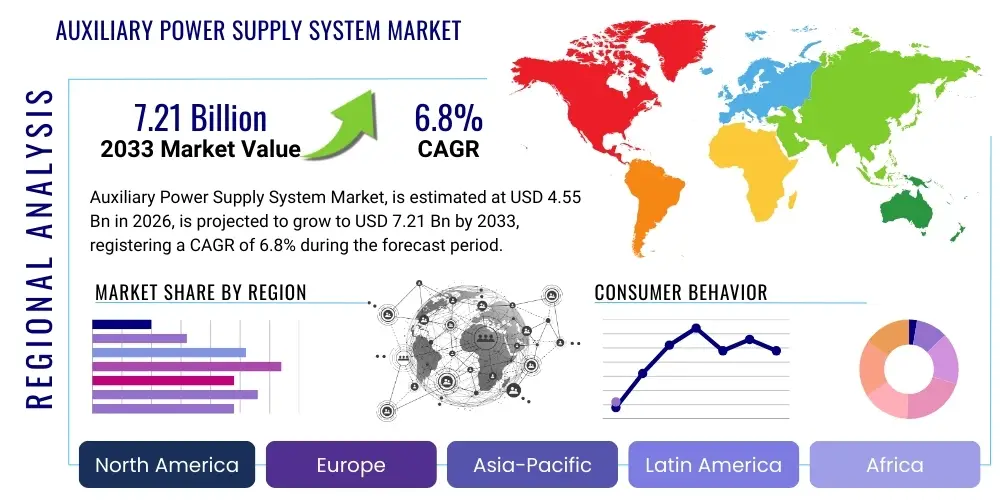

Auxiliary Power Supply System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436748 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Auxiliary Power Supply System Market Size

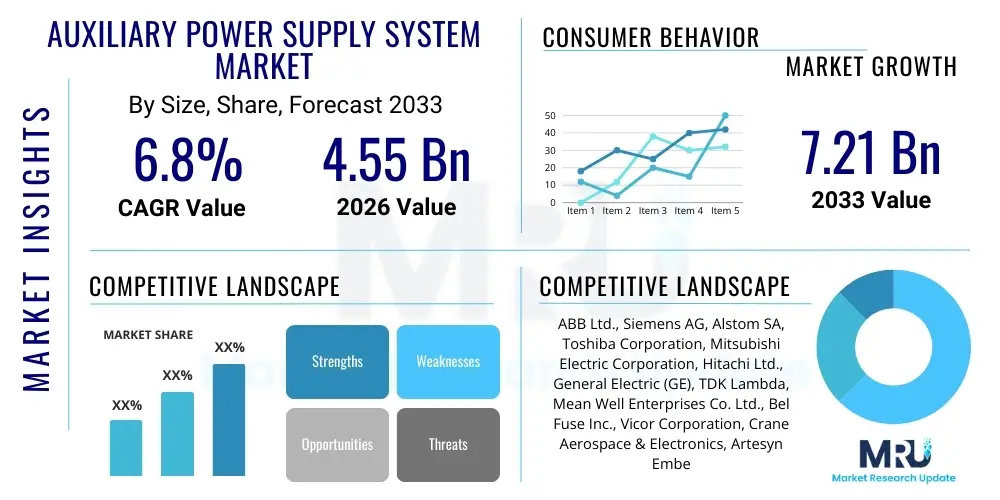

The Auxiliary Power Supply System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.55 Billion in 2026 and is projected to reach USD 7.21 Billion by the end of the forecast period in 2033.

Auxiliary Power Supply System Market introduction

The Auxiliary Power Supply (APS) System Market encompasses specialized electronic equipment designed to convert primary power sources (such as overhead lines, battery banks, or generators) into stable, regulated secondary power required for non-propulsion applications within transportation sectors and heavy industry. These systems are crucial for operating vital onboard services, including lighting, Heating, Ventilation, and Air Conditioning (HVAC), communication systems, control circuits, door mechanisms, and safety features in applications like rail vehicles, aircraft, and large marine vessels. The reliability and efficiency of APS systems directly impact operational safety and passenger comfort, positioning them as non-negotiable components in modern infrastructure projects globally.

Product descriptions within this sector range from sophisticated static converters and inverters to high-efficiency DC-DC converters and transformers, engineered to withstand extreme environmental conditions, vibrations, and voltage fluctuations inherent in their operational environments. Major applications center heavily on the railway industry, particularly high-speed trains, urban metro systems, and modern electric locomotives, where increasing demand for power-intensive passenger amenities and advanced signaling equipment necessitates robust power management. Furthermore, the burgeoning electrification of the automotive sector, focusing on electric buses and specialized utility vehicles, is broadening the application scope of these resilient power supply solutions.

The primary benefits derived from advanced APS systems include enhanced energy efficiency through optimized power conversion, weight reduction compared to older mechanical systems, and improved system reliability leading to reduced maintenance overheads and increased operational uptime. Key driving factors include global investments in modernizing railway infrastructure, stringent regulations mandating higher energy efficiency and safety standards in transportation, and the rapid adoption of sophisticated electronics and automation tools in industrial settings that require highly stable and clean power inputs. These systems are the backbone ensuring that critical ancillary functions operate flawlessly, irrespective of variations in the main power source.

Auxiliary Power Supply System Market Executive Summary

The Auxiliary Power Supply System market is characterized by robust growth, driven primarily by significant governmental and private sector investments in sustainable and high-efficiency transportation infrastructure, particularly across Asia Pacific and Europe. Business trends indicate a strong move towards modular, fault-tolerant, and smart APS units capable of remote diagnostics and predictive maintenance, leveraging silicon carbide (SiC) and gallium nitride (GaN) technologies for higher power density and reduced footprint. Competitive dynamics highlight strategic mergers and acquisitions among major multinational players aiming to consolidate technological expertise, expand geographic presence, and achieve economies of scale necessary for large-scale public transit contracts. Furthermore, increasing standardization efforts for interoperability across different rolling stock platforms are influencing product development and procurement processes.

Regional trends demonstrate that Asia Pacific, spearheaded by China and India, represents the fastest-growing market segment due to extensive railway network expansion, replacement of aging fleets, and rapid urbanization demanding new metro systems. Europe maintains its leadership in technological innovation and standardization, driven by the shift towards high-speed rail and strict adherence to environmental efficiency directives, favoring manufacturers capable of delivering highly efficient, regenerative braking compatible APS solutions. North America, while mature, shows steady demand driven by locomotive modernization programs and increasing investment in electrical grid resilience, prompting demand for robust industrial auxiliary power solutions.

Segment trends reveal that the rail application segment remains the dominant revenue contributor, with static converters, particularly those incorporating advanced cooling systems and redundancy features, seeing the highest adoption rates. Within technology, the focus is shifting towards integrated APS architectures that combine multiple power conversion stages into a single unit, enhancing overall system reliability and minimizing installation complexity. The OEM segment currently holds the largest share, but the aftermarket segment, driven by scheduled maintenance, upgrades, and mid-life overhauls of existing rolling stock, is projected to exhibit a stronger CAGR, reflecting the long asset life cycles typical of the transportation industry. Regulatory emphasis on enhanced safety, particularly fire resistance and electromagnetic compatibility (EMC), continues to dictate segment-specific product specifications.

AI Impact Analysis on Auxiliary Power Supply System Market

User inquiries regarding AI's influence on the Auxiliary Power Supply System Market primarily revolve around predictive maintenance, optimization of energy consumption, and autonomous diagnostics. Users seek confirmation on whether AI can significantly extend the operational lifespan of critical APS components, reduce unscheduled downtime, and facilitate real-time load management in highly dynamic environments like high-speed rail. Key concerns often center on the security implications of integrating smart, interconnected APS units and the requisite investment in sensor technology and data infrastructure needed to support AI algorithms. The consensus expectation is that AI integration will fundamentally transform the maintenance model from time-based to condition-based, optimizing inventory management for spare parts and maximizing fleet availability through highly accurate failure prediction.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze power consumption patterns, temperature data, and vibration signatures to predict imminent component failure (e.g., capacitors, semiconductor switches) in APS units, drastically reducing unplanned operational disruptions.

- Energy Management Optimization: Implementing AI to dynamically adjust power distribution and conversion ratios based on real-time load requirements (e.g., passenger density, HVAC demand), leading to substantial efficiency gains and reduced auxiliary power consumption.

- Autonomous Fault Diagnosis: Integrating AI into APS control units to isolate complex faults immediately and autonomously suggest mitigation strategies or temporary operational configurations, enhancing system resilience.

- Digital Twin Simulation: Using AI to create digital replicas of APS systems for virtual testing of environmental stresses, software updates, and operational scenarios before physical deployment, accelerating product validation cycles.

- Supply Chain and Inventory Planning: AI systems analyze historical failure rates and usage patterns across large fleets to optimize the stocking levels and distribution of high-value spare APS components, minimizing capital tied up in inventory.

DRO & Impact Forces Of Auxiliary Power Supply System Market

The Auxiliary Power Supply System Market dynamics are shaped by a confluence of accelerating infrastructure modernization efforts (Drivers), high initial investment costs and specialized regulatory hurdles (Restraints), and emerging technological shifts towards cleaner energy and smart grids (Opportunities). The dominant impact force is the necessity for operational reliability in critical transport applications; failure of an APS unit can halt an entire operation, making redundancy and durability paramount and thus favoring premium, high-specification products. Furthermore, environmental regulations driving the electrification of transportation globally create powerful market momentum, forcing continuous technological iteration toward lighter and more efficient power conversion systems.

Drivers are predominantly centered around global urbanization and corresponding demand for reliable public transport systems, particularly metro and high-speed rail networks, which require sophisticated and robust auxiliary power for operation. Government mandates for energy-efficient rolling stock and increased passenger amenities (such as advanced infotainment and high-speed Wi-Fi) necessitate greater and more stable auxiliary power generation capacity. The shift away from conventional mechanical APS systems toward static electronic converters further drives the market, offering superior efficiency, reduced noise, and lower lifetime maintenance requirements. Additionally, the industrial sector's move towards Industry 4.0 and increased automation demands highly regulated and clean power for sensitive control electronics.

Restraints include the long product life cycles in rail and aerospace sectors, meaning fleet replacement and large-scale APS system upgrades occur infrequently. High initial capital expenditure required for purchasing advanced, high-power-density converters utilizing SiC technology can be prohibitive for some smaller operators. Furthermore, the complexity of certifying APS systems to meet stringent international standards (such as EN 50155 for rail applications) and local regulatory requirements creates significant barriers to entry and increases development time and cost. The dependence on a few specialized semiconductor suppliers for power modules also poses supply chain fragility risks.

Opportunities lie significantly in the integration of smart grid technologies, enabling APS units in electric vehicles (e.g., electric buses or trains) to participate in vehicle-to-grid (V2G) solutions, utilizing stored battery power to support the main grid during peak demand. The growing marine industry, specifically the electrification of commercial and naval vessels, represents a nascent, high-potential vertical requiring custom-built, rugged APS solutions. Moreover, the adoption of modular and scalable APS platforms allows manufacturers to quickly adapt to diverse voltage requirements across global markets, opening avenues for strategic global partnerships and rapid market penetration in developing regions focused on infrastructural development.

Segmentation Analysis

The Auxiliary Power Supply System market segmentation provides a granular view of diverse product capabilities and application-specific demands, allowing stakeholders to identify high-growth niches. Segmentation is primarily based on the core technology (Type), the operating environment (Application), the required stable output characteristics (Output Voltage), and the stage of equipment lifecycle (End-User). The complexity of power conversion requirements in specialized transport means that each segment demands highly tailored specifications regarding thermal management, vibration resistance, and fault tolerance.

The Type segmentation, covering converters, inverters, rectifiers, and regulators, highlights the essential functions required to stabilize and condition electrical power derived from the primary source. Converters (DC/DC and AC/DC) dominate due to the fundamental requirement to transform overhead AC or battery DC into suitable internal DC voltages for electronics. The Application segment underlines the market's heavy reliance on the Rail sector, although Aerospace & Defense and Marine segments drive demand for extremely high-reliability, custom-engineered solutions that command premium pricing due to regulatory compliance costs.

Further analysis of the Output Voltage segment reveals critical differences in engineering complexity; High Voltage (HV) systems are prevalent in traction applications and large industrial motors, while Low Voltage (LV) systems are essential for sensitive control systems, lighting, and communication infrastructure. Understanding these segment dynamics is vital for effective product portfolio management and targeted marketing efforts, particularly as the market accelerates towards high-power-density solutions incorporating advanced wide-bandgap semiconductors for efficiency improvements across all voltage ranges.

- By Type

- Converters (DC-DC Converters, AC-DC Converters)

- Inverters (DC-AC Inverters)

- Rectifiers

- Transformers (Isolation and Step-Down)

- Regulators (Linear and Switching)

- By Application

- Rail Transportation (Metro Rail, High-Speed Rail, Locomotives, Passenger Coaches)

- Aerospace and Defense (Avionics, Ground Support Equipment, Missile Systems)

- Marine (Naval Vessels, Commercial Ships, Offshore Platforms)

- Automotive (Electric Buses, Hybrid Utility Vehicles)

- Industrial Automation and Power Generation (Critical Control Systems, Substations)

- By Output Voltage

- Low Voltage (Below 100V)

- Medium Voltage (100V to 1000V)

- High Voltage (Above 1000V)

- By End-User

- Original Equipment Manufacturers (OEMs)

- Aftermarket (Maintenance, Repair, and Overhaul - MRO)

Value Chain Analysis For Auxiliary Power Supply System Market

The value chain for the Auxiliary Power Supply System market begins with Upstream activities focused heavily on the procurement and development of critical raw materials and components. This stage involves the supply of highly specialized electronic components, predominantly wide-bandgap semiconductors (SiC, GaN), high-performance capacitors, magnetic materials for transformers, and robust thermal management solutions (heatsinks, cooling liquids). Dependency on a small number of global high-technology semiconductor manufacturers creates concentrated supply chain risk. Key success factors at this stage include negotiating long-term supply contracts and ensuring the reliability and quality certification of all components, as component failure can lead to catastrophic system failure in the field.

Midstream activities involve the design, manufacturing, assembly, testing, and integration of the APS units. Manufacturers focus on highly customized, ruggedized designs that meet stringent reliability (e.g., MTBF) and safety standards (e.g., fire, smoke, toxicity regulations). Manufacturing requires advanced automated assembly lines and meticulous quality control protocols, particularly for power electronics packaging. Distribution channels are predominantly indirect, relying heavily on specialized system integrators, large engineering procurement and construction (EPC) contractors, and rolling stock manufacturers (OEMs like Alstom or Siemens). Direct sales are typically reserved for specialized aftermarket services or highly customized defense contracts.

Downstream activities center on deployment, maintenance, and end-of-life services. The relationship between the APS manufacturer and the end-user (e.g., railway operator) is crucial, often spanning decades due to the long operational life of the equipment. Aftermarket services, including predictive maintenance agreements, spare parts supply, and system upgrades, represent a growing and high-margin component of the value chain. Effective monitoring, remote diagnostic capabilities, and efficient spare part logistics are critical for maximizing the operational efficiency and lifetime value proposition of the installed APS systems.

Auxiliary Power Supply System Market Potential Customers

The primary customers and end-users of Auxiliary Power Supply Systems are organizations operating capital-intensive, high-reliability infrastructure where sustained and clean power for ancillary functions is paramount for safety and efficiency. The largest customer base resides within the public and private entities responsible for managing global transportation networks. These buyers prioritize product longevity, compliance with rigorous industry standards (e.g., EN 50155 for rail), and the manufacturer's ability to provide long-term service and support throughout the equipment's multi-decade lifecycle.

In the rail sector, the critical buyers are Rolling Stock Manufacturers (OEMs) who integrate the APS into new vehicles, and Transit Authorities/Railway Operators who are key purchasers for aftermarket upgrades, maintenance, and system overhauls. These customers require highly modular and scalable APS solutions that can handle fluctuating power quality and operate reliably under extreme temperature and vibration stress. Their buying decisions are often heavily influenced by lifecycle cost analysis rather than initial purchase price alone, valuing factors such as Mean Time Between Failures (MTBF) and energy consumption efficiency.

Beyond transportation, significant potential customers include large industrial complexes requiring redundant power for critical control systems (e.g., chemical processing, nuclear facilities), military and naval organizations demanding extreme ruggedization and electromagnetic compatibility (EMC) compliance for mission-critical applications, and specialized automotive manufacturers focusing on high-capacity electric buses and heavy-duty utility trucks. These diverse end-users emphasize customization, robust communication interfaces (e.g., CAN bus, Ethernet), and proven adherence to stringent quality management systems specific to their respective industries, driving continued innovation in thermal and mechanical design aspects of the power supply units.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.55 Billion |

| Market Forecast in 2033 | USD 7.21 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Alstom SA, Toshiba Corporation, Mitsubishi Electric Corporation, Hitachi Ltd., General Electric (GE), TDK Lambda, Mean Well Enterprises Co. Ltd., Bel Fuse Inc., Vicor Corporation, Crane Aerospace & Electronics, Artesyn Embedded Technologies, Schaefer Systems International, Statcon Energiaa, PCE Power, Advanced Energy Industries, Delta Electronics, Murata Manufacturing Co., Ltd., Sine Power Private Limited. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Auxiliary Power Supply System Market Key Technology Landscape

The technology landscape of the Auxiliary Power Supply System Market is undergoing a rapid evolution, primarily driven by the imperative for higher power density, increased energy efficiency, and reduced size/weight, especially in mobile applications. The most significant technological shift is the widespread adoption of Wide Bandgap (WBG) semiconductors, specifically Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials enable power electronic switching at much higher frequencies, dramatically reducing the size of passive components (capacitors and inductors) and overall system weight, while simultaneously minimizing switching losses, leading to significantly improved thermal performance and efficiency exceeding 95% in many converter designs. This transition directly addresses the limitations of traditional silicon-based insulated-gate bipolar transistors (IGBTs) and metal-oxide-semiconductor field-effect transistors (MOSFETs).

Another crucial technological focus is the development of modular and redundant architectures. Modular APS designs allow operators to easily scale power capacity and facilitate quick replacement of faulty units, minimizing downtime. Redundancy features, such as N+1 configurations and hot-swap capabilities, are becoming standard requirements, particularly in safety-critical rail and aerospace applications. Furthermore, advanced digital control systems are replacing traditional analog controls. These digital controllers offer superior precision in output regulation, faster response to load changes, and built-in diagnostic features, which are foundational for implementing AI-driven monitoring and predictive maintenance protocols across the fleet. Software-defined power management is therefore a major technology trend.

Integration technology, focusing on consolidating multiple power supply functions (e.g., battery charger, inverter, various DC/DC outputs) into a single, compact unit, is also gaining traction. This integration minimizes electromagnetic interference (EMI) issues, simplifies wiring, and reduces the installation footprint—a critical factor in space-constrained environments like aircraft cockpits and train underframes. Furthermore, advanced passive cooling techniques and liquid-cooling solutions are being developed for high-power APS units, necessary to manage the significant heat generated by high-density electronics, thereby ensuring reliable performance and extending the lifespan of key internal components under harsh environmental conditions.

Regional Highlights

Regional dynamics play a vital role in shaping the Auxiliary Power Supply System market, influenced by varying levels of infrastructure investment, regulatory frameworks, and technological adoption rates across different geographies.

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, driven primarily by massive investments in new public transportation infrastructure, particularly in China, India, and Southeast Asian nations. China's extensive high-speed rail network expansion and India's metro projects represent substantial, continuous demand for large volumes of APS systems. The focus here is on achieving cost-effectiveness while meeting moderate to high technical specifications.

- Europe: Europe is characterized by a mature market with high technological standards and strict regulatory compliance (e.g., stringent efficiency targets and EN 50155 compliance). The region leads in the adoption of high-efficiency SiC-based converters and regenerative braking compatible systems. Key markets include Germany, France, and the UK, driven by fleet modernization, high-speed rail connections, and cross-border compatibility requirements.

- North America: The market is driven primarily by long-term locomotive modernization programs, refurbishment of existing rail transit systems, and strong demand from the aerospace and defense sectors. Regulatory emphasis on safety and reliability, particularly in freight rail, drives demand for rugged, high-reliability APS units. The US defense expenditure contributes significantly to the aerospace auxiliary power segment.

- Latin America (LATAM): This region shows moderate growth linked to specific urbanization projects and mining sector investments. Brazil and Mexico are the largest markets, focusing on metropolitan railway expansion and upgrades. The market often requires robust systems capable of operating in challenging environmental conditions, often balancing cost against longevity.

- Middle East and Africa (MEA): Growth is propelled by large-scale infrastructural projects, including ambitious cross-country rail links in the Gulf Cooperation Council (GCC) countries and significant urban transit projects in major cities. Demand is characterized by a need for highly reliable systems that can withstand extreme heat and dust, often relying on international standards and expertise.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Auxiliary Power Supply System Market.- ABB Ltd.

- Siemens AG

- Alstom SA

- Toshiba Corporation

- Mitsubishi Electric Corporation

- Hitachi Ltd.

- General Electric (GE)

- TDK Lambda

- Mean Well Enterprises Co. Ltd.

- Bel Fuse Inc.

- Vicor Corporation

- Crane Aerospace & Electronics

- Artesyn Embedded Technologies (now part of Advanced Energy)

- Schaefer Systems International

- Statcon Energiaa

- PCE Power

- Advanced Energy Industries, Inc.

- Delta Electronics, Inc.

- Murata Manufacturing Co., Ltd.

- Amco Power Systems Ltd.

Frequently Asked Questions

Analyze common user questions about the Auxiliary Power Supply System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary technological advancements driving the efficiency of Auxiliary Power Supply systems?

The primary technological driver for enhanced efficiency is the widespread adoption of Wide Bandgap (WBG) semiconductors, specifically Silicon Carbide (SiC) and Gallium Nitride (GaN). These materials enable higher switching frequencies and lower power losses compared to traditional silicon, resulting in APS units that are significantly lighter, smaller, and achieve power conversion efficiencies often exceeding 95%. This transition minimizes thermal management challenges and improves overall system reliability, critical for constrained mobile environments like rail and aerospace.

How is the Auxiliary Power Supply Market segmented by end-user, and which segment shows the highest growth potential?

The market is segmented into Original Equipment Manufacturers (OEMs) and Aftermarket. While the OEM segment currently holds the dominant revenue share due to new vehicle production (trains, aircraft), the Aftermarket segment is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This growth is fueled by the necessity for routine maintenance, scheduled mid-life overhauls, and the technical requirement to upgrade aging fleets with modern, more efficient APS systems that comply with new safety and energy standards without replacing the entire vehicle.

What role does the railway industry play in the global demand for Auxiliary Power Supply Systems?

The railway industry is the single largest application segment and the central demand driver for the APS market. Auxiliary power supplies are indispensable for non-propulsive functions such as HVAC, lighting, safety systems, and onboard electronics in locomotives, metros, and high-speed trains. Global infrastructure modernization, coupled with the rising implementation of high-speed rail in Asia Pacific and extensive fleet electrification in Europe, guarantees sustained, high-volume demand for ruggedized and certified power conversion solutions like static converters and inverters.

Which regulatory standards are most critical for manufacturers operating in the Auxiliary Power Supply System market?

For manufacturers serving the railway sector, compliance with the European standard EN 50155 (Railway applications - Electronic equipment used on rolling stock) is absolutely critical, as it dictates stringent requirements for shock, vibration, temperature range, electrical insulation, and electromagnetic compatibility (EMC). Additionally, standards related to fire safety (EN 45545-2) and quality management systems (IRIS/ISO 22163) are vital for market access and demonstrating product reliability and adherence to strict lifecycle requirements.

How is predictive maintenance technology influencing the operational expenses associated with APS systems?

The integration of predictive maintenance, often enabled by AI and IoT sensors, significantly reduces the operational expenses (OPEX) of Auxiliary Power Supply Systems. By analyzing real-time performance data, operators can accurately predict component failures (e.g., cooling fans, capacitors) before they occur. This transition from costly reactive or rigid time-based maintenance to condition-based maintenance maximizes the useful life of components, minimizes the need for high-cost emergency repairs, reduces unscheduled downtime, and optimizes the inventory management of spare parts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager