Axial Piston Hydraulic Motor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432752 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Axial Piston Hydraulic Motor Market Size

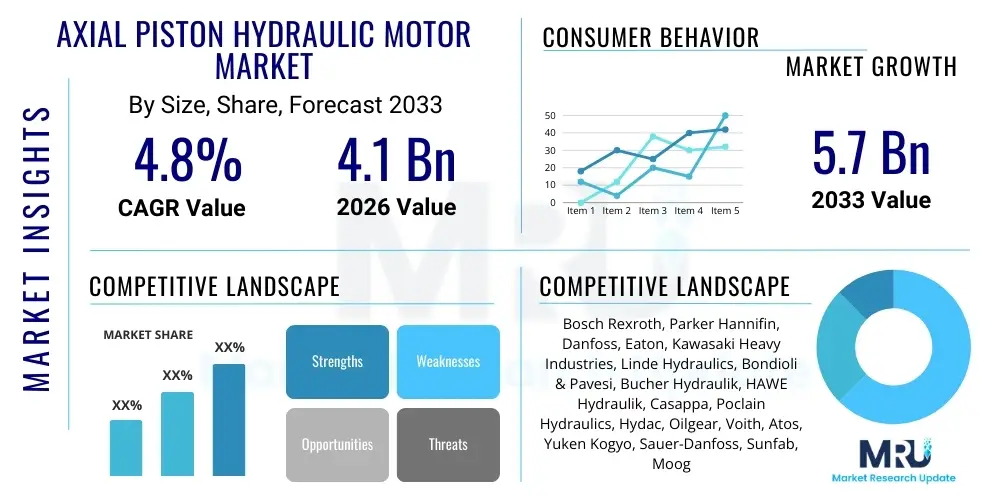

The Axial Piston Hydraulic Motor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 5.7 Billion by the end of the forecast period in 2033.

Axial Piston Hydraulic Motor Market introduction

Axial piston hydraulic motors are high-performance devices integral to modern industrial and mobile equipment, designed to convert fluid pressure and flow into rotational motion, offering high power density and efficiency. These motors are fundamentally characterized by pistons arranged parallel to the axis of the cylinder block, typically utilizing a swash plate or bent axis design to generate torque. They are favored in applications demanding high speed, variable displacement control, and continuous high-pressure operation. Major applications span heavy industries including construction machinery (excavators, loaders), agricultural equipment (tractors, combines), mining vehicles, and specialized marine and offshore machinery, where reliability under severe operating conditions is non-negotiable. The primary benefits of these motors include superior volumetric efficiency, compact design, rapid response times, and the ability to operate effectively within closed-loop hydraulic systems, providing precise motion control necessary for modern automated processes. Market growth is primarily driven by global infrastructure development projects, increasing mechanization in the agriculture sector across developing economies, and the continuous technological push towards more energy-efficient and digitized mobile hydraulic solutions.

Axial Piston Hydraulic Motor Market Executive Summary

The Axial Piston Hydraulic Motor Market is experiencing robust growth fueled by cyclical demands in the global construction and agriculture industries, coupled with a fundamental shift towards more efficient and controllable hydraulic systems. Business trends indicate a strong competitive focus on product differentiation, particularly in variable displacement motor technology, which allows for optimization of power consumption and better system integration with electronic controls. Key manufacturers are prioritizing the integration of IoT and smart sensor technology into motors to enable predictive maintenance and real-time performance monitoring, transforming traditional hydraulic components into smart nodes within complex machinery. Regionally, the Asia Pacific (APAC) sector, specifically China and India, is dominating market expansion due to rapid urbanization, massive infrastructure investments, and increasing agricultural mechanization, making it the highest-growth area. Conversely, established markets in Europe and North America emphasize compliance with stringent emission standards, driving demand for hydraulic motors optimized for hybridization and electro-hydraulic solutions. Segment trends show that the Variable Displacement Motor segment is gaining significant traction over Fixed Displacement types, attributed to their inherent flexibility and efficiency advantages in dynamic load applications, while the OEM segment maintains the largest market share owing to high volume demand from heavy equipment manufacturers.

AI Impact Analysis on Axial Piston Hydraulic Motor Market

Common user questions regarding the impact of Artificial Intelligence (AI) frequently center on how AI can enhance the operational reliability, predictive lifespan, and design optimization of complex hydraulic systems, particularly axial piston motors which are subject to high wear and tear. Users are keen to understand the shift from time-based maintenance to condition-based monitoring, questioning the accuracy and implementation cost of AI-driven diagnostic tools. The analysis indicates that AI is significantly influencing the market by enabling advanced predictive maintenance protocols. By processing vast datasets collected from integrated sensors (vibration, temperature, pressure), AI algorithms can detect subtle anomalies that signal impending motor failure long before traditional methods, drastically reducing unplanned downtime and optimizing system longevity. Furthermore, AI is being utilized in the design phase for topology optimization and fluid dynamics simulations, creating lighter, more efficient motor geometries. This convergence of hydraulics and data science is setting new industry benchmarks for performance and reliability, ensuring that future generations of axial piston motors are intelligent, self-diagnosing components integral to autonomous and highly automated machinery.

- AI facilitates advanced predictive maintenance by analyzing sensor data for early failure signatures, enhancing operational uptime.

- Integration of machine learning algorithms optimizes motor control logic, improving volumetric and mechanical efficiency under varying load conditions.

- AI-driven simulation and generative design tools are used to rapidly develop lighter, more compact, and high-performance motor structures.

- Automated fault detection and diagnostics utilizing AI reduce the reliance on specialized technical expertise for troubleshooting complex hydraulic systems.

- AI-enabled condition monitoring extends the lifespan of axial piston motors by ensuring optimal lubrication and timely component replacement.

DRO & Impact Forces Of Axial Piston Hydraulic Motor Market

The Axial Piston Hydraulic Motor Market is governed by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), significantly shaped by global industrial and technological trends. The primary driver is the accelerating pace of global infrastructure development, especially in emerging economies, which necessitates large volumes of heavy construction and earthmoving equipment, all relying heavily on high-power hydraulic motors. Further impetus comes from the increasing trend towards machine automation and the demand for high-efficiency hydraulic systems that comply with strict environmental regulations aimed at reducing energy consumption and greenhouse gas emissions. However, the market faces restraints, chiefly the high initial cost and complexity associated with precision-engineered axial piston motors, making them susceptible to competition from simpler, lower-cost hydraulic motor alternatives in less demanding applications. Additionally, the requirement for specialized maintenance knowledge and the vulnerability of these systems to contamination pose ongoing challenges. Opportunities reside predominantly in the development of electro-hydraulic actuators and hybrid systems, combining electric power with hydraulics to enhance energy recovery and efficiency, aligning the market with the broader electrification trend in mobile machinery. The impact forces are characterized by moderate-to-high bargaining power of OEMs (as primary purchasers) and intense technological competition among established manufacturers focused on digitalization and robust design.

Segmentation Analysis

The Axial Piston Hydraulic Motor Market is comprehensively segmented based on Type, Application, and End-Use, providing a detailed view of technological preferences and consumer adoption patterns across various industries. The segmentation by Type, distinguishing between Fixed Displacement and Variable Displacement motors, is crucial as Variable Displacement motors are increasingly sought after for their superior flexibility and precise control capabilities in modern machinery requiring dynamic performance adjustments. Application segmentation highlights the dominance of heavy-duty sectors like Construction and Agriculture, which drive the highest volume demand. End-Use segmentation delineates the distinct requirements and purchasing behaviors of Original Equipment Manufacturers (OEMs) versus the Aftermarket sector, with OEMs dominating sales for new machine installations. This structural breakdown allows market participants to tailor their product offerings, sales strategies, and technological developments to meet specific sectoral needs and capitalize on high-growth niches within the global hydraulic industry.

- By Type:

- Fixed Displacement Motor

- Variable Displacement Motor

- By Application:

- Construction Machinery

- Agricultural Equipment

- Mining Equipment

- Material Handling

- Marine and Offshore

- Industrial Machinery

- By End-Use:

- Original Equipment Manufacturer (OEM)

- Aftermarket

- By Operating Pressure:

- Low Pressure (Up to 250 Bar)

- Medium Pressure (250 Bar to 350 Bar)

- High Pressure (Above 350 Bar)

Value Chain Analysis For Axial Piston Hydraulic Motor Market

The value chain for the Axial Piston Hydraulic Motor Market begins upstream with the highly specialized procurement of raw materials and precision components. This stage involves securing high-grade steel alloys, specialized seals, bearings, and advanced metallurgical powders required for producing components like cylinder blocks, pistons, and valve plates that must withstand extreme operational pressures and friction. Given the micron-level tolerances required for motor assembly to ensure high volumetric efficiency and durability, manufacturers maintain stringent quality control over their suppliers. Key relationships are established with certified metal fabricators and specialized bearing manufacturers, where stability in sourcing and material consistency directly impacts the final product quality and manufacturing cost structures. Efficiency in this upstream segment is crucial for overall cost management, particularly as material costs fluctuate based on global commodity markets.

The core manufacturing and assembly stage involves sophisticated processes, including precision casting, advanced machining (using multi-axis CNC machines), heat treatment, lapping, and final high-pressure testing. Major manufacturers often employ a degree of vertical integration, producing proprietary core components internally to protect intellectual property related to design and material specifications, which are key determinants of motor performance and noise reduction. This stage is capital-intensive, requiring substantial investment in automation and quality assurance technologies to minimize defects and ensure compliance with international industrial standards (e.g., ISO, SAE). The operational focus is on achieving maximum power density and durability while implementing lean manufacturing principles to enhance throughput.

Downstream activities are dominated by distribution channels, which primarily flow directly to Original Equipment Manufacturers (OEMs) and indirectly through a robust network of authorized distributors and system integrators serving the aftermarket. Direct sales channels manage high-volume, long-term contracts with global leaders in construction and agricultural machinery. Indirect channels provide geographical reach, technical support, and critical service functions, supplying replacement units and customizing hydraulic solutions for smaller industrial clients. The strength of the distribution network is pivotal for competitive differentiation, ensuring rapid delivery, comprehensive technical training, and reliable post-sales support, which are highly valued by both OEM and aftermarket customers.

Axial Piston Hydraulic Motor Market Potential Customers

The primary cohort of potential customers for axial piston hydraulic motors consists overwhelmingly of Original Equipment Manufacturers (OEMs) operating within the heavy machinery sectors. These buyers, including global manufacturers of construction equipment (such as excavators, bulldozers, and cranes), agricultural machinery (high-horsepower tractors, combines, and harvesters), and mining equipment (haul trucks and drill rigs), require motors that can deliver consistent, high torque, and excellent efficiency under continuous, heavy-duty operational cycles. The purchasing criteria for OEMs are highly technical, focusing on specific performance metrics such as power-to-weight ratio, maximum operating pressure, noise reduction capabilities, and the ease of electronic integration, often leading to custom-designed motors that meet unique platform requirements and regulatory standards.

A secondary, but rapidly growing, customer base is the Aftermarket sector, composed of maintenance, repair, and overhaul (MRO) service providers, and end-users who operate and maintain fleets of heavy equipment. These customers primarily purchase replacement units or components to repair existing systems. Their purchasing decisions are less driven by cutting-edge design and more by reliability, availability, cost-effectiveness, and compatibility with legacy systems. The aftermarket demand is closely tied to the average lifespan of hydraulic machinery and the utilization rate of existing equipment fleets worldwide, providing a steady and non-cyclical revenue stream for motor manufacturers and their specialized distributors.

Furthermore, specialized industrial sectors, including marine and offshore engineering (winches, propulsion systems), material handling (large lift trucks, container movers), and stationary industrial applications (metal forming presses, large test rigs), represent highly attractive niche customer segments. These applications demand motors optimized for specific environments, such as high resistance to corrosion in marine settings or extreme precision in industrial processes. The continuous push toward automation in manufacturing and logistics further expands the potential customer pool, as axial piston motors are essential components in sophisticated, power-dense drive systems necessary for high-throughput automated operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 5.7 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth, Parker Hannifin, Danfoss, Eaton, Kawasaki Heavy Industries, Linde Hydraulics, Bondioli & Pavesi, Bucher Hydraulik, HAWE Hydraulik, Casappa, Poclain Hydraulics, Hydac, Oilgear, Voith, Atos, Yuken Kogyo, Sauer-Danfoss, Sunfab, Moog Inc., Continental Hydraulics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Axial Piston Hydraulic Motor Market Key Technology Landscape

The technological landscape of the Axial Piston Hydraulic Motor Market is rapidly evolving, driven primarily by the imperatives of energy efficiency, noise reduction, and integration with digital control systems. A central focus is the development of electro-hydraulic systems, where traditional mechanical controls are replaced by precise electronic control units (ECUs) and proportional valves. This shift allows for the integration of motors into intelligent drive systems that optimize power usage based on real-time load requirements, significantly reducing fuel consumption in mobile applications. Manufacturers are actively investing in new materials and design methodologies, such as low-friction coatings and optimized internal porting, to minimize energy losses and enhance volumetric efficiency, which is critical for meeting modern performance benchmarks.

Another significant technological trend is the proliferation of sensor integration and IoT capabilities, leading to the emergence of 'smart hydraulics.' Modern axial piston motors are being equipped with internal sensors (monitoring pressure, temperature, vibration, and speed) that feed data into onboard microprocessors or cloud-based platforms. This capability supports predictive maintenance by detecting component wear or fluid contamination before catastrophic failure occurs, thereby maximizing equipment uptime and minimizing lifetime operational costs. Furthermore, advancements in noise and vibration damping are crucial, particularly for motors used in urban construction and interior industrial environments, leading to the adoption of bent-axis designs and advanced housing structures optimized for quiet operation.

The pursuit of higher power density continues to shape design innovations. Manufacturers are utilizing advanced manufacturing techniques, including additive manufacturing (3D printing) for complex internal components, to achieve designs that can handle increasingly high operating pressures (often exceeding 400 Bar) while maintaining a compact footprint and reducing overall weight. The continuous refinement of swash plate and bent-axis geometry, coupled with advanced sealing technologies, ensures greater torque density and longer operational life. These technological advancements are pivotal for competitive positioning, allowing leading players to offer robust solutions compatible with the next generation of hybrid and electric construction and agricultural machinery.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing and largest regional market, driven by massive governmental investments in infrastructure (roads, rail, urban development) in countries like China, India, and Southeast Asian nations. Rapid industrialization, combined with the increasing scale and mechanization of the agricultural sector, fuels overwhelming demand for heavy construction and material handling equipment, bolstering OEM sales of hydraulic motors.

- North America: This region represents a mature, high-value market characterized by demand for highly sophisticated, large-capacity motors suitable for advanced mining, forestry, and high-tech agricultural machinery. Strict safety regulations and a strong emphasis on productivity drive demand for premium, durable, and technologically integrated hydraulic systems, including AI-enabled predictive maintenance features.

- Europe: The European market is highly regulated, focusing intensely on environmental standards (Stage V emissions mandates). This regulatory environment necessitates the adoption of highly efficient, low-noise axial piston motors suitable for closed-loop, electro-hydraulic, and hybrid vehicle architectures. Germany, Italy, and Scandinavia are key manufacturing and technological innovation hubs, driving demand for precision engineering.

- Latin America (LATAM): Growth in LATAM is moderately steady, buoyed by mining operations (especially in Chile and Peru) and large-scale agricultural expansions in Brazil and Argentina. The market is sensitive to commodity price cycles, with demand often fluctuating based on investment levels in resource extraction and large infrastructure projects.

- Middle East and Africa (MEA): This region is characterized by substantial investments in energy infrastructure, oil and gas extraction, and large-scale construction projects (e.g., UAE, Saudi Arabia). Demand focuses on rugged, reliable motors capable of operating efficiently in harsh, high-temperature, and dusty environments, with significant demand coming from the heavy lifting and marine sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Axial Piston Hydraulic Motor Market.- Bosch Rexroth

- Parker Hannifin

- Danfoss

- Eaton

- Kawasaki Heavy Industries

- Linde Hydraulics

- Bondioli & Pavesi

- Bucher Hydraulik

- HAWE Hydraulik

- Casappa

- Poclain Hydraulics

- Hydac

- Oilgear

- Voith

- Atos

- Yuken Kogyo

- Sauer-Danfoss

- Sunfab

- Moog Inc.

- Continental Hydraulics

Frequently Asked Questions

Analyze common user questions about the Axial Piston Hydraulic Motor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between fixed displacement and variable displacement axial piston motors?

Fixed displacement motors provide constant speed at a constant flow input, while variable displacement motors utilize a mechanism (like a swash plate) to adjust the output speed and torque by changing the displacement volume per revolution, offering superior flexibility and efficiency control.

Which application segment drives the highest demand for axial piston hydraulic motors globally?

The Construction Machinery application segment, encompassing heavy equipment such as excavators, loaders, and mobile cranes, typically generates the highest volume and revenue demand due to the requirement for high power density and reliable continuous operation.

How is digitalization impacting the performance and maintenance of axial piston motors?

Digitalization involves integrating sensors and IoT connectivity into motors, enabling predictive maintenance, real-time performance monitoring, and advanced diagnostic capabilities, which significantly reduce unplanned downtime and optimize energy efficiency through intelligent control.

What are the main advantages of using axial piston motors over gear or vane hydraulic motors?

Axial piston motors offer significantly higher power density, volumetric efficiency, and the capacity to operate reliably at much higher pressures (often above 350 bar) and faster speeds, making them ideal for heavy-duty, high-performance applications.

Which geographic region exhibits the strongest growth potential for this market?

The Asia Pacific (APAC) region, driven by rapid urbanization, massive infrastructure spending, and expansion of mechanized agriculture in key economies like China and India, is projected to maintain the strongest and fastest growth rate through the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Axial Piston Hydraulic Motor Market Statistics 2025 Analysis By Application (Construction Machinery, Industrial Machinery, Agriculture Machines), By Type (Swash Plate, Bent Axis), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Axial Piston Hydraulic Motor Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Closed Circuit Axial Piston Motors, Open Circuit Axial Piston Motors), By Application (Petroleum Machinery, Crane, Coal Mine Machinery, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager