Automotive Suede Material Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435637 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Automotive Suede Material Market Size

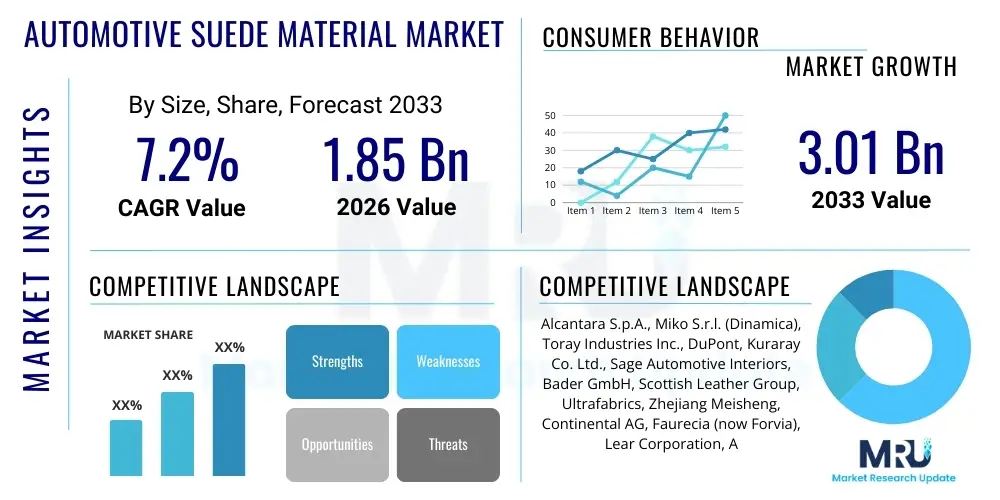

The Automotive Suede Material Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. This robust expansion is fueled by increasing consumer preference for premium, luxurious, and lightweight interior solutions across vehicle segments, particularly in the luxury and performance car categories. The shift towards sustainable and ethically sourced materials also drives the adoption of high-quality synthetic suede alternatives, influencing market valuation substantially during the forecast period. The material's ability to offer superior tactile feedback and acoustic dampening qualities, combined with its aesthetic appeal, positions it as a preferred choice over traditional fabric or low-grade leather options. The persistent pressure on automotive manufacturers to enhance perceived quality without dramatically increasing vehicle weight serves as a foundational driver for market size growth, making lightweight microfiber suede materials a strategic component in new vehicle designs. This material demand is further solidified by the increasing standardization of advanced interiors even in mid-range vehicle trim levels globally, broadening the addressable market.

The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 3.01 billion by the end of the forecast period in 2033. This significant valuation growth reflects the escalating production volumes of high-end vehicles and the standardization of suede-like materials in trim levels previously reserved for natural leather. Moreover, the aftermarket customization sector is contributing meaningful revenue, as vehicle owners seek to upgrade or personalize their existing car interiors with premium, durable materials. Advancements in textile engineering, resulting in enhanced durability, stain resistance, and UV stability of synthetic suede, are making these materials increasingly viable for high-wear applications such as seat covers and steering wheel wraps, thereby justifying the higher material cost and contributing significantly to market size expansion. The technological maturity in microfiber manufacturing, ensuring color consistency and strict adherence to automotive flammability and fade resistance standards, ensures supplier reliability, encouraging OEMs to lock in long-term supply agreements that underpin the projected revenue figures. Furthermore, the rising investment in developing bio-based or recycled content synthetic suede further stabilizes the long-term growth forecast by mitigating environmental concerns related to petrochemical sourcing.

Automotive Suede Material Market introduction

The Automotive Suede Material Market encompasses the manufacturing, distribution, and utilization of high-performance textile materials designed to emulate the soft texture and luxurious aesthetic of natural suede, specifically for vehicle interiors. These materials, which include both genuine suede leather and advanced synthetic microfibers like Alcantara, Dinamica, and proprietary textile blends, are integral to the aesthetic and functional design of modern vehicle cabins. The primary usage spans critical interior surfaces: seating upholstery, protective and decorative headliners, instrument panel coverings, door panel inserts, and crucial driver-interface elements such as steering wheel wraps and gear selector boots. The market’s evolution is characterized by a strong consumer migration away from traditional, heavy materials towards lighter, more technical alternatives that still convey exclusivity and high quality. The synthetic variants, utilizing complex non-woven microfiber techniques often involving polyurethane impregnation, represent the technological vanguard, offering superior mechanical properties over their natural counterparts.

The core product characteristic is superior tactility combined with excellent acoustic dampening properties and visual appeal. Automotive-grade suede is specifically engineered to meet demanding vehicular specifications, which include stringent tests for abrasion resistance (e.g., Martindale test cycles), light fastness (resistance to fading under UV exposure), and strict flammability standards (FMVSS 302). Major applications span passenger vehicles, including high-volume sedans, luxury SUVs, and specialized high-performance sports cars, along with targeted uses in specialized commercial and recreational vehicles requiring durable and aesthetically pleasing, easy-to-clean finishes. The material's inherent flexibility allows for complex thermoforming and stitching, facilitating intricate interior designs that are often impossible with stiffer materials, thus enhancing design freedom for automotive stylists and engineers globally. The market growth is also intrinsically linked to the expanding customization culture within the automotive domain, where bespoke interior finishes are key differentiators.

The primary benefits associated with automotive suede materials include lightweight construction, which contributes positively to critical metrics such as fuel efficiency in Internal Combustion Engine (ICE) vehicles and extended battery range in Electric Vehicles (EVs); enhanced grip, particularly vital for performance-oriented steering wheels; and a globally recognized perceived upgrade in interior luxury and quality. Synthetic variants specifically offer advantages in uniformity, allowing for flawless large-panel applications; ethical sourcing advantages, appealing to sustainability-conscious consumers; and superior resistance to common automotive environmental stressors like temperature fluctuations, fading, and localized abrasion, outperforming traditional natural leather or basic textiles. Key driving factors propelling market growth involve the consistent global rise in demand for premium and customized vehicle interiors, the stringent regulatory focus on vehicle lightweighting as a means to reduce emissions, and the growing technological sophistication in microfiber manufacturing, which ensures that these materials meet and exceed strict automotive safety and long-term durability standards while maintaining a desired luxurious, soft touch.

Automotive Suede Material Market Executive Summary

The Automotive Suede Material Market is experiencing accelerated expansion driven by concurrent shifts in consumer preferences towards customized, premium, and sustainable vehicle interiors, directly translating into higher demand for advanced microfiber textiles. Current business trends indicate a strong, strategic pivot by Original Equipment Manufacturers (OEMs) towards integrating high-performance synthetic suedes as standard or optional features across mid-range, luxury, and performance vehicle segments. This integration is motivated by a desire to differentiate products based on tactile experience, aesthetic sophistication, and the incorporation of lightweight materials essential for modern vehicle architecture. Major textile manufacturers are aggressively investing in Research and Development (R&D) to establish robust, closed-loop supply chains for recycled and bio-based synthetic materials, directly responding to escalating environmental scrutiny and the global automotive industry’s push towards carbon neutrality. Furthermore, strategic partnerships between primary textile producers, Tier 1 automotive suppliers (e.g., Lear, Adient), and specialized chemical companies are crucial for continuous product innovation concerning fire retardancy, low VOC emissions, and advanced surface treatments for easy cleaning and maintenance, ensuring materials meet stringent vehicular safety and longevity requirements before mass deployment.

Regional trends distinctly illustrate the dynamic market landscape. Asia Pacific (APAC), particularly driven by the exponential growth in China’s domestic market and rapid industrialization in Southeast Asia, is indisputably emerging as the fastest-growing market. This acceleration is due to rising disposable incomes, rapid urbanization, and a significant surge in domestic premium vehicle production and sales volumes, especially concerning New Energy Vehicles (NEVs) where interior quality is a key competitive factor. Conversely, Europe, historically the leader, maintains its technological superiority in terms of material quality, specialization, and ethical sourcing, largely influenced by heritage high-performance vehicle manufacturers who prioritize lightweight, meticulously finished, tactile materials for driver-centric cabins. North America sustains robust, consistent growth, primarily fueled by the continued strong demand for high-end luxury SUVs and large trucks, where comprehensive interior customization and comfort are substantial purchasing determinants. The increasing transition within North American OEMs towards electric platforms is further boosting the adoption of lighter, synthetic suedes as a design necessity.

Analysis of market segmentation trends unequivocally highlights the dominance of the synthetic suede microfiber segment. Driven by intrinsic advantages such as superior cost control, unparalleled material uniformity, enhanced physical durability, and a favorable ethical sourcing profile, synthetic suedes are growing at a rate significantly outpacing genuine suede leather applications. While genuine suede maintains a small, exclusive niche in ultra-luxury and bespoke vehicle customization, synthetic alternatives capture the vast majority of volume across mainstream premium and performance vehicles. In terms of application, seating components—including both the main surface and bolsters—and large-area headliner applications constitute the largest market share. These two applications collectively require the highest volume of specialized material, driving the bulk of manufacturing output. Furthermore, the continuous miniaturization and integration of electronics into cockpits are creating new opportunities for suede materials on complex console surfaces and display surrounds, where their anti-glare and non-slip properties are highly valued, indicating future diversification in application demand within the automotive interior.

AI Impact Analysis on Automotive Suede Material Market

User queries regarding the impact of Artificial Intelligence (AI) on the Automotive Suede Material Market typically center on themes of enhanced supply chain optimization, advanced predictive maintenance protocols for complex machinery, automated quality control systems, and the ability of AI tools to facilitate personalized manufacturing and bespoke material design. Users frequently inquire about the feasibility of leveraging AI to precisely forecast material demand fluctuations based on complex, frequently changing automotive OEM production schedules, asking how Machine Learning (ML) algorithms can be deployed to detect microscopic textural and structural defects in high-speed fabric manufacturing processes. Furthermore, there is significant interest in whether Generative AI-driven design tools will accelerate the creation and prototyping of novel, personalized suede-like textures, colors, and perforation patterns specific to individual vehicle model lines. Key operational concerns revolve around the substantial capital investment and integration costs required to retrofit AI tools into existing, often traditional, textile manufacturing environments, and the critical need for specialized data infrastructure and engineering expertise to effectively handle and process the vast, continuous datasets generated during high-throughput quality monitoring and machine sensor readings.

The analysis confirms that AI's most profound and immediate influence will be stabilizing and significantly optimizing the intricate global supply chain for raw microfiber polymers, specialized chemical treatments, and ancillary dyeing agents. Predictive analytics, dynamically powered by sophisticated AI models, empowers manufacturers to anticipate potential material stress points, optimize complex inventory management strategies to minimize costly storage and stockouts, and crucially, reduce overall material waste. These functions are particularly vital given the high cost, long lead times, and rigorous quality specifications associated with automotive-grade materials. In parallel, AI is fundamentally revolutionizing the quality assurance pipeline. Computer vision systems employing advanced deep learning models are achieving real-time, high-precision surface defect identification—including subtle color variances, weaving anomalies, and minor tears—at manufacturing speeds that far surpass any reliance on human or traditional inspection capabilities. This guarantees the flawless uniformity and absolute quality required for premium interior components, substantially increasing material yield efficiency and drastically reducing scrap rates, thereby lowering overall production costs while rigorously maintaining the elevated aesthetic standard demanded by leading OEMs.

In the domain of manufacturing execution systems (MES), AI is deployed for optimization of energy consumption and process parameter control, ensuring highly consistent batch-to-batch material output. For instance, ML algorithms fine-tune the polyurethane impregnation process in synthetic suede production to achieve perfect density and softness, compensating dynamically for slight variations in environmental conditions or raw material input. Looking forward, AI-enhanced CAD/CAM systems are drastically improving the efficiency of material layout and cutting (nesting). By running millions of simulations, AI generates optimal nesting patterns that minimize wastage of expensive suede fabric, a direct cost-saving measure for both the manufacturer and the Tier 1 suppliers. This technological adoption underscores a shift from reactive quality control to proactive process optimization, positioning AI as a critical enabler for scalability and adherence to the automotive sector’s exacting standards for high-volume, customized premium textiles.

- AI-driven predictive maintenance optimizes textile machinery uptime, proactively preventing failures and ensuring consistent material production quality.

- Machine Learning algorithms enhance supply chain resilience by accurately forecasting nuanced material demand fluctuations based on volatile automotive OEM production forecasts.

- Computer Vision systems integrated into manufacturing lines provide real-time, high-resolution defect detection for superior, automated quality control and zero-defect initiatives.

- Generative AI tools assist automotive designers in rapidly prototyping and validating new suede textures, bespoke colors, and surface patterns customized for specific vehicle models and brand identities.

- Advanced data analytics optimize material cutting patterns (nesting) using complex algorithms to minimize waste of expensive suede materials, improving cost efficiency dramatically.

DRO & Impact Forces Of Automotive Suede Material Market

The Automotive Suede Material Market operates under the influence of powerful macro and microeconomic impact forces, defined by a critical examination of its Drivers, Restraints, and Opportunities (DRO). Key market drivers include the overwhelming global demand for premium, customized, and lightweight vehicle interiors, a trend spanning both traditional luxury manufacturers and new electric vehicle players. This demand is intrinsically linked to rising global wealth and consumer aspiration for high-quality, tactile cabin environments. Furthermore, the increasing prominence of high-performance and racing-inspired vehicle trims necessitates materials like suede that offer superior grip and low reflectivity. The continuous technological breakthroughs in synthetic suede formulation, delivering enhanced performance metrics (e.g., higher resistance to fire, better acoustic properties, and superior durability) compared to basic textiles, are significantly bolstering adoption rates, allowing suppliers to meet stringent OEM requirements and drive market expansion globally.

Conversely, significant restraints impose limitations on market growth. The primary challenge remains the high initial manufacturing cost associated with producing advanced, high-performance microfiber technology, particularly materials requiring complex, multi-stage processing and proprietary chemical treatments. This higher cost relative to standard automotive fabrics restricts its widespread use across low-to-mid-range vehicle segments. A second major restraint is the historical dependence on petroleum-based raw materials (e.g., polyester, polyurethane) for many high-performance synthetics, which runs counter to the automotive industry's pervasive sustainability agenda. Although manufacturers are heavily investing in bio-based alternatives, this raw material constraint poses an ethical and supply chain vulnerability. Finally, manufacturers must navigate and adhere to extremely rigorous global automotive safety and volatile organic compound (VOC) emission standards, especially in North America and Europe, requiring costly, time-consuming material certification and continuous quality monitoring, which acts as a substantial barrier to entry for smaller or less technologically advanced producers.

Nevertheless, significant opportunities are reshaping the market trajectory, often mitigating the restraints. The most prominent opportunity lies in the rapidly expanding electric vehicle (EV) segment. Lightweight materials like synthetic suede are not merely aesthetic choices for EVs; they are critical functional components directly impacting vehicle efficiency and battery range, thus becoming an essential design parameter rather than just a luxury add-on. This creates a captive market opportunity where high-performance materials are functionally necessary. A parallel opportunity exists in the intensive development and commercialization of truly bio-based, recycled, or upcycled synthetic suede materials that successfully meet high-performance criteria while boasting certified sustainability credentials. These advancements align perfectly with the circular economy goals mandated by major global automotive groups, opening doors for lucrative, long-term supply contracts. Geographically, aggressive market expansion into emerging Asian automotive manufacturing hubs, where interior luxury is rapidly transitioning from a high-end novelty to a standard selling feature, presents substantial scalable growth prospects. The combined impact forces show a strong long-term positive vector, predicated on sustained innovation in sustainable manufacturing processes and the continued global premiumization of vehicle interiors, ensuring the suede material market remains dynamic and highly profitable.

Segmentation Analysis

The Automotive Suede Material Market is meticulously segmented across four primary dimensions: material type, application, vehicle type, and distribution channel, providing a comprehensive framework for understanding localized demand dynamics, competitive positioning, and strategic investment areas. Segmentation by material type—natural suede leather versus synthetic suede microfiber—is fundamentally important, as industry consumption heavily trends toward high-performance synthetic alternatives. These microfibers offer superior attributes such as enhanced resistance to pilling, easier maintenance, guaranteed uniformity across large panels, and ethical sourcing compliance, factors which are prioritized by OEMs engaged in mass-scale production. The synthetic segment’s structural advantages, coupled with its increasing cost-efficiency driven by production scale, confirm its dominance over natural materials, which are now largely confined to the bespoke or ultra-luxury vehicle customization domain.

Application segmentation details where these specialized materials are predominantly integrated within the vehicle cabin, providing insights into revenue density by usage area. Key revenue streams are clearly dominated by high-contact areas like seating upholstery, where durability and comfort are paramount, and large-area low-contact surfaces such as headliners and A/B/C pillar trim. Suppliers must tailor their product specifications, including material thickness, acoustic absorption properties, and specialized wear resistance coatings, to align precisely with these specific end-use requirements. For instance, material used on dashboards must feature extreme anti-glare properties and UV stability, whereas material used on steering wheels requires enhanced grip and high abrasion tolerance. Understanding these functional demands is crucial for optimizing material portfolio development and maximizing market penetration across varied interior components.

Furthermore, segmentation by vehicle type differentiates consumption patterns between high-volume passenger vehicles (including standard sedans and SUVs), ultra-premium high-performance vehicles (sports cars and supercars), and utilitarian commercial vehicles. High-performance and luxury vehicles invariably demand the most technologically advanced, lightweight, and custom-finished suede materials, justifying the highest price points and margins. In contrast, standard passenger vehicles utilize mid-range synthetics for specific trim upgrades. The final layer of segmentation, focusing on distribution channels—Original Equipment Manufacturer (OEM) versus aftermarket—reveals that the overwhelming majority of market volume and strategic engagement flows through direct, long-term contracts with OEMs and their Tier 1 suppliers. This channel necessitates rigorous compliance with high-volume quality mandates and integrated supply chain management. The aftermarket, while smaller, offers important avenues for innovation and rapid adoption of new colors and patterns catering to vehicle personalization, contributing specialized, high-margin revenue streams. This multi-layered segmentation structure is essential for suppliers to precisely target investment, tailor manufacturing capabilities, and formulate dynamic market entry and expansion strategies aligned with prevailing automotive manufacturing cycles and regional consumer luxury expectations.

- Material Type:

- Genuine Suede Leather: High-cost, niche luxury, unique texture.

- Synthetic Suede Microfiber (e.g., Alcantara, Dinamica, Microfaser): High volume, lightweight, durable, uniform, and sustainable focus.

- Application:

- Seating: Largest volume segment, demands high durability and comfort.

- Headliners and Pillars: Large surface area, crucial for acoustic quality and luxury feel.

- Dashboards and Consoles: Requires anti-glare and UV stability.

- Door Panels: Medium volume, aesthetic and tactile component.

- Steering Wheels and Gear Knobs: High friction, requires specialized grip and abrasion resistance.

- Others (e.g., Trunk lining, Sun visors): Niche applications.

- Vehicle Type:

- Passenger Vehicles (Sedans, SUVs, Hatchbacks): High-volume synthetic use in premium trims.

- High-Performance Vehicles: Requires ultralight and advanced technical suede materials.

- Commercial Vehicles: Specialized use for driver comfort and durability in specific heavy-duty segments.

- Distribution Channel:

- Original Equipment Manufacturer (OEM): Dominant channel, long-term contracts, strict quality control.

- Aftermarket: Customization, restoration, and replacement services.

Value Chain Analysis For Automotive Suede Material Market

The Value Chain for the Automotive Suede Material Market is intricate, starting with upstream raw material acquisition and culminating in the final integration into the vehicle interior assembly. Upstream analysis focuses critically on the sourcing and processing of core input materials. For synthetic suede, this involves securing stable supplies of high-quality petrochemical derivatives such as polyethylene terephthalate (PET) and polyurethanes (PU) from specialized chemical manufacturers. The volatility in global oil and polymer markets directly dictates the cost structure of synthetic suede, necessitating hedging strategies and long-term contracts with primary chemical suppliers. Ethical and regulatory compliance is also paramount, particularly regarding the development of certified recycled or bio-based polymers to reduce dependency on virgin fossil fuels. For genuine suede, the upstream stage involves the global hide market, tanneries, and strict monitoring of animal welfare standards and associated chemical treatments used in the tanning and splitting processes. The efficiency of polymerization and microfiber extrusion technology is the first critical value-add stage, determining the base quality, fineness, and uniformity of the filaments that form the textile.

Midstream activities represent the highly specialized manufacturing and conversion phase where the material gains its automotive-grade functionality and aesthetic appeal. This includes advanced non-woven textile processes such as needle punching or water jet entanglement, followed by the crucial impregnation phase using proprietary polyurethane resins (coagulation). This phase creates the dense, consistent structure characteristic of high-quality synthetic suede. Specialized finishing treatments—dyeing, calendering, brushing, and surface treatments for fire retardancy and UV stability—are applied here. Key players in this stage, such as Alcantara S.p.A. or Toray Industries, possess proprietary technological know-how that provides a distinct competitive advantage, acting as major barriers to entry. The ability to achieve perfect color matching across massive production batches, critical for OEM requirements, is a significant value differentiator established in this midstream conversion process.

Downstream analysis focuses on the efficient distribution and integration of the finished suede material into the vehicle production cycle. The primary distribution channel is direct sales to Tier 1 automotive interior systems suppliers—such as Adient, Lear Corporation, and Forvia (Faurecia)—who take the bulk material and integrate it into sub-assemblies like complete seat covers, door panels, and headliners. This relationship is characterized by just-in-time (JIT) logistics and highly precise quality control checks. Direct distribution to OEMs occurs primarily for specialized, low-volume projects or high-performance vehicle lines. Indirect distribution channels cater to the aftermarket, involving specialized wholesalers and distributors supplying independent upholstery shops, customizers, and classic car restorers. Optimizing this downstream supply chain, particularly minimizing lead times and ensuring global logistics efficiency, is crucial, as any delay can halt massive OEM assembly lines. The effective management of direct and indirect channels ensures market coverage across both new car production and the lucrative personalization and repair segments.

Automotive Suede Material Market Potential Customers

The primary and most significant customer segment for automotive suede materials comprises global Original Equipment Manufacturers (OEMs) and their network of specialized Tier 1 interior system suppliers. OEMs, including industry giants across Europe, North America, and Asia (such as luxury marques like Mercedes-Benz and Audi, performance specialists like Porsche and Ferrari, and high-volume manufacturers like Toyota and Volkswagen), leverage suede materials to distinctly elevate the aesthetic and tactile quality of their vehicle interiors. These customers demand not only superior visual and haptic qualities but also rigorous compliance with global standards, specifically the Federal Motor Vehicle Safety Standards (FMVSS) in the US and the European Union’s REACH regulations regarding chemical composition. Their purchasing rationale is centered on long-term supplier stability, guaranteed volume capacity, technological innovation (especially in sustainability), and the ability of the material to withstand the extreme environmental cycling (heat, cold, UV) inherent in automotive use. Purchasing cycles are typically long, dictated by multi-year model development and production contracts, requiring suppliers to demonstrate impeccable quality management systems.

A substantial secondary customer base operates within the automotive aftermarket and customization sphere. This segment includes specialized high-end modification companies, independent luxury vehicle restorers, large national and regional upholstery repair and replacement service providers, and niche parts retailers. These buyers typically operate on smaller, more irregular purchasing cycles but often require a wider diversity of colors, textures, and bespoke options for personalization projects. This market segment places a high premium on material availability and the ability to source specialized batches quickly. For instance, classic car restoration often requires sourcing materials that closely match original specifications, while modern customization focuses on unique, high-contrast color schemes and exotic finishes. Though lower in volume than the OEM channel, the aftermarket often yields higher profit margins due to the specialized nature of the service and the willingness of end-consumers to pay a premium for personalized interior upgrades and high-quality repairs.

Emerging potential customers are strongly associated with the technological evolution of vehicle usage models, particularly in autonomous and shared mobility fleet operations. As vehicles transition to Level 4 and Level 5 autonomy, interior design shifts focus from driver control to passenger comfort and lounge-like environments. This paradigm change increases the surface area allocated to soft-touch, premium materials, expanding the application scope of suede beyond traditional seating and dashboards to expansive consoles, ambient lighting panels, and internal dividers. Furthermore, the specialized military and emergency vehicle segments, although small, represent a demanding customer niche requiring materials with specific technical attributes, such as extreme resistance to tearing, inherent anti-microbial properties, and non-reflective finishes, all of which high-tech synthetic suedes can deliver, providing tailored market opportunities for specialized suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.01 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alcantara S.p.A., Miko S.r.l. (Dinamica), Toray Industries Inc., DuPont, Kuraray Co. Ltd., Sage Automotive Interiors, Bader GmbH, Scottish Leather Group, Ultrafabrics, Zhejiang Meisheng, Continental AG, Faurecia (now Forvia), Lear Corporation, Adient plc, Suminoe Textile Co., Ltd., R.E.D. S.r.l., Seiren Co., Ltd., JBS Couros, Wollsdorf Leder Schmidt GmbH, Tapis Corporation, Kyoritsu Sangyo Co., Ltd., Asahi Kasei Corporation, Sioen Industries NV. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Suede Material Market Key Technology Landscape

The technological landscape of the Automotive Suede Material Market is highly dynamic, characterized by continuous investment in microfiber composition and advanced finishing chemistry, fundamentally aimed at replicating the luxurious haptic feedback of genuine suede while significantly enhancing the operational performance attributes required for vehicle longevity. The foundational technology remains the precise non-woven processing of ultra-fine polyester or polyamide filaments, which are meticulously entangled using proprietary mechanical (e.g., needle punching) or hydraulic (e.g., water jet) methods, followed by complex impregnation with specialized polyurethane resins. This proprietary process, central to leading brands, ensures critical material properties such as superior uniformity, high tensile strength, and optimized density for minimal weight, offering significant structural advantages over bulkier, natural leather options. Recent technological breakthroughs are heavily focused on environmental impact reduction, specifically the transition to developing entirely solvent-free coagulation processes, moving away from conventional methods that utilized hazardous substances like Dimethylformamide (DMF). This shift improves the safety profile for manufacturing personnel, reduces industrial effluent, and lowers the material’s final VOC (Volatile Organic Compound) emissions, aligning with increasingly rigorous global regulatory frameworks in key markets like the EU and California.

A second crucial area of technological innovation involves sophisticated surface modification and the application of functional coatings that dictate the material’s interaction with the harsh automotive environment. Suppliers are aggressively employing advanced plasma treatments, nano-coatings, and specialized pigment integration techniques to impart highly demanded performance characteristics. These include extreme resistance to UV degradation (preventing fading on dashboards), enhanced hydrophobic or oleophobic properties for stain and spill resistance, and integrated anti-microbial treatments crucial for shared or public-use vehicle fleets. These coatings must exhibit exceptional durability to withstand the cyclical thermal stresses and physical friction experienced in vehicle interiors, particularly on high-wear surfaces such as seat bolsters and armrests. Furthermore, research and development efforts are intensely focused on leveraging sustainable input materials. Technology enabling the use of recycled PET bottles (Post-Consumer Recycled content) and sourcing bio-based polyols derived from non-food agricultural feedstocks is rapidly scaling up, allowing major manufacturers to produce materials with audited recycled content certification, significantly boosting the sustainability quotient and catering directly to the growing market segment demanding ethically and environmentally conscious luxury finishes.

Digital manufacturing processes are also playing a transformative role in optimizing the economics and precision of suede material deployment. Advanced Computer-Aided Design (CAD) systems integrated with sophisticated robotic cutting systems utilize intricate optimization algorithms to plan material layout (nesting). By minimizing the unusable scrap material generated during component cutting, these technologies dramatically improve the yield rate of expensive suede fabric, contributing substantially to manufacturing efficiency, cost control, and waste reduction—a paramount concern given the premium cost structure of high-performance microfibers. Additionally, emerging R&D targets the integration of smart textiles functionalities. Although still in the nascent phase, this involves weaving or bonding thin, flexible conductive elements or sensors directly within the suede substrate. Future applications include seamless integration of high-efficiency heating elements (for rapid seat heating without bulky wiring), non-intrusive occupant sensing systems for enhanced safety protocols, or subtly integrated fiber optics for dynamic ambient lighting displays, transforming the automotive suede material from a passive aesthetic surface into an active, intelligent part of the vehicle’s Human-Machine Interface (HMI) and comfort system.

Regional Highlights

Regional analysis critically highlights the divergent consumption patterns, growth trajectories, and regulatory influences across the primary global automotive markets. Europe maintains its traditional leadership position, not necessarily in sheer volume growth, but in technological innovation, quality benchmark setting, and high value-per-unit sales. This market strength is attributed to the concentrated presence of premium and ultra-high-performance vehicle manufacturers, particularly in Germany, Italy, and the UK, where suede materials are deeply ingrained in brand identity and performance aesthetics. European demand is uniquely characterized by an exceptionally strong preference for synthetic suedes that carry stringent certifications related to sustainability, low VOC emissions, and adherence to complex chemical regulations such as REACH. Europe remains the key innovation hub for developing new solvent-free processes and bio-based material compositions, influencing global quality standards.

Asia Pacific (APAC) stands out as the global growth engine and is projected to exhibit the most rapid Compound Annual Growth Rate (CAGR) throughout the forecast period. This rapid expansion is underpinned by two major factors: the immense scale of automotive production, especially in China, which leads global output, and the simultaneous rise of middle-class consumer segments across major Asian economies (China, India, South Korea). These consumers are increasingly demanding premium interior features previously exclusive to imported luxury models. China’s aggressive push for New Energy Vehicles (NEVs), coupled with intense domestic competition, necessitates interior differentiation, leading to wide-scale adoption of cost-effective, high-quality synthetic suede materials. The large-scale manufacturing capacity and vertical integration capabilities emerging within APAC also contribute to competitive pricing, further accelerating market penetration across all vehicle segments, cementing its role as the dominant volume consumer.

North America commands a substantial and resilient market share, characterized by its focus on large vehicles—luxury SUVs, full-size trucks, and performance muscle cars—where interior comfort, spaciousness, and premium material quality are non-negotiable consumer expectations. The North American market emphasizes durability, resistance to temperature extremes, and stain-resistant finishes, often favoring robust synthetic compositions. Although growth rates are steady rather than explosive, the ongoing high-value sales of these large vehicles ensure consistent revenue for suede suppliers. Furthermore, the region’s accelerating transition toward high-end Electric Vehicles (EVs) is generating new pockets of high demand for lightweight, high-acoustic performance suede materials that improve cabin quietness and minimize vehicle mass. The Middle East and Africa (MEA) and Latin America represent geographically dispersed markets. MEA demand is highly concentrated in the Gulf Cooperation Council (GCC) countries, focusing predominantly on ultra-luxury vehicle customization and high-end imports, while Latin America’s market is maturing, showing growth driven by imported premium vehicle sales and selective domestic manufacturing improvements focusing on interior upgrades.

- North America: Stable demand driven by large SUVs and trucks; focus on durability and customization; increasing lightweight material adoption in EVs.

- Europe: Market leader in high-performance and luxury segments; stringent VOC and sustainability regulations; key innovation center for advanced synthetic materials.

- Asia Pacific (APAC): Fastest-growing region, fueled by China’s NEV boom and escalating consumer demand for interior luxury in mass-market vehicles.

- Latin America: Emerging market, concentrated growth in premium imported vehicle segments.

- Middle East and Africa (MEA): High demand for ultra-luxury and high-end customization in Gulf Cooperation Council (GCC) countries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Suede Material Market. These companies are profiled based on their product portfolio, technological innovation, strategic initiatives, geographical presence, and overall market contribution. The synthetic microfiber segment sees intense competition, driving continuous innovation in sustainability credentials and functional performance attributes such as wear resistance and acoustic quality, which are paramount to securing long-term OEM contracts. Genuine suede suppliers focus on specialized luxury niches and ethical sourcing compliance.- Alcantara S.p.A.

- Miko S.r.l. (Dinamica)

- Toray Industries Inc.

- DuPont

- Kuraray Co. Ltd.

- Sage Automotive Interiors

- Bader GmbH

- Scottish Leather Group

- Ultrafabrics

- Zhejiang Meisheng

- Continental AG

- Faurecia (now Forvia)

- Lear Corporation

- Adient plc

- Suminoe Textile Co., Ltd.

- R.E.D. S.r.l.

- Seiren Co., Ltd.

- JBS Couros

- Wollsdorf Leder Schmidt GmbH

- Tapis Corporation

- Kyoritsu Sangyo Co., Ltd.

- Asahi Kasei Corporation

- Sioen Industries NV

Frequently Asked Questions

Analyze common user questions about the Automotive Suede Material market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between genuine suede and synthetic suede in automotive applications?

The primary difference lies in composition and performance characteristics. Genuine suede is derived from natural animal hide splits, offering a unique, soft texture but requiring extensive care and often exhibiting less uniformity. Synthetic suede (like Alcantara or Dinamica) is manufactured from highly specialized non-woven polyester microfibers, chemically impregnated with polyurethane. Synthetics are heavily favored by OEMs due to their superior performance in automotive contexts: enhanced durability, lightweight construction, guaranteed consistency in color and texture, higher resistance to abrasion, and strong ethical sourcing credentials, making them better suited for high-wear automotive environments and large production scales.

How does the shift to Electric Vehicles (EVs) impact the demand for automotive suede materials?

The transition to Electric Vehicles (EVs) significantly accelerates the demand for lightweight synthetic suede materials. Reducing vehicle weight is paramount for maximizing EV battery range and overall energy efficiency, making lightweight materials a functional necessity. Synthetic suedes offer substantial mass savings compared to traditional leather. Moreover, EV interior design trends prioritize creating quieter, more luxurious, and futuristic cabins, where the excellent acoustic dampening properties and soft-touch aesthetic of advanced microfibers are highly valued, driving higher adoption across new EV platforms globally.

Which application segment accounts for the largest market share in the Automotive Suede Material Market?

The seating upholstery segment, including the main seating surfaces and lateral bolsters, consistently accounts for the largest market share both in terms of material volume consumed and resulting revenue. Automotive seating demands the highest standards for material safety, comfort, durability, and fire retardancy, requiring massive, flaw-free material quantities. While headliners and dashboards are important for perceived luxury, the extensive surface area, complexity, and high contact nature of seating components drive the dominant demand for high-performance suede and synthetic microfiber materials.

What are the key sustainability trends influencing the procurement of automotive suede?

Key sustainability trends critically influencing material procurement involve a rapid industry transition towards certified, bio-based polymers (sourced from non-food feedstocks) and the mandatory utilization of recycled content, primarily Post-Consumer Recycled (PCR) polyester, in synthetic suede production. Global OEMs and stringent environmental regulators are demanding reduced carbon footprints, pushing leading suppliers to abandon solvent-based manufacturing processes and ensure their materials offer certified, audited sustainability credentials, thus supporting the automotive sector's overarching circular economy and decarbonization commitments.

Which region is expected to demonstrate the highest growth rate for automotive suede materials by 2033?

The Asia Pacific (APAC) region, driven intensely by the escalating automotive production volumes and the rapid expansion of the consumer base demanding premiumization in China, India, and South Korea, is projected to demonstrate the highest Compound Annual Growth Rate (CAGR) through 2033. This high growth is supported by significant government backing for New Energy Vehicles (NEVs), which utilize lightweight interiors, and the overall societal trend of increasing aspirational luxury consumption across emerging middle-class populations within the region.

This concludes the comprehensive market insights report on the Automotive Suede Material Market. The analysis underscores the critical role of advanced synthetic microfibers in supporting the twin industry trends of vehicle lightweighting and interior luxury premiumization. Strategic imperatives for suppliers involve continuous technological innovation in sustainable, high-performance material formulation and securing robust supply chain partnerships within the rapidly expanding Asia Pacific and Electric Vehicle segments. The consistent upward market trajectory, driven by these foundational technological and consumer demands, confirms the material's increasing importance within the global automotive supply chain ecosystem.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager