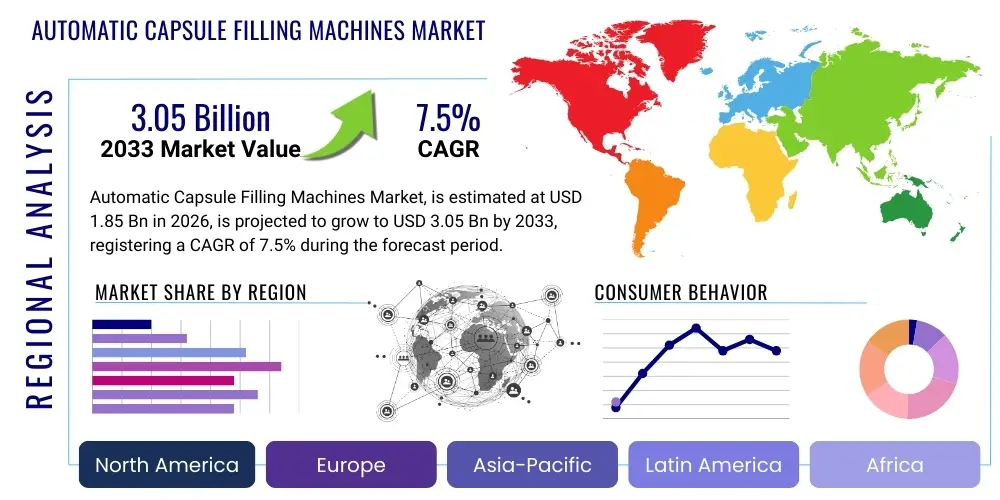

Automatic Capsule Filling Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431662 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Automatic Capsule Filling Machines Market Size

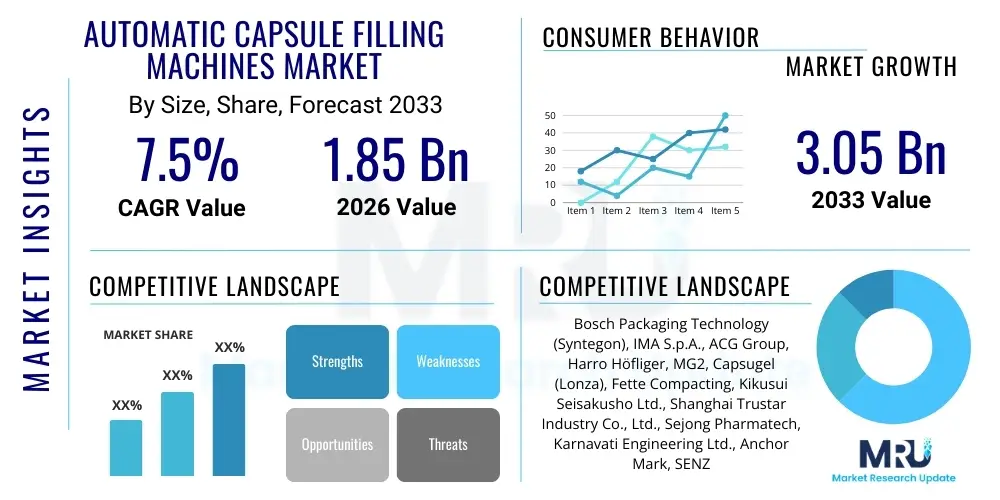

The Automatic Capsule Filling Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $3.05 Billion by the end of the forecast period in 2033.

Automatic Capsule Filling Machines Market introduction

The Automatic Capsule Filling Machines Market encompasses sophisticated equipment designed for the high-speed, precise, and automated filling of hard gelatin and non-gelatin capsules with various substances, including powders, granules, pellets, liquids, or combinations thereof. These machines are indispensable in the pharmaceutical, nutraceutical, and cosmetic industries, offering unparalleled efficiency and accuracy compared to manual or semi-automatic alternatives. Key applications span the production of prescription drugs, over-the-counter medications, dietary supplements, and specialized pharmaceutical formulations. The core benefit derived from utilizing these automatic systems is the substantial improvement in production throughput, coupled with enhanced dosage uniformity and reduced risk of contamination, crucial factors for maintaining regulatory compliance, such as adhering to Good Manufacturing Practices (GMP). Market expansion is primarily driven by the escalating demand for pharmaceutical products globally, particularly due to the rising prevalence of chronic diseases, the rapid expansion of the generic drugs sector, and continuous technological advancements aimed at increasing machine versatility and operational speed.

Automatic Capsule Filling Machines Market Executive Summary

The Automatic Capsule Filling Machines Market is characterized by robust business trends focusing on integration capabilities, high-speed output, and compliance with stringent global regulatory mandates. Key industry shifts include the adoption of modular designs, allowing manufacturers to rapidly switch between different filling methods (e.g., tamper, dosing disk, auger), and the increasing incorporation of sensor technology for real-time monitoring and quality control, thereby aligning with Industry 4.0 principles. Regionally, Asia Pacific is anticipated to exhibit the fastest growth, propelled by massive investments in pharmaceutical manufacturing infrastructure in countries like China and India, alongside expanding access to healthcare. North America and Europe currently dominate the market share, driven by advanced technological adoption and the presence of major pharmaceutical innovators demanding high-precision equipment. Segmentation trends reveal that high-speed, fully automatic machines (above 150,000 capsules/hour) are dominating the volume segment, while powder and pellet filling systems remain the primary application based on substance type, reflecting the traditional drug formulation preference. Furthermore, the nutraceutical sector's rapid growth is boosting demand for machines capable of handling diverse excipients and formulations for supplements.

AI Impact Analysis on Automatic Capsule Filling Machines Market

User queries regarding AI integration in capsule filling machines frequently center on predictive maintenance capabilities, optimization of dosing parameters, and enhanced quality assurance through visual inspection systems. Users are concerned about how AI algorithms can minimize product wastage, reduce downtime, and ensure compliance in complex filling processes involving multiple substance types (e.g., combinations of pellets and liquids). The consensus expectation is that AI will transform these machines from automated tools into intelligent, self-optimizing systems. Specifically, users anticipate AI-powered solutions to automatically adjust critical parameters like weight variation and consistency based on real-time feedback loops, drastically improving production yields and facilitating faster, more accurate troubleshooting. This shift represents a move toward zero-defect manufacturing, addressing the critical industry challenge of maintaining strict uniformity under high-throughput conditions.

- AI-driven predictive maintenance forecasts component failure, minimizing unexpected production halts.

- Machine Learning algorithms optimize dosing precision for complex formulations, improving yield and uniformity.

- AI-enhanced vision systems automate visual inspection, detecting minute defects in capsules and filling accuracy faster than human operators.

- Real-time process control through AI ensures dynamic adjustment of operational speed and pressure, enhancing overall equipment effectiveness (OEE).

- AI facilitates faster calibration and setup times for different product batches, increasing manufacturing agility.

DRO & Impact Forces Of Automatic Capsule Filling Machines Market

The market growth is primarily driven by the global expansion of the pharmaceutical industry, particularly the robust growth in generic drug production and the increasing demand for specialized dosage forms requiring precise filling techniques. However, this growth is significantly restrained by the high initial capital investment required for purchasing and installing fully automatic machinery, coupled with the necessity for highly skilled technical personnel to operate and maintain these complex systems. The major opportunities lie in the development of modular, flexible machines that can accommodate multiple filling technologies and the increasing utilization of automation and robotics (aligned with Industry 4.0) to enhance operational efficiency and data collection capabilities. Impact forces are strong, driven positively by stringent regulatory standards (e.g., FDA, EMA) that necessitate high-precision, validated equipment to ensure patient safety and dosage accuracy, pushing manufacturers toward advanced automatic systems. Conversely, pricing pressure from contract manufacturing organizations (CMOs) seeking cost-effective solutions exerts downward pressure on the average selling price of mid-range machines, impacting profit margins for equipment suppliers.

Segmentation Analysis

The Automatic Capsule Filling Machines Market is broadly segmented based on the type of machine automation, the filling material handled, the speed of operation, and the end-user industry. Analyzing these segments provides a granular view of market dynamics, revealing that the preference for high-speed, fully automatic machines is paramount among large pharmaceutical manufacturers seeking maximum output efficiency. Furthermore, the versatility of filling materials, particularly the shift towards liquid and powder combination fillings, is driving specialized machine development. The nutraceutical segment, while smaller than pharmaceuticals, is rapidly expanding due to the global consumer trend toward dietary supplements, demanding flexible machines capable of handling complex natural extracts and highly abrasive ingredients.

- Type of Automation: Fully Automatic, Semi-Automatic, Manual.

- Filling Material: Powder, Pellets, Granules, Tablets, Liquids, Combination Fillings.

- Operating Speed: Low Speed (< 50,000 capsules/hour), Medium Speed (50,000 - 150,000 capsules/hour), High Speed (> 150,000 capsules/hour).

- End-User: Pharmaceutical Companies, Nutraceutical Companies, Contract Manufacturing Organizations (CMOs), Cosmetic Companies, Others.

Value Chain Analysis For Automatic Capsule Filling Machines Market

The value chain for automatic capsule filling machines begins upstream with the crucial sourcing of precision components, including high-grade stainless steel, advanced electronic control systems (PLCs, HMIs), and specialized dosing tools (e.g., tamping pins, dosing disks). Suppliers of these components significantly influence the final machine quality, reliability, and cost. The midstream involves the core manufacturing process, where original equipment manufacturers (OEMs) focus on design, assembly, software integration, and rigorous factory acceptance testing (FAT) to meet GMP standards. Downstream activities involve distribution, which typically occurs through direct sales channels for major pharmaceutical clients requiring custom integration, or through specialized distributors and agents, particularly in developing markets. The direct channel offers better technical support and customization, essential for complex installations. After-sales service, including validation, training, and maintenance contracts, forms a vital part of the downstream value proposition, ensuring long-term machine operational efficiency.

Automatic Capsule Filling Machines Market Potential Customers

The primary end-users and potential customers for automatic capsule filling machines are globally recognized pharmaceutical corporations and their affiliated manufacturing facilities. These organizations require high-throughput, validated machinery for the mass production of both patented and generic drug formulations, prioritizing precision and regulatory compliance above all else. Secondarily, the rapidly growing sector of Contract Manufacturing Organizations (CMOs) represents a significant customer base, as CMOs invest heavily in flexible, multi-functional equipment to service diverse client requirements ranging from small clinical batches to large-scale commercial runs. The third key customer segment comprises nutraceutical and dietary supplement manufacturers, who demand machines capable of handling non-pharmaceutical powders and unique combination fillings, driven by the expanding consumer health market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $3.05 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Packaging Technology (Syntegon), IMA S.p.A., ACG Group, Harro Höfliger, MG2, Capsugel (Lonza), Fette Compacting, Kikusui Seisakusho Ltd., Shanghai Trustar Industry Co., Ltd., Sejong Pharmatech, Karnavati Engineering Ltd., Anchor Mark, SENZANI BREVETTI, Accura Pharmaquip Pvt. Ltd., Tecnicaps, SaintyCo, NJP Group, Hanlin Hangyu Industrial. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automatic Capsule Filling Machines Market Key Technology Landscape

The technological landscape in the automatic capsule filling sector is rapidly advancing, focusing on enhancing precision, flexibility, and connectivity. Modern machines predominantly employ modular dosing systems, allowing manufacturers to quickly interchange filling stations—such as the tamping pin system for powder dosage, the auger system for low-flow materials, and specialized pumps for liquids or semi-solids. This modularity is critical for Contract Manufacturing Organizations (CMOs) that handle varied product specifications. A significant technological shift involves the integration of sophisticated Weight Control Systems (WCS), often utilizing 100% check-weighing coupled with statistical process control (SPC) feedback loops. These systems ensure that every filled capsule falls within the permissible weight tolerance, a non-negotiable requirement under GMP standards.

Furthermore, connectivity and digitalization, aligned with Industry 4.0, are becoming standard features. Machines are equipped with advanced Human-Machine Interfaces (HMIs) and connectivity modules (IoT sensors) that allow for real-time data acquisition regarding throughput, downtime, and quality metrics. This data is essential for operational excellence and regulatory auditing. Vacuum technology plays a crucial role in the precise separation and orientation of capsules, minimizing damaged or wasted shells. Innovation is also focusing on containment technology, specifically for handling highly potent and cytotoxic substances, where dust control and isolation systems are integrated directly into the filling machinery to protect operators and prevent cross-contamination.

Advanced material science is also influencing the market, with equipment manufacturers utilizing specialized coatings and materials within the contact parts to reduce friction, minimize static electricity buildup (especially problematic with fine powders), and improve cleaning efficacy (Clean-in-Place or CIP systems). The drive towards faster, cleaner, and more validated production processes dictates the technology roadmap, leading to continuous improvements in servo motor control for smoother, more repeatable movements, which is paramount for maintaining high speeds while ensuring dosing accuracy, particularly in machines exceeding 200,000 capsules per hour.

Regional Highlights

- North America: Dominates the market value due to the presence of major pharmaceutical innovators, stringent regulatory environments (FDA mandates), and high adoption rates of fully automated, technologically advanced, high-speed machinery. Significant investment in specialty drug formulation fuels demand for highly precise liquid and pellet combination filling systems.

- Europe: Characterized by strong regulatory compliance (EMA) and a mature manufacturing sector. Western European countries, particularly Germany and Switzerland, are hubs for advanced machine manufacturing and innovation, focusing on energy efficiency and modular design for pan-European supply chains.

- Asia Pacific (APAC): Expected to register the highest CAGR, driven by massive domestic demand for affordable generic drugs, significant government investment in local pharmaceutical manufacturing (especially in China, India, and South Korea), and the establishment of new CMOs expanding capacity using modern, large-scale automation equipment.

- Latin America (LATAM): Exhibits moderate growth, primarily centered in Brazil and Mexico. Market growth is spurred by increased efforts to standardize pharmaceutical production and greater foreign direct investment, leading to the gradual replacement of older semi-automatic machinery with new, automatic systems to meet growing regional healthcare needs.

- Middle East and Africa (MEA): Represents an emerging market. Growth is localized, concentrated in technologically advanced economies like Saudi Arabia and UAE, which are investing in local drug production capacity to reduce import reliance, requiring modern, efficient capsule filling machinery often sourced from European or Indian manufacturers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automatic Capsule Filling Machines Market.- Bosch Packaging Technology (Syntegon)

- IMA S.p.A.

- ACG Group

- Harro Höfliger Verpackungsmaschinen GmbH

- MG2 S.r.l.

- Capsugel (Lonza Group)

- Fette Compacting GmbH

- Kikusui Seisakusho Ltd.

- Shanghai Trustar Industry Co., Ltd.

- Sejong Pharmatech Co., Ltd.

- Karnavati Engineering Ltd.

- Anchor Mark Pvt. Ltd.

- SENZANI BREVETTI S.p.A.

- Accura Pharmaquip Pvt. Ltd.

- Tecnicaps S.A.

- SaintyCo

- NJP Group

- Hanlin Hangyu Industrial Co., Ltd.

- Torpac Inc.

- Dott. Bonapace & C. srl

Frequently Asked Questions

Analyze common user questions about the Automatic Capsule Filling Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automatic capsule fillers?

The primary driver is the accelerating global production of generic pharmaceuticals, which requires high-throughput, precision machinery to maintain strict dosage uniformity and adhere to Good Manufacturing Practices (GMP) across large-scale commercial batches.

How are Industry 4.0 principles being integrated into modern capsule filling machines?

Integration involves using IoT sensors for real-time performance monitoring, advanced data analytics for predictive maintenance, and seamless connectivity (SCADA/MES integration) to enable remote diagnostics and self-optimizing operational control.

Which regional market offers the highest growth potential for capsule filling machines?

Asia Pacific (APAC) is projected to offer the highest growth potential, largely fueled by aggressive governmental spending on expanding local pharmaceutical manufacturing capacities and the increasing presence of Contract Manufacturing Organizations (CMOs) in nations like India and China.

What are the main technical challenges associated with automatic liquid filling into hard capsules?

Key technical challenges include maintaining temperature control and viscosity stability of the liquid medium, ensuring a hermetic capsule seal post-filling to prevent leakage, and achieving highly accurate volumetric dosing using specialized pump systems.

What is the typical lifespan and return on investment (ROI) for a high-speed automatic capsule filler?

A high-quality automatic capsule filler typically has an operational lifespan exceeding 15 years, provided proper maintenance is performed. The ROI is generally achieved within 3 to 5 years, driven by significant labor cost reductions, minimized product wastage, and substantially increased production throughput capacity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager