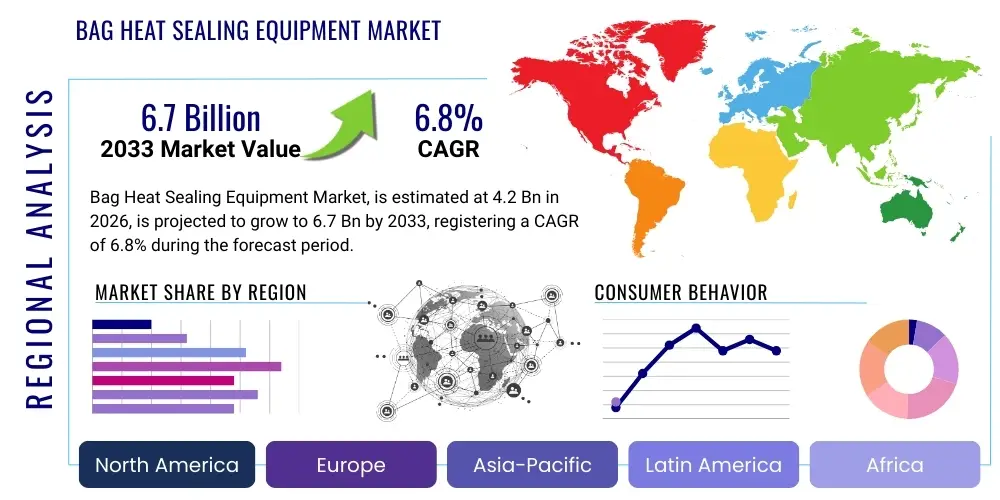

Bag Heat Sealing Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440125 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Bag Heat Sealing Equipment Market Size

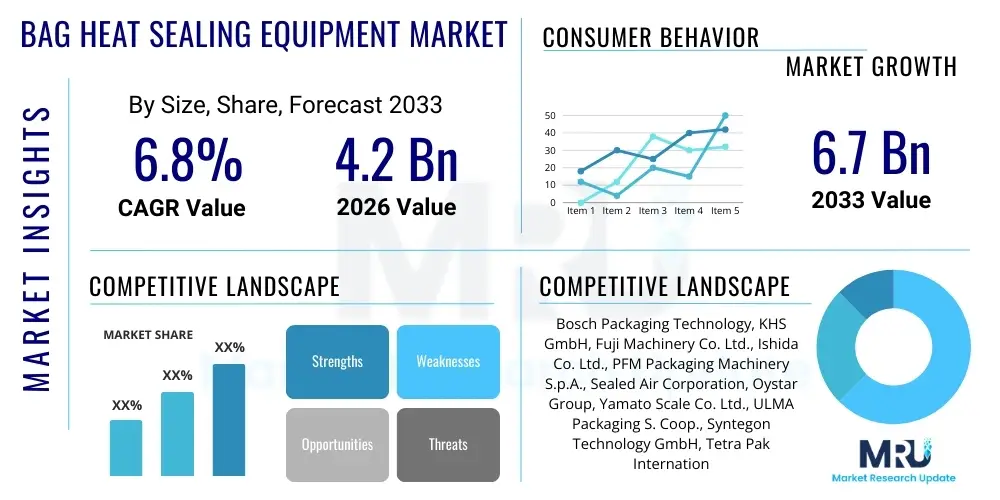

The Bag Heat Sealing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Bag Heat Sealing Equipment Market introduction

The Bag Heat Sealing Equipment market encompasses a wide array of machinery designed to securely close bags, pouches, and other flexible packaging materials using heat and pressure. This essential equipment is critical across numerous industries, from food and beverage to pharmaceuticals, chemicals, and consumer goods, ensuring product integrity, hygiene, and extended shelf life. The primary function involves creating an airtight or watertight seal by melting layers of thermoplastic material together, preventing contamination and leakage while also providing tamper evidence. The versatility of these machines allows for handling various bag types, sizes, and film materials, making them indispensable in modern packaging operations and contributing significantly to supply chain efficiency.

Product descriptions for bag heat sealing equipment range from compact, portable manual sealers suitable for low-volume operations to sophisticated, fully automated systems integrated into high-speed production lines. These machines often feature precise temperature control, adjustable sealing times, and varying jaw configurations to accommodate diverse packaging requirements, including vacuum sealing, gas flushing, and impulse sealing. Major applications span retort pouches for ready-to-eat meals, vacuum-sealed food bags for freshness preservation, sterile medical device packaging, bulk chemical sacks for industrial transport, and consumer product packaging, highlighting their broad utility in preserving quality and safety. The continuous evolution of packaging materials, including sustainable and compostable films, further drives innovation in sealing technologies to maintain compatibility and efficiency across different production scales.

The benefits of advanced bag heat sealing equipment are manifold, including enhanced product freshness and extended shelf life, improved hygiene and sterility, reduced product spoilage, and increased packaging efficiency. Automation in heat sealing reduces labor costs, minimizes human error, and significantly boosts throughput, directly impacting profitability for manufacturers. Key driving factors for market growth include the burgeoning global demand for packaged goods due to urbanization and changing consumer lifestyles, stringent food safety and pharmaceutical regulations necessitating secure and tamper-evident packaging, the rapid expansion of e-commerce requiring robust and protective packaging solutions, and ongoing advancements in packaging materials and automation technologies. The pursuit of sustainable packaging solutions also pushes manufacturers to develop more energy-efficient and material-compatible sealing systems capable of handling new eco-friendly films without compromising seal integrity or speed.

Bag Heat Sealing Equipment Market Executive Summary

The global Bag Heat Sealing Equipment market is currently experiencing robust growth, driven by an increasing demand for packaged products across diverse sectors and a heightened focus on automation and efficiency in manufacturing processes. Business trends indicate a significant shift towards more intelligent, high-speed, and versatile sealing solutions capable of handling a broader range of packaging materials, including those with sustainable properties. Manufacturers are investing in research and development to integrate advanced control systems, such as Human Machine Interfaces (HMI) and Programmable Logic Controllers (PLC), enhancing operational precision and ease of use. The competitive landscape is characterized by both established global players offering comprehensive packaging lines and specialized manufacturers providing niche sealing technologies, all vying for market share through innovation and strategic partnerships.

Regional trends reveal Asia Pacific as a primary growth engine, fueled by rapid industrialization, expanding manufacturing bases, and a burgeoning consumer class driving demand for packaged food and consumer goods. North America and Europe continue to be significant markets, distinguished by their emphasis on high-quality, automated, and hygiene-compliant packaging solutions, particularly in the pharmaceutical and processed food industries. These regions also lead in the adoption of advanced technologies and sustainable practices, influencing global market developments. Latin America, the Middle East, and Africa are emerging markets showing promising growth, attributed to increasing disposable incomes, urbanization, and the development of local manufacturing capabilities, creating new opportunities for market expansion and the adoption of modern sealing equipment.

Segment trends highlight a strong preference for automated heat sealing equipment due to its superior efficiency, consistency, and reduced labor requirements compared to manual or semi-automatic alternatives. Continuous band sealers and impulse sealers remain dominant due to their versatility and reliability across various applications. The food and beverage sector continues to be the largest end-user, propelled by the demand for extended shelf life and hygiene. However, the pharmaceutical, chemical, and consumer goods industries are rapidly increasing their adoption of advanced sealing technologies to meet regulatory compliance and enhance product presentation. There is a growing demand for equipment compatible with new, environmentally friendly packaging materials, influencing future product development and market dynamics towards more sustainable and adaptable solutions.

AI Impact Analysis on Bag Heat Sealing Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the Bag Heat Sealing Equipment market, focusing on aspects like enhancing operational efficiency, improving seal quality consistency, enabling predictive maintenance, and facilitating smart factory integration. Key themes include expectations for AI-driven automation to reduce waste, optimize production parameters in real-time, and provide deeper insights into machine performance. Concerns often revolve around the initial investment costs, the complexity of implementing AI solutions, and the need for skilled personnel to manage and maintain AI-powered systems. Users are keenly interested in understanding the tangible benefits of AI in terms of cost savings, increased throughput, and superior product integrity, seeking concrete examples of how AI algorithms can address common sealing challenges and contribute to more sustainable and adaptive manufacturing processes within the packaging industry.

- Predictive Maintenance: AI algorithms analyze sensor data from heat sealing equipment to predict potential mechanical failures or performance degradation before they occur, enabling proactive maintenance scheduling. This minimizes unexpected downtime, extends the lifespan of machinery, and significantly reduces operational costs associated with emergency repairs and lost production time, ensuring higher equipment availability and reliability.

- Enhanced Quality Control: AI-powered vision systems can continuously monitor the sealing process, detecting even minute imperfections in seal integrity, alignment, and appearance with unparalleled precision. This ensures consistent, high-quality seals, reduces product recalls due to faulty packaging, and maintains brand reputation by preventing contaminated or improperly sealed goods from reaching the market.

- Optimized Sealing Parameters: AI can dynamically adjust sealing temperature, pressure, and dwell time based on real-time data from packaging materials and environmental conditions. This intelligent adaptation ensures optimal seal strength and integrity for varying film types and thicknesses, minimizes energy consumption, and prevents material damage, leading to more efficient and adaptable production runs.

- Process Optimization and Efficiency: AI analyzes production data to identify bottlenecks, optimize line speed, and manage material flow, leading to improved overall equipment effectiveness (OEE). By learning from operational patterns, AI can suggest adjustments to maximize throughput, reduce material waste, and streamline the entire packaging process, contributing to significant cost savings and increased productivity.

- Autonomous Operation and Smart Factories: AI integration moves towards more autonomous heat sealing machines capable of self-diagnosing issues, adapting to new packaging formats, and communicating with other machinery in a smart factory ecosystem. This fosters fully automated production lines, reduces human intervention, and enables remote monitoring and control, paving the way for highly flexible and responsive manufacturing environments.

- Waste Reduction and Sustainability: By precisely controlling sealing parameters and identifying defects early, AI helps minimize material waste from failed seals or rejected products. Furthermore, AI can optimize energy usage during the sealing process, contributing to more sustainable manufacturing practices and reducing the environmental footprint of packaging operations through efficient resource management.

- Supply Chain Integration and Traceability: AI can integrate sealing data with broader supply chain management systems, providing real-time insights into packaged goods' status and location. This enhances product traceability, improves inventory management, and offers valuable data for quality assurance and regulatory compliance throughout the product lifecycle, from production to consumer delivery.

DRO & Impact Forces Of Bag Heat Sealing Equipment Market

The Bag Heat Sealing Equipment market is influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory. Key drivers include the ever-expanding global demand for packaged goods across all sectors, driven by changing consumer lifestyles, urbanization, and the proliferation of e-commerce platforms requiring robust packaging solutions. Additionally, stringent food safety and pharmaceutical regulations worldwide mandate reliable and tamper-evident sealing, propelling the adoption of advanced heat sealing technologies. The increasing focus on automation in manufacturing processes to enhance efficiency, reduce labor costs, and improve consistency further accelerates market expansion. These factors create a fertile ground for continuous innovation and investment within the packaging machinery sector, underscoring the critical role of secure and efficient sealing.

However, several restraints pose challenges to the market's unbridled growth. The high initial capital investment required for advanced, automated heat sealing equipment can be a significant barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Technical complexities associated with integrating sophisticated machinery into existing production lines and the need for skilled labor to operate and maintain these systems also present hurdles. Moreover, the volatility in raw material prices for components of the sealing equipment, coupled with global supply chain disruptions, can impact manufacturing costs and lead times. The increasing push for sustainable packaging materials, which often require new or modified sealing technologies, adds another layer of complexity and R&D investment for equipment manufacturers.

Despite these challenges, substantial opportunities exist for market players to innovate and expand. The growing trend towards sustainable and eco-friendly packaging materials, such as compostable films and recyclable plastics, creates a demand for new heat sealing solutions capable of effectively working with these materials without compromising seal integrity. The integration of smart technologies, including the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML) for predictive maintenance, process optimization, and enhanced quality control, presents significant avenues for technological advancement and market differentiation. Furthermore, the untapped potential in emerging economies with their rapidly expanding industrial bases and increasing consumer purchasing power offers lucrative market entry and expansion opportunities. Customization and modularity of equipment to cater to diverse industry needs also represent a key area for strategic development.

Segmentation Analysis

The Bag Heat Sealing Equipment market is extensively segmented to reflect the diverse needs and applications within the packaging industry. These segmentations provide a granular view of the market dynamics, allowing for a deeper understanding of specific product types, technological preferences, end-user demands, and operational scales. The market can be broadly categorized by the level of automation, ranging from manual to fully automatic systems, and by the underlying sealing technology employed, which significantly impacts performance and material compatibility. Further segmentation by the type of end-user industry highlights the varying requirements of sectors such as food and beverage, pharmaceuticals, chemicals, and consumer goods, each demanding specialized equipment to meet their unique packaging standards and regulatory compliances. The growing complexity of packaging formats and materials also necessitates robust segmentation to capture market nuances effectively.

- By Type of Automation:

- Manual Heat Sealers: Simple, hand-operated or foot-pedal operated machines, ideal for low-volume production, small businesses, or specialized sealing tasks requiring operator control. They are cost-effective and versatile for various bag sizes.

- Semi-Automatic Heat Sealers: Offer increased speed and consistency over manual options, often requiring operator intervention for bag placement but automating the sealing process. Suitable for medium-volume production across diverse industries.

- Automatic Heat Sealers: High-speed, integrated systems that automate the entire sealing process from bag feeding to sealing and sometimes even cutting. Essential for large-scale production, continuous operations, and high throughput requirements, minimizing human error.

- By Sealing Technology:

- Impulse Heat Sealers: Utilize a heated element for a short, controlled burst of heat to create a seal, then cool immediately. Effective for a wide range of thermoplastic films, known for energy efficiency and clean seals.

- Continuous Band Sealers: Employ heated belts to continuously seal bags as they pass through, ideal for high-volume production lines. Offers fast sealing speeds and can handle a variety of bag materials and sizes.

- Hot Bar Sealers: Use constantly heated bars to melt and press film layers together. Known for strong, consistent seals, often used for thicker films, laminates, and vacuum packaging applications.

- Ultrasonic Sealers: Use high-frequency vibrations to create localized heat for sealing, suitable for delicate materials or applications where heat-sensitive products are involved. Offers clean, strong seals without external heat.

- Induction Sealers: Primarily used for sealing bottle caps or container liners, creating an airtight seal by inducing heat in a foil layer. While not direct bag sealing, it complements overall product integrity in packaging.

- By End-User Industry:

- Food and Beverage: The largest segment, driven by the need for extended shelf life, hygiene, and product presentation for items like snacks, frozen foods, fresh produce, coffee, and ready meals.

- Pharmaceuticals and Medical: Requires sterile, tamper-evident seals for drugs, medical devices, and diagnostic kits, adhering to strict regulatory standards for patient safety and product integrity.

- Chemical and Petrochemical: Used for sealing bags of fertilizers, powders, granules, and hazardous materials, demanding durable and chemical-resistant seals to prevent leakage and contamination.

- Consumer Goods: Encompasses sealing for personal care products, detergents, toys, textiles, and other household items, focusing on attractive packaging and protection.

- Industrial Packaging: Includes bulk packaging for construction materials, agricultural products, and various raw materials, prioritizing strength, durability, and secure containment for transport and storage.

- E-commerce and Logistics: Growing rapidly, demanding robust and secure seals for mailing bags, protective packaging, and fulfillment operations to prevent damage and tampering during transit.

- By Bag Type:

- Stand-up Pouches: Increasingly popular for their shelf appeal and convenience, requiring specialized sealing for gusseted bottoms and zippers.

- Flat Pouches/Bags: Traditional bag type for various products, sealed across the top or multiple sides.

- Gusseted Bags: Feature expandable sides or bottom, often used for bulk products, requiring robust seals to accommodate varying fills.

- Vacuum Bags: Used with vacuum sealing equipment to remove air, extending shelf life for food products.

- Retort Pouches: Designed to withstand high-temperature sterilization, demanding very strong and hermetic seals.

Value Chain Analysis For Bag Heat Sealing Equipment Market

The value chain for the Bag Heat Sealing Equipment market begins with the upstream analysis, focusing on the procurement of essential raw materials and core components. This includes suppliers of various metals such as stainless steel and aluminum for machine frames and sealing jaws, precision electronic components like microcontrollers, sensors, and actuators for control systems, and specialized heating elements and pneumatics. Manufacturers also source highly specialized materials for consumables like sealing bands and non-stick coatings. The quality and availability of these upstream inputs are crucial for the performance, durability, and cost-effectiveness of the final sealing equipment. Relationships with reliable and innovative component suppliers are therefore paramount, influencing the overall technological capability and competitive pricing of the finished machinery.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing phases of the heat sealing equipment, followed by its distribution and ultimate deployment at the end-user facilities. Manufacturers leverage their engineering expertise to design and produce a range of sealers, from manual devices to fully automated, integrated systems. Post-manufacturing, these machines are then channeled to end-users through various distribution channels. Direct sales allow manufacturers to engage closely with large industrial clients, offering custom solutions, direct support, and comprehensive after-sales services. This direct approach fosters stronger client relationships and provides valuable feedback for product development, often preferred for complex, high-value integrated systems.

Indirect distribution channels typically involve a network of distributors, agents, and resellers who stock and sell the equipment to a broader base of small and medium-sized enterprises (SMEs) and specific regional markets. These intermediaries often provide localized sales, technical support, and spare parts, playing a critical role in market penetration and accessibility. The choice between direct and indirect channels depends on the target market, product complexity, and desired reach, with many manufacturers employing a hybrid strategy. Ultimately, the efficiency of the distribution network and the effectiveness of after-sales support significantly contribute to customer satisfaction and loyalty, completing the value chain by ensuring seamless integration and optimal performance of the bag heat sealing equipment in diverse end-user applications.

Bag Heat Sealing Equipment Market Potential Customers

The Bag Heat Sealing Equipment market caters to a vast and diverse customer base, primarily comprising industries that rely heavily on robust and reliable packaging for their products. The largest segment of potential customers resides within the food and beverage industry, which utilizes heat sealing for everything from snack bags and frozen food pouches to coffee packaging, fresh produce, and retort-ready meals. These customers prioritize equipment that ensures product freshness, extends shelf life, and meets stringent hygiene standards, often requiring high-speed, automated solutions to manage massive production volumes. The demand for tamper-evident and hermetic seals is paramount to maintaining food safety and consumer trust, making efficient heat sealing equipment an indispensable asset in this sector.

Beyond food, the pharmaceutical and medical device industries represent another critical segment of potential customers. Here, the emphasis is on precision, sterility, and compliance with rigorous regulatory requirements. Packaging for drugs, medical instruments, and diagnostic kits demands absolutely secure and often sterile seals to prevent contamination and ensure patient safety. These customers typically seek highly accurate, validated, and often customized heat sealing solutions that can integrate seamlessly into cleanroom environments and meet specific industry certifications. The need for precise temperature control, validation capabilities, and traceability features in sealing equipment is a key driver for investment in this highly specialized segment, highlighting the critical role of advanced technology.

Other significant end-users and buyers include manufacturers in the chemical, petrochemical, and industrial sectors for packaging bulk powders, granules, and hazardous materials, where strong, durable, and leak-proof seals are essential for safe storage and transportation. The consumer goods industry, encompassing products like cosmetics, detergents, and household items, also constitutes a substantial customer base, focusing on aesthetic appeal, product protection, and efficient production. Furthermore, the burgeoning e-commerce and logistics sectors are increasingly investing in heat sealing equipment for protective and secure mailing bags and fulfillment packaging, driven by the need to prevent damage and tampering during transit. This broad range of applications underscores the universal demand for reliable bag heat sealing capabilities across the modern economy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Packaging Technology, KHS GmbH, Fuji Machinery Co. Ltd., Ishida Co. Ltd., PFM Packaging Machinery S.p.A., Sealed Air Corporation, Oystar Group, Yamato Scale Co. Ltd., ULMA Packaging S. Coop., Syntegon Technology GmbH, Tetra Pak International SA, Graphic Packaging International LLC, Smurfit Kappa Group Plc, Crown Holdings Inc., Barry-Wehmiller Companies Inc., Pro Mach Inc., Accraply Inc., Rovema GmbH, Sidel Group, GEA Group AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bag Heat Sealing Equipment Market Key Technology Landscape

The Bag Heat Sealing Equipment market is continuously evolving, driven by advancements in various core technologies aimed at enhancing efficiency, precision, and adaptability. Central to modern sealing systems are sophisticated Programmable Logic Controllers (PLCs) and Human Machine Interfaces (HMIs), which provide precise control over sealing parameters such as temperature, pressure, and dwell time, alongside intuitive operator interaction. Servo motor technology is increasingly integrated into automated systems to achieve high-speed, accurate, and repeatable movements, leading to faster production cycles and consistent seal quality. These control systems and motion technologies form the backbone of high-performance heat sealers, enabling manufacturers to meet the stringent demands of modern packaging lines with exceptional reliability and minimal manual intervention.

Beyond fundamental control, the market is witnessing a strong uptake of advanced sensor technologies and vision systems. High-resolution cameras combined with image processing software are used for real-time quality inspection, detecting seal imperfections, material misalignments, or foreign particles before products leave the production line. This significantly reduces waste and ensures compliance with quality standards. Furthermore, the integration of Internet of Things (IoT) capabilities allows for remote monitoring, data collection, and connectivity of sealing equipment within a broader smart factory ecosystem. IoT sensors gather critical operational data, enabling predictive maintenance, performance analytics, and seamless communication with other machinery, facilitating a holistic approach to production management and optimization, leading to fewer breakdowns and longer equipment lifespans.

Material science also plays a crucial role in the technology landscape, as innovations in packaging films, particularly sustainable and multi-layer structures, necessitate new sealing techniques. Equipment manufacturers are developing specialized sealing jaws and heating elements capable of working effectively with a broader range of films, including bio-based, compostable, and recyclable materials, without compromising seal integrity. Advanced temperature control mechanisms, such as PID controllers and infrared heating, ensure uniform heat distribution and accurate temperature maintenance, critical for high-quality seals. The ongoing research into ultrasonic sealing and induction sealing technologies for specific applications further demonstrates the market's commitment to developing versatile and energy-efficient solutions that cater to the diverse and evolving needs of the packaging industry while also addressing environmental concerns.

Regional Highlights

- North America: This region demonstrates a strong demand for high-speed, automated, and technologically advanced bag heat sealing equipment, primarily driven by stringent food safety regulations, pharmaceutical packaging standards, and a robust e-commerce sector. The emphasis is on energy efficiency, precision, and integration with existing smart factory systems. Significant investments in research and development and the presence of major packaging machinery manufacturers further bolster market growth.

- Europe: Europe is characterized by a mature market with a strong focus on sustainable packaging solutions, necessitating heat sealing equipment compatible with eco-friendly materials. Regulatory frameworks promoting circular economy principles influence product innovation, driving demand for efficient and adaptable sealers. Germany, Italy, and France are key manufacturing hubs, known for high-quality engineering and advanced automation in packaging technology.

- Asia Pacific (APAC): Expected to be the fastest-growing market, APAC is fueled by rapid industrialization, expanding manufacturing capabilities, and a burgeoning consumer base demanding packaged goods. Countries like China, India, and Japan are experiencing significant investments in food processing, pharmaceuticals, and consumer goods sectors, driving the adoption of both semi-automatic and fully automatic heat sealing solutions to meet scalability and cost-efficiency demands.

- Latin America: This region presents emerging opportunities, with increasing urbanization and disposable incomes contributing to the growth of packaged food and beverage industries. Brazil and Mexico are leading markets, showing a rising adoption of modern packaging machinery to enhance productivity and comply with evolving quality standards. The focus is on robust, adaptable equipment that can handle diverse product types efficiently.

- Middle East and Africa (MEA): The MEA market is gradually expanding due to industrial diversification, government initiatives supporting local manufacturing, and rising consumer spending on packaged products. Growth is observed in the food processing, pharmaceutical, and construction sectors, creating demand for basic to moderately automated heat sealing equipment. Investments in infrastructure and manufacturing capabilities are key drivers for future market development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bag Heat Sealing Equipment Market.- Bosch Packaging Technology

- KHS GmbH

- Fuji Machinery Co. Ltd.

- Ishida Co. Ltd.

- PFM Packaging Machinery S.p.A.

- Sealed Air Corporation

- Oystar Group

- Yamato Scale Co. Ltd.

- ULMA Packaging S. Coop.

- Syntegon Technology GmbH

- Tetra Pak International SA

- Graphic Packaging International LLC

- Smurfit Kappa Group Plc

- Crown Holdings Inc.

- Barry-Wehmiller Companies Inc.

- Pro Mach Inc.

- Accraply Inc.

- Rovema GmbH

- Sidel Group

- GEA Group AG

Frequently Asked Questions

Analyze common user questions about the Bag Heat Sealing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is bag heat sealing equipment and how does it function?

Bag heat sealing equipment refers to machinery used to securely close flexible packaging materials, such as bags and pouches, by applying controlled heat and pressure to melt and fuse thermoplastic layers together. This process creates a strong, airtight, or watertight seal, preventing leakage, contamination, and preserving product freshness. The equipment can range from simple manual devices to fully automated systems, with various technologies like impulse, continuous band, or hot bar sealing, each suited for different materials and production volumes. The core function is to ensure product integrity and extend shelf life by creating a hermetic barrier.

What are the primary benefits of using advanced bag heat sealing machinery in industrial applications?

Advanced bag heat sealing machinery offers numerous benefits for industrial applications, including significantly enhanced product freshness and extended shelf life due to secure, hermetic seals. It ensures superior hygiene and sterility, critical for food and pharmaceutical products, while also reducing product spoilage and waste. Automation in these machines boosts packaging efficiency, increases throughput, and reduces labor costs by minimizing human intervention and error. Furthermore, modern sealers can handle a wide variety of packaging materials, including sustainable films, offering versatility and contributing to cost savings and improved brand reputation through consistent, high-quality packaging.

Which industries are the major end-users of bag heat sealing equipment?

The major end-users of bag heat sealing equipment span a wide range of industries. The food and beverage sector is the largest, utilizing these machines for snacks, frozen foods, fresh produce, and ready-to-eat meals to ensure freshness and compliance with safety standards. The pharmaceutical and medical industries rely on heat sealers for sterile packaging of drugs and medical devices, demanding precision and tamper-evidence. Other significant users include the chemical and petrochemical industries for bulk material packaging, consumer goods manufacturers for household items and personal care products, and increasingly, the e-commerce and logistics sectors for secure shipping and fulfillment packaging, highlighting the universal need for reliable sealing.

What are the key technological trends shaping the future of the Bag Heat Sealing Equipment market?

The Bag Heat Sealing Equipment market is being shaped by several key technological trends. There's a strong shift towards greater automation, incorporating advanced robotics, servo motors, and high-speed controls to maximize efficiency and consistency. Integration of smart technologies like IoT, AI, and machine learning is enabling predictive maintenance, real-time quality control via vision systems, and process optimization for energy efficiency and waste reduction. Furthermore, there's a significant focus on developing equipment compatible with sustainable and eco-friendly packaging materials, such as compostable and recyclable films, without compromising seal integrity or production speed, reflecting an industry-wide commitment to environmental responsibility and innovation.

What impact do rising sustainability concerns have on the development of bag heat sealing equipment?

Rising sustainability concerns are profoundly impacting the development of bag heat sealing equipment, driving innovation towards environmentally responsible solutions. Manufacturers are challenged to design machines capable of effectively sealing new, eco-friendly packaging materials like bio-plastics, compostable films, and thinner recyclable plastics, which often have different thermal and mechanical properties. This necessitates advancements in sealing technologies, including more precise temperature control, adaptable sealing jaws, and energy-efficient heating methods to ensure strong, reliable seals with these novel materials. The focus is on reducing material waste, optimizing energy consumption, and supporting the transition to a circular economy, making sustainability a core driver of future equipment design and market differentiation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Bag Heat Sealing Equipment Market Statistics 2025 Analysis By Application (Food & Beverage, Medical & Daily Chemicals), By Type (Impulse Heat Sealers, Hot Bar Sealers, Continuous Heat Sealers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Bag Heat Sealing Equipment Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Manual Type, Automatic Type), By Application (Industrial, Commercial, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager