Automatic Medical Thermosealer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432136 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Automatic Medical Thermosealer Market Size

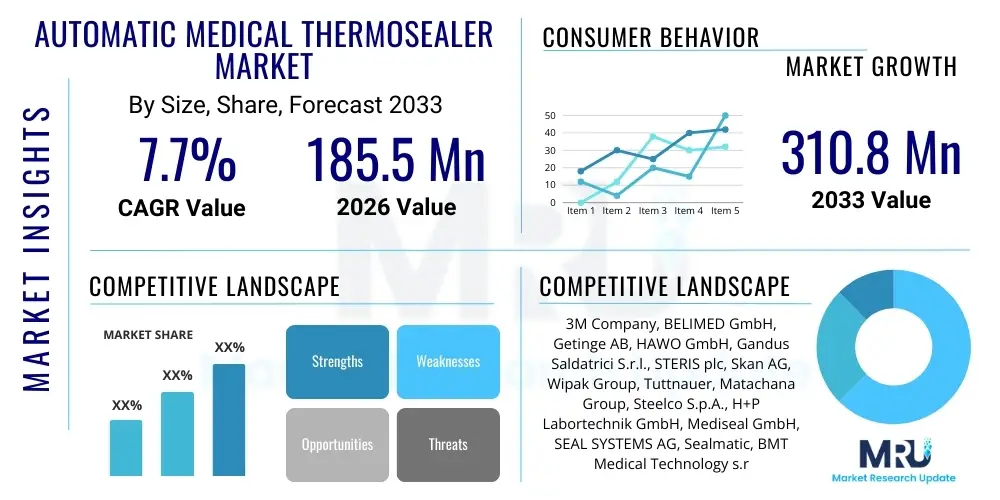

The Automatic Medical Thermosealer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.7% between 2026 and 2033. The market is estimated at USD 185.5 Million in 2026 and is projected to reach USD 310.8 Million by the end of the forecast period in 2033.

Automatic Medical Thermosealer Market introduction

The Automatic Medical Thermosealer Market encompasses equipment designed specifically for sealing sterilized pouches and reels used in medical device packaging, ensuring the integrity and sterility of instruments prior to use. These sophisticated machines are essential components in sterile processing departments (SPDs) of hospitals, ambulatory surgical centers, and pharmaceutical manufacturing facilities. Unlike manual sealers, automatic devices offer highly consistent sealing parameters—including temperature, pressure, and sealing time—which are critical for compliance with international standards such as ISO 11607, governing the packaging for terminally sterilized medical devices. The primary function is to provide an impermeable microbial barrier, thus minimizing the risk of Healthcare-Associated Infections (HAIs).

The core product description involves advanced sealing mechanisms, often utilizing continuous rotary sealing or impulse heat technology, coupled with integrated validation systems. These systems frequently include features like integrated printers for tracking sealing variables directly onto the pouch, ensuring traceability and documentation required for auditing purposes. Major applications span surgical instrument preparation, sterile supply processing, and packaging lines for disposable medical kits. The precision and automation offered by these devices significantly reduce operator error and improve throughput in high-volume settings, making them indispensable for modern healthcare infrastructure striving for optimal patient safety standards.

Key benefits driving market adoption include enhanced patient safety through verified sterile barriers, significant operational efficiency improvements by automating a critical quality control step, and stringent regulatory compliance adherence. Driving factors prominently feature the increasing volume of complex surgeries requiring diverse instrument sets, the continuous global emphasis on infection prevention and control (IPC) protocols, and the expansion of healthcare infrastructure, particularly in emerging economies. Moreover, the shift towards smart, connected devices within hospital logistics further stimulates demand for automatic thermosealers capable of integrating with central tracking and inventory management systems.

Automatic Medical Thermosealer Market Executive Summary

The Automatic Medical Thermosealer Market is undergoing robust expansion, fundamentally driven by escalating regulatory scrutiny over sterilization processes and the inherent need for high-throughput, error-free packaging in clinical environments. Business trends indicate a strong move toward advanced, high-speed continuous rotary sealers that can handle diverse material types while offering integrated process monitoring capabilities. Furthermore, there is a distinct shift toward modular systems that allow customization based on facility size and specific sealing requirements, coupled with software solutions for automated documentation and record-keeping, crucial for audit readiness. Strategic collaborations between thermosealer manufacturers and major sterile processing solution providers are becoming common, aiming to offer bundled solutions that cover washing, disinfection, packaging, and sterilization validation.

Regional trends highlight North America and Europe maintaining dominance, primarily due to established healthcare systems, strict regulatory mandates such as the FDA requirements and the European Medical Device Regulation (EU MDR), and high levels of healthcare expenditure enabling investment in premium automated equipment. However, the Asia Pacific (APAC) region is demonstrating the fastest growth trajectory, fueled by rapid urbanization, significant government investments in healthcare infrastructure expansion, and a growing awareness of infection control standards in countries like China and India. This regional growth is characterized by increasing demand for mid-range, reliable automated sealers that balance cost efficiency with compliance needs.

Segmentation trends reveal that the Continuous Rotary Sealer segment dominates the market due to its speed and efficiency, especially in high-volume central sterile supply departments (CSSDs). In terms of application, hospitals remain the largest end-user group, yet the fastest growth is observed in Ambulatory Surgical Centers (ASCs) and specialized medical device manufacturing units that demand validated, standardized sealing processes for outsourced sterilization services. The key market segments are increasingly defined by features such such as data logging capabilities, compatibility with varying pouch materials, and the ability to interface with electronic health record (EHR) and instrument tracking systems, ensuring seamless integration into the modern digital hospital workflow.

AI Impact Analysis on Automatic Medical Thermosealer Market

User queries regarding the impact of Artificial Intelligence (AI) on the Automatic Medical Thermosealer Market primarily revolve around questions concerning quality assurance automation, predictive maintenance capabilities, and the integration of machine learning algorithms to optimize sealing parameters. Users are highly interested in how AI can move beyond simple sensor monitoring to truly predict seal integrity failures before they occur, reducing waste and reprocessing costs. Key themes frequently emerging include the feasibility of AI-driven visual inspection systems replacing human checks, the complexity of regulatory approval for AI-validated processes, and the long-term return on investment (ROI) for implementing such sophisticated technologies in sterilization departments, traditionally operating on tight budgets. The consensus expectation is that AI will transform thermosealing from a reactive process into a proactive quality control checkpoint.

AI's initial influence is centered on enhancing operational predictability and minimizing downtime. By analyzing historical data related to seal temperature fluctuations, pressure inconsistencies, and machine wear patterns—collected through integrated sensors and IoT connectivity—AI algorithms can forecast potential equipment malfunctions or drift in calibration. This enables facilities to schedule maintenance proactively, ensuring continuous availability of the sterilization packaging line, which is critical for smooth surgical scheduling. Moreover, AI is being deployed in sophisticated image recognition systems that scan sealed packages immediately post-sealing to identify minute flaws, such as crimping errors, material folds, or incomplete sealing zones, providing a level of quality verification unattainable through conventional human inspection or simple parameter logging.

The integration of machine learning further allows thermosealers to adapt dynamically to varying environmental conditions (e.g., humidity or temperature changes within the SPD) or slight variations in packaging material lots, automatically fine-tuning sealing profiles to maintain optimal seal strength and microbial barrier properties. This adaptive sealing intelligence ensures compliance is maintained under diverse operational pressures, significantly elevating the standard of sterile packaging consistency globally. While full AI integration is nascent, the focus on leveraging large datasets generated by connected thermosealers to drive process improvement and automated compliance checks represents the most significant paradigm shift expected in the medium term, ultimately leading to higher standards of infection control and substantial labor savings.

- Enhanced Predictive Maintenance: AI algorithms analyze operational data (temperature, cycle time, vibrations) to predict component failure, maximizing uptime.

- Automated Quality Control (AQC): Machine vision systems utilize AI to instantly inspect seal integrity, detecting microscopic flaws and ensuring compliance with ISO 11607.

- Dynamic Parameter Optimization: Machine learning models adjust sealing parameters in real-time based on environmental conditions and material input, optimizing seal consistency.

- Regulatory Documentation Automation: AI assists in compiling comprehensive, tamper-proof audit trails of sealing processes, simplifying regulatory reporting.

- Training and Simulation: Virtual reality and AI-powered simulation tools are used for training SPD staff on complex thermosealer operation and troubleshooting.

DRO & Impact Forces Of Automatic Medical Thermosealer Market

The Automatic Medical Thermosealer Market is profoundly shaped by a confluence of driving factors centered around patient safety and regulatory mandates, balanced against cost constraints and technological hurdles. The primary driver is the stringent enforcement of global sterilization and packaging standards, such as ISO 11607 and national health authority guidelines, which necessitate repeatable, validated sealing processes that only automatic machinery can reliably provide. This regulatory pressure is amplified by the continuous threat of Healthcare-Associated Infections (HAIs), compelling healthcare facilities to invest in superior equipment that guarantees the integrity of sterile supplies. However, restraining forces include the high initial capital investment required for advanced automated thermosealers, especially those with integrated data logging and validation capabilities, posing a significant hurdle for smaller clinics or facilities in developing regions. Furthermore, the specialized maintenance and calibration requirements of these precise instruments demand highly trained personnel, adding to operational expenditure.

Opportunities within the market largely stem from technological convergence and geographic expansion. The proliferation of smart hospitals and the push toward integrating medical devices into the Internet of Medical Things (IoMT) creates significant opportunities for thermosealers equipped with advanced networking capabilities for remote diagnostics, centralized monitoring, and seamless data transfer to instrument tracking systems (ITS). Geographically, untapped markets in Latin America, Southeast Asia, and parts of the Middle East, where healthcare modernization is accelerating, represent substantial growth opportunities as facilities transition away from manual or semi-automatic sealing methods to meet evolving international standards. The expansion of specialized surgical procedures, particularly in orthopedics and cardiac care, which rely heavily on complex, reusable instrument sets, further cements the need for validated packaging solutions.

Impact forces affecting the market include the enduring influence of sterilization standards harmonization efforts globally, which dictate fundamental machine design and required validation features. The escalating cost pressures within healthcare systems, driven by payor demands and budget caps, force manufacturers to innovate towards devices that offer efficiency and durability alongside high quality, minimizing the total cost of ownership (TCO). Furthermore, the supply chain resilience post-pandemic has highlighted the need for robust, reliable equipment less prone to component scarcity, influencing procurement decisions toward trusted, established manufacturers. The shift toward specialized sterilization solutions, such as low-temperature sterilization methods, also impacts the types of packaging materials used and, consequently, the heat tolerance and sealing profiles required from the automatic thermosealers.

Segmentation Analysis

The Automatic Medical Thermosealer market is comprehensively segmented based on Type, Application, and End-User, reflecting the diverse requirements across the sterile processing and medical manufacturing landscape. The segmentation ensures that offerings are tailored to specific volume requirements, material handling needs, and regulatory environments of various healthcare providers and industrial clients. Analyzing these segments provides deep insights into consumer behavior, guiding product development towards features like increased throughput, enhanced traceability, and better integration with digital hospital systems. The distinct operational needs of large CSSDs (requiring high-speed continuous sealers) versus specialized clinics (needing precise, validated impulse sealers) drive the differentiation within the Type segment, while regulatory compliance needs strongly define the Application segment, specifically focusing on critical vs. non-critical instruments.

- Type:

- Continuous Rotary Sealer

- Impulse Sealer

- Application:

- Sterilization Pouches

- Sterilization Reels/Gusseted Reels

- Tyvek Packaging

- End-User:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Medical Device Manufacturers (MDMs) and Third-Party Sterilization Services

- Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Automatic Medical Thermosealer Market

The value chain for the Automatic Medical Thermosealer Market begins with the Upstream Analysis, which focuses heavily on the procurement of high-precision components, including specialized heating elements, highly sensitive temperature and pressure sensors, sophisticated microprocessors for control systems, and high-quality stainless steel for chassis construction to ensure durability and sanitation compliance. Manufacturers rely on specialized suppliers for these validated components, where quality control is paramount as the performance of the final product is directly tied to the precision of these inputs. Logistics and inventory management at this stage are crucial, requiring efficient coordination to maintain production schedules while adhering to rigorous material qualification standards necessary for medical-grade equipment.

The Manufacturing and Assembly phase involves the complex integration of these electronic and mechanical components. This step requires advanced engineering expertise to ensure precise calibration of temperature and pressure mechanisms, which are the core functions defining the quality of the seal. Stringent quality checks, often including calibration certification traceable to national standards, are performed before the product moves to distribution. The Downstream Analysis focuses on the Distribution Channel, which is predominantly a mix of Direct Sales (for large hospital networks or MDMs) and Indirect Sales through specialized medical equipment distributors who provide local sales support, installation, and essential technical training. Due to the technical nature of the product and the need for ongoing maintenance, the indirect channel requires distributors with deep clinical and technical competence.

The final stage involves Post-Sales Support and Service, which is a critical differentiator in this market. Automatic thermosealers require regular preventative maintenance and calibration to maintain regulatory compliance (IQ/OQ/PQ protocols). Manufacturers and their distributors offer comprehensive service contracts, calibration verification services, and technical support. Direct distribution channels are often preferred by large clients who require bespoke integration services and immediate access to factory-trained technicians, while indirect channels serve dispersed smaller clinics efficiently. The effectiveness of this service network significantly impacts customer retention and overall market reputation, underpinning the value derived by the end-user through assured compliance and minimal operational disruption.

Automatic Medical Thermosealer Market Potential Customers

Potential customers for Automatic Medical Thermosealers are entities requiring validated and repeatable sterile barrier packaging for medical instruments and devices, primarily segmented across clinical settings and industrial operations. The most significant end-users are Hospitals and large Integrated Delivery Networks (IDNs), specifically their Central Sterile Supply Departments (CSSDs), which handle thousands of reusable surgical instruments daily. These customers demand high-speed Continuous Rotary Sealers that offer integrated documentation features, seamless integration with instrument tracking systems, and robust performance under high utilization rates. The procurement decisions in this segment are heavily influenced by clinical efficacy, regulatory compliance (e.g., Joint Commission accreditation), and the total cost of ownership over the equipment lifespan.

Ambulatory Surgical Centers (ASCs) represent a rapidly expanding customer base. ASCs prioritize efficiency and space-saving solutions, often opting for more compact, reliable Impulse Sealers or mid-range continuous sealers that provide the necessary validation features without the excessive throughput capacity required by major hospitals. Their purchase criteria focus on ease of use, compliance documentation, and minimal footprint, often favoring models that integrate printer functionality for immediate labeling. As ASC volumes increase and procedures become more complex, the need for validated packaging standards aligns directly with the capabilities of automatic thermosealers, making them a crucial investment for these outpatient facilities.

A third major segment comprises Medical Device Manufacturers (MDMs) and specialized Third-Party Sterilization Services, including contract sterilization organizations (CSOs). These industrial customers use thermosealers in their primary packaging lines, where quality and scalability are paramount. They often require specialized sealing capabilities for complex barrier materials like Tyvek and high-volume Continuous Rotary Sealers built for 24/7 operational environments. For MDMs, the thermosealer is an integral component of their ISO 13485 quality system, necessitating extremely high precision, continuous process monitoring, and sophisticated data logging capabilities to ensure batch traceability and regulatory submission compliance globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 310.8 Million |

| Growth Rate | 7.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, BELIMED GmbH, Getinge AB, HAWO GmbH, Gandus Saldatrici S.r.l., STERIS plc, Skan AG, Wipak Group, Tuttnauer, Matachana Group, Steelco S.p.A., H+P Labortechnik GmbH, Mediseal GmbH, SEAL SYSTEMS AG, Sealmatic, BMT Medical Technology s.r.o., SteriPackGroup, Ritter Medical, Harro Höfliger GmbH, KEOH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automatic Medical Thermosealer Market Key Technology Landscape

The technological landscape of the Automatic Medical Thermosealer Market is rapidly advancing, moving beyond simple heat application to include integrated validation, sophisticated digital controls, and enhanced material compatibility. The defining technology remains the sealing mechanism itself, segmented into Continuous Rotary Sealing and Impulse Sealing. Continuous rotary sealers employ continuously heated wheels to seal large volumes rapidly, achieving high throughput necessary for major hospital CSSDs or manufacturing lines. Recent innovations in this area focus on maintaining consistent temperature distribution across the entire sealing width, minimizing thermal inertia, and improving the speed without compromising seal integrity. Advanced models now feature self-calibration routines and integrated pressure monitoring to ensure the sealing process meets stringent performance qualification (PQ) standards automatically.

Impulse sealing technology, conversely, uses a brief, high-energy impulse of heat followed by cooling under pressure. While typically slower than continuous sealers, impulse sealers are highly valued for their energy efficiency and ability to produce exceptionally strong, clean seals, often preferred for delicate or specialized materials and for use in smaller clinical environments like ASCs. A significant technological advancement across both types is the integration of advanced microcontroller units (MCUs) that facilitate precise control over dwell time, temperature uniformity, and applied pressure, moving away from analog control systems. These digital controls are essential for providing the detailed process documentation required by regulatory bodies, ensuring that every cycle is logged and validated against set parameters.

Furthermore, the contemporary technological evolution is heavily focused on connectivity and data management. Modern thermosealers are increasingly equipped with Ethernet or Wi-Fi capabilities, allowing them to integrate directly with hospital information systems (HIS), instrument tracking software (ITS), and remote maintenance platforms. This IoMT integration facilitates real-time monitoring of operational status, centralized reporting, and automated generation of documentation packets, significantly reducing manual administrative load and improving audit readiness. Critical features include integrated thermal printers capable of printing 2D barcodes or specific batch information directly onto the pouch, ensuring traceability of the sealed package back to the specific sterilization cycle, the operator, and the thermosealer used. The adoption of advanced sensors for material recognition and automatic adjustment of sealing profiles based on the detected packaging material (e.g., paper/film versus Tyvek) represents the frontier of smart sealing technology, promising error minimization and maximized regulatory compliance.

Regional Highlights

Regional dynamics within the Automatic Medical Thermosealer Market are characterized by varying levels of healthcare infrastructure maturity, regulatory stringency, and adoption rates of automation technology.

- North America (USA and Canada)

- North America commands a significant market share, driven primarily by the presence of a mature healthcare industry, high levels of surgical procedures, and extremely rigorous regulatory environments enforced by the FDA and other accreditation bodies.

- The demand here is heavily focused on premium, fully automated thermosealers that offer advanced features like full IoMT connectivity, extensive data logging, and integrated validation tools to meet the high standards of traceability required for reducing litigation risks and ensuring patient safety compliance in large hospital networks and leading ASCs.

- Investment in replacement and upgrade cycles is constant, supported by high healthcare spending and a strong emphasis on evidence-based infection prevention protocols, necessitating adherence to standards like AAMI ST79.

- Europe (Germany, UK, France, Italy)

- Europe represents the second-largest market, strongly influenced by the implementation of the European Medical Device Regulation (EU MDR), which mandates enhanced quality control and documentation throughout the medical device lifecycle, including packaging.

- Germany and the Nordic countries, in particular, show high adoption of advanced, sustainable thermosealing technologies. The region favors highly energy-efficient equipment and systems that integrate seamlessly into decentralized sterilization models.

- Emphasis is placed on long-term equipment reliability and compliance with European norms (EN series), driving demand for sealers from established European manufacturers known for precision engineering and robust after-sales support networks.

- Asia Pacific (APAC) (China, India, Japan, South Korea)

- APAC is projected to be the fastest-growing region, fueled by massive government investments in expanding healthcare capacity, a rapidly increasing population requiring surgical intervention, and a rising awareness of international infection control standards.

- Growth is characterized by a dual market structure: advanced economies like Japan and South Korea demand premium, high-tech sealers similar to North America, while emerging economies like China and India drive demand for reliable, cost-effective mid-range automatic sealers to replace aging semi-automatic equipment.

- The increasing presence of global medical device manufacturing operations in this region significantly contributes to the industrial segment of the market, necessitating high-throughput sealers for sterile barrier systems production.

- Latin America (LATAM) (Brazil, Mexico)

- The LATAM market is experiencing steady growth, motivated by the ongoing modernization of private hospital systems and increased regulatory oversight in major economies like Brazil and Mexico.

- Market adoption often follows technological trends established in North America, but with a greater focus on maximizing cost efficiency and managing logistical challenges associated with equipment maintenance and spare parts availability.

- Infrastructure development, particularly in ambulatory care, is creating new pockets of demand for automated equipment that improves process standardization.

- Middle East and Africa (MEA) (GCC Countries, South Africa)

- Growth in the MEA region is concentrated primarily in the Gulf Cooperation Council (GCC) countries, driven by significant government spending on establishing world-class medical facilities and medical tourism initiatives.

- These regions typically invest in the latest technology, favoring full automation and digital integration, mirroring the requirements of large North American hospitals.

- Adoption rates are slower in the broader African continent due to varying levels of healthcare spending and limited infrastructure, leading to slower uptake of high-cost, fully automated solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automatic Medical Thermosealer Market.- 3M Company

- BELIMED GmbH

- Getinge AB

- HAWO GmbH

- Gandus Saldatrici S.r.l.

- STERIS plc

- Skan AG

- Wipak Group

- Tuttnauer

- Matachana Group

- Steelco S.p.A.

- H+P Labortechnik GmbH

- Mediseal GmbH

- SEAL SYSTEMS AG

- Sealmatic

- BMT Medical Technology s.r.o.

- SteriPackGroup

- Ritter Medical

- Harro Höfliger GmbH

- KEOH

Frequently Asked Questions

Analyze common user questions about the Automatic Medical Thermosealer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary regulatory standard governing automatic medical thermosealing?

The primary standard is ISO 11607, which specifies the requirements for developing and validating packaging systems for terminally sterilized medical devices. Automatic thermosealers must demonstrate and log that they meet the defined process parameters (temperature, pressure, time) to comply with this standard, ensuring the integrity of the sterile barrier system (SBS).

How do Continuous Rotary Sealers differ fundamentally from Impulse Sealers in clinical settings?

Continuous Rotary Sealers are designed for high-volume throughput, using constantly heated rollers to quickly seal pouches and reels, making them ideal for large Central Sterile Supply Departments (CSSDs). Impulse Sealers, conversely, apply a brief burst of heat followed by cooling under maintained pressure, offering high seal quality for specialized materials and are often preferred in lower-volume Ambulatory Surgical Centers (ASCs).

What role does IoMT play in the adoption of modern thermosealing equipment?

The Internet of Medical Things (IoMT) enables modern thermosealers to connect to hospital networks, allowing for automated documentation, remote monitoring of performance, real-time diagnostics, and seamless data transfer to Instrument Tracking Systems (ITS). This connectivity minimizes manual errors, enhances traceability for regulatory audits, and facilitates predictive maintenance.

What key factors drive the demand for automatic thermosealers in the Asia Pacific region?

Demand in APAC is driven by rapid investment in public and private healthcare infrastructure, increasing surgical volumes, and the necessary harmonization of local infection control practices with international standards. The rising awareness of Healthcare-Associated Infections (HAIs) and the expansion of medical device manufacturing further accelerate adoption.

Is AI integration standard in automatic medical thermosealers, and what benefit does it provide?

AI integration is not yet standard but represents a key innovation frontier. AI is primarily used for Automated Quality Control (AQC) through machine vision to instantaneously detect seal flaws and for predictive maintenance scheduling. This results in higher quality assurance, reduced waste, and maximized operational uptime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager