisely managing complex timing sequences (heating, stretching, blowing, exhausting), temperature control, and integrating robotics. A sophisticated PLC minimizes process variability, enables rapid fault detection, and facilitates quick product changeovers, maximizing operational throughput.

What are the key concerns when running high percentages of rPET through SBM machines?

The primary concerns are Reduced Intrinsic Viscosity (IV) and inconsistent preform clarity. rPET often degrades slightly during recycling, requiring customized thermal profiles to prevent material degradation and ensure the final bottle maintains adequate strength, clarity, and gas barrier properties without stress whitening.

Besides beverages, what other emerging applications are driving machine demand?

Emerging demand is significantly driven by the Ready-to-Drink (RTD) dairy/tea sector, requiring aseptic packaging capabilities, and the growing market for e-commerce friendly packaging. The latter requires machines capable of producing robust, stable containers suitable for direct shipping without secondary packaging damage, influencing structural design requirements.

What is the function of the air recovery system in automatic bottle blowing?

The air recovery system captures the high-pressure air used in the final blowing process immediately after the bottle is formed. This captured air is often reused for lower-pressure applications, such as internal machine actuation or initial pre-blowing stages, significantly reducing the energy demand placed on the primary high-pressure compressors.

How critical is mold temperature control for the final bottle quality?

Mold temperature control is highly critical. Precise cooling ensures the immediate setting of the bottle shape after blowing, directly affecting crystallization, surface finish, clarity, and dimensional accuracy. Inconsistent cooling leads to stress points, poor clarity, and structural weaknesses, necessitating advanced chiller and fluid circulation systems.

What are the typical maintenance requirements for high-speed linear machines?

High-speed linear machines require regular preventative maintenance focused on critical moving parts, including belt systems, clamping mechanisms, and the stretching rods. Key maintenance activities include lubrication, alignment checks, inspection of heating lamps, and ensuring the precision of pneumatic seals and valves to prevent air leaks.

In the Value Chain, why is the procurement of high-grade steel essential for machine longevity?

High-grade steel is essential for constructing the machine frame, clamping units, and high-pressure blow molds. These components must withstand continuous high-stress cycles (high pressure and rapid thermal cycling) over decades of operation. Using inferior materials would lead to premature wear, structural fatigue, and inaccuracies in the final product dimensions.

How do competitive dynamics influence pricing strategies in the automatic bottle blowing machine market?

Competitive dynamics lead to a bifurcated pricing strategy: premium pricing for highly integrated, ultra-high-speed rotary systems offered by European manufacturers (emphasizing TCO and efficiency), and highly competitive, cost-effective pricing for robust linear machines offered by Asian manufacturers (emphasizing low initial capital expenditure and volume throughput).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager