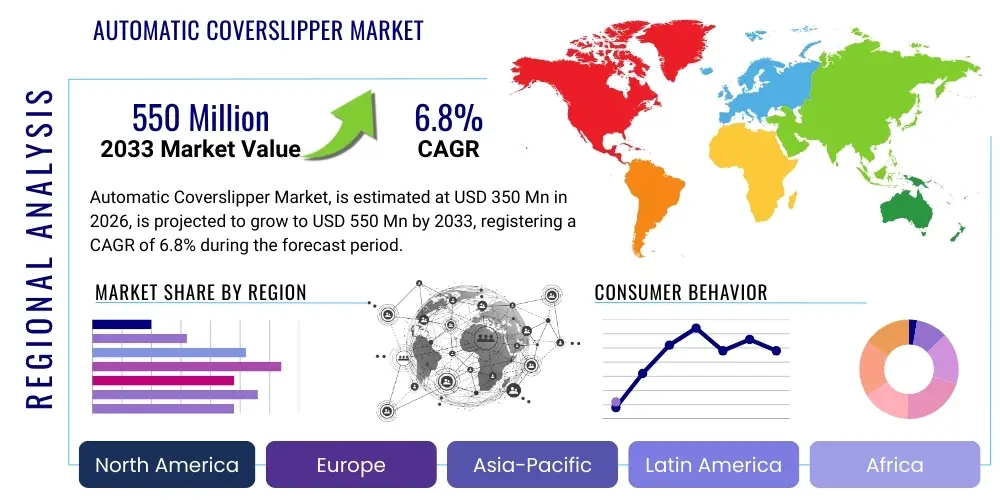

Automatic Coverslipper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436512 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Automatic Coverslipper Market Size

The Automatic Coverslipper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. This substantial expansion is fundamentally driven by the escalating demand for operational efficiency and high throughput in clinical pathology laboratories globally, coupled with the increasing volume of histological slides requiring processing for diagnostic evaluation. The shift from manual to automated processes minimizes human error, standardizes slide quality, and accelerates turnaround times, which are critical factors in timely patient diagnosis and treatment initiation. The steady adoption across large hospital networks and reference laboratories establishes a robust baseline for continuous market growth throughout the forecast period.

The market is estimated at USD 350 Million in 2026, benefiting significantly from technological advancements in robotic handling systems and sophisticated fluidics management, which enhance the reliability and speed of coverslipping procedures. These innovations are making automatic coverslippers indispensable tools in modern high-volume histology labs. Furthermore, the rising prevalence of chronic diseases, such as cancer, necessitating extensive biopsy analysis and pathological review, directly correlates with the increased requirement for automated slide preparation equipment. This growing diagnostic load necessitates investments in fully integrated laboratory automation solutions where coverslippers play a central, bottleneck-reducing role.

The market is projected to reach USD 550 Million by the end of the forecast period in 2033. This forecast growth trajectory is supported by expansion into emerging economies, where healthcare infrastructure improvements and rising quality standards are driving the adoption of advanced laboratory equipment. Additionally, the development of compact, benchtop models suitable for smaller laboratories and research facilities, alongside systems capable of handling different slide sizes and mounting media, further broadens the addressable market. The integration capabilities of these systems with digital pathology scanners and Laboratory Information Management Systems (LIMS) are key factors contributing to their long-term value proposition and market penetration.

Automatic Coverslipper Market introduction

The Automatic Coverslipper Market encompasses sophisticated laboratory instrumentation designed to automate the final, critical stage of histological slide preparation: the application of a thin glass or plastic coverslip onto a stained tissue section mounted on a slide. This automation process replaces manual techniques, offering superior consistency, reduced contamination risks, and significantly improved workflow efficiency in high-volume pathology settings. Automatic coverslippers utilize integrated robotic arms and precise dispensing mechanisms to apply mounting medium and place the coverslip, ensuring bubble-free and uniform coverage, which is paramount for high-quality microscopic examination and subsequent digital scanning.

The primary applications of these devices span across clinical pathology labs, academic research institutions, and pharmaceutical toxicology testing centers where consistent, rapid slide preparation is mandatory. Key benefits driving their adoption include the standardization of slide quality, a drastic reduction in specimen handling time, increased laboratory safety by minimizing exposure to solvents, and improved operational throughput, allowing laboratories to manage ever-growing case volumes without proportional increases in staffing. The driving factors for this market expansion include the global increase in biopsy procedures, the sustained investment in laboratory automation infrastructure, and the regulatory push for standardized diagnostic practices.

Modern Automatic Coverslippers are often integrated into larger processing lines, linked with automated strainers and drying ovens, forming a seamless, end-to-end histology workflow solution. This integration ensures minimal downtime and maximum efficiency. These systems are essential for laboratories transitioning to digital pathology, as consistently high-quality coverslipping is fundamental to successful, artifact-free whole-slide imaging. The market is continuously evolving with newer models offering variable throughput capacities, adaptability to different solvent-based or aqueous mounting media, and enhanced features for tracking and monitoring slide status via LIMS integration, solidifying their role as cornerstone equipment in modern diagnostics.

Automatic Coverslipper Market Executive Summary

The Automatic Coverslipper Market is experiencing robust growth driven predominantly by global trends favoring comprehensive laboratory automation and digital pathology integration. Business trends indicate a strong preference among large hospital systems and reference laboratories for high-throughput, fully enclosed systems that offer direct linkage with preceding staining instrumentation, thus maximizing efficiency and sample integrity. Key market players are concentrating on developing modular systems that provide scalability and flexibility, ensuring applicability across varying laboratory sizes and processing needs. Furthermore, sustainability in lab operations is gaining importance, pushing manufacturers towards developing systems that minimize solvent waste and energy consumption, aligning with broader environmental, social, and governance (ESG) goals.

Regionally, North America and Europe currently dominate the market due to established healthcare infrastructure, high adoption rates of advanced diagnostic technologies, and significant institutional budgets allocated for automation upgrades. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period. This accelerated growth in APAC is fueled by massive government and private sector investments in modernizing pathology labs, a rapid expansion of medical tourism, and a growing emphasis on early and accurate disease diagnosis, particularly in rapidly developing economies like China and India. The Middle East and Africa (MEA) and Latin America (LATAM) markets, while smaller, present lucrative opportunities as they move away from traditional, manual methodologies toward reliable automated solutions.

Segment trends highlight the dominance of High-Throughput Coverslippers (processing 400+ slides per hour) owing to the needs of central and reference laboratories handling extremely large volumes. Based on end-users, hospitals and clinical laboratories retain the largest market share due to the sheer volume of routine diagnostic work. Technologically, there is a clear shift toward coverslippers that feature integrated drying or curing capabilities, ensuring immediate readiness for digital scanning, and robust mechanisms for real-time quality control checks (e.g., detecting bubbles or misplaced coverslips). Aqueous-based mounting media systems are also gaining traction as laboratories seek safer and less volatile alternatives to traditional solvent-based compounds.

AI Impact Analysis on Automatic Coverslipper Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Automatic Coverslipper Market primarily revolve around how AI can enhance quality control, optimize workflow scheduling, and integrate the coverslipping output seamlessly into the digital pathology pipeline. Users are highly concerned about the reliability and consistency of slides pre-AI integration and look to AI for proactive failure prediction and superior defect detection (such as air bubbles or poor mounting medium application) which might compromise subsequent whole-slide imaging (WSI). The expectation is that AI-powered cameras or sensors embedded within the coverslipper will perform instantaneous, automated image analysis, certifying the quality of the slides before they move to the scanning stage, thereby reducing rescans and operational waste. Furthermore, users question how AI algorithms can optimize the coverslipping speed and timing based on the current workload and sample priority, contributing to better overall laboratory management and resource allocation in complex, interconnected automation systems.

- AI-driven Quality Control (QC): Utilizing machine vision algorithms to detect micro-bubbles, uneven mounting media distribution, or slide positioning errors in real-time, drastically reducing the need for manual inspection.

- Predictive Maintenance: AI analyzing operational data (motor strain, cycle times, fluid usage) to forecast component failure, allowing preventative maintenance scheduling and maximizing equipment uptime.

- Workflow Optimization: Integrating AI scheduling systems that prioritize slides based on urgency (STAT cases) and manage the queue flowing from automated stainers to the coverslipper, minimizing bottlenecks.

- Data Logging and Traceability: AI systems enhancing the metadata generated during coverslipping, linking quality metrics directly to the LIMS record for comprehensive end-to-end sample traceability.

- Digital Pathology Integration: Ensuring slides are optimally prepared (flatness, clarity) for WSI through AI feedback loops, maximizing the success rate of high-resolution scanning and downstream AI diagnostic analysis.

DRO & Impact Forces Of Automatic Coverslipper Market

The Automatic Coverslipper Market is shaped by a confluence of powerful drivers that underscore the essential role of automation in modern pathology, balanced against significant restraints primarily related to implementation costs and technical complexity, alongside compelling opportunities stemming from geographical expansion and technological synergy. The dominant driver remains the increasing volume of histological samples requiring rapid and accurate processing, often linked to rising global cancer incidence and screening programs. This high volume necessitates efficient automation to maintain diagnostic throughput. Impact forces such such as stringent regulatory mandates promoting quality control and standardization in clinical labs also amplify the need for highly consistent automated coverslipping, reducing the variability inherent in manual techniques. The negative impact force of high initial investment, however, presents a barrier, particularly for smaller diagnostic facilities, necessitating careful consideration of return on investment (ROI).

Restraints are prominently associated with the substantial capital expenditure required to procure advanced coverslipping systems, coupled with the ongoing costs for specialized consumables (mounting media, coverslips) and necessary system maintenance. Furthermore, integrating new, highly automated equipment into existing, sometimes fragmented, laboratory information management systems (LIMS) can pose technical challenges and require specialized IT support, which can be a significant drag on adoption rates in less technologically mature institutions. Opportunities, conversely, are abundant in untapped emerging markets where modernization of healthcare facilities is prioritized. These regions offer a burgeoning environment for adoption as they often leapfrog older technologies directly to fully automated solutions, driven by competitive pressure to meet international healthcare standards.

The convergence of digital pathology and automation provides a major opportunity force, as coverslippers are the last line of preparation before whole-slide imaging (WSI). Systems designed for superior quality and consistency for digital scanning gain a competitive edge. Drivers promoting market acceleration include the growing shortage of skilled laboratory technicians globally, making automation an operational necessity rather than merely a convenience. The push for faster diagnosis in precision medicine further necessitates the reliability and speed provided by automatic systems. Ultimately, while initial costs remain a constraint, the overwhelming demand for high-quality, standardized diagnostic throughput and the long-term labor savings solidify the positive trajectory driven by operational necessity and technological integration.

Segmentation Analysis

The Automatic Coverslipper Market is comprehensively segmented based on technology type, throughput capacity, end-user application, and mounting medium compatibility, providing a structured view of diverse market needs and product offerings. Segmentation based on throughput capacity—ranging from low/medium-throughput systems tailored for specialized labs to ultra-high-throughput systems designed for central reference laboratories—is crucial as it directly aligns equipment capabilities with laboratory volume demands. The choice of coverslipper is often dictated by the existing integration needs within the pathology workflow, particularly its connectivity with automated tissue processors and stainers. Furthermore, the segmentation by mounting media (solvent-based vs. aqueous) reflects the growing laboratory preference for safer, environmentally friendlier, non-toxic alternatives, although solvent-based systems still dominate historically established workflows.

- By Technology:

- Automated Robotic Systems

- Semi-Automated Systems (Integrated)

- Benchtop Compact Systems

- By Throughput Capacity:

- Low-to-Medium Throughput (<200 Slides/Hour)

- High Throughput (200-400 Slides/Hour)

- Ultra-High Throughput (>400 Slides/Hour)

- By Mounting Medium Type:

- Solvent-Based Coverslippers (e.g., Xylene substitutes)

- Aqueous-Based Coverslippers

- By End User:

- Hospitals and Clinical Laboratories

- Reference Laboratories

- Academic and Research Institutes

- Pharmaceutical and Biotechnology Companies

Value Chain Analysis For Automatic Coverslipper Market

The value chain for the Automatic Coverslipper Market initiates with the upstream supply of sophisticated components, encompassing precision engineering, robotics, and advanced optical systems. Key raw materials include high-grade plastics and metals for chassis and mechanical parts, specialized micro-motors and robotic arms for precise slide handling, and optical sensors crucial for quality checks. Manufacturers rely heavily on specialized component suppliers for reliable fluidics systems—pumps, valves, and dispensers—that ensure the accurate and bubble-free application of the mounting medium. The competitive landscape at this stage is focused on securing reliable sourcing, minimizing component defects, and maintaining cost-effectiveness, as the complexity of the integrated system dictates high manufacturing costs.

The core manufacturing and assembly phase involves integrating these complex sub-systems, including software development for user interfaces, LIMS connectivity, and internal quality control processing. This phase adds substantial value through proprietary automation algorithms and system reliability testing. Distribution channels are typically a mix of direct sales forces (especially for high-value contracts with large hospital networks or reference labs) and indirect channels utilizing regional distributors or third-party representatives who possess deep knowledge of local regulatory requirements and technical support capabilities. Manufacturers must provide extensive training and documentation to ensure channel partners can effectively install, calibrate, and service these specialized instruments.

The downstream segment involves product installation, post-sales service, and the continuous supply of specialized consumables, primarily mounting media and disposable coverslips, which form a recurring revenue stream critical to market profitability. Direct distribution is favored for high-volume sales where specialized technical support and long-term service contracts are essential, ensuring maximum uptime for critical diagnostic equipment. Indirect channels often dominate penetration into smaller, geographically dispersed laboratories or emerging markets, leveraging the distributor's established logistical network. Ultimately, customer satisfaction and sustained value are heavily dependent on robust field service engineering and prompt access to certified replacement parts and specialized chemicals.

Automatic Coverslipper Market Potential Customers

Potential customers for Automatic Coverslipper technology are predominantly institutions that manage high volumes of histological samples and require high consistency and speed in slide preparation for diagnostic and research purposes. The largest segment of end-users comprises hospitals and their affiliated clinical pathology laboratories. These facilities operate under immense pressure to deliver rapid and accurate results for patient care, making the efficiency gains provided by automatic coverslippers indispensable. Modern hospital labs prioritize seamless integration with other automated histology equipment (stainers, processors) to establish a truly hands-off workflow from tissue embedding to final slide preparation, supporting their high-throughput diagnostic environment.

Reference laboratories, which handle outsourced pathology testing for multiple smaller clinics and hospitals across vast geographical regions, represent another critical customer segment. These labs demand ultra-high-throughput systems capable of processing hundreds of slides per hour with minimal staff intervention, requiring the most advanced, robust, and often floor-standing coverslipper models. Their emphasis is on scalability, redundancy, and LIMS integration to manage massive data streams and ensure rigorous quality assurance across all processed samples, making automation an absolute requirement for sustaining their business model and competitive edge.

Furthermore, academic research institutes, university medical centers, and pharmaceutical/biotechnology companies focused on drug discovery, toxicology screening, and preclinical studies constitute a specialized customer base. While their volume might be lower than central reference labs, their demand for unparalleled consistency, precision, and the ability to process specialized slides (e.g., thin sections, non-standard sizes) is high. These research customers often seek features that enable customization of mounting media and coverslip thickness, ensuring the compatibility of slides with highly sensitive analytical instruments or specialized whole-slide imaging protocols required for complex scientific investigations and regulatory submissions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 550 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Leica Biosystems, Sakura Finetek, Thermo Fisher Scientific, Dako (Agilent Technologies), Roche Diagnostics, General Data Co., Inc., Ventana Medical Systems, MEDITE GmbH, SLEE medical GmbH, Milestone Medical, Motic, PathShodh Healthcare, Bio-Optica, Histo-Line Laboratories, Epredia, Diapath S.p.A., Avantor, StatLab Medical Products, Biolab Diagnostics, A. De Wever SAS. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automatic Coverslipper Market Key Technology Landscape

The technological landscape of the Automatic Coverslipper Market is defined by the necessity for extreme precision, high reliability, and seamless integration within highly sensitive histology workflows. Advanced systems incorporate sophisticated robotic mechanisms, often utilizing multi-axis robotics, to ensure gentle and precise handling of fragile glass slides and coverslips, minimizing breakage and sample loss, which is crucial given the irreplaceable nature of biopsy samples. These robotic components are complemented by integrated vision systems that precisely locate the stained tissue section and guide the dispensing head, ensuring optimal coverslip placement and mounting medium application, thereby eliminating common manual errors such as misalignment or excessive medium use. Furthermore, modern coverslippers feature rapid drying or curing functions, often employing controlled heat or UV light, to ensure the slide is immediately ready for subsequent digital scanning or microscopic examination, significantly accelerating the total diagnostic turnaround time.

A central technological focus is on the development of highly accurate fluidics management systems. These systems utilize calibrated peristaltic or syringe pumps to dispense microliter-level volumes of mounting medium with high consistency, which is fundamental to achieving bubble-free and uniform slide preparation. The ability to manage both traditional solvent-based media (like xylene substitutes) and newer, safer aqueous media within the same system or across specialized modules is a key differentiator among competing technologies. Ongoing research is also concentrating on improving the environmental profile of these instruments, promoting reduced chemical consumption and incorporating closed-loop solvent recycling systems to enhance laboratory safety and sustainability, aligning with broader industrial standards and worker safety regulations.

The integration capabilities of the latest generation of coverslippers are paramount, reflecting the industry's shift toward the fully automated pathology lab. Systems must offer robust bidirectional connectivity with Laboratory Information Management Systems (LIMS) and Laboratory Automation Systems (LAS), allowing for automated slide tracking, real-time status updates, and logging of quality control metrics. Furthermore, the integration with digital pathology platforms is becoming standard, with coverslippers optimized to produce slides with minimal geometric distortions or artifacts, which is essential for accurate whole-slide imaging (WSI). The incorporation of real-time imaging sensors and AI algorithms, as previously noted, for on-the-fly quality assurance is the cutting edge, further cementing the role of technology in ensuring diagnostic reliability and enhancing overall laboratory operational efficiency through automated decision-making and defect identification.

Regional Highlights

- North America: North America holds the largest market share due to its advanced healthcare infrastructure, significant per capita expenditure on diagnostics, and the early and extensive adoption of full laboratory automation suites. The presence of major market players and the high volume of specialized research and development activities in biotechnology and pharmaceuticals further drives demand. Stringent regulatory standards (e.g., CLIA certification) require high consistency, compelling labs to invest in automated, high-precision coverslipping systems. Market maturity is high, with demand focusing on replacing older automated models and integrating next-generation systems with comprehensive digital pathology solutions and AI-driven quality assurance features to handle massive reference lab volumes.

- Europe: Europe represents a mature market characterized by robust public healthcare spending and a strong focus on diagnostic quality standardization, often driven by EU directives. Countries such as Germany, the UK, and France are primary contributors to market revenue, prioritizing systems that offer efficiency, reduce environmental impact (favoring aqueous media systems), and comply with stringent data privacy regulations (GDPR). The market growth is stable, fueled by the replacement of manual processes in regional and local hospital laboratories and the strategic consolidation of testing facilities into high-throughput hubs requiring centralized automation.

- Asia Pacific (APAC): APAC is anticipated to be the fastest-growing region, presenting substantial growth opportunities fueled by rapid infrastructural development, increasing awareness of advanced diagnostics, and massive investments by governments in healthcare modernization, particularly in China, India, and Japan. The transition from manual and semi-automatic methods to fully automated coverslippers is accelerating to manage the huge, rapidly growing patient populations and address the rising incidence of lifestyle diseases requiring histopathology. Competitive pricing and local manufacturing partnerships are critical strategies for vendors seeking to penetrate this dynamic and volume-driven market.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, primarily driven by improved economic conditions, increased access to private healthcare, and expanding adoption of international quality standards in countries like Brazil and Mexico. Adoption rates are moderate, often focusing on high-value, medium-throughput systems that offer a manageable entry point into automation for mid-sized private laboratories seeking to improve efficiency and reduce operational costs associated with manual slide processing.

- Middle East and Africa (MEA): The MEA region exhibits heterogeneous growth, with significant spending concentrated in Gulf Cooperation Council (GCC) countries (UAE, Saudi Arabia) driven by substantial government funding aimed at establishing world-class medical cities and reference centers. Automation adoption here is high-end, focusing on premium systems that support cutting-edge research and sophisticated diagnostic practices. Sub-Saharan Africa's market remains nascent but offers long-term growth potential as basic healthcare infrastructure and quality control mechanisms continue to develop and expand, eventually creating demand for affordable, reliable automation solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automatic Coverslipper Market.- Leica Biosystems (Part of Danaher Corporation)

- Sakura Finetek USA, Inc.

- Thermo Fisher Scientific Inc.

- F. Hoffmann-La Roche Ltd (Ventana Medical Systems)

- Agilent Technologies (Dako)

- MEDITE GmbH

- SLEE medical GmbH

- Milestone Medical

- Motic Group

- General Data Co., Inc.

- Histo-Line Laboratories S.r.l.

- Bio-Optica Milano S.p.A.

- Epredia

- Diapath S.p.A.

- Avantor, Inc.

- StatLab Medical Products

- Hubei Slicing Science & Technology Co., Ltd.

- Suzhou Hongjing Medical Technology Co., Ltd.

- Biolab Diagnostics

- A. De Wever SAS

Frequently Asked Questions

Analyze common user questions about the Automatic Coverslipper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of switching from manual to automatic coverslipping?

The primary benefit is the dramatic improvement in consistency, standardization, and throughput, which minimizes human variability and ensures slides are optimally prepared for microscopy or high-resolution whole-slide imaging (WSI), essential for reliable digital pathology.

How do automatic coverslippers integrate with digital pathology workflows?

Automatic coverslippers are crucial for digital pathology by producing slides that are bubble-free, uniformly mounted, and flat, which are prerequisites for successful, artifact-minimized high-speed scanning required for accurate computer-assisted diagnostic analysis and viewing on WSI systems.

Are solvent-based or aqueous-based coverslippers dominating the market?

While solvent-based systems historically dominate due to established protocols and speed, there is a strong shift toward aqueous-based systems driven by laboratory safety regulations, reduced toxicity concerns, and environmental sustainability initiatives, especially in developed markets.

What are the key technical features differentiating high-throughput coverslippers?

High-throughput models are distinguished by rapid cycle times (over 400 slides/hour), large capacity input/output hoppers, sophisticated robotic handling to manage multiple slides simultaneously, and integrated LIMS connectivity for continuous, real-time operational monitoring and traceability.

What factor is restraining the adoption of automatic coverslippers in emerging markets?

The main restraint is the high initial capital expenditure (CapEx) required for procurement, installation, and associated costs of integrating the complex equipment, making the return on investment (ROI) less immediate for smaller, budget-constrained laboratories in developing regions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager